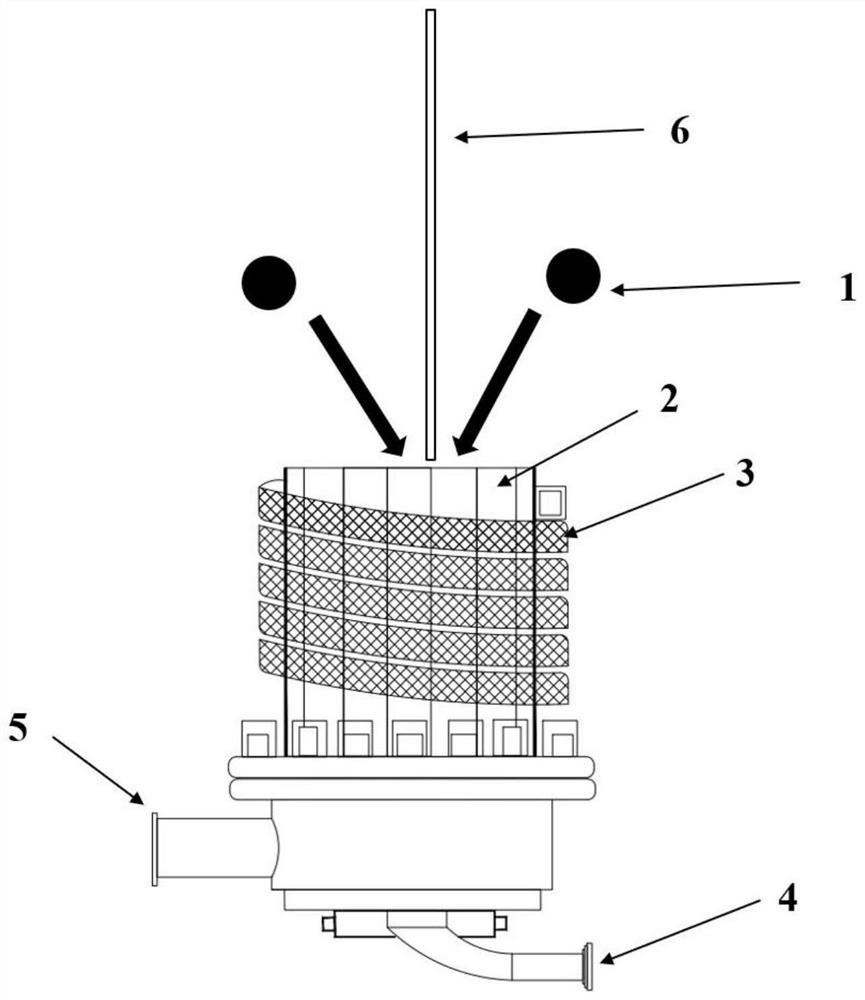

Optical auxiliary induction heating self-crucible single crystal growth device and application thereof

An induction heating and growth device technology, which is applied in the direction of single crystal growth, crystal growth, chemical instruments and methods, etc., can solve the problems of high crystal defect density, large investment in crystal growth, high cost, etc., and achieve the regulation and reduction of physical properties. Crystal growth cost, effect of low-cost growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In Example 1, crystals were obtained by adopting spontaneous nucleation without adopting processes such as pulling and seeding. The device used in Examples 2-3 is an upper weighing automatic diameter control (ADC) system device, and a rear heater temperature zone is set on the crucible. The upper weighing automatic equal diameter control (ADC) system device is conventional equipment in this field, and the commonly used device models are TDL2J50A or TDL2J60.

Embodiment 4

[0041] In Example 4, a noble metal iridium or platinum-rhodium alloy is added to make a mold, and crystals grow controllably on the upper surface of the mold.

[0042] Example 1:

[0043] Gallium oxide spontaneous nucleation crystal growth, the steps are as follows:

[0044] (1) Selection and processing of raw materials

[0045] Gallium oxide powder with a purity of 99.99% is used and put into a crucible with a diameter of 200 mm surrounded by copper tubes, and the gap between the copper tubes is 0.5 mm. Circulating water is passed through the copper pipe, and the water temperature is <80°C;

[0046] (2) Melt melting and crystal growth

[0047] The crystal growth atmosphere is air, start the LD heat source to irradiate the center of the crucible, adjust the heating power to form a liquid pool, start induction heating, adjust the heating power until the area of the liquid pool gradually increases, turn off the LD heat source, and continue to increase the heating power of t...

Embodiment 2

[0049] Directional seed crystal growth of gallium oxide crystals, the steps are as follows:

[0050] (1) Selection and processing of raw materials

[0051] Gallium oxide powder with a purity of 99.99% was used and put into a crucible with a diameter of 200 mm surrounded by copper tubes, and the gap between the copper tubes was 0.5 mm. Circulating water is passed through the copper pipe, and the water temperature is <80°C;

[0052] (2) Selection of seed crystal

[0053] Choose β-Ga in direction 2 o 3 seed crystal

[0054] (3) Melt melting and crystal growth

[0055] The crystal growth atmosphere is air, start the LD heat source to irradiate the center of the crucible, adjust the heating power to form a liquid pool, start the induction heating power supply, adjust the heating power until the area of the liquid pool gradually increases, turn off the LD heat source, put in the gallium oxide seed crystal and collect it. Neck, when the seed crystal is as thin as 1mm, it ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com