Method of using high-pressure water injection to prevent and treat gas coal dust

A gas-coal, high-pressure technology, applied in the field of high-pressure water injection to prevent gas and coal dust, can solve problems such as poor water injection in coal seams, reduce gas emission and dust concentration, prevent and control gas and coal dust, and improve the working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

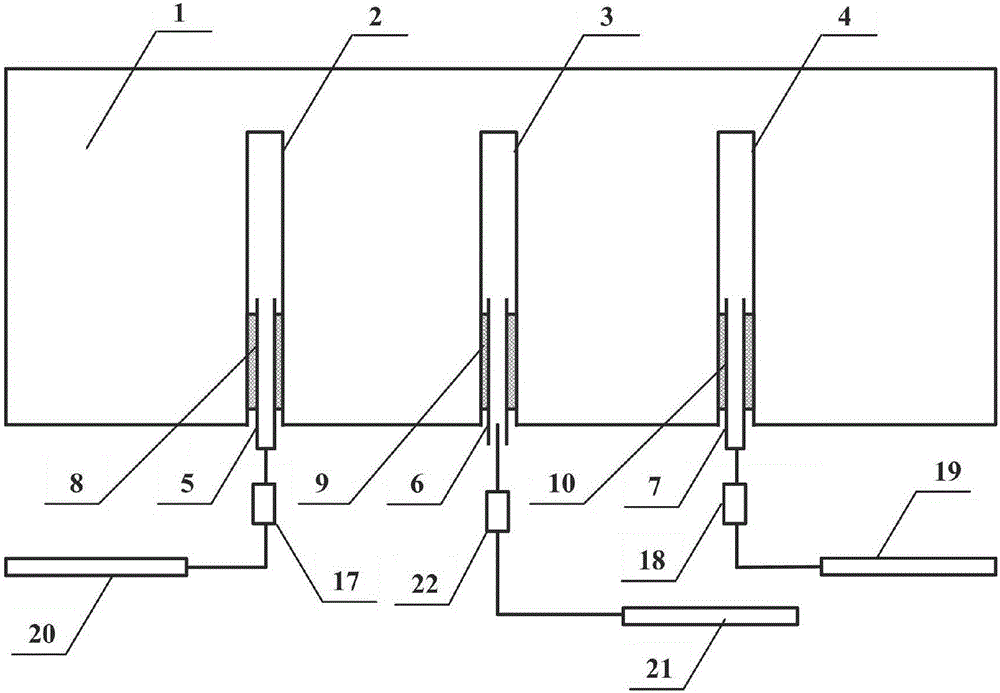

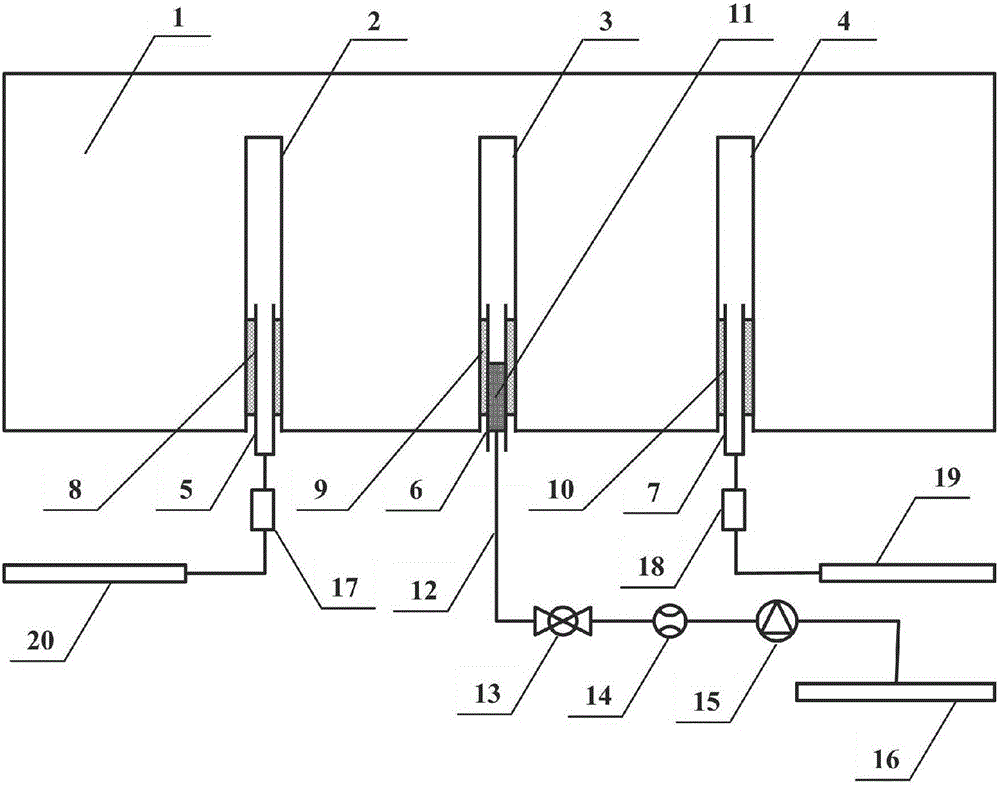

[0027] The invention provides a method for preventing and controlling gas and coal dust by high-pressure water injection, specifically as figure 1 and figure 2 shown, including the following steps:

[0028] Step 1: If figure 1 As shown, in the coal seam 1, the first borehole 2, the second borehole 3 and the third borehole 4 are extracted at intervals in the coal seam 1, and the boreholes are arranged alternately, and the borehole spacing fully considers the requirements of gas drainage and water injection in the coal seam; Insert the first extraction pipe 5 at the entrance of the first borehole 2, insert the second extraction pipe 6 at the entrance of the second borehole 3, insert the third extraction pipe 7 at the entrance of the third borehole 4, At the same time, the "two plugging and one injection" sealing process under pressure is adopted, and the gap between the first borehole 2 and the first extraction pipe 5 is sealed by using the sealing material to form the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com