High-temperature resistant and acid-and-alkali resistant industrial filter cloth material

An acid and alkali resistant and high temperature resistant technology, applied in filtration and separation, membrane filters, non-woven fabrics, etc., can solve the problem of reduced water permeability of filter cloths, and achieve improved folding resistance, beautiful, flat and clean hand feel, and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A high-temperature-resistant, acid-alkali-resistant industrial filter cloth material is made of the following raw materials in parts by weight:

[0021] 30-60 parts of polyfluoroethylene propylene, 30-60 parts of polyphenylene sulfide, 20-30 parts of ethanol, 20-30 parts of distilled water and ethanol, 10-15 parts of polyester, 1-5 parts of polytetrafluoroethylene powder, trioxide 1-3 parts of dichrome, 10-15 parts of polydiphenol-propane terephthalate, and 1-5 parts of graphite powder.

[0022] A method for preparing a high temperature resistant, acid and alkali resistant industrial filter cloth material, comprising the following steps: (1) Weighing the raw materials of each component and setting aside; (2) Putting half of the total weight of polyphenylene sulfide resin into a ball mill After the dry grinding is completed, put ethanol and distilled water into a porcelain jar for wet grinding to obtain a polyphenylene sulfide resin suspension; (3) glass fiber, carbon fi...

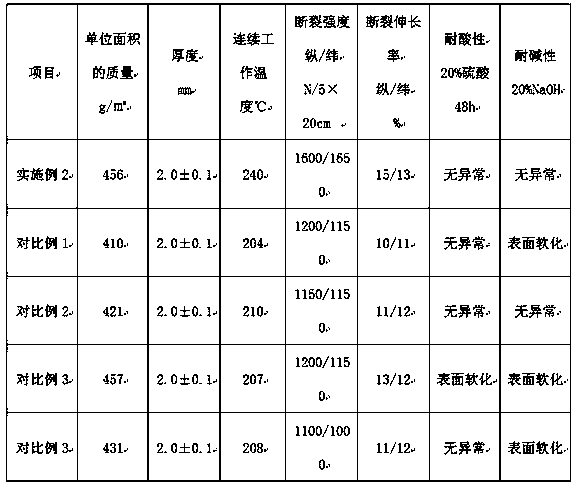

Embodiment 2

[0026] A high-temperature-resistant, acid-alkali-resistant industrial filter cloth material is made of the following raw materials in parts by weight:

[0027] 30-60 parts of polyfluoroethylene propylene, 30-60 parts of polyphenylene sulfide, 20-30 parts of ethanol, 20-30 parts of distilled water and ethanol, 10-15 parts of polyester, 1-5 parts of polytetrafluoroethylene powder, trioxide 1-3 parts of dichrome, 10-15 parts of polydiphenol-propane terephthalate, and 1-5 parts of graphite powder.

[0028] A method for preparing a high temperature resistant, acid and alkali resistant industrial filter cloth material, comprising the following steps: (1) Weighing the raw materials of each component and setting aside; (2) Putting half of the total weight of polyphenylene sulfide resin into a ball mill After the dry grinding is completed, put ethanol and distilled water into a porcelain jar for wet grinding to obtain a polyphenylene sulfide resin suspension; (3) glass fiber, carbon fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com