Unpowered draught fan with support frames as wing-shaped blades

A technology of airfoil blades and support frames, which is applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc., can solve the problems of unreasonable fan support frames, small effective aerodynamic area, and high turbulence intensity, so as to improve flow disturbance, Effect of reducing turbulence intensity and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

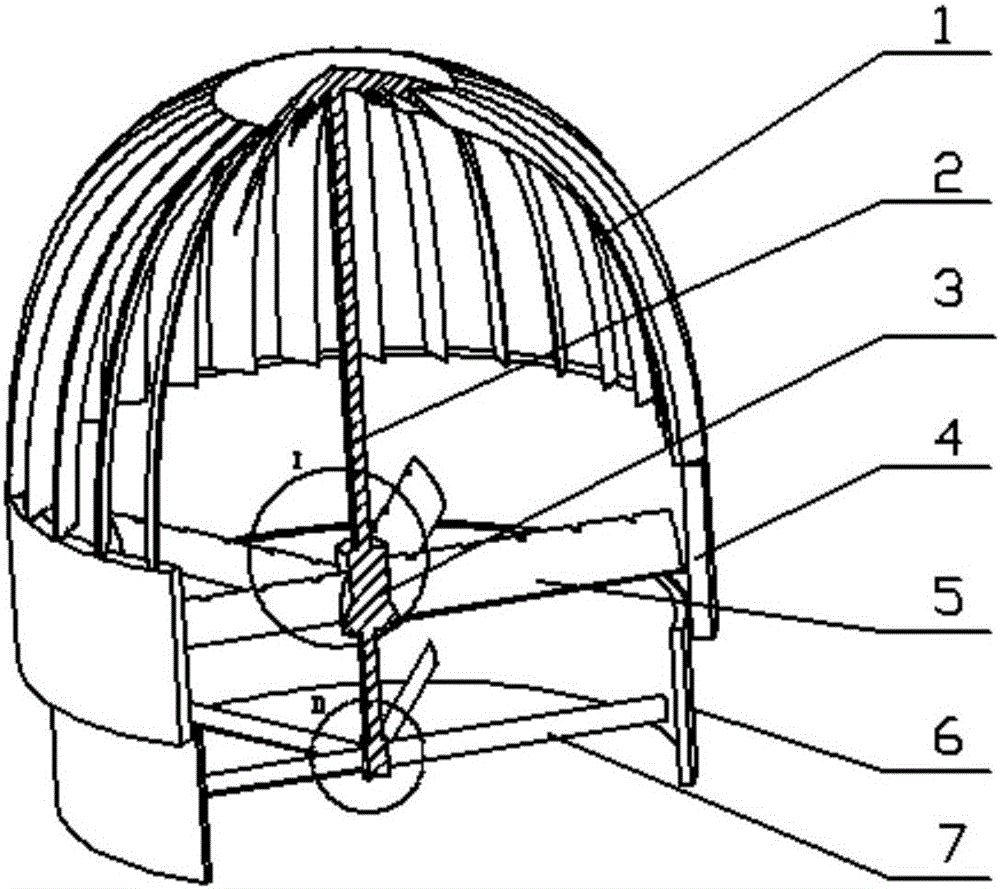

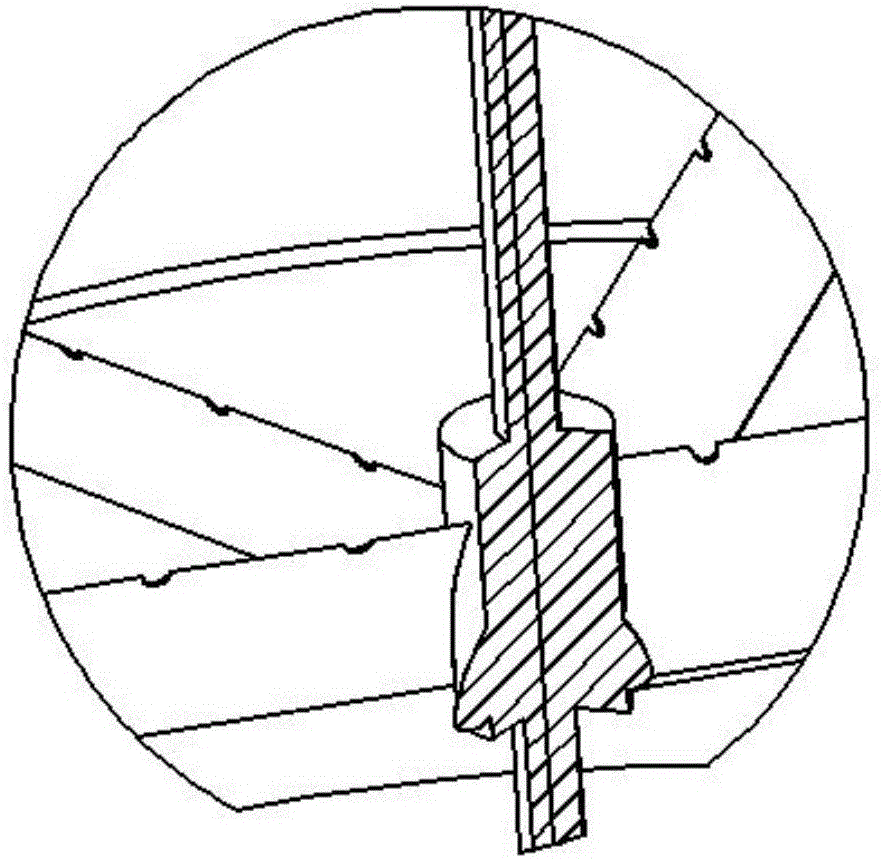

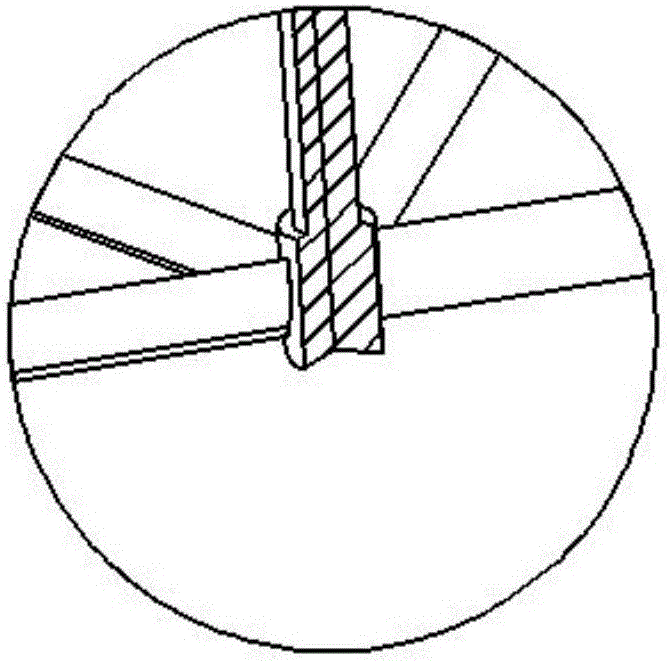

[0030] Such as figure 1 , 2 As shown in and 3, the support frame is a non-powered fan with airfoil blades, which is supported by a wind cutting blade 1, a central shaft 2, a bearing, a positioning sleeve 3, a cylindrical pipe diameter 4, an upper end support frame 5, a variable angle pipe diameter 6, and a lower end support Frame 7 and turbine top plate form. The lower end support frame 7 is a plurality of lower end airfoil blades, one end of the lower end airfoil blade is fixed on the bottom of the central shaft 2, and the other end is fixed on the inner wall of the variable angle pipe diameter 6; the upper end support frame 5 is a plurality of upper end airfoil blades, the upper end wing One end of the type blade is fixed on the positioning sleeve 3, and the other end is fixed on the inner wall of the cylindrical pipe diameter 4; the positioning sleeve 3 is supported on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com