A method of manufacturing a framed door

A manufacturing method and frame door technology, which is applied in the direction of wing leaf frame, etc., can solve the problems of low processing efficiency, complicated processing process, and low assembly precision of assembled frame doors, so as to achieve easy control of heating process, simplify processing process, and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

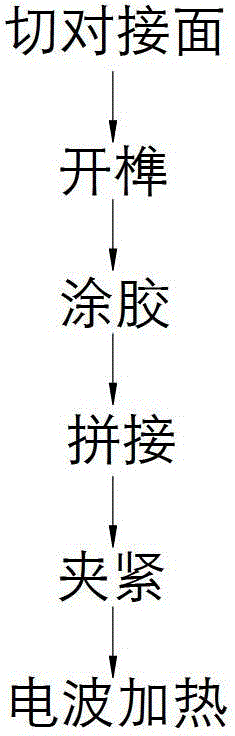

[0020] see figure 1 , the manufacture method of framed door of the present invention, comprises the steps:

[0021] A. Select four solid wood door frames, and cut the ends of the solid wood door frames into 45° chamfers, so that the two solid wood door frames that are spliced together form a 90° angle after butt joint, and the end faces of the chamfered parts form the butt joint of the solid wood door frames noodle;

[0022] B. On the joint surfaces of two adjacent solid wood door frames, respectively process the tenon and tenon with matching shapes. The shape of the tenon and tenon can be set according to the shape of the joint surface of the solid wood door frame, for example, the cross section of the tenon and the tenon It can be a rectangle, or it can be composed of multiple circles;

[0023] C. Apply white latex on the surface of the tenon and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com