Electromagnetic heating rotary kiln with function of controlling reducing atmosphere

A rotary kiln and electromagnetic technology, applied in the field of rotary kiln, can solve the problems of increased cost of transmission motor and supporting device, easy agglomeration on the surface, heavy weight of rotary kiln, etc., and achieves improved service life, reduced equipment cost, installation and maintenance The effect of reducing the maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

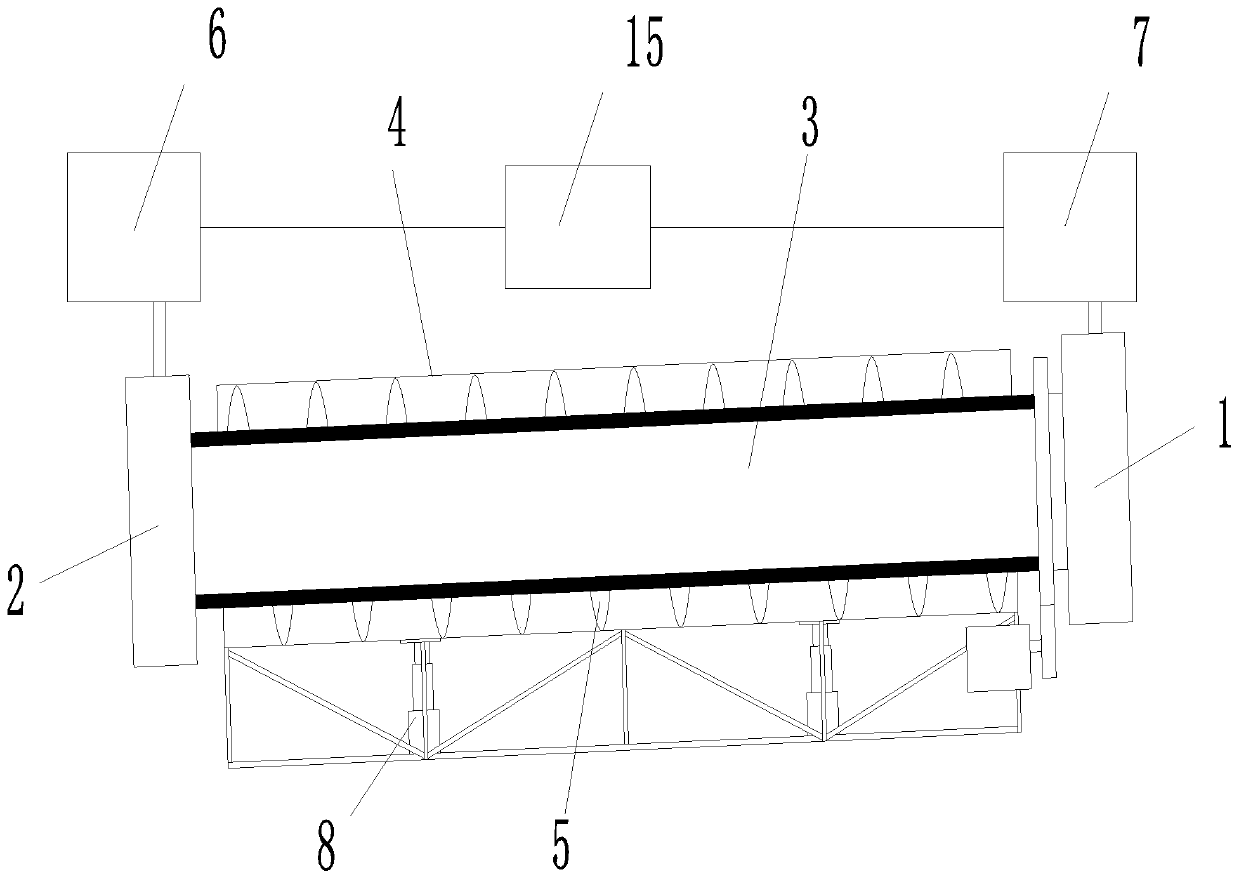

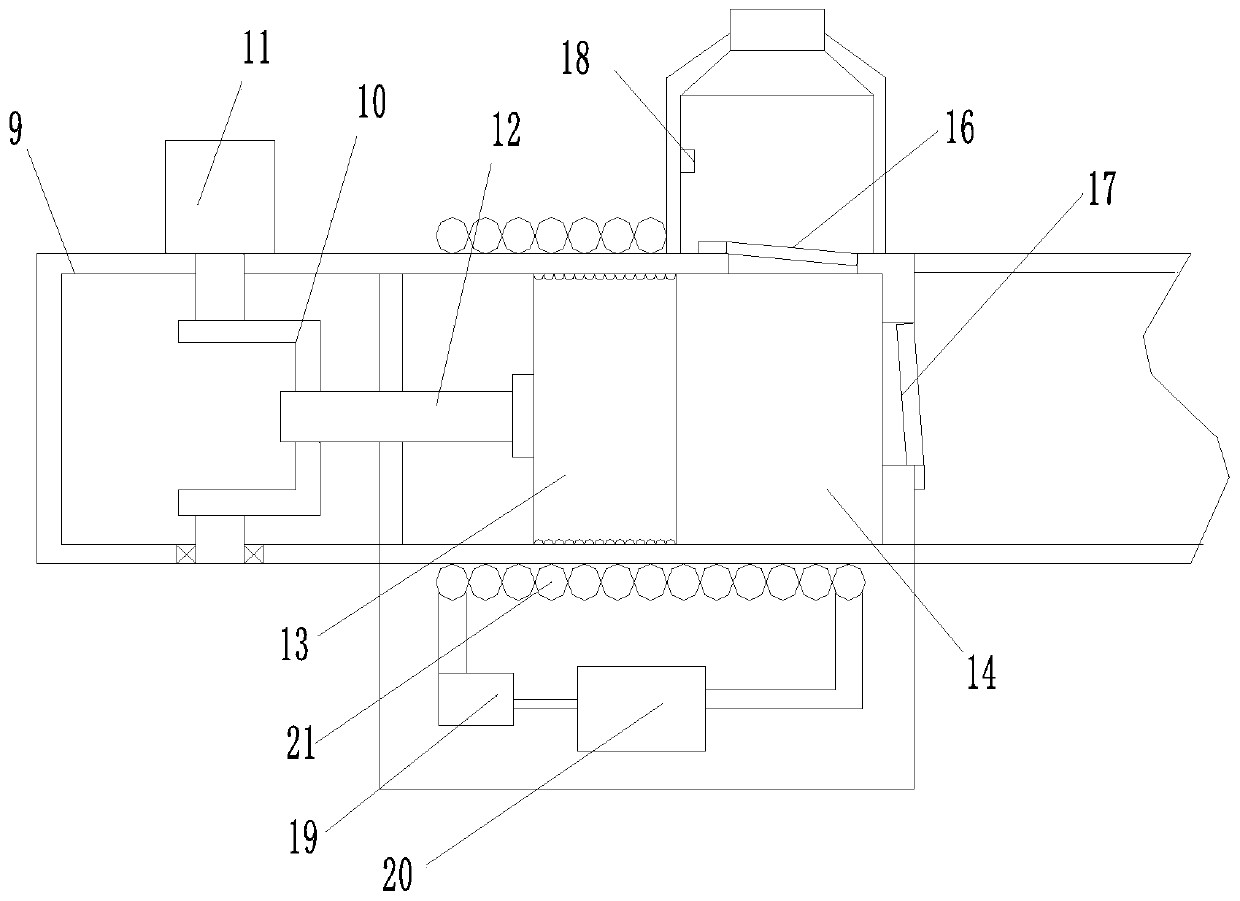

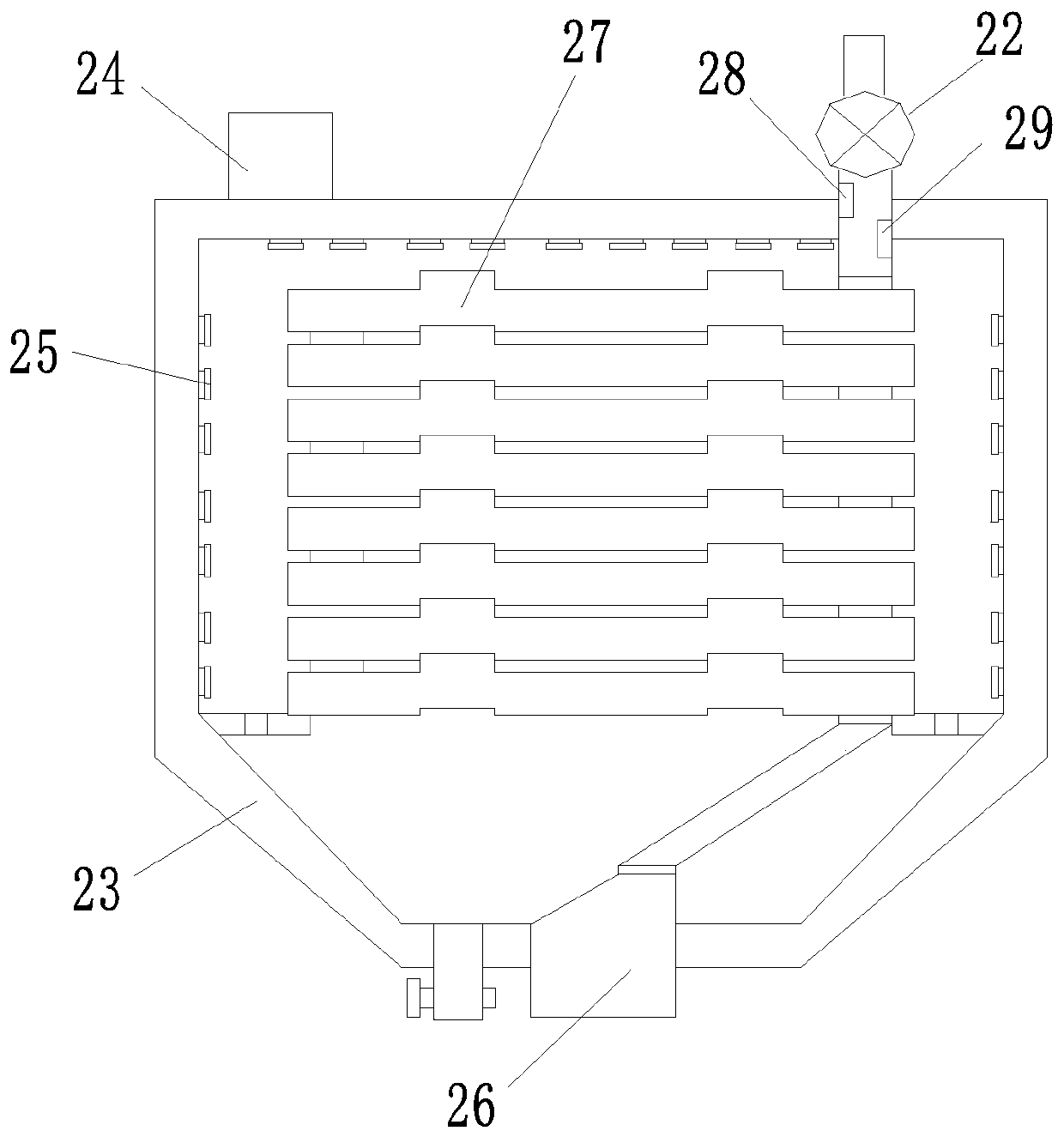

[0029] Such as figure 1 with Figure 5 As shown, an electromagnetic heating rotary kiln with the function of controlling the reducing atmosphere has a feeding part 1, a main kiln part and a discharging part 2. The feeding part 1 and the discharging part 2 are respectively sealed and connected to the ports of the corresponding main kiln part The main kiln section includes a high-temperature oxidation resistant movement 3, a back-end gas transmission device 6, a front-end exhaust emission device 7 and a control system 15. The movement 3 is made of Cr-Ni-Mo-W-Fe-Si alloy series material The movement 3 is arranged low to the left and high to the right. A protective cover 4 is provided on the outside of the movement 3. A gap is reserved between the movement 3 and the protective cover 4, and an electromagnetic induction heating structure 5 is provided in the gap, which is heated by electromagnetic induction Structure 5 generates eddy current heating on the conductive movement 3 and t...

Embodiment 2

[0031] The difference from Embodiment 1 is that the bottom of the protective cover 4 is provided with a height adjustment device 8, such as a hydraulic lifting device, and the movement 3 and the protective cover 4 are adjusted by the height adjustment device 8 at an angle of 0.5°-8°. The control system 15 is used to control the reducing gas delivery volume and the exhaust gas discharge volume, and the height adjustment device 8 is used to adjust the inclination angle of the movement 3 to further ensure the flow speed of the reducing gas inside the movement 3, so that the chlorination reduction reaction of the material It is carried out in a controllable reduction range, which greatly improves the efficiency of the reaction and the speed of sublimation and separation.

[0032] In this embodiment, the solution is further optimized, the movement 3 is provided with six transversely, and two adjacent movement 3 are detachably connected by flanges, and the electromagnetic induction heat...

Embodiment 3

[0034] Further optimized on the basis of Example 1, the raw materials of movement 3 specifically include components by weight: 12 parts of Cr, 56 parts of Ni, 16 parts of Mo, 8 parts of W, 6 parts of Fe, 1.0 Parts of mixed rare earth RE and 1.0 part of Si, wherein the mixed rare earth RE contains the following components by weight percentage: 6.5% Ce, 8.6% Nd, 5.4% Pm, 6.2% Sm, the balance is La, S1, movement base Material production: All the movement raw materials are mixed in proportion and then smelted, and casted by centrifugal casting method, followed by solution heat treatment: 1180℃ for 4h, and then water quenched, so that the structure becomes a single-phase solid solution to achieve uniformity of the structure, and then natural Cool to room temperature to obtain the core substrate, and then mechanically process the inner surface of the core substrate to smooth; S2, cladding anti-element depletion barrier layer coating: mix the anti-element depletion coating powder unifo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com