Experimental device and test method for electrochemical corrosion of specimens loaded with bidirectional tensile stress

A technology of two-way stretching and experimental equipment, applied in the direction of applying stable tension/pressure to test material strength, measuring equipment, testing wear resistance, etc., to achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below in conjunction with the accompanying drawings.

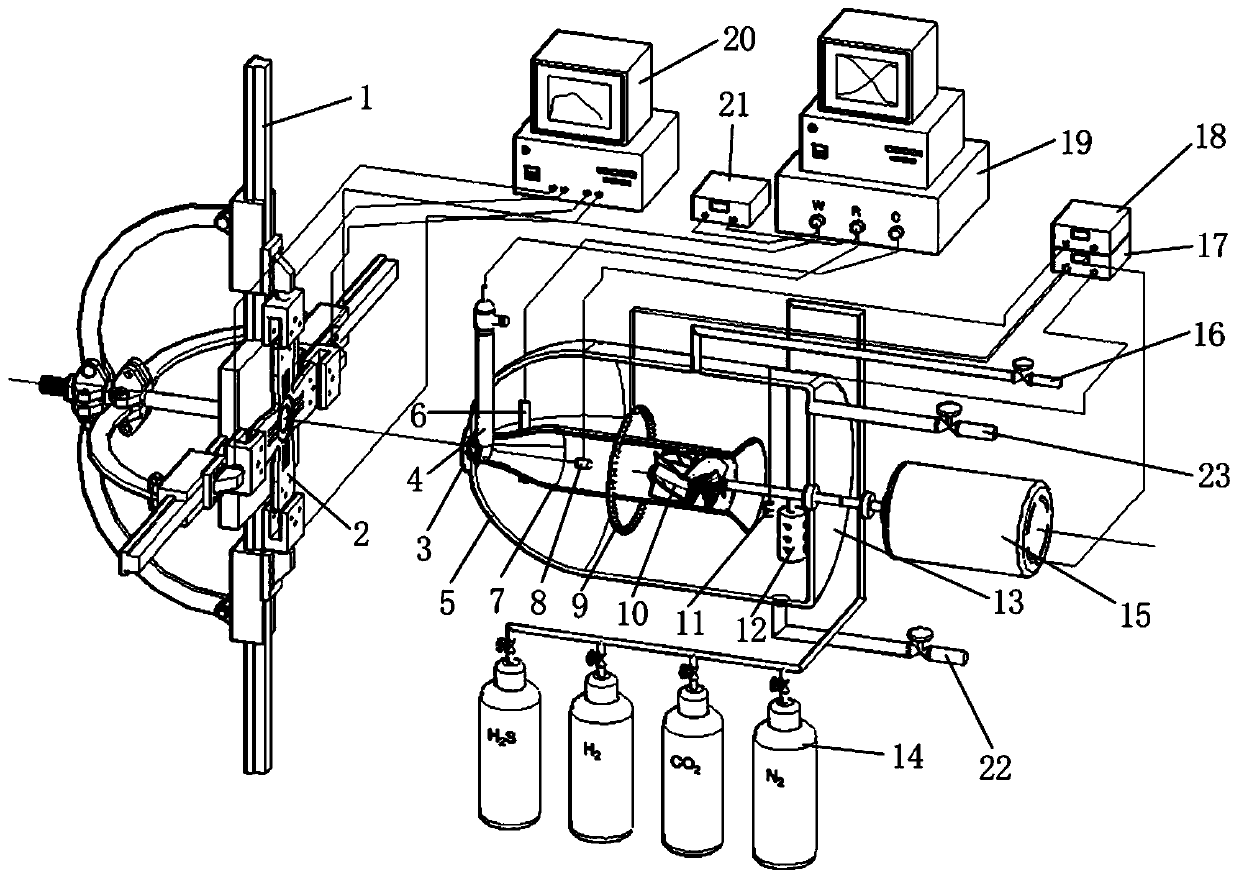

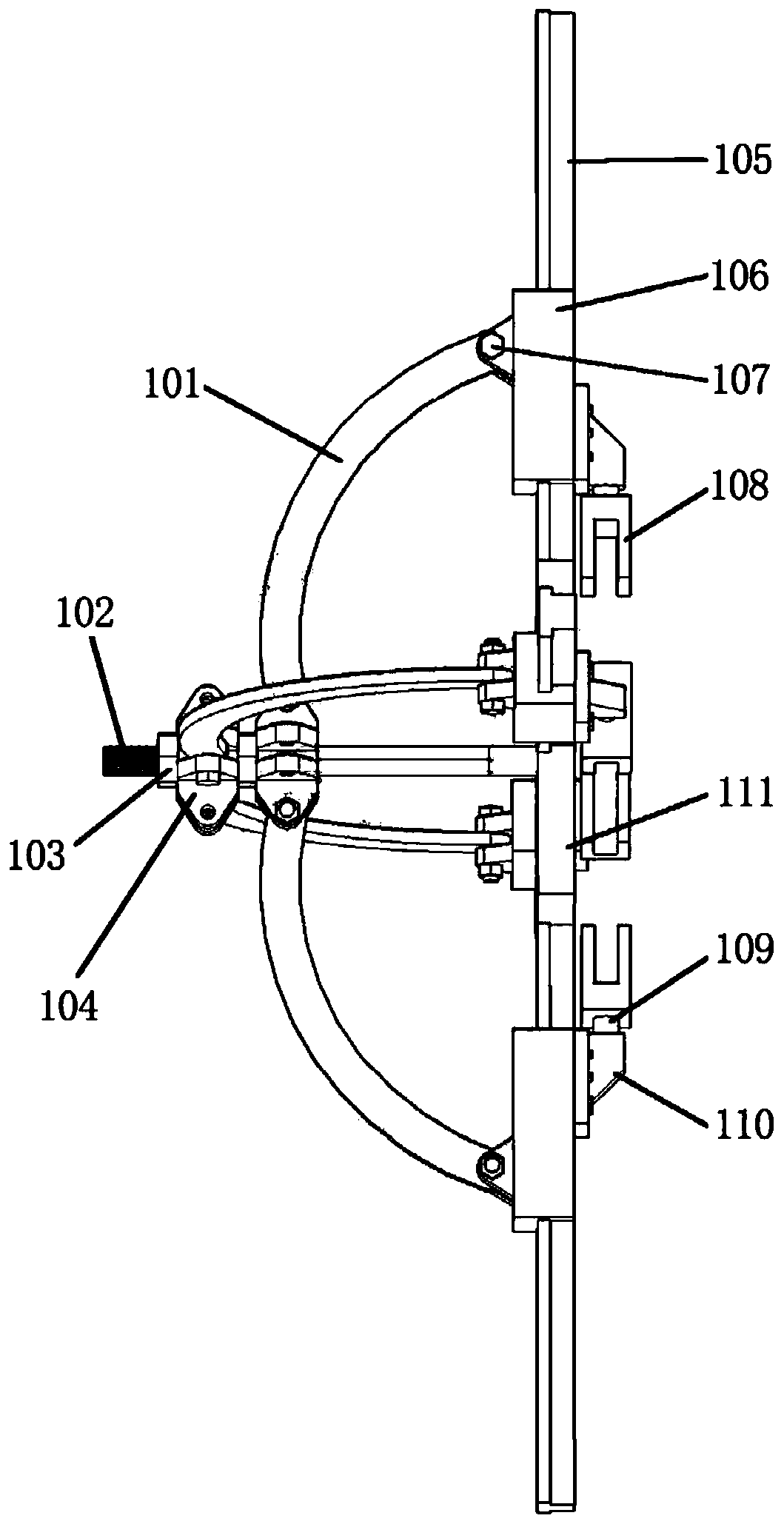

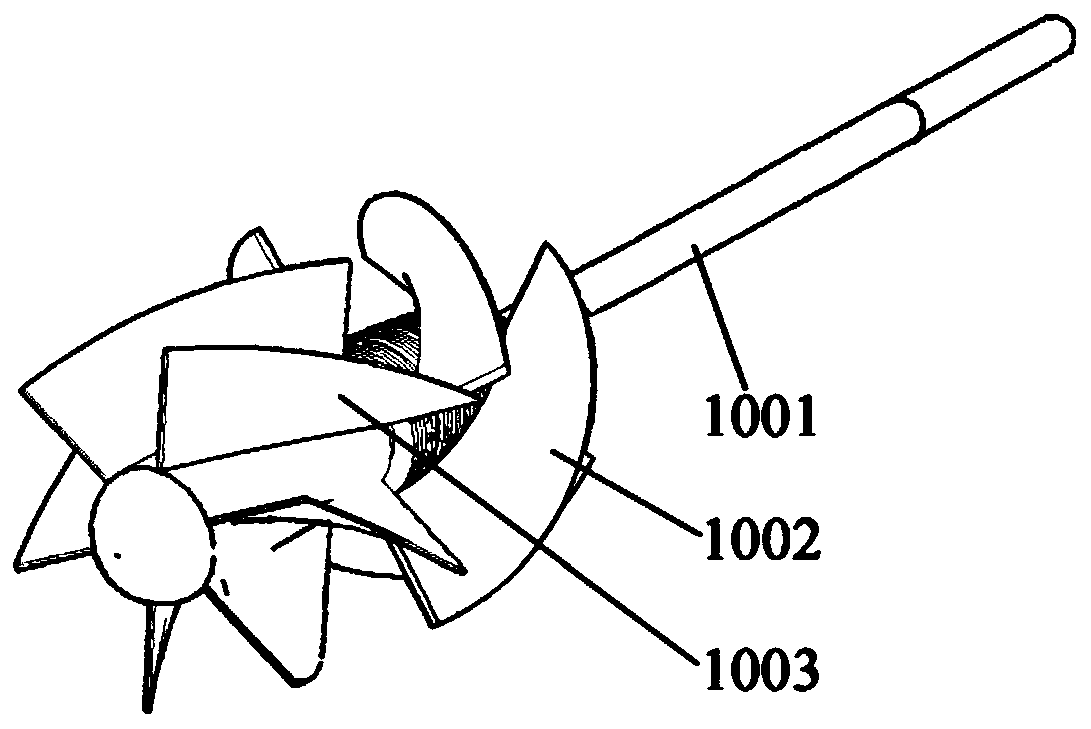

[0039] refer to Figure 1 to Figure 5 As shown in the present invention, a corrosion electrochemical experimental device for loading a biaxial tensile stress sample includes a biaxial tensile stress loading mechanism 1, a cross sample 2, a corrosion reaction pool 5, an electrochemical testing system and a control system.

[0040] Such as figure 1 As shown, in the experimental device of the present invention, the bidirectional tensile stress loading mechanism 1, the electrochemical test system and the control system are all placed outside the corrosion reaction pool 5, and the corrosion reaction pool 5 itself as the main body of the device mainly includes a box body 13, a shaft The flow pump self-circulation module 10 and the gas filling module. The opening of the left end of the box body 13 of the corrosion reaction pool 5 is provided with a sealing insulating gaske...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com