Nanometer layered horizontal homogeneous PN diode and fabrication method and application thereof

A nano-layered, diode-based technology, applied in the direction of nanotechnology, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of slow photoresponse, low success rate of homogeneous PN diodes, complex preparation process, etc., and achieve the preparation method Simple, no directional transfer process, good photoresponse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

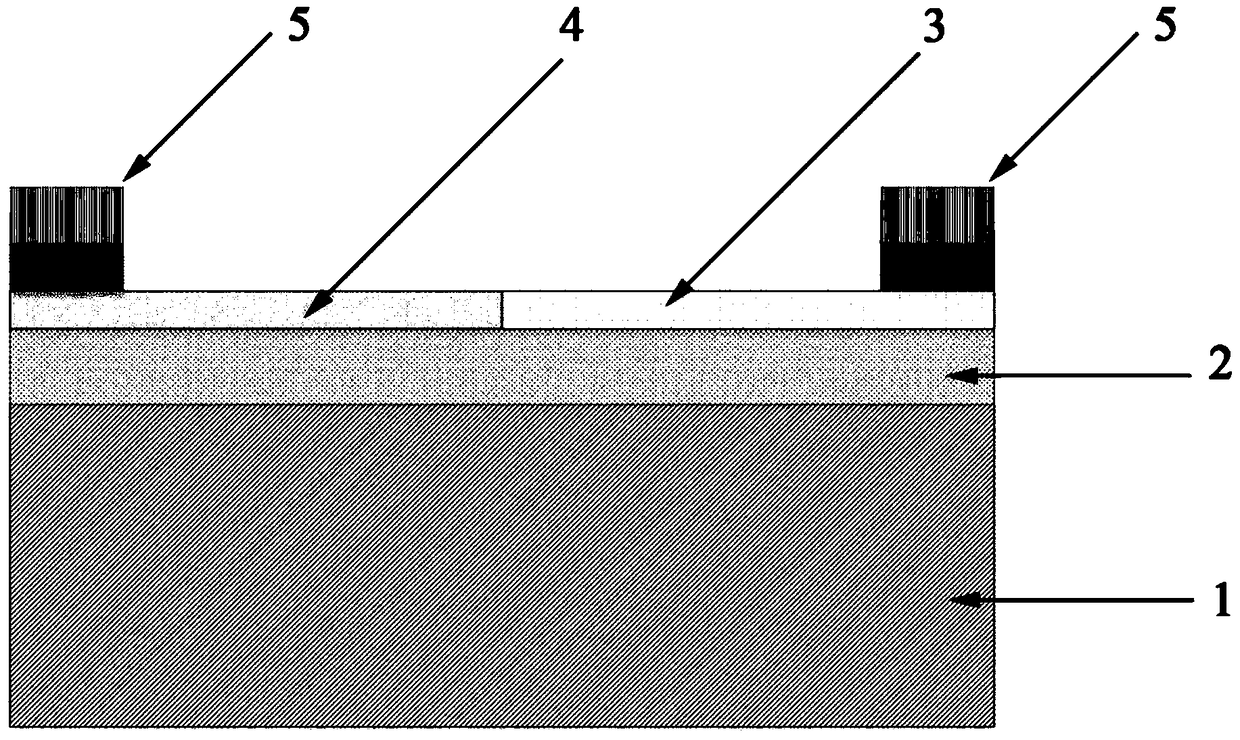

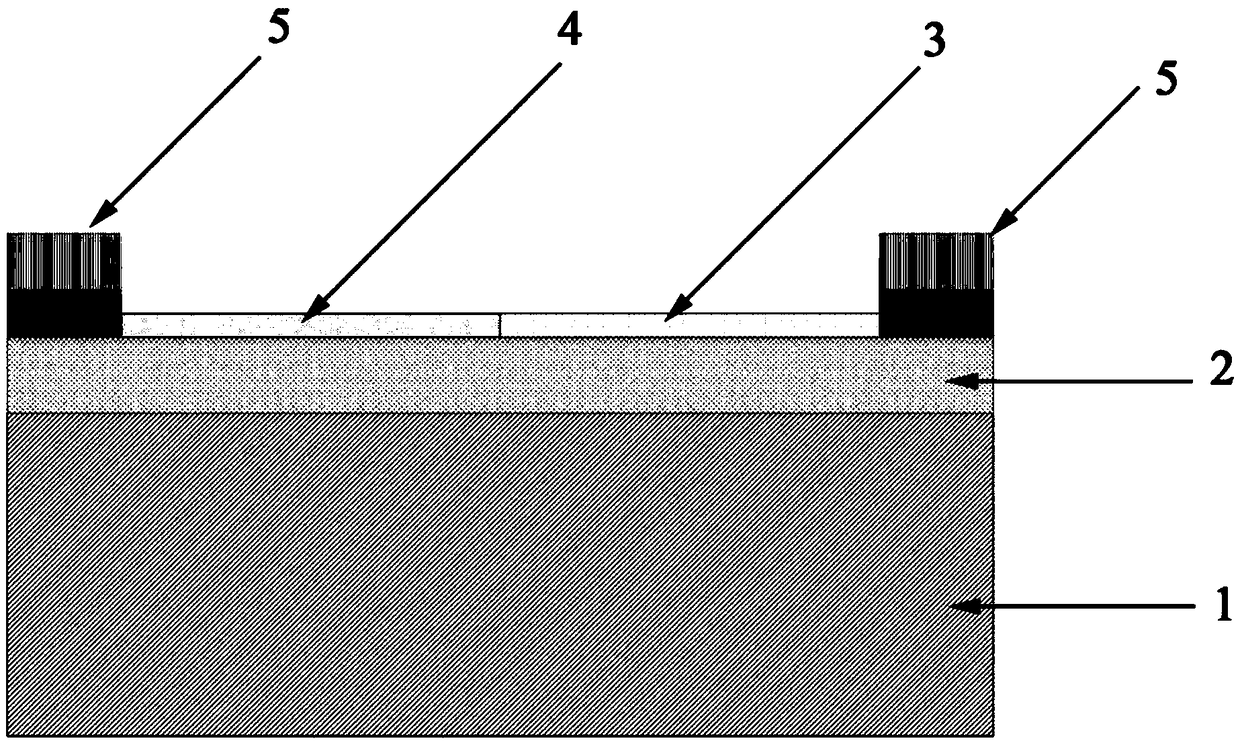

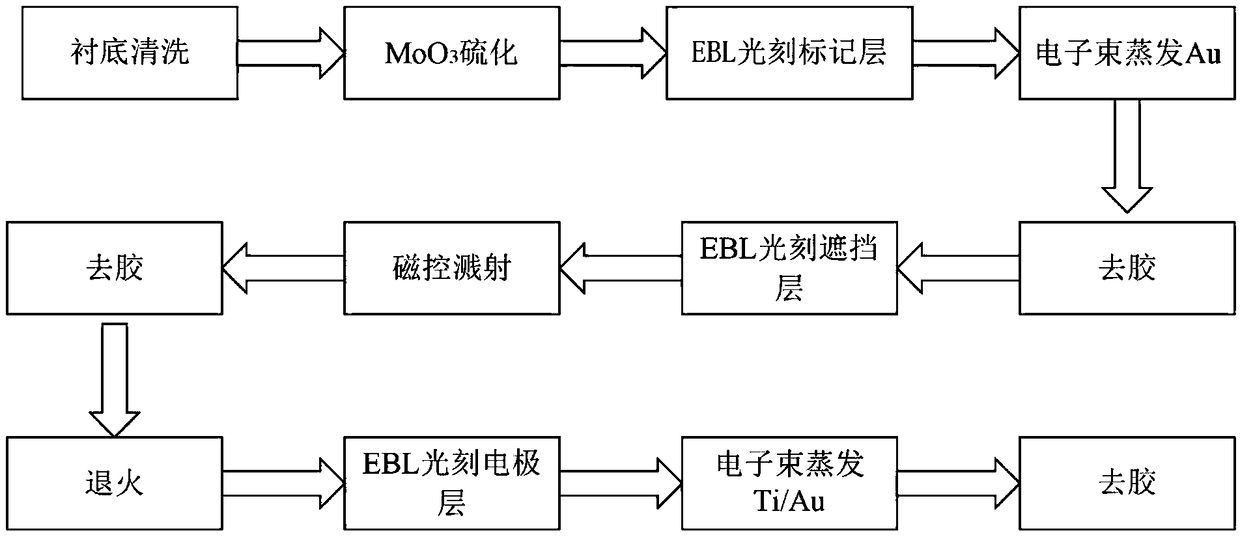

[0037] image 3 It is a flow chart of the process for preparing a horizontally homogeneous PN diode of a nano-layered transition metal chalcogenide compound in the present invention. Figure 4 It is the corresponding schematic diagram of the process flow chart of preparing nano-layered transition metal chalcogenide laterally homogeneous PN diodes in the present invention. The specific steps of the preparation method of the nano-layered transition metal chalcogenide laterally homogeneous PN diode provided by the present invention are as follows:

[0038] (1) Use acetone solution to have SiO on the surface 2 The p-type single crystal silicon wafer of the dielectric layer is ultrasonically cleaned to remove organic dirt on the substrate surface, and the substrate is ultrasonically cleaned with alcohol to remove acetone on the substrate surface, and rinsed with deionized water for 3 times.

[0039] (2) The above substrate is cleaned with buffered etchant BOE to remove the natura...

Embodiment 1

[0053] The invention discloses a method for preparing a nano-layered transition metal chalcogenide laterally homogeneous PN diode, comprising the following steps:

[0054] (1) Use acetone solution to have 50nm thick SiO on the surface 2 The thickness of the dielectric layer is 300 μm p-type single crystal silicon wafer, ultrasonic cleaning is performed to remove organic dirt on the substrate surface, and the substrate is ultrasonically cleaned with alcohol to remove acetone on the substrate surface, and deionized water is rinsed 3 times .

[0055] (2) The above substrate is cleaned with buffered etchant BOE to remove the natural oxide layer on the surface, then rinsed with deionized water, and dried with nitrogen. The cleaned surface has SiO 2 The single crystal silicon wafer of the dielectric layer is referred to as substrate A.

[0056] (3) For molybdenum trioxide powder MoO 3 n-type layered MoS was prepared on substrate A by chemical vapor deposition CVD with sulfur pow...

Embodiment 2

[0068] The invention discloses a method for preparing a nano-layered transition metal chalcogenide laterally homogeneous PN diode, comprising the following steps:

[0069] (1) Use acetone solution to have 80nm thick SiO on the surface 2 A p-type single crystal silicon wafer with a dielectric layer thickness of 325 μm was ultrasonically cleaned to remove organic dirt on the substrate surface, and the substrate was ultrasonically cleaned with alcohol to remove acetone on the substrate surface, and rinsed with deionized water for 3 Second-rate.

[0070] (2) The above substrate is cleaned with buffered etchant BOE to remove the natural oxide layer on the surface, then rinsed with deionized water, and dried with nitrogen. The cleaned surface has SiO 2 The single crystal silicon wafer of the dielectric layer is referred to as substrate A.

[0071] (3) For molybdenum trioxide powder MoO 3 n-type layered MoS was prepared on substrate A by chemical vapor deposition CVD with sulfur ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com