Offline ash removal online overhauling rotary pulse blowing filter-bag dust catcher

A technology of pulse jet and dust collector, which is applied in the field of off-line dust cleaning and online maintenance of rotary pulse jet filter bag filter and bag filter. problem, to achieve the effect of good cleaning effect, small footprint, and low power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

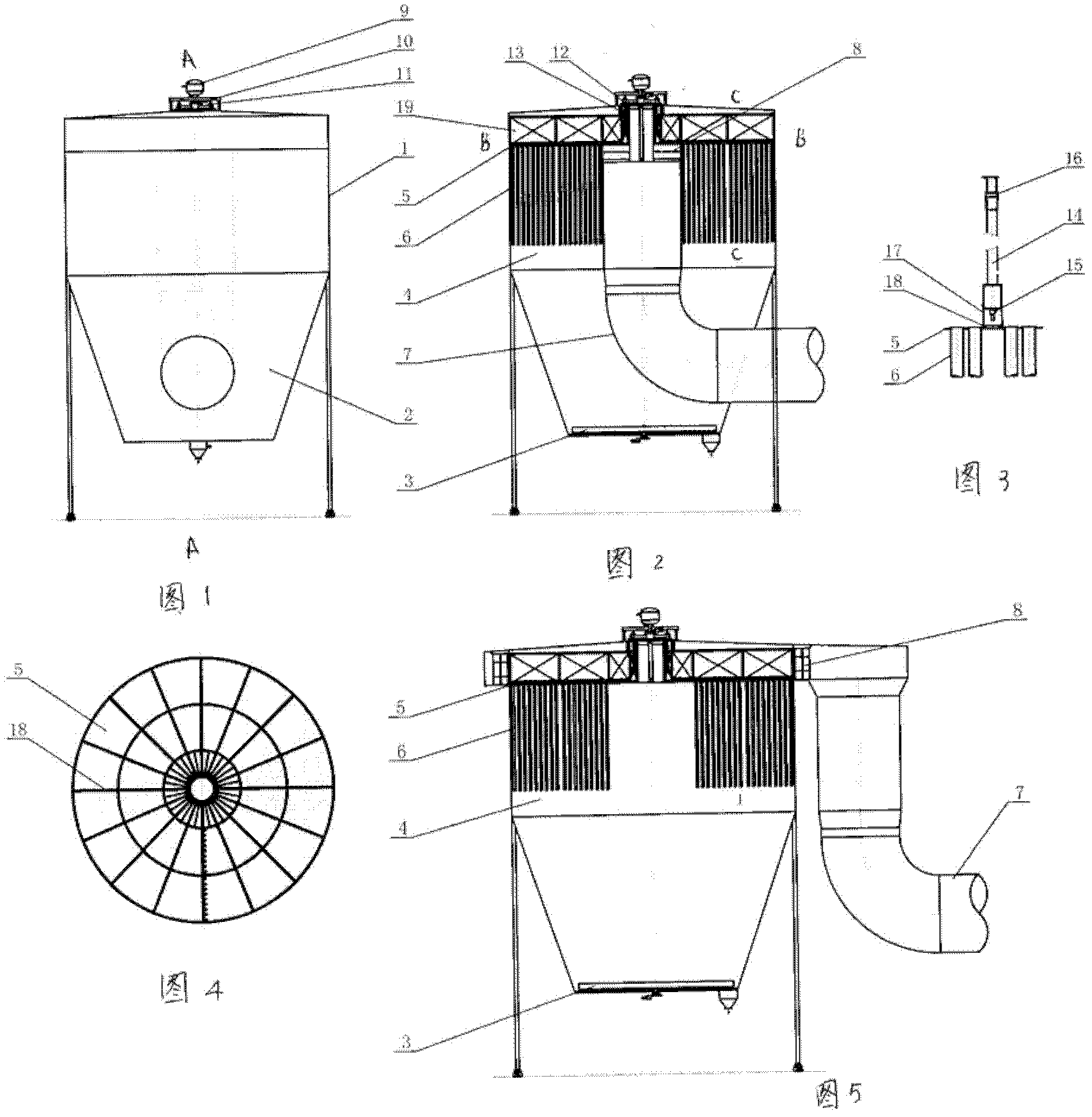

[0012] In order to make the above-mentioned purposes, features and advantages of the present invention more obvious and understandable, the following embodiments are described in detail in conjunction with the accompanying drawings as follows:

[0013] The accompanying drawings are main / side / overhead / sectional schematic diagrams of the dust collector with the upper outer peripheral air outlet structure and the middle inner air outlet structure type dust collector according to the embodiment of the present invention.

[0014] In this embodiment, the present invention adopts a filter bag dust collector whose main shell is cylindrical in shape. It is mainly adopted that an ash hopper (2) is provided at the lower part of the main shell (1); a rotary plow scraper type ash unloader (3) is installed at the lower part of the ash hopper (2); and a filter chamber (4) is provided at the upper part of the ash hopper (2); A flower plate (5) is installed on the top of the filter chamber (4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com