Railway wheel heat treatment heating furnace and heat treatment process thereof

A process method and heating furnace technology, which is applied in the field of heat treatment process, railway wheel manufacturing, and railway wheel heat treatment heating furnace, can solve the problems of high temperature retention time, etc., achieve short residence time, good process repeatability, and good surface quality of workpieces Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

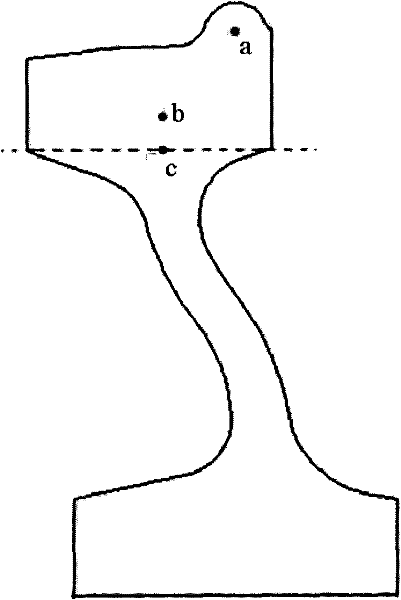

[0084] Take two railway wheels 1 with the same furnace number, the composition of which is shown in Table 1, and one of them has a pre-processed thermocouple temperature measuring hole, the position is as follows figure 2 Shown (a, b, c point among the figure); Another piece is the comparative example that adopts prior art. ( figure 2 It is a sectional view along the railway wheel 1 axis. )

[0085] The two railway wheels 1 are simultaneously subjected to normalizing at 820° C. for 1 hour, followed by annealing pretreatment at 710° C. to 740° C. for 1 hour.

[0086] Then using the above-mentioned device and the above-mentioned method of the present invention, the rim of a piece of railway wheel 1 processed with a temperature measuring hole is induction heated, and the temperature is set to 850 ° C, and the temperature measurement result inside the rim is as follows Figure 4 As shown, quenching and tempering are carried out after heating. ( Figure 4 The curves of a, b,...

Embodiment 2

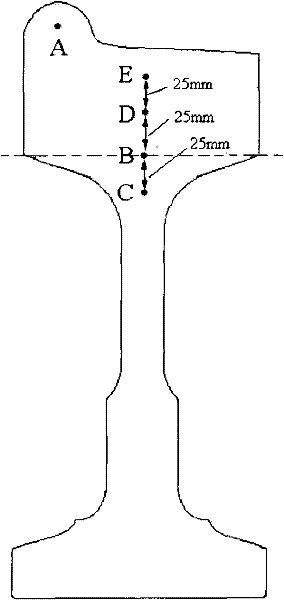

[0093] Take two railway wheels 1 with the same furnace number, the composition of which is shown in Table 1, and one of them has a pre-processed thermocouple temperature measuring hole, the position is as follows image 3 Show (A, B, C, D, E point among the figure); Another piece is the comparative example that adopts prior art. ( image 3 is a sectional view along the axis of the railway wheel 1. )

[0094] The two railway wheels 1 are simultaneously subjected to normalizing at 820° C. for 1 hour, followed by annealing pretreatment at 710° C. to 740° C. for 1 hour.

[0095] Then, using the above-mentioned device and the above-mentioned method of the present invention, the rim of a railway wheel 1 processed with a temperature measuring hole is induction heated, and the temperature is set to 860° C., and the temperature measurement result inside the rim is as follows Figure 5 As shown, quenching and tempering are carried out after heating. ( Figure 4 The A, B, C, D, E cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com