Filter drum type precipitator

A dust collector and filter cartridge technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of large air consumption, weak airflow, incomplete cleaning, etc., to improve the cleaning efficiency, reduce Small blowing area, the effect of improving the cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

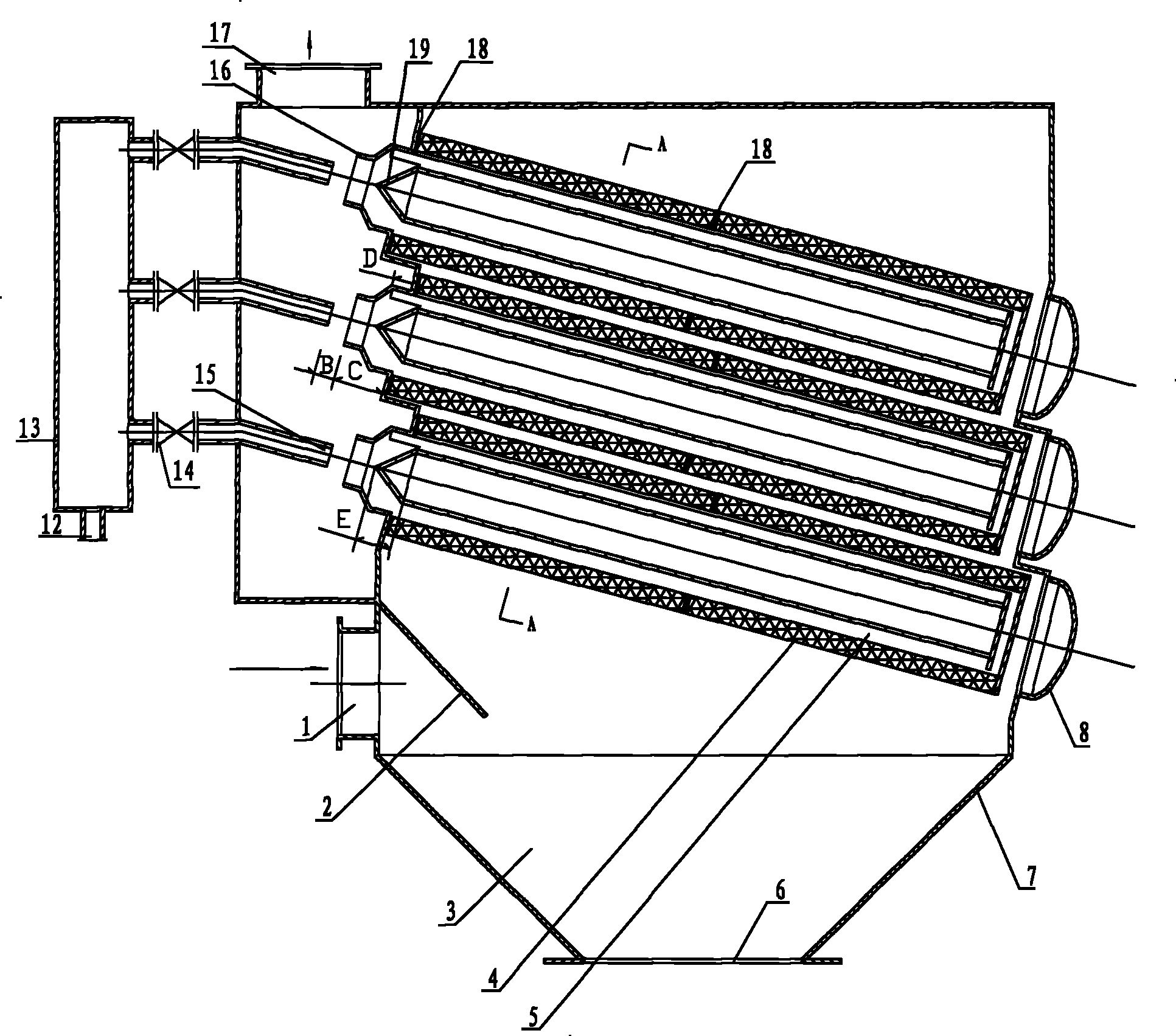

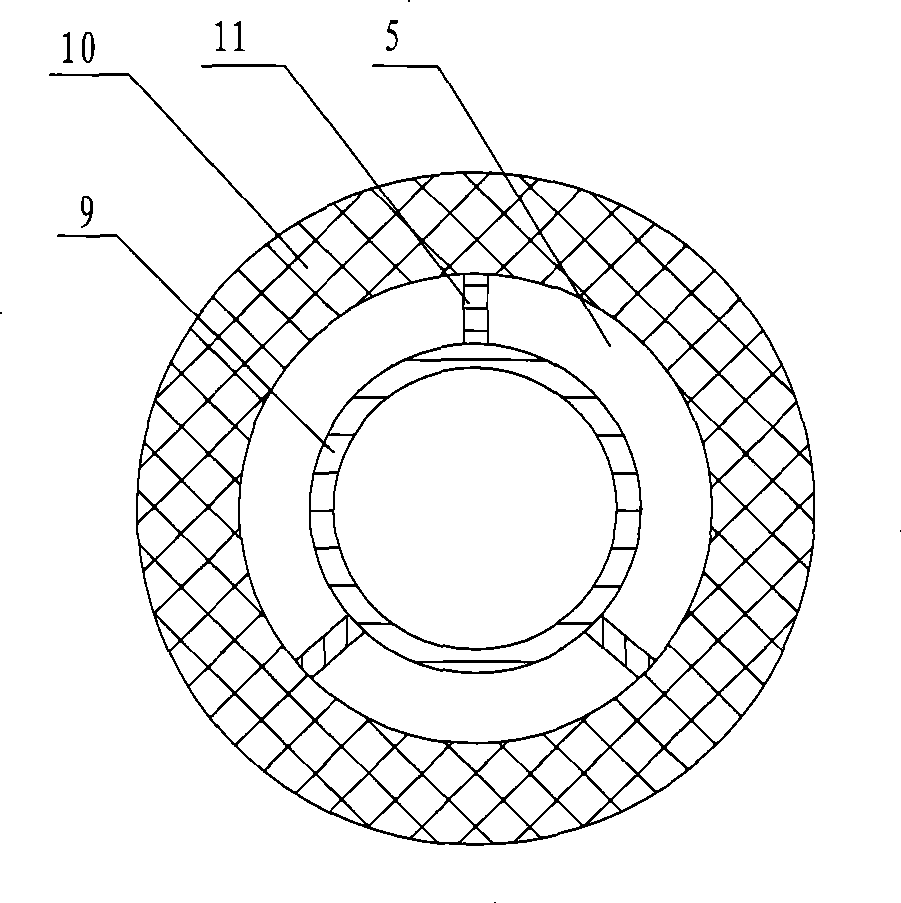

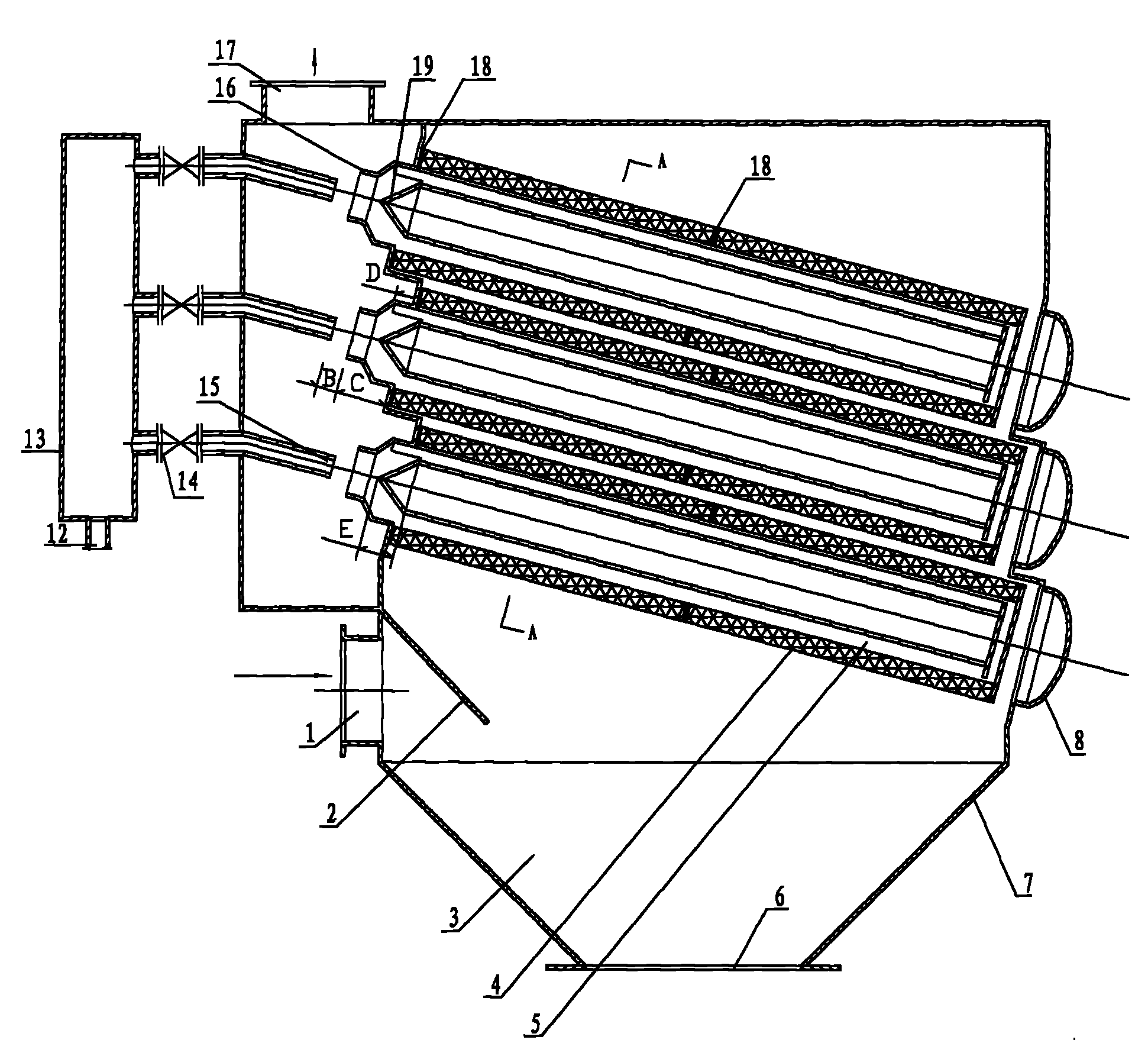

[0017] as attached figure 1 As shown, the filter cartridge dust collector implemented according to the present invention consists of a box body 7, a plurality of filter cartridges 10 arranged obliquely in the box body 7, and compressed air is blown into the filter cartridge 10 from the upper open end of the filter cartridge 10. Cleaning device constitutes.

[0018] Wherein, the bottom of the box body 7 is an ash hopper 3, and the ash hopper 3 is provided with an ash outlet 6. The air inlet 1 for the flue gas to enter is set at the lower end of the box body 7, and a baffle 2 is provided for the air inlet 1, so that when the flue gas enters the box body 7 from the air inlet 1, it is received by the baffle 2 Settling occurs due to the blockage of the ash hopper, so that part of the larger smoke and dust sinks into the ash hopper 3 under the action of its own we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com