Fast preparation method of silicon dioxide aerogel

A silica and aerogel technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of long preparation cycle, poor product uniformity, long drying process, etc., and achieve mild and controllable hydrolysis reaction , Reduce process cost, shorten the effect of aging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

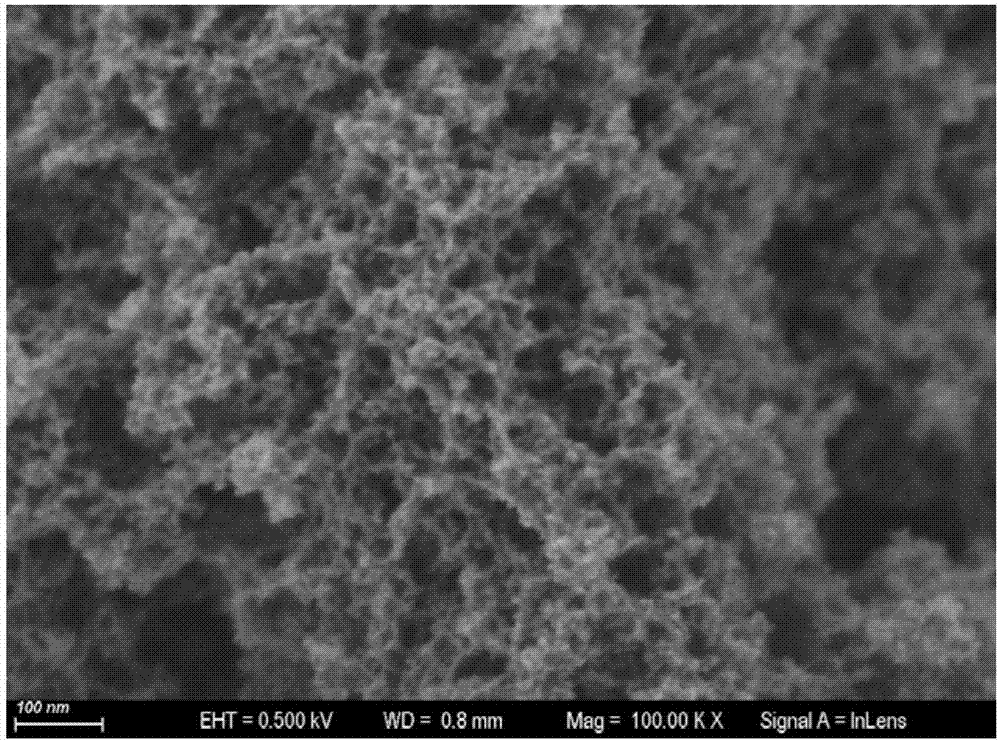

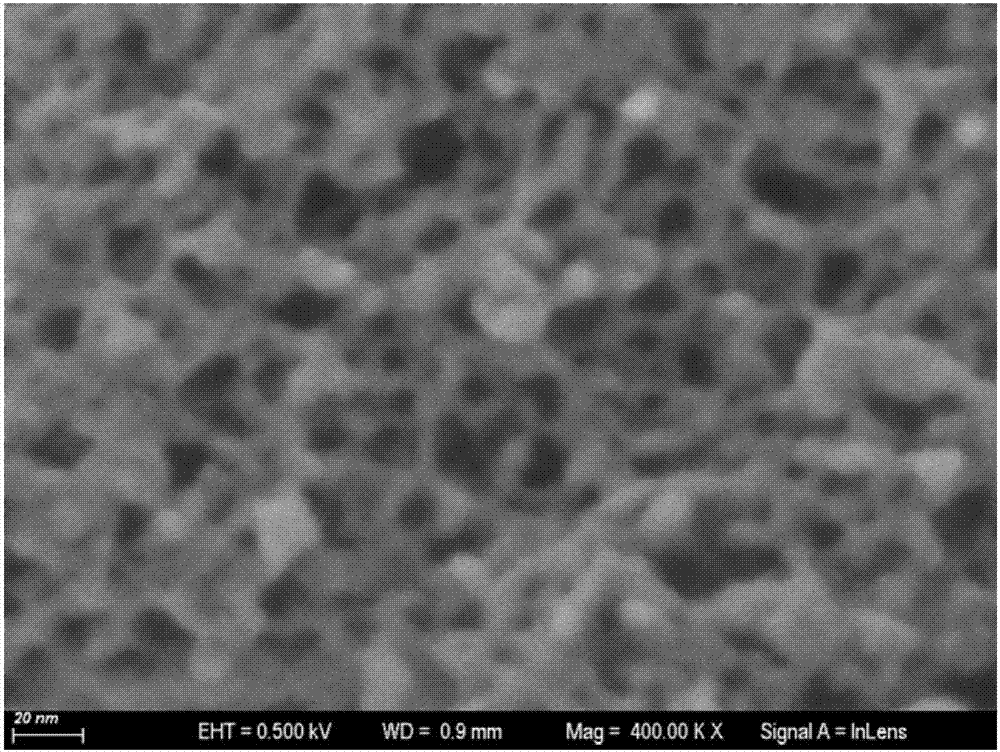

Image

Examples

Embodiment 1

[0031] Add 1L ethyl orthosilicate to 2L methanol solvent, mix and stir evenly, add 120ml of oxalic acid solution with a concentration of 0.005mol / L, stir well and let stand for 10h; mix 140ml tetramethyldisilazane with Slowly add 0.75ml / min into the above reaction system drop by drop, the total dropping time is 3h, after standing to get the gel, aging at 50℃ for 0.5h, after aging, microwave drying at 600W power for 300s before drying in oven Drying, the oven drying condition is to dry at 120°C for 1.5h, and the obtained product is silica airgel;

[0032] The tested silica airgel product has a density of 57kg / m 3 , specific surface area 920m 2 / g, thermal conductivity 0.016W / (m.K).

Embodiment 2

[0034] Add 1L tetraethyl orthosilicate to 2.5L ethanol solvent, mix and stir evenly, add 220ml of benzoic acid solution with a concentration of 0.002mol / L, stir evenly and let stand for 12h; mix 270ml hexamethyldisilazane with Slowly add dropwise into the above reaction system at a rate of 1ml / min. The total dropping time is 4.5h. After standing still to obtain the gel, age at 50°C for 1h. After aging, microwave dry at 450W for 120s before drying in an oven. , the oven drying condition is to dry at 150°C for 1.5h, and the obtained product is silica airgel;

[0035] The tested silica airgel product has a density of 45kg / m 3 , specific surface area 1050m 2 / g, thermal conductivity 0.013W / (m.K).

Embodiment 3

[0037]Add 1L tetraethyl orthosilicate to 2L ethanol solvent, mix and stir evenly, add 310ml of glacial acetic acid solution with a concentration of 0.001mol / L, stir well and let stand for 3h; mix heptamethyldisilazane with hexamethyl Cyclotrisilazane was mixed at a molar ratio of 1:3 to form a 200ml mixed solution, and the mixed solution was slowly dropped into the reaction system at a rate of 1ml / min. The total reaction time was 3.3 hours. Microwave drying at 200W power for 200s and then oven drying, the condition of oven drying is 2h at 105°C, the obtained product is silica airgel;

[0038] The tested silica airgel product has a density of 60kg / m 3 , specific surface area 865m 2 / g, thermal conductivity 0.018W / (m.K).

[0039] The preparation method of the present invention realizes gel polycondensation reaction and hydrophobic modification in one step by rationally controlling the addition amount, dropping rate and reaction time of nitrogen-containing silane, taking hexame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com