Portable membrane filter bag

A film-coated filter bag, a portable technology, applied in the direction of dispersed particle filtration, layered products, glass/slag layered products, etc., can solve the problem of damage to the health of workers, poor filter effect of filter bags, reduced labor efficiency, etc. problem, achieve the effect of reducing the use volume and investment cost, prolonging the service life, reducing the use volume and investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

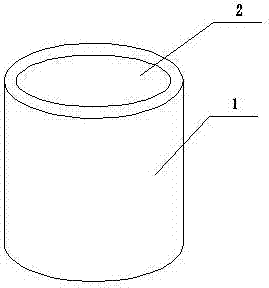

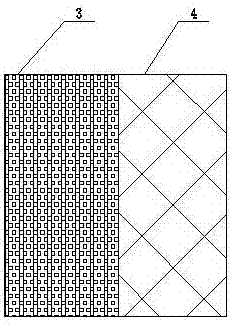

[0012] like figure 1 , figure 2 As shown, the portable film-coated filter bag of the present invention comprises: bag body 1, pocket mouth 2, film-covered film 3, base cloth 4, and described filter film 3 is positioned at the outside of base cloth 4, and filter film 3 adopts polytetrafluoroethylene microporous Membrane, biaxially stretched, laminated to base fabric using pressure and heat. The base cloth layer 4 adopts non-alkali glass fiber continuous bulked yarn fiber, and the mass per unit area is 60g / m 2 , the thickness is 1.2mm, and the average pore size of the fiber web is 16μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com