Denitration system and method which are capable of realizing direct utilization of agglomerate heat energy

A sintering and denitrification technology, applied in the field of denitrification system, can solve the problems of affecting the solid balance of the wet desulfurization system and the crystallization of by-products, destroying the long-term stable operation of the system, and low denitrification efficiency, so as to achieve high utilization efficiency, large operating flexibility, The effect of reducing system investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

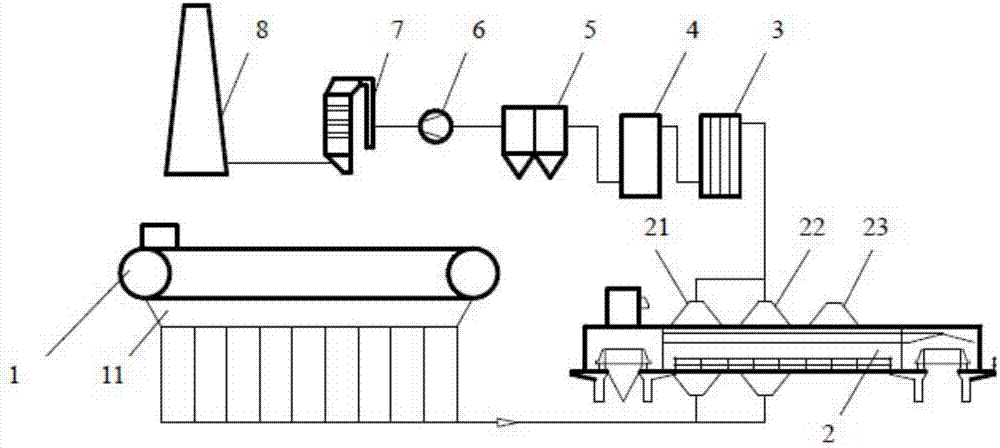

[0048] See figure 1 , which is a diagram of the low-temperature denitrification system that directly utilizes the heat of sinter in this embodiment. The low-temperature denitrification system includes a sintering machine 1, a sinter cooling device 2, a waste heat recovery device 3, a dry desulfurization device 4, a dust removal device 5, and a denitrification reactor 7 and chimney 8; the sintering machine is provided with a sintering machine bellows 11, and the sinter cooling equipment 2 is an existing ring cooler, which is provided with a first cooling equipment wind box 21 (high temperature section wind box), a cooling equipment second section bellows 22 (medium temperature section bellows) and the third section bellows 23 (low temperature section bellows) of cooling equipment, the flue gas outlet of the sintering machine bellows 11 is connected to the first section bellows 21 of the cooling equipment and the The flue gas inlet of the second-stage air box 22 of the cooling e...

Embodiment 2

[0057] The low-temperature denitrification system used in this embodiment is basically the same as that in Embodiment 1, except that this embodiment is an existing sintering machine, which itself has a sintering machine dust removal device (not shown in the figure), and the dust removal device is an electric dust collector. device, the electrostatic precipitator is installed on the connecting pipeline between the wind box 11 of the sintering machine, the wind box 21 of the first section of the cooling equipment, and the wind box of the second section of the cooling equipment.

[0058] The flue gas drawn from the wind box 11 of the existing sintering machine is collected together. At this time, the SO in the flue gas 2 The concentration is 2000mg / Nm 3 , NO x The concentration is 500mg / Nm 3 , the dust content is 2000mg / Nm 3 , the flue gas temperature is 140°C, the sintering flue gas is passed through the electrostatic precipitator to reduce the dust content to 150mg / Nm 3, an...

Embodiment 3

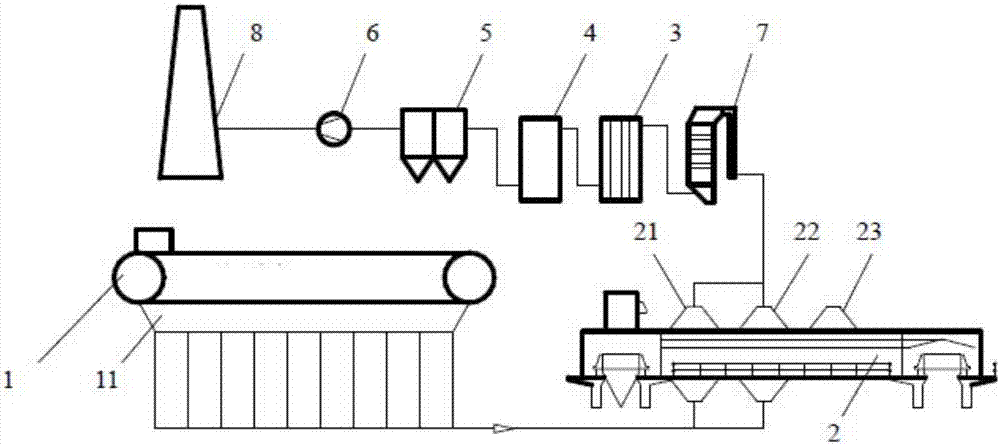

[0060] See figure 2 , which is a diagram of the medium-temperature denitrification system that directly utilizes the heat of sinter in this embodiment. The medium-temperature denitrification system includes a sintering machine 1, a sinter cooling device 2, a waste heat recovery device 3, a dry desulfurization device 4, a dust removal device 5, and a medium-temperature denitrification reaction 7 and chimney 8; the sintering machine is provided with a sintering machine air box 11, and the sinter cooling equipment 2 is an existing ring cooler, which is provided with a cooling equipment first section air box 21 (high temperature section air box), a cooling equipment first The second section wind box 22 (medium temperature section wind box) and the third section wind box 23 (low temperature section wind box) of the cooling equipment, the flue gas outlet of the sintering machine bellows 11 is connected to the first section wind box 21 and The flue gas inlet of the second-stage wind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com