Film tearing system for tread rubber

A technology of tread rubber and membrane system, applied in the field of tread rubber tearing membrane, can solve the problem that both ends of the tread rubber cannot be heated at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0022] As described in the background technology, in the related art, it is necessary to manually peel off the rubber plastic wrap, and a single heater is placed at the front or rear end of the bonding template, and the position of the heater is fixed. No matter what kind of tire is made, only the glue is heated one end of the material. This kind of technical structure is simple, and the operator's work intensity is high. At the same time, only one end of the material head can be heated, and the other end is in a normal temperature state, so the improvement of the quality of the joint is very limited.

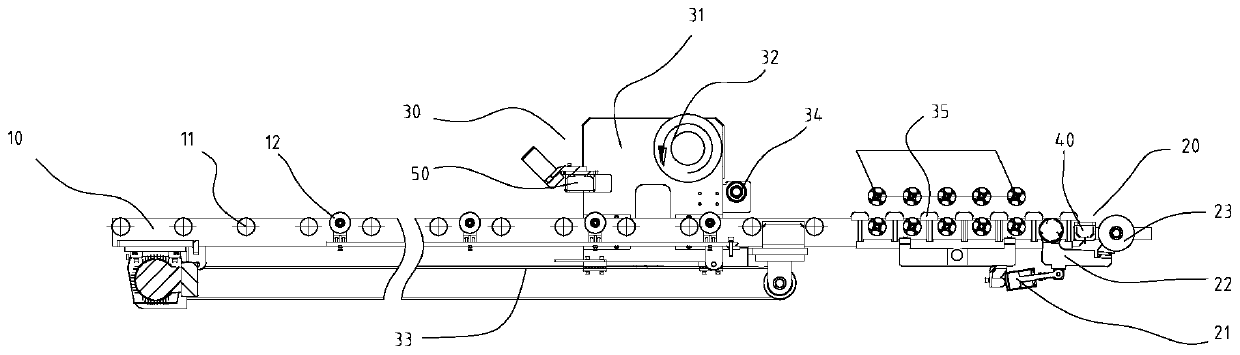

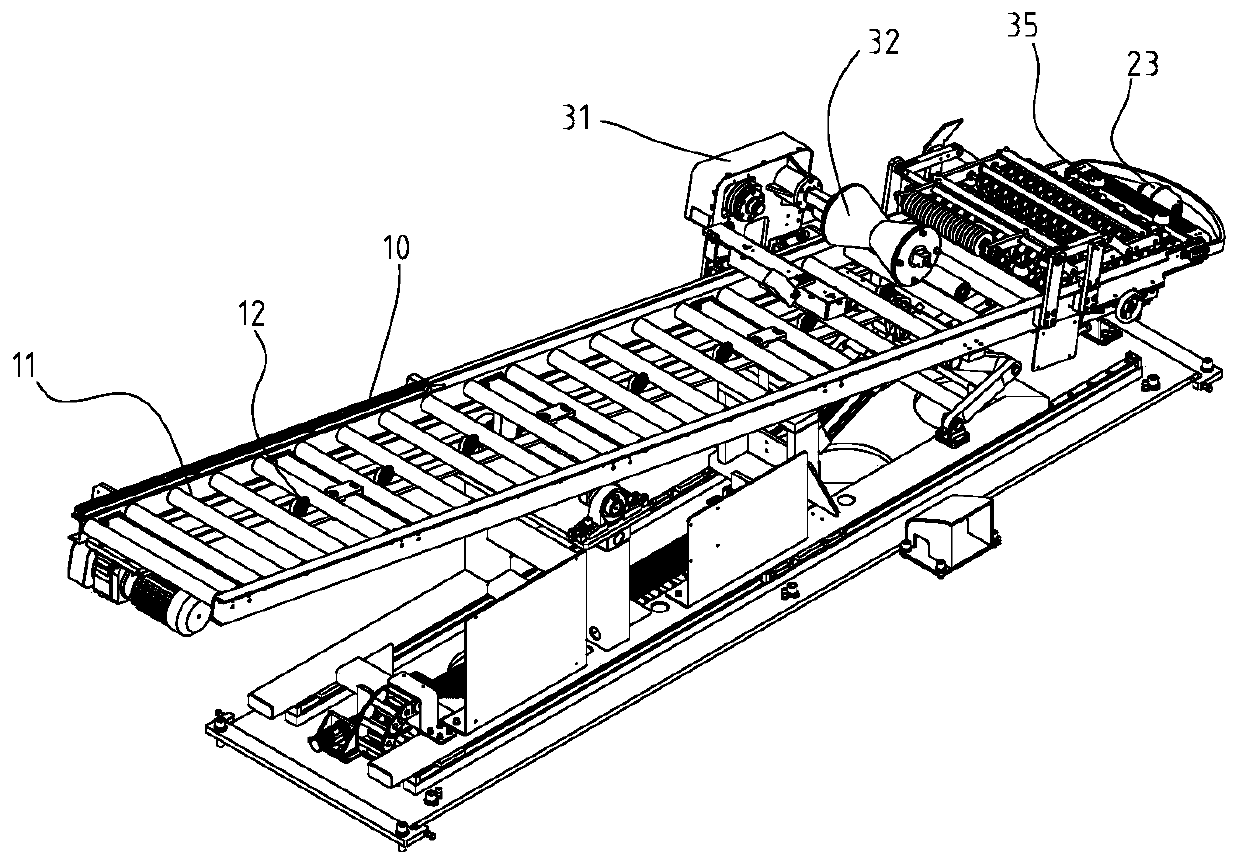

[0023] To solve the above problems, see figure 1 and figure 2 As shown, the embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com