Three-dimensional roof controlling method for fully mechanized caving of steeply inclined and extremely thick coal seam

A technology of ultra-thick coal seam and steep inclination, which is applied in the field of fully-mechanized opening of steeply inclined ultra-thick coal seam and adopts three-dimensional roof control, which can solve the problems of inability to provide all-round three-dimensional defense, large uncertainty of roof migration, and low degree of coal fragmentation , to achieve high practical value, increase production efficiency and yield, and eliminate potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

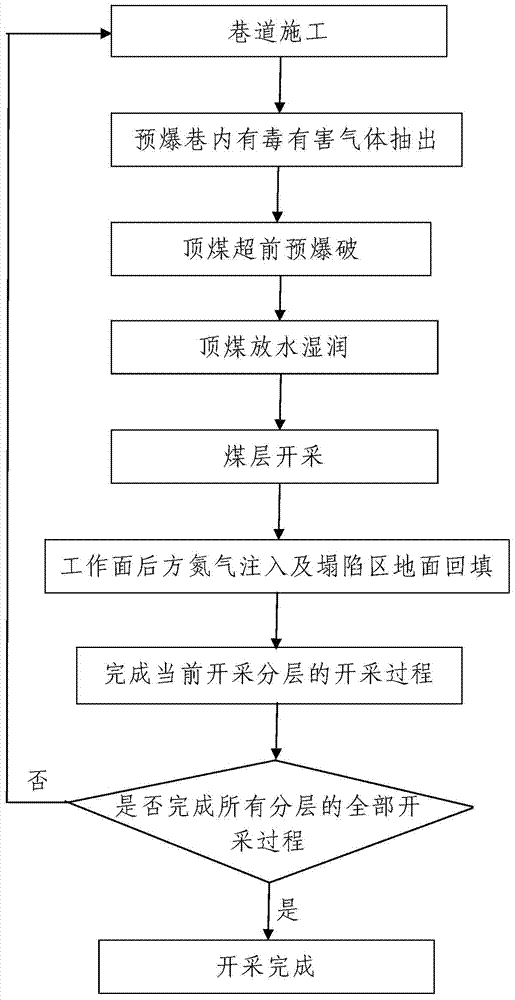

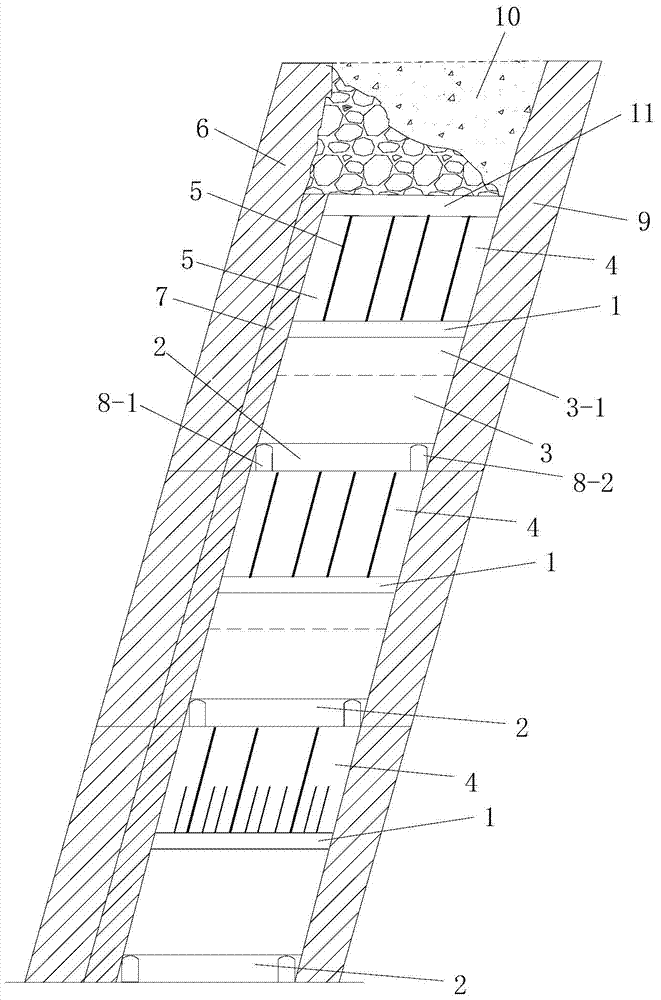

[0046] Such as figure 1 The fully-mechanized caving of a steeply inclined extra-thick coal seam shown adopts a three-dimensional roof control method. The steeply inclined extra-thick coal seam mined is a coal seam with a coal seam dip angle of more than 45° and a coal seam thickness of more than 8m. The steeply inclined extra-thick coal seam is carried out During mining, the steeply inclined extra-thick coal seam is mined in multiple mining sections from back to front along the coal seam trend. The mining methods of the multiple mining sections are the same and their lengths along the coal seam trend are all L , where L=15m~30m; each of the mining sections is divided into multiple layers from top to bottom, and the multiple layers are arranged horizontally, and the uppermost part of the multiple layers is Layer is the top layer; when mining any mining segment of the steeply inclined extra-thick coal seam, multiple layers of the mining segment are mined from top to bottom, and ...

Embodiment 2

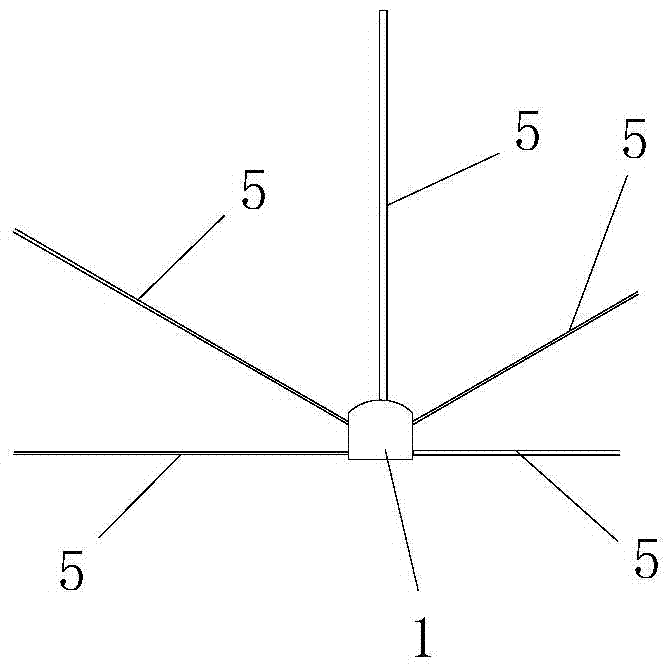

[0091] Such as Image 6 , Figure 7 As shown, in the present embodiment, different from Embodiment 1: the quantity of the pre-explosion roadway 1 constructed in the step 101 is multiple; The number of pre-explosion lanes 1 is three.

[0092] The three pre-explosion lanes 1 are respectively the first pre-explosion lane, the second pre-explosion lane and the third pre-explosion lane from top to bottom. The blastholes 5 are arranged in multiple rows, and the blastholes 5 in multiple rows are arranged from left to right along the length direction of the working face. With the blastholes 5 on both sides, a plurality of blastholes 5 in each row of blastholes 5 includes a middle blasthole above the middle of the pre-explosion lane 1 and a plurality of blastholes located on both sides of the middle blasthole. side blast holes.

[0093] In step 104, during the wetting process of top coal dewatering, install water injection equipment in the bottom pre-explosion roadway, and inject w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com