Microelectronic machinery microwave frequency detector and method for making same

A micro-electromechanical, microwave frequency technology, applied in the direction of frequency measurement device, frequency to phase shift conversion, generator/motor, etc., can solve the problems of small signal amplitude, DC power consumption, etc., and achieve the effect of wide measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

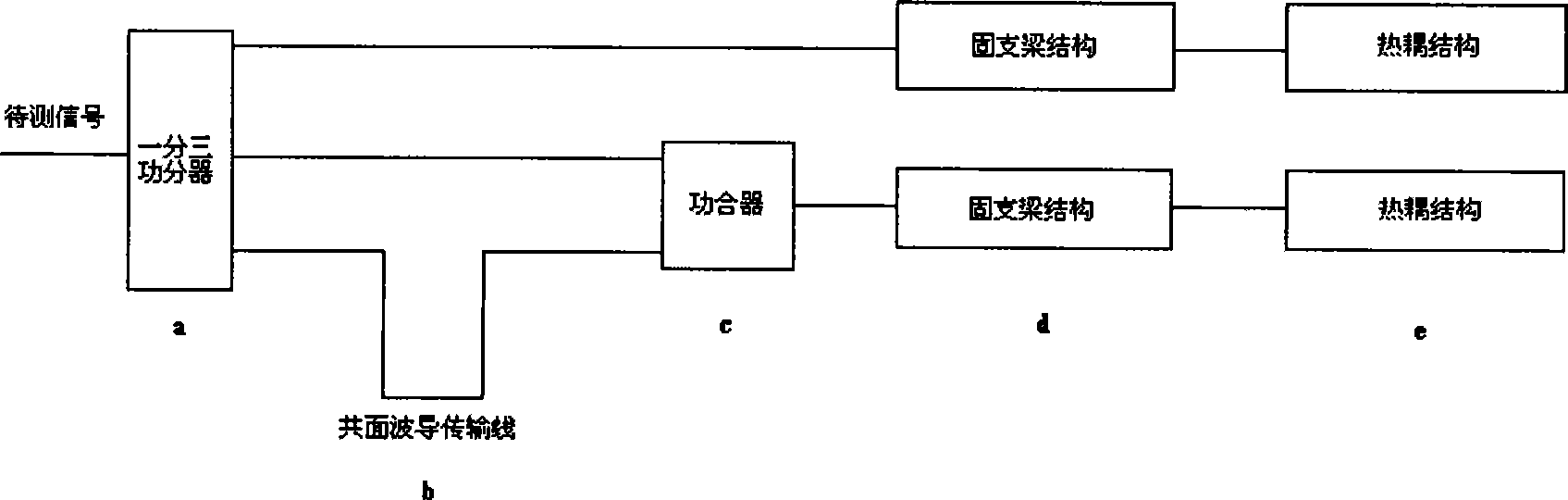

[0039] Micro-electromechanical microwave frequency detector of the present invention is a kind of microwave instantaneous frequency on-line detector, is substrate with GaAs substrate, and specific embodiment is as follows:

[0040] Design one-to-three power splitter a, coplanar waveguide transmission line b, two-in-one power combiner c, fixed beam structure d and thermal coupling structure e on the substrate:

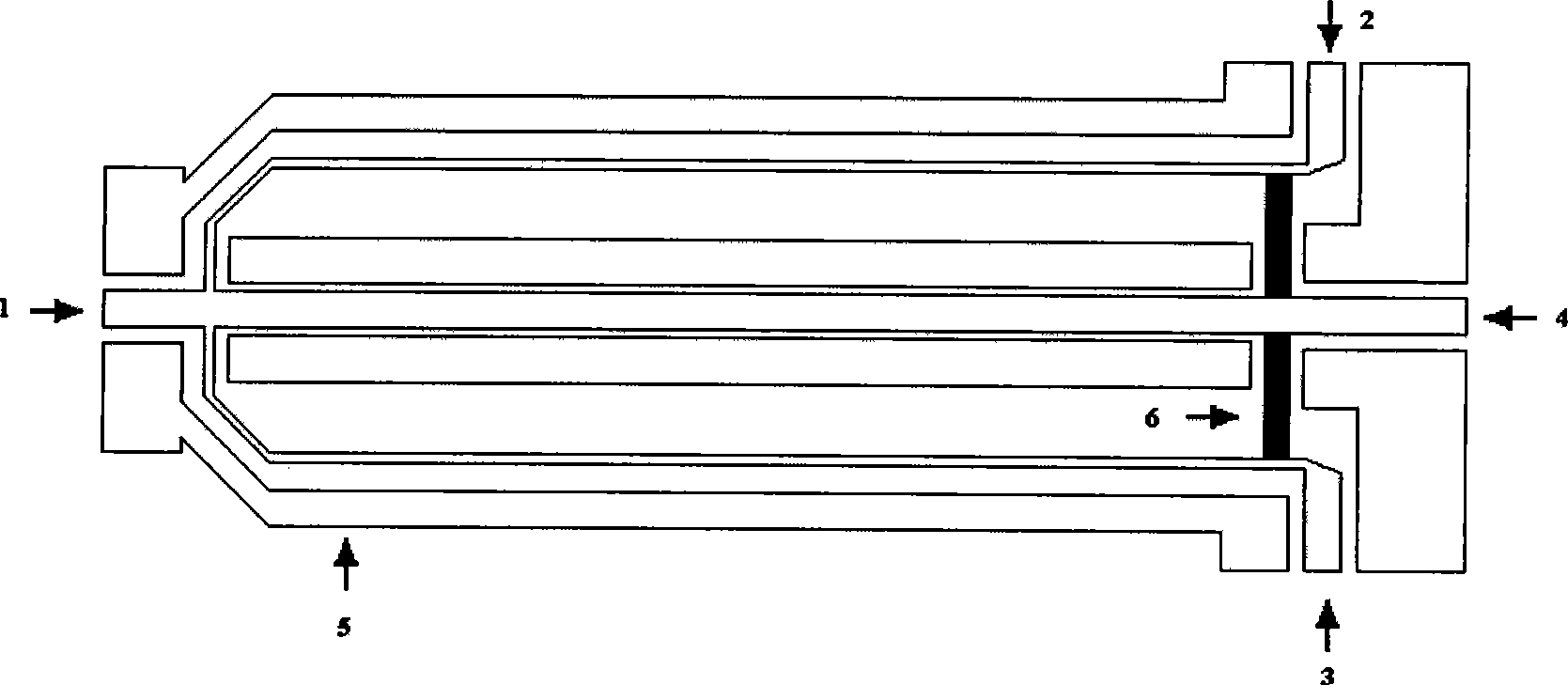

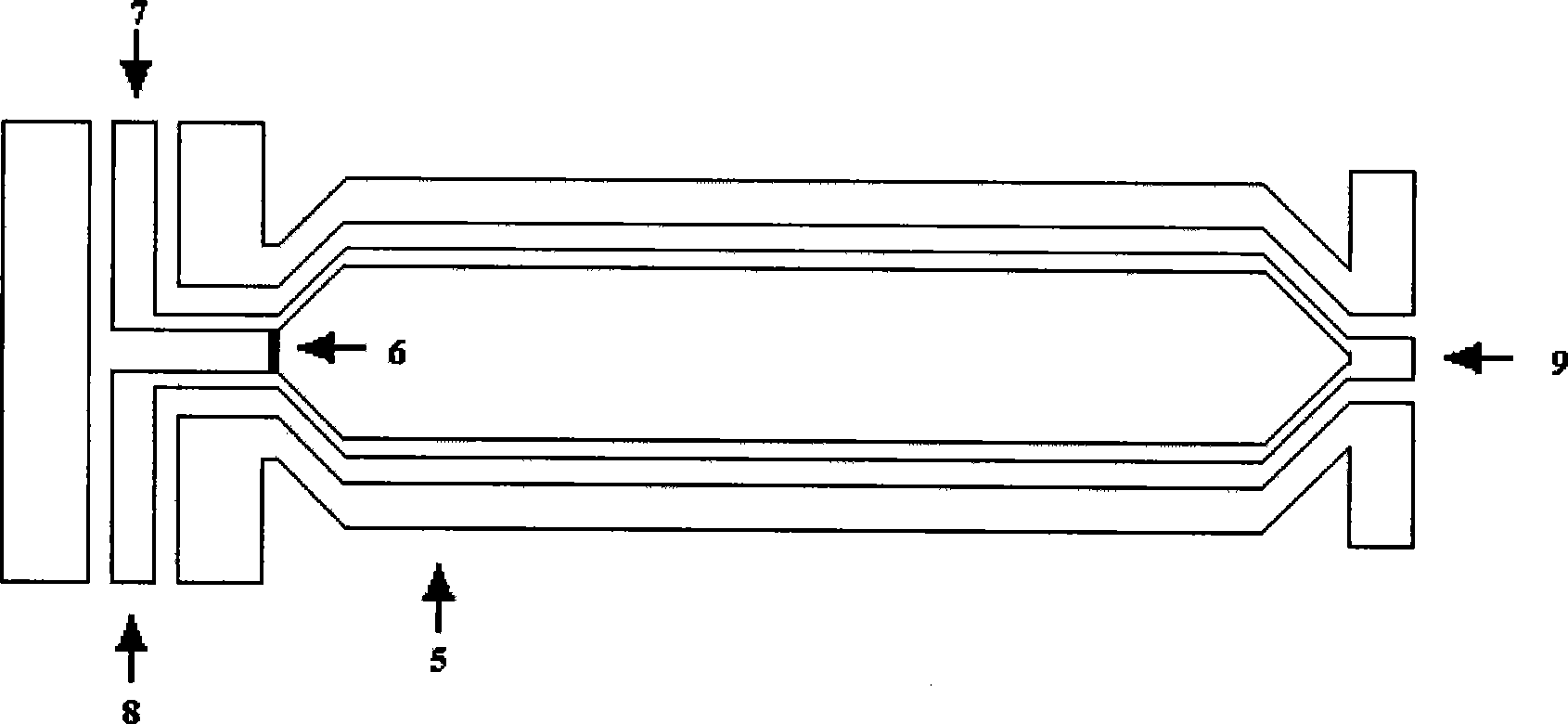

[0041] One-to-three power splitter a is composed of port one 1, port two 2, port three 3, port four 4, asymmetric coplanar stripline 5 and tantalum nitride resistor 6 composed of coplanar waveguides. Port one 1 passes through asymmetric The coplanar stripline 5 is respectively connected to port two 2 and port three 3, and is connected to port 4 through a coplanar waveguide structure. A tantalum nitride resistor 6 is connected between them; the two-in-one power combiner c is composed of port one 7, port two 8, port three 9, asymmetric coplanar stripline 5 and tantalum ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com