Lens electric-bag complex dust collector

A technology of electric bag compounding and dust collector, which is applied in the direction of combined devices, electrostatic effect separation, chemical instruments and methods, etc., which can solve the problems of filter bag life impact, small running resistance, and increased running resistance of filter bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

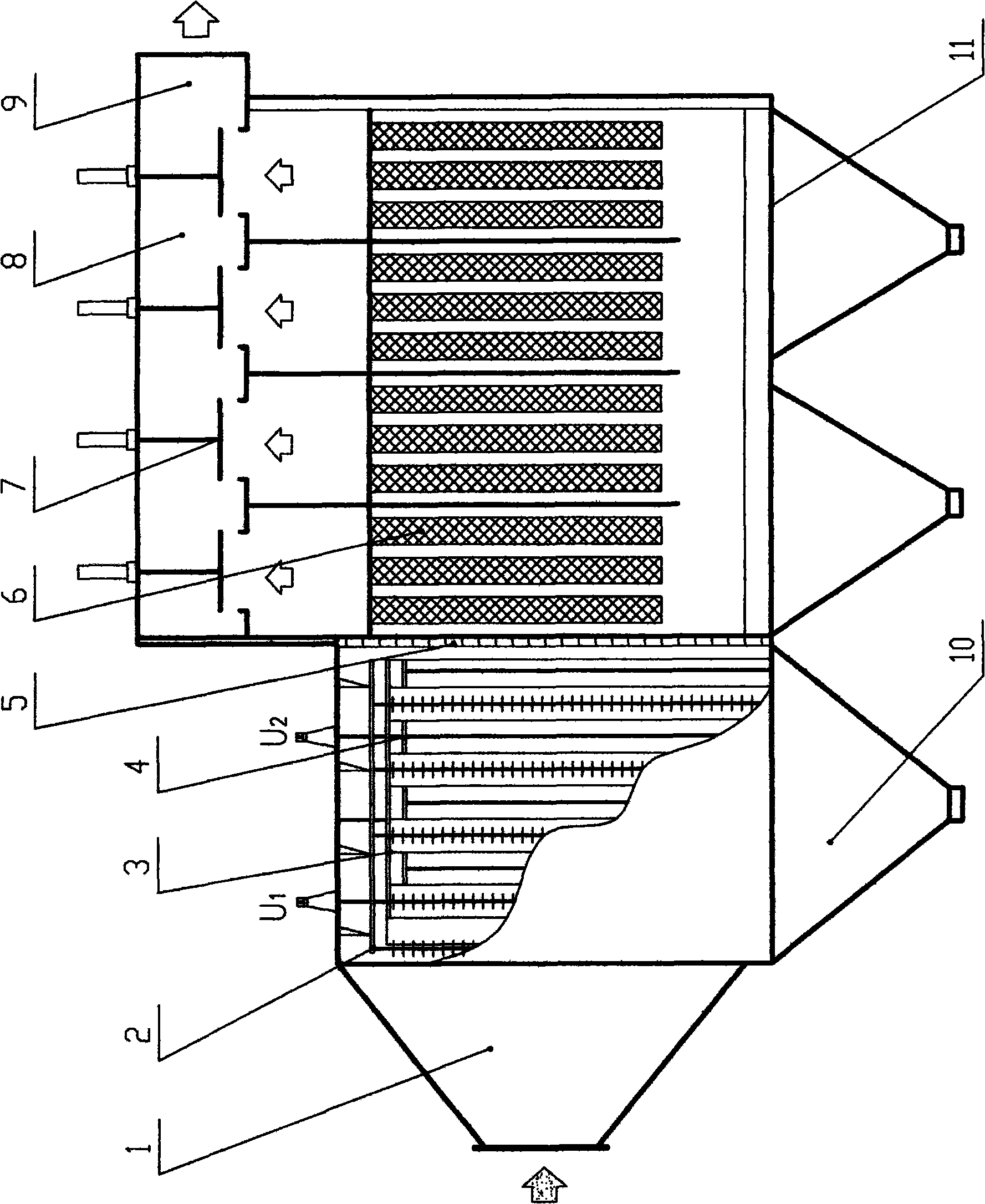

[0022] Please refer to the accompanying drawings, which are structural distribution diagrams of the present invention. Consists of air intake horn (1), housing (11), ash hopper (10), negative corona pole assembly (2), lens pole assembly (3), positive corona pole assembly (4) and airflow transition uniform flow device ( 5), bag dust removal device (6), filter airflow control switch (7), collecting chamber (8), airflow outlet channel (9) and power supply electrical equipment for it. When the dust collector is officially in operation, the dusty gas enters the inside of the box-shaped housing (11) from the intake horn, and the dusty gas is first pre-collected by the front-stage lens-type electric dust collector, and then passes through the airflow transition uniform flow device (5 ) and then enter the bag-type dust collector of the subsequent stage for ultimate dust removal, and finally discharge through the collecting chamber (8) and the air outlet channel (9); the collected dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com