SCR (silicon controlled rectifier) denitration system of cement kiln gas

A cement kiln and flue gas technology, applied in the field of SCR denitrification system, can solve the problems of increasing the use cost, catalyst poisoning, shortening the service life of the catalyst, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

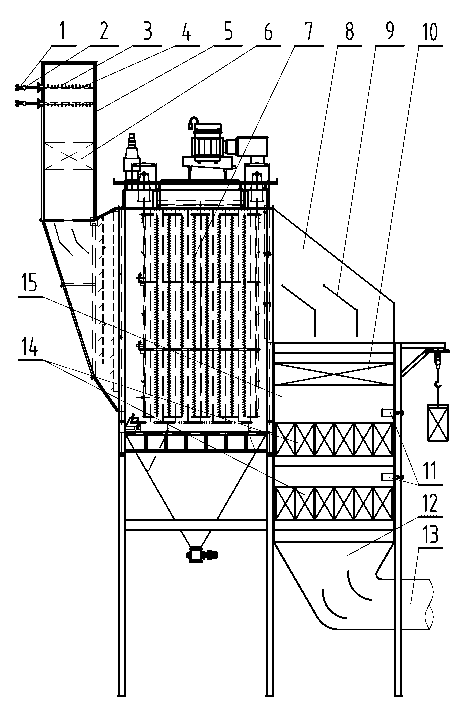

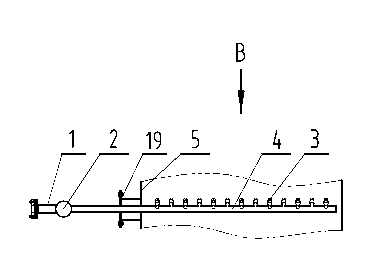

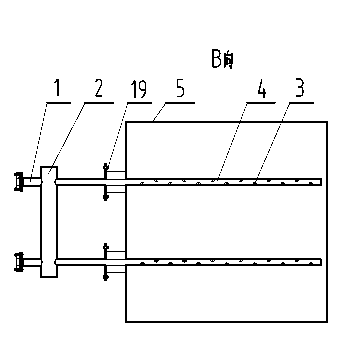

[0015] figure 1 Among them, an SCR denitrification system for flue gas from a cement kiln according to the present invention includes an ammonia injection device, a reactor box 15 , an air equalizing rectification device 10 , a catalyst 14 and a sonic soot blower 11 . The air uniform rectifying device 10 and the catalyst 14 are respectively arranged at the inner upper part and the lower part of the reactor box 15 . The sonic soot blower 11 is arranged in the reactor box 15 . The above-mentioned SCR denitrification system for cement kiln flue gas also includes an electrostatic precipitator 7 and a mixing device. This electrostatic precipitator 7 contains an air inlet and an air outlet, and the air inlet of the electric precipitator 7 is provided with an air inlet pipe 5, and the ammonia injection device and the mixing device 6 are arranged on the air inlet pipe 5 respectively, and the mixing Unit 6 is located downstream of the ammonia injection unit. The outlet of the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com