Electromagnetic ultrasonic brazing method for SiC ceramic

A technology of electromagnetic ultrasonic and brazing method, applied in the field of SiC ceramic welding, can solve the problems of difficult connection at low temperature, large residual stress of joint, cracking of base metal, etc., and achieve the effect of improving comprehensive mechanical properties, improving joint strength and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

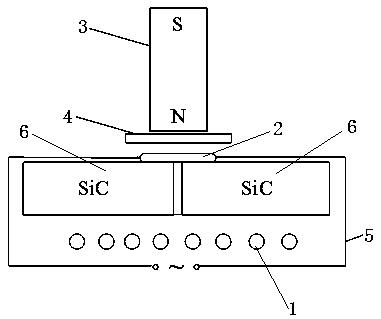

[0024] This electromagnetic ultrasonic brazing method for SiC ceramics includes the following steps:

[0025] Step 1, the width of the solder foil 2 is processed to be completely consistent with the width and size of the SiC ceramic 6; the solder foil 2 is a Sn-Zn-Ti-Al foil.

[0026] Step 2: Grinding the surfaces of the solder foil 2 and the SiC ceramic 6 with sandpaper, and cleaning with acetone for 10-30 min.

[0027] Step 3. Fill the solder foil 2 processed in step 2 between the two surfaces of the SiC ceramics 6 to be welded, so that the two SiC ceramics 6 are horizontally placed side by side, and another solder foil 2 is horizontally placed between the two surfaces. on the upper edge of each surface to be welded, and put them in the muffle furnace, set it directly above the heating device 1, raise the temperature to 100 °C at a rate of 10 °C / min and keep it for 8 minutes, and then set it in the vertical direction In the static magnetic field, the permanent magnet 3 and ...

Embodiment 2

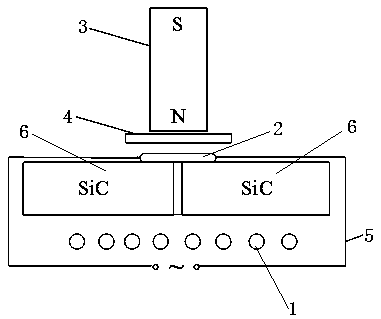

[0029] This electromagnetic ultrasonic brazing method for SiC ceramics includes the following steps:

[0030] Step 1, the width of the solder foil 2 is processed to be completely consistent with the width and size of the SiC ceramic 6; the solder foil 2 is a Sn-Zn-Ti-Al foil.

[0031] Step 2, using sandpaper to polish the surfaces of the solder foil 2 and the SiC ceramic 6, and cleaning with acetone for 10-30 min.

[0032] Step 3. Fill the solder foil 2 processed in step 2 between the two surfaces of the SiC ceramics 6 to be welded, so that the two SiC ceramics 6 are horizontally placed side by side, and another solder foil 2 is horizontally placed between the two surfaces. on the upper edge of each surface to be welded, and put them in the muffle furnace, set it directly above the heating device 1, raise the temperature to 400 °C at a rate of 30 °C / min and keep it for 10 minutes, and then set it in the vertical direction In the static magnetic field, the permanent magnet 3 a...

Embodiment 3

[0034] This electromagnetic ultrasonic brazing method for SiC ceramics includes the following steps:

[0035] Step 1, the width of the solder foil 2 is processed to be completely consistent with the width and size of the SiC ceramic 6; the solder foil 2 is a Sn-Zn-Ti-Al foil.

[0036] Step 2, using sandpaper to polish the surfaces of the solder foil 2 and the SiC ceramic 6, and cleaning with acetone for 10-30 min.

[0037] Step 3. Fill the solder foil 2 processed in step 2 between the two surfaces of the SiC ceramics 6 to be welded, so that the two SiC ceramics 6 are horizontally placed side by side, and another solder foil 2 is horizontally placed between the two surfaces. on the upper edge of each surface to be welded, and put them in the muffle furnace, set it directly above the heating device 1, raise the temperature to 260 °C at a rate of 20 °C / min and keep it for 5 minutes, and then set it in the vertical direction In the static magnetic field, the permanent magnet 3 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com