Preparation method of metal powder materials

A technology of metal powder and powder materials, which is applied in the field of preparation of metal powder materials, can solve problems such as complex process, high cost, and difficult classification, and achieve the effects of simple operation, low cost, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention provides a kind of preparation method of metal powder material, it comprises the following steps:

[0028] S1, providing an alloy sheet, wherein the composition of the alloy sheet is M a N b , M is selected from Mg, Ca, Li, Na, K, Ba, Al, Co, Cu, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, At least one of Yb and Lu, N selected from at least one of W, Cr, Mo, V, Ta, Nb, Zr, Hf, Ti, a and b represent the atomic percentage content of the corresponding constituent elements, and 0.1% ≤b≤45%, a+b=100%, the microstructure of the alloy sheet is composed of a matrix phase with a composition of M and a dispersed particle phase with a composition of N;

[0029] S2, reacting the alloy sheet with an acid solution, so that the matrix phase composed of M and the H of the acid solution + The reaction turns metal ions into the solution, and the dispersed particles whose composition is N are separated out, that is, the metal N powder material is obtain...

Embodiment 1

[0049] This embodiment provides a preparation method of submicron V powder, which preparation method comprises the following steps:

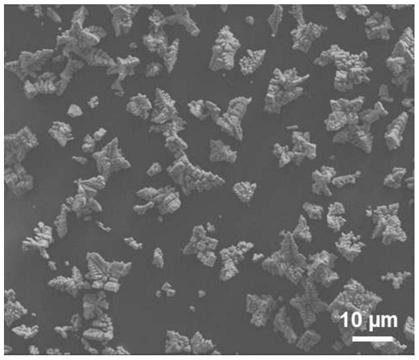

[0050] (1) The molecular formula of the selected formula is Ca 98.5 V 1.5 alloy, according to the formula to weigh the raw materials, after arc melting to get Ca 98.5 V 1.5 Alloy, the alloy is heated and remelted by an electric arc and then sucked into a copper mold (cooling rate is about 500K / s) to prepare Ca 98.5 V 1.5 alloy sheet. The alloy structure includes a matrix phase composed of Ca and a submicron (100nm-1μm) dispersed particle phase composed of V.

[0051] (2) At room temperature, 0.2 gram of Ca prepared in step (1) 98.5 V 1.5 The alloy sheet was submerged in 50 mL of sulfuric acid aqueous solution with a concentration of 0.1 mol / L for reaction. During the reaction process, the matrix composed of the active element Ca reacts with the acid and enters the solution, and the submicron-sized near-spherical V particles that do not r...

Embodiment 2

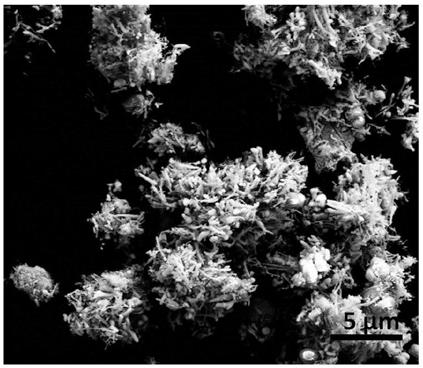

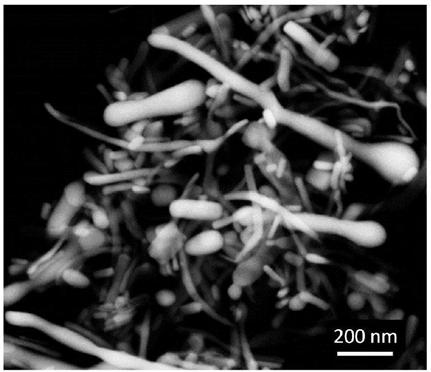

[0053] The present embodiment provides a kind of preparation method of submicron NbV alloy powder, and this preparation method comprises the following steps:

[0054] (1) The molecular formula of the selected formula is Y 98 (Nb 50 V 50 ) 2 Alloy, weigh the raw material according to the formula, and get Y after arc melting 98 (Nb 50 V 50 ) 2 Alloy, the alloy is remelted by arc heating and then sucked into a copper mold (cooling rate is about 500K / s) to prepare a Y with a size of 1mm×2mm×10mm 98 (Nb 50 V 50 ) 2 An alloy thin plate, the alloy structure includes a matrix composed of Y and a submicron (100nm-1μm) dispersed particle phase composed of NbV.

[0055] (2) At room temperature, 0.2 gram of Y prepared in step (1) 98 (Nb 50 V 50 ) 2 The alloy sheet was submerged in 50 mL of sulfuric acid aqueous solution with a concentration of 0.1 mol / L for reaction. During the reaction process, the matrix composed of active element Y reacts with the acid and enters the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com