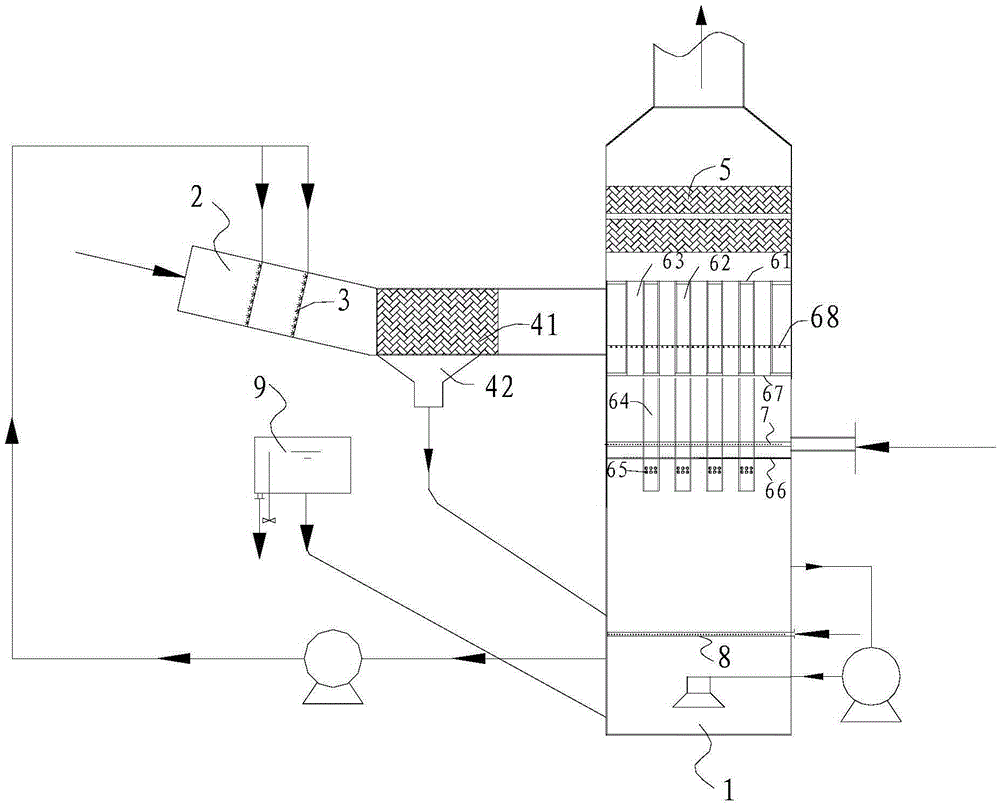

Bubble tower and method for wet flue gas desulphurization

A technology of wet flue gas desulfurization and bubble tower, which is applied in the field of flue gas desulfurization, can solve problems such as easy fouling of the bubble tube and blockage of the normal operation of the bubble tower, so as to increase the gas-liquid contact area, improve the desulfurization efficiency, and reduce the Effect of perforation air velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

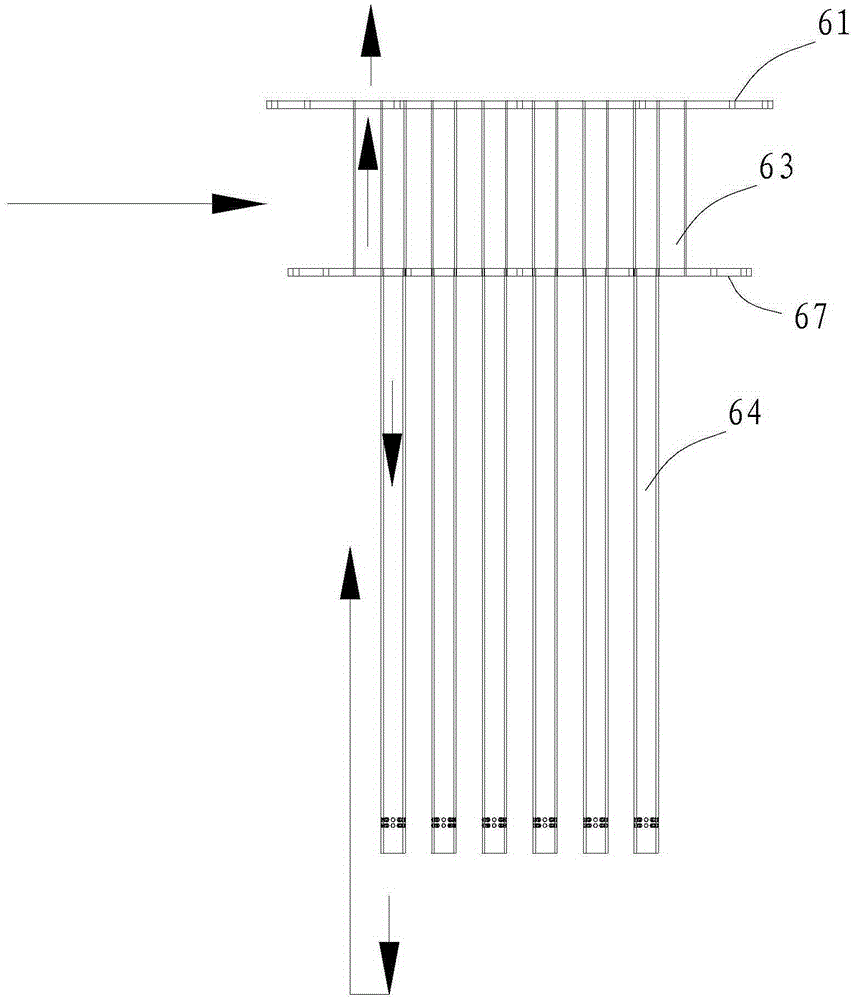

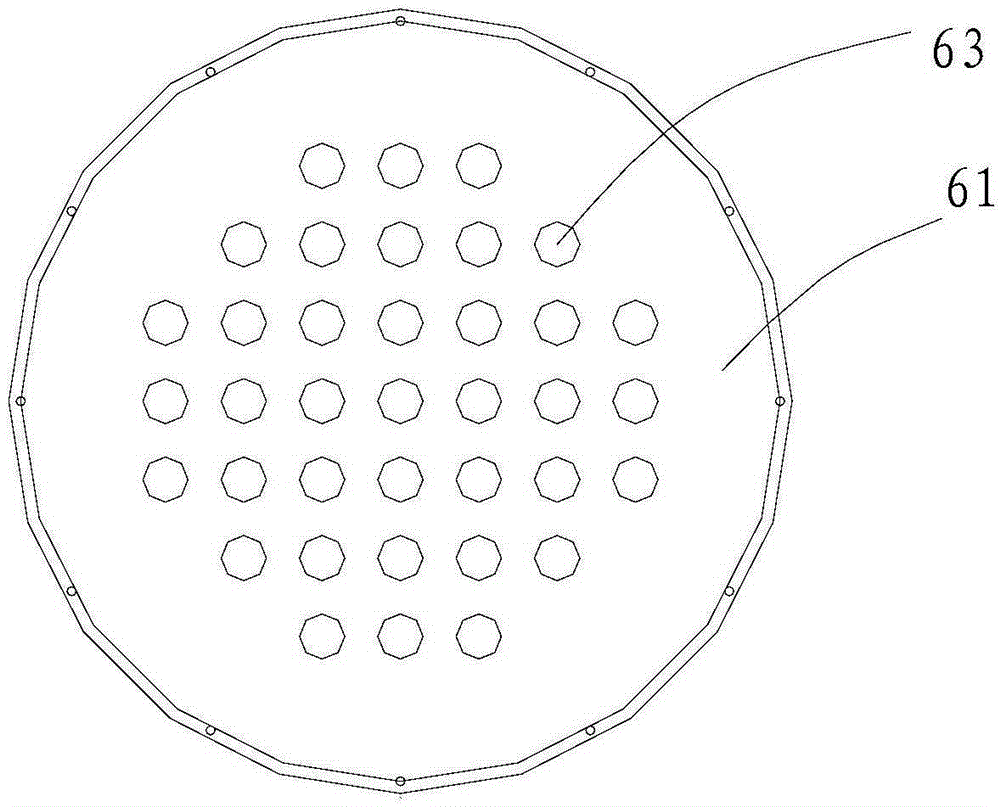

Embodiment 1

[0076] The flue gas desulfurization project of two 75T heating boilers in a printing and dyeing factory adopts this process, and the SO in the flue gas 2 The concentration is 2316mg / Nm 3 , the dust concentration is 85mg / Nm 3, the flue gas temperature is 142°C; the humidification spray liquid-gas ratio is 2.8L / Nm 3 , the diameter of the bubble hole is 25mm, the diameter of the rectifier plate is 30mm, the opening rate is 30%, and the liquid-gas ratio of the flushing water pipe is 1.5L / Nm 3 ; The diameter of the slurry hole is 15mm; the desulfurization efficiency is 98.9%, and the dust content at the outlet is 3.7mg / Nm 3 .

Embodiment 2

[0078] A thermal power plant, a 130T boiler flue gas desulfurization project adopts this process, SO in the flue gas 2 The concentration is 3060mg / Nm3, the dust concentration is 122mg / Nm3, the flue gas temperature is 118°C; the humidification spray liquid-gas ratio is 2.4L / Nm 3 , the diameter of the bubble hole is 30mm, the diameter of the rectifier plate is 30mm, the opening rate is 33%, and the liquid-gas ratio of the flushing water pipe is 1.2L / Nm 3 ; The diameter of the slurry hole is 18mm; the desulfurization efficiency is 99.2%, and the dust content at the outlet is 4.1mg / Nm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com