Image identification method of stirring friction welding arc stripe interval

A friction stir welding and arc-shaped technology, which is applied in character and pattern recognition, measuring devices, instruments, etc., can solve the problem of not being able to obtain the arc-shaped pattern spacing in real time, so as to improve the degree of recognition, increase the value of research, and enrich the acquisition methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0052] like Figure 1-19 shown.

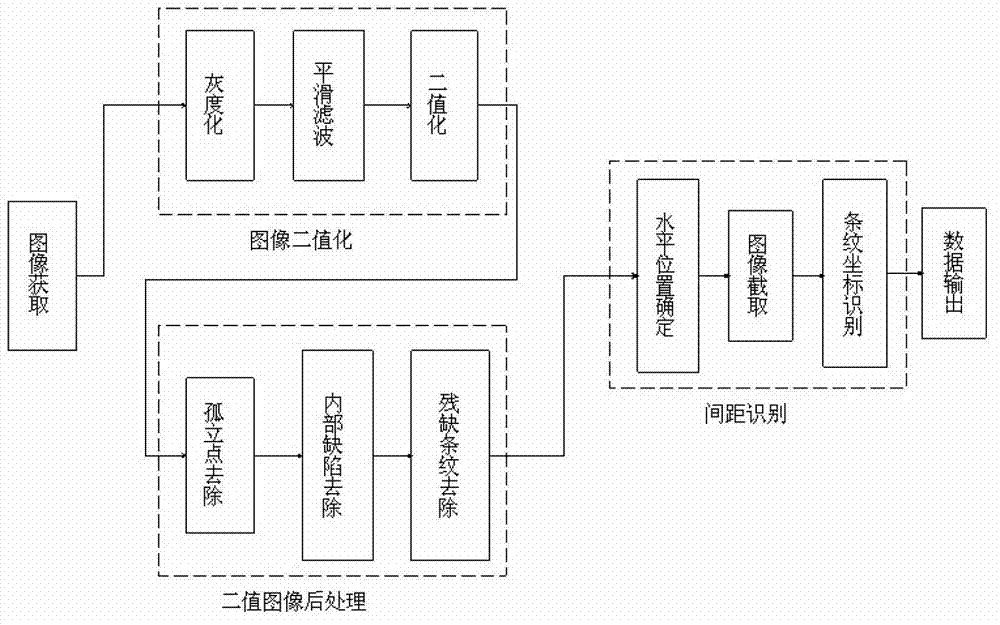

[0053] An image recognition method for friction stir welding arc groove spacing, the process is as follows figure 1 As shown, it includes the following steps:

[0054] (1) Acquisition of arc pattern images, including the following steps:

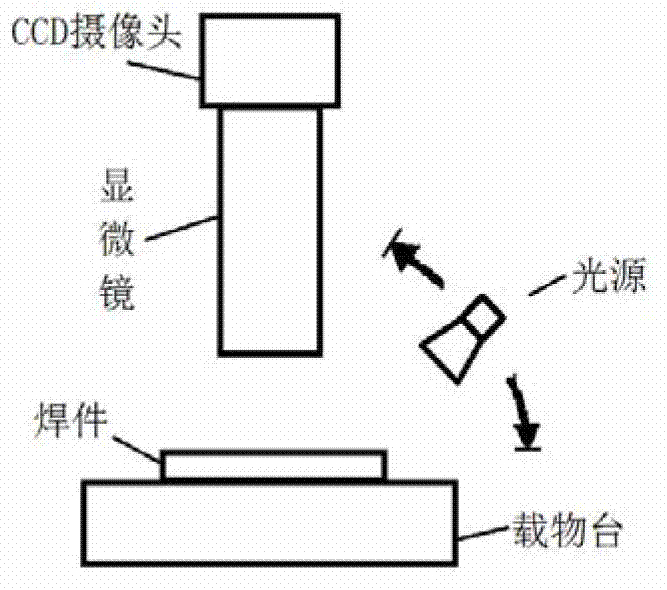

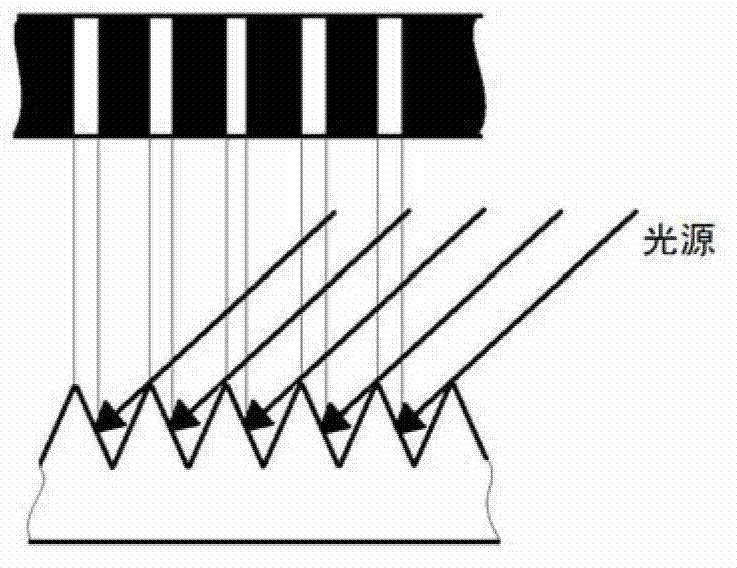

[0055] When image acquisition is performed on the arc pattern on the friction stir welding surface, the light source with a certain angle of incidence relative to the arc pattern surface is the only light source, and the image acquisition device such as figure 2 As shown, the incident light source effect diagram is as follows image 3 As shown, the angle between the incident angle and the horizontal plane should be less than 90 degrees, image 3 The incident angle is between 45 degrees and 60 degrees.

[0056] (2) Binarization of the arc pattern image, including the following s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com