High-temperature dust-removing filter material and preparation method thereof

A high-temperature dust removal and filter material technology, which is applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problem of continuous work in an environment of 240~280°C, and achieve simple, convenient and economical reverse dust cleaning Production cost, impact resistance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

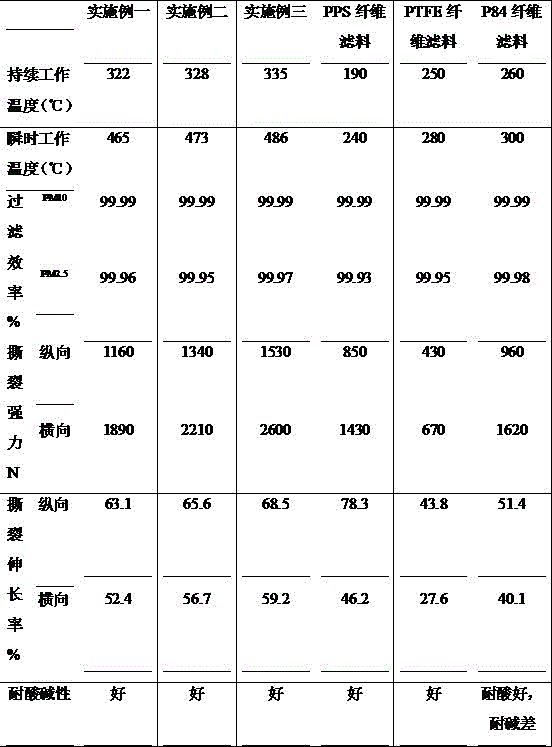

Examples

Embodiment 1

[0027] A high-temperature dust-removing filter material and a preparation method thereof, characterized in that the high-temperature dust-removal filter material comprises a metal fiber felt layer, a PTFE film layer, and a PPS fiber layer arranged in sequence, and the PTFE film layer is bonded to the The metal fiber layer is bonded, and the PPS fiber layer is entangled with the PTFE film layer through a hydroentanglement process, and its specific production process is as follows:

[0028] 1) Preparation of metal fiber felt: Metal fiber filaments are produced by melt spinning, and the metal contained in the metal fiber filaments includes 1.20wt% magnesium, 2.30wt% manganese, 0.15wt% titanium, and the rest is aluminum and impurities (iron, copper, zinc, etc.), in which impurities should be less than 0.80wt%, the diameter of the metal fiber is 2μm, and the length is 1.5m; the metal fiber is non-woven, laminated and then sintered at a high temperature of 1700°C Make a metal fiber ...

Embodiment 2

[0036] A high-temperature dust-removing filter material and a preparation method thereof, characterized in that the high-temperature dust-removal filter material comprises a metal fiber felt layer, a PTFE film layer, and a PPS fiber layer arranged in sequence, and the PTFE film layer is bonded to the The metal fiber layer is bonded, and the PPS fiber layer is entangled with the PTFE film layer through a hydroentanglement process, and its specific production process is as follows:

[0037]1) Preparation of metal fiber felt: Metal fiber filaments are produced by melt spinning, and the metal contained in the metal fiber filaments includes 1.20wt% magnesium, 2.30wt% manganese, 0.15wt% titanium, and the rest is aluminum and impurities (iron, copper, zinc, etc.), in which impurities should be less than 0.80wt%, the diameter of the metal fiber is 2μm, and the length is 1.5m; the metal fiber is non-woven, laminated and then sintered at a high temperature of 1700°C Make a metal fiber f...

Embodiment 3

[0045] A high-temperature dust-removing filter material and a preparation method thereof, characterized in that the high-temperature dust-removal filter material comprises a metal fiber felt layer, a PTFE film layer, and a PPS fiber layer arranged in sequence, and the PTFE film layer is bonded to the The metal fiber layer is bonded, and the PPS fiber layer is entangled with the PTFE film layer through a hydroentanglement process, and its specific production process is as follows:

[0046] 1) Preparation of metal fiber felt: Metal fiber filaments are produced by melt spinning, and the metal contained in the metal fiber filaments includes 1.20wt% magnesium, 2.30wt% manganese, 0.15wt% titanium, and the rest is aluminum and impurities (iron, copper, zinc, etc.), in which impurities should be less than 0.80wt%, the diameter of the metal fiber is 2μm, and the length is 1.5m; the metal fiber is non-woven, laminated and then sintered at a high temperature of 1700°C Make a metal fiber ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com