Bonding device and bonding method

A fixed mechanism and fixed platform technology, applied in the manufacturing of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc. The effect of improving efficiency and quality, small heat affected area and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

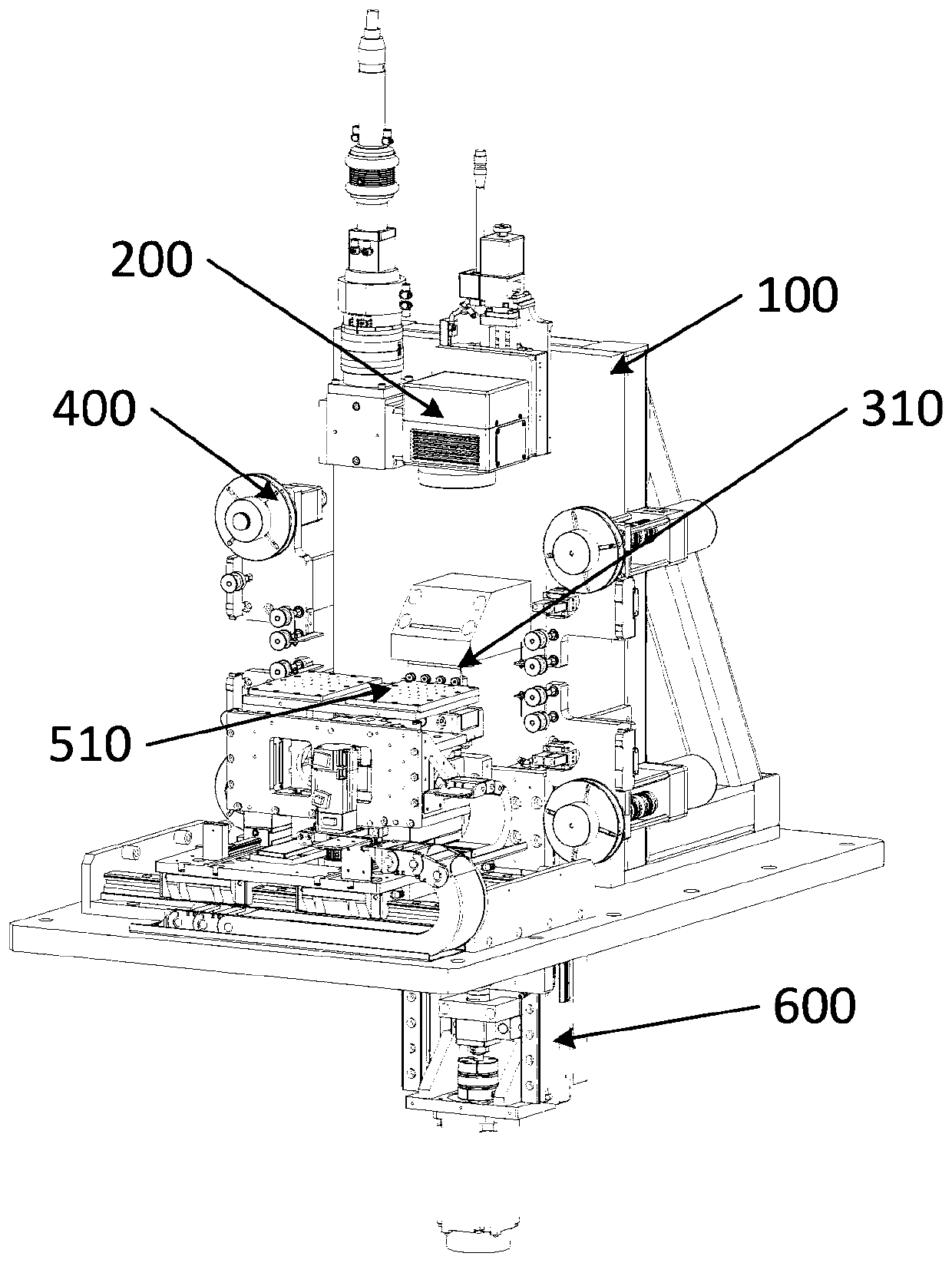

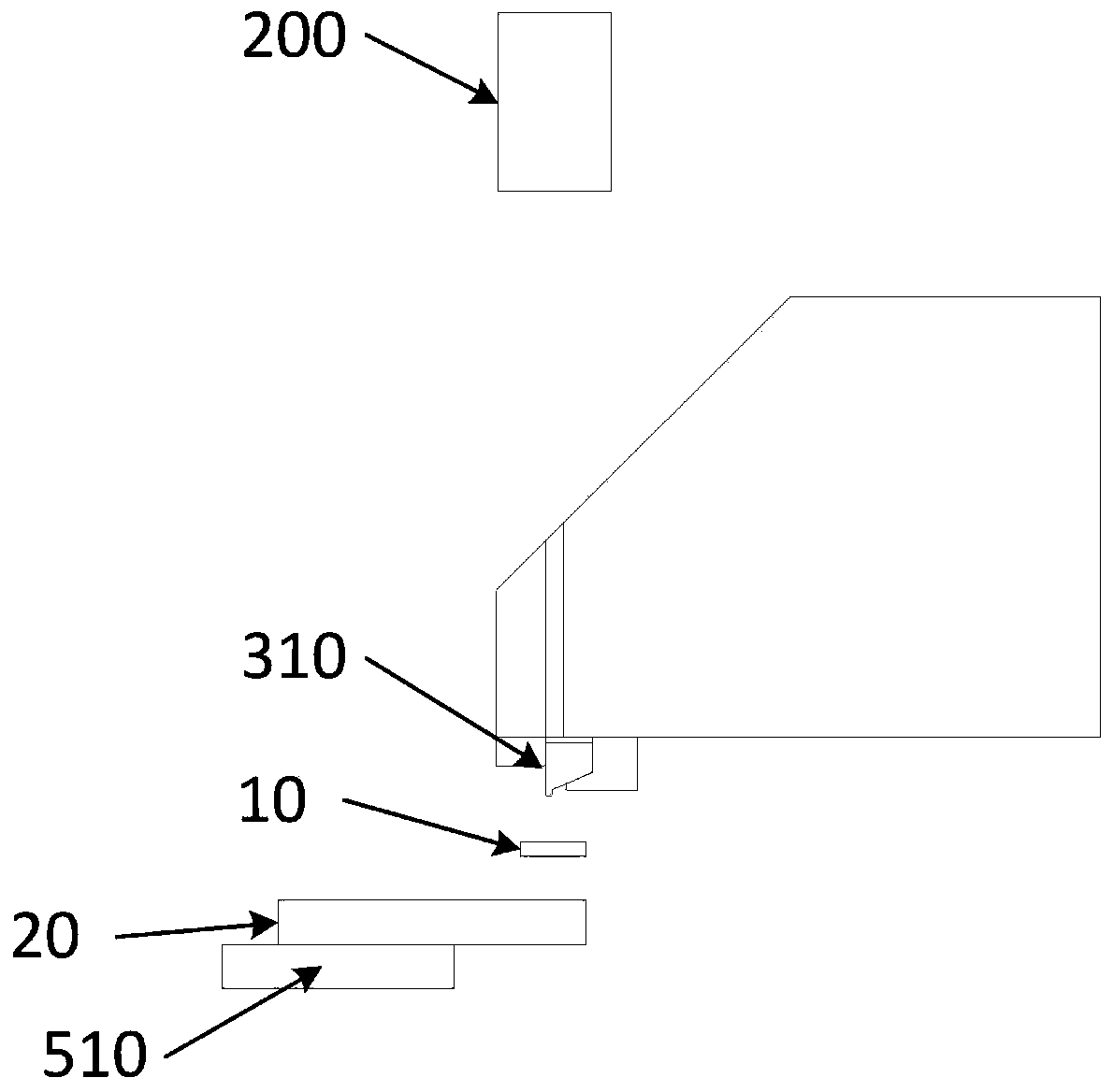

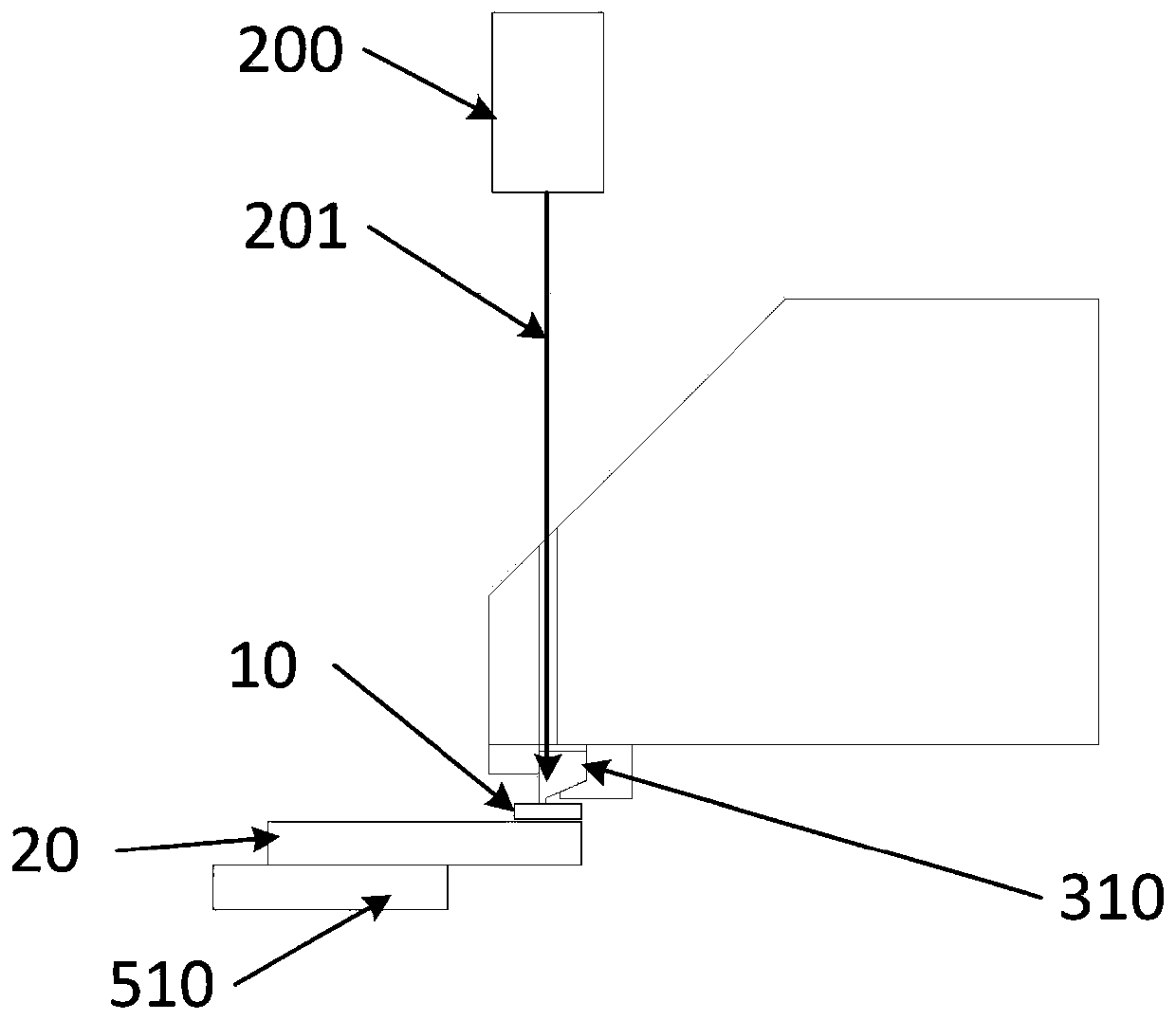

[0039] Such as Figures 1 to 3 As shown, the present invention provides a preferred embodiment of a bonding device based on a display panel.

[0040] A bonding device based on a product 20, the bonding device includes a laser 200, an indenter 310, a first buffer material fixing mechanism 400, a fixing platform and a pressing mechanism, and the fixing platform includes a fixing component 510 for fixing the product 20 , the material of the indenter 310 is a material with good light transmission and thermal conductivity; wherein, the pins of the product 20 are covered with a pre-pressed chip-on-chip film, and the pins of the product 20 are in contact with the An ACF is arranged between the COFs; and, the first buffer material fixing mechanism 400 clamps the buffer material 10 between the crimping surface of the pressure head 310 and the COF ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com