A method for preparing nanoparticle-reinforced aluminum matrix composites

A composite material, a technology for reinforcing aluminum matrix, which is applied in the field of preparing nano-ceramic particle reinforced aluminum-matrix composite material, can solve the problems of poor dispersion of nano-ceramic particles, difficult wetting of nano-ceramic particles and metal matrix, etc., and achieves short ball milling time and high efficiency. High, improve the effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

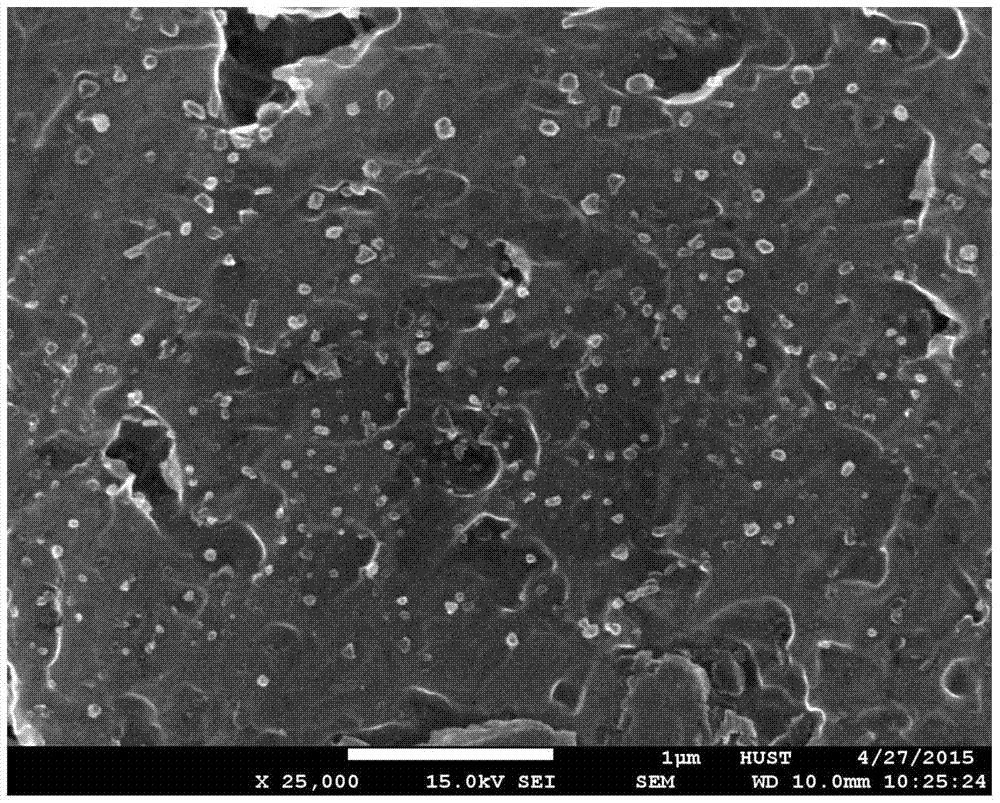

[0040] Step 1: Weigh 2g of SiC powder with an average particle size of 40nm and a purity greater than 99.9% and 98g of pure Al powder with an average particle size of 70 μm and a purity of 99.85% or higher, wherein the volume of nano-SiC accounts for about 20% of the total volume.

[0041] Step 2: Add 500g of stainless steel grinding balls to a 500ml metal ball mill tank, 20 large balls with a diameter of 10mm, and the rest are small balls with a diameter of 6mm; pour the SiC powder and Al powder weighed in the first step Mill jar.

[0042] The third step: evacuate the ball mill tank, pass argon gas, and evacuate.

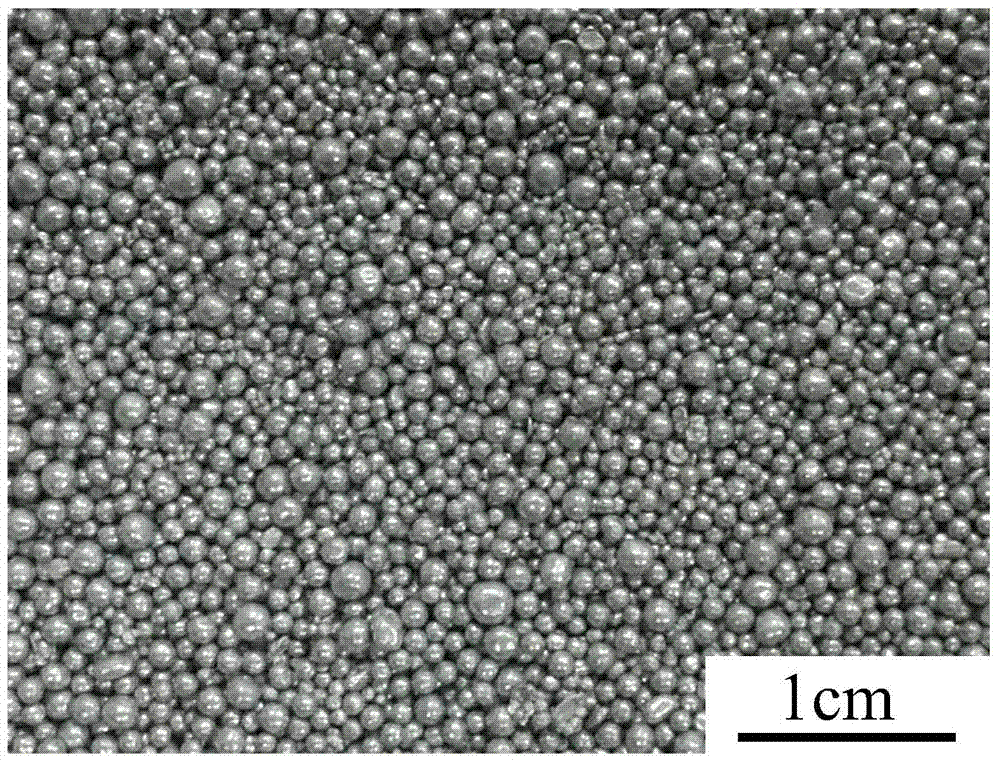

[0043] Step 4: Start ball milling. Ball milling parameter is 300r / min, intermittent ball milling, ball milling for 1h, stop for 20min, take out millimeter-scale nano-SiC after ball milling for 10h p / Al composite particles.

[0044] The fifth step: the 500g millimeter-scale nano-SiC prepared by the above method p / Al composite particles were directly melted in ...

Embodiment 2

[0049] Step 1: Weigh 4g of SiC powder with an average particle size of 50nm and a purity of greater than 99.9% and 100g of pure Al powder with an average particle size of 80μm and a purity of greater than or equal to 99.85%, wherein the volume of SiC accounts for about 40% of the total volume.

[0050] Step 2: Add 1000g of stainless steel grinding balls to a 500ml metal ball mill tank, 50 large balls with a diameter of 10mm, and the rest are small balls with a diameter of 6mm; pour the SiC powder and Al powder weighed in the first step into the ball mill Can.

[0051] The third step: evacuate the ball mill tank, pass argon gas, and evacuate.

[0052] Step 4: Start ball milling. Ball milling parameter is 400r / min, intermittent ball milling, ball milling for 1h, stop for 20min, take out millimeter-sized nano-SiC after ball milling for 8h p / Al composite particles.

[0053] Step 5: Incorporate millimeter-scale nano-SiC by mechanical stirring p / Al composite particles were add...

Embodiment 3

[0058] Step 1: Weigh 4g of SiC powder with an average particle size of 60nm and a purity greater than 99.9% and 100g of pure Al powder with an average particle size of 90μm and a purity of 99.85% or higher, wherein the volume of SiC accounts for about 40% of the total volume.

[0059] Step 2: Add 1500g of stainless steel grinding balls to a 500ml metal ball mill tank, 60 large balls with a diameter of 10mm, and the rest are small balls with a diameter of 6mm; pour the SiC powder and Al powder weighed in the first step into the ball mill Can.

[0060] The third step: evacuate the ball mill tank, pass argon gas, and evacuate.

[0061] Step 4: Start ball milling. Ball milling parameter is 500r / min, intermittent ball milling, ball milling for 1h, stop for 20min, take out millimeter-sized nano-SiC after ball milling for 6h p / Al composite particles.

[0062] Step 5: Millimeter nano-SiC was mixed by mechanical stirring method p / Al composite particles were added to the Al-Si all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com