Modified PPS (polyphenylene sulfide) and PTFE (polytetrafluoroethylene) layered coating method for glass fiber filter material

A technology of polytetrachlorethylene and polyphenylene sulfide, applied in separation methods, filtration separation, fiber treatment, etc., can solve the problems of high melt viscosity that cannot be completely melted and leveled, and poor oxidation resistance of polyphenylene sulfide needle felt , high post-processing equipment requirements, etc., to achieve the effect of improving thermal stability and leveling performance, low cost, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

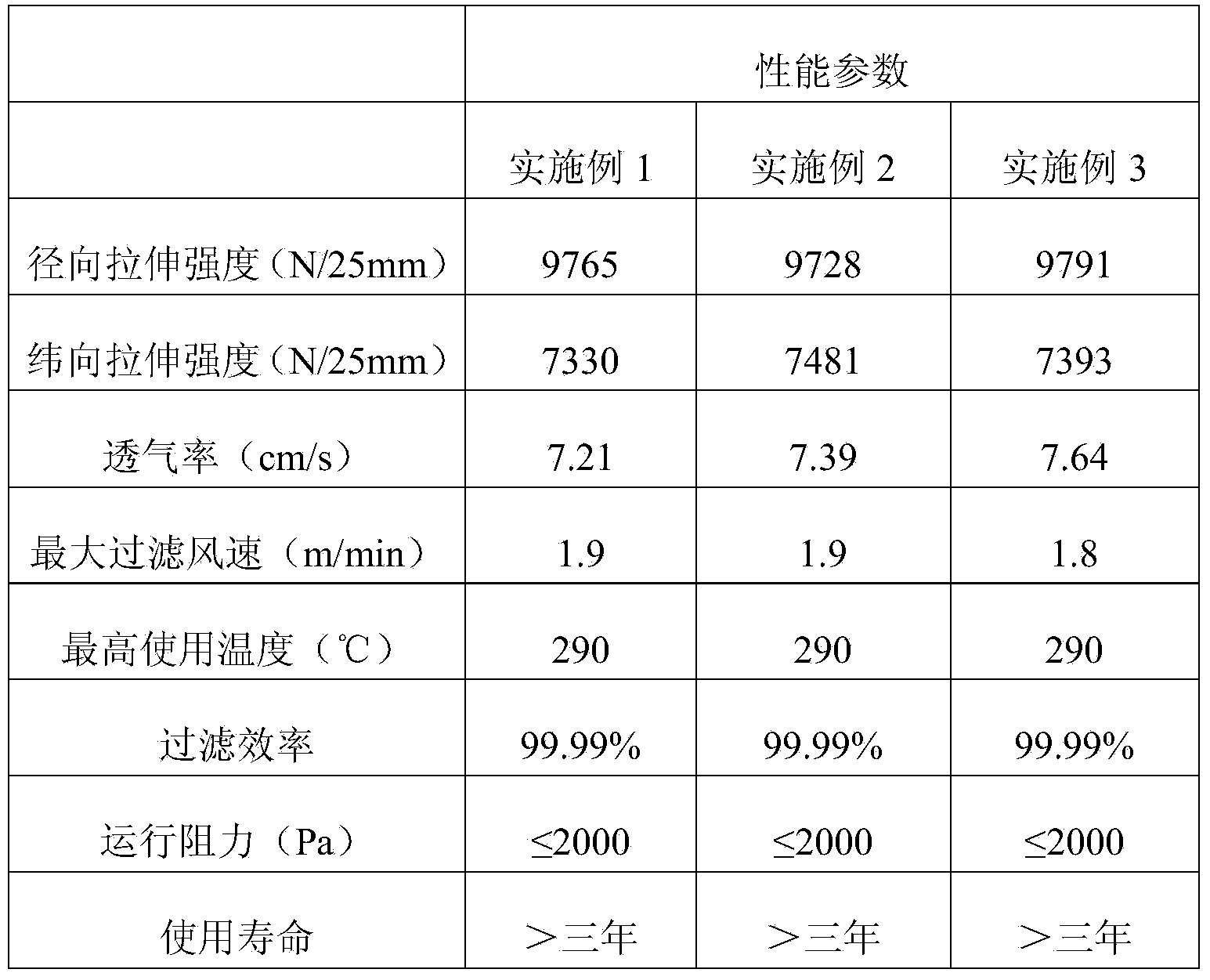

Embodiment 1

[0024] Preparation of glass fiber needled felt base cloth: select glass fiber needled felt base cloth, and make filter material base cloth through carding, web laying, and needle punching processes.

[0025] Preparation of hyperbranched polyphenylene sulfide: Add 10g of 3,4-dichlorothiophenol, 13.4g of anhydrous potassium carbonate and 80mL of N-methylpyrrolidone into a 250mL three-necked flask, heat to 150°C, and keep warm for 8.5h. The product was washed and filtered with hydrochloric acid, dissolved in tetrahydrofuran, extracted with hexane, filtered and dried to obtain light brown hyperbranched PPS powder with a degree of polymerization of 8-12.

[0026] Preparation of modified polyphenylene sulfide fiber emulsion: 6% by mass percentage of linear polyphenylene sulfide powder, 4% hyperbranched polyphenylene sulfide powder, and the balance being mixed with water, and then mixed evenly by an ultrasonic cleaner. Formulated as a lotion.

[0027] Preparation of primer: mix 35% ...

Embodiment 2

[0032] Preparation of glass fiber needled felt base cloth: select glass fiber needled felt base cloth, and make filter material base cloth through carding, web laying, and needle punching processes.

[0033] Preparation of hyperbranched polyphenylene sulfide: Add 10g of 3,4-dichlorothiophenol, 13.4g of anhydrous potassium carbonate and 80mL of N-methylpyrrolidone into a 250mL three-necked flask, heat to 150°C, and keep warm for 8.5h. The product was washed and filtered with hydrochloric acid, dissolved in tetrahydrofuran, extracted with hexane, filtered and dried to obtain light brown hyperbranched PPS powder with a degree of polymerization of 8-12.

[0034] Preparation of modified polyphenylene sulfide fiber emulsion: 12% by mass percentage of linear polyphenylene sulfide powder, 3% hyperbranched polyphenylene sulfide powder, and the balance being mixed with water, and then mixed evenly by an ultrasonic cleaner. Formulated as a lotion.

[0035] Preparation of primer: mix 35%...

Embodiment 3

[0040] Preparation of glass fiber needle-punched felt base cloth: select glass fiber needle-punched base cloth, and make filter material base cloth through carding, web laying, and needle-punched processes.

[0041] Preparation of hyperbranched polyphenylene sulfide: Add 10g of 3,4-dichlorothiophenol, 13.4g of anhydrous potassium carbonate and 80mL of N-methylpyrrolidone into a 250mL three-necked flask, heat to 150°C, and keep warm for 8.5h. The product was washed and filtered with hydrochloric acid, dissolved in tetrahydrofuran, extracted with hexane, filtered and dried to obtain light brown hyperbranched PPS powder with a degree of polymerization of 8-12.

[0042]Preparation of modified polyphenylene sulfide fiber emulsion: 8% by mass percentage of linear polyphenylene sulfide powder, 3% hyperbranched polyphenylene sulfide powder, and the balance being mixed with water, and then mixed evenly by an ultrasonic cleaning machine. Formulated as a lotion.

[0043] Preparation of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com