Air curtain sealing dedusting system on fully-mechanized excavating face

A technology of dust removal system and air curtain, which is applied in the direction of dust prevention, safety devices, mining equipment, etc., which can solve the problems of unable to isolate the dust head-on, hindering the walking and operation of the operator, and deformation of the roadway due to scratching, so as to improve the efficiency of dust extraction and purification , reduce the impact of line of sight, and protect the effect of physical and mental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

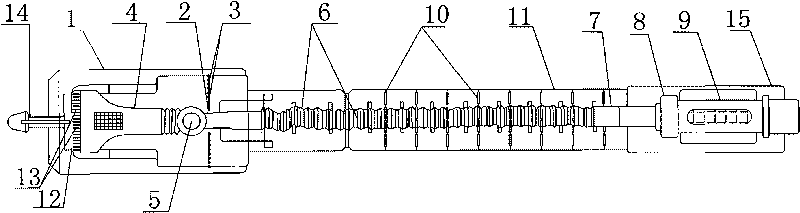

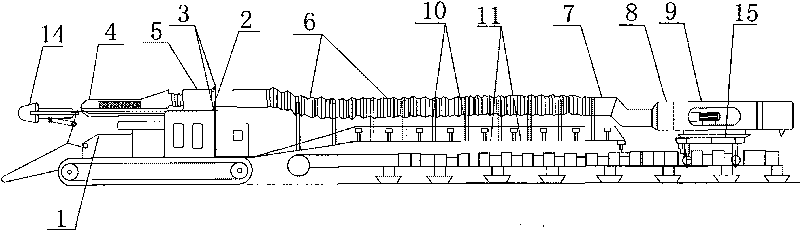

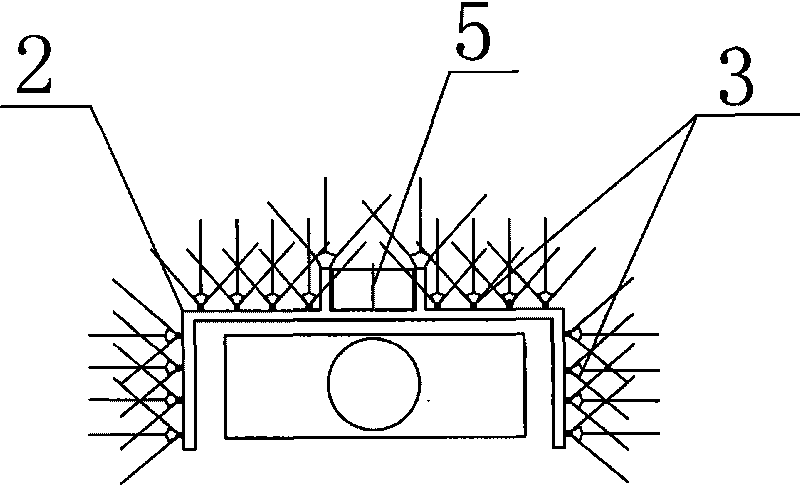

[0022] The present invention provides an air curtain closed dust removal system for fully mechanized excavation face. In order to make the purpose, technical solution and advantages of the present invention clearer and clearer, the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments below.

[0023] The present invention provides an air-curtain-enclosed and dust-removing system for a fully-mechanized excavation machine. An air-curtain generating device and a dust-removing device are installed on the machine body of the fully-mechanized excavator, so that the dust is effectively enclosed in a space where no one works, ensuring the safety of the driver and the working place. The reduction of the dust concentration improves the dust collection efficiency of the head-on dust in the tunneling, reduces the impact on the operator's sight, the operator can clearly see the tunneling level, and improves the safety of the opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com