ratchet for bicycle hub

A bicycle and wheel hub technology, applied in the field of ratchet, can solve the problems of high wear, slow return speed, affecting the conduction efficiency of the ratchet, and achieve the effect of low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

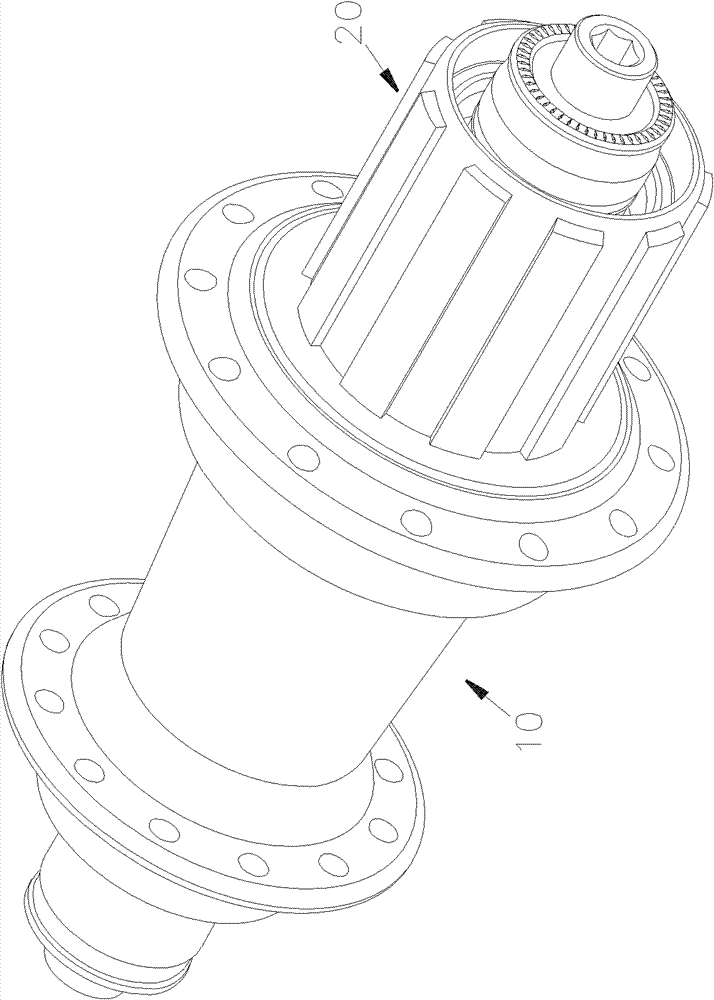

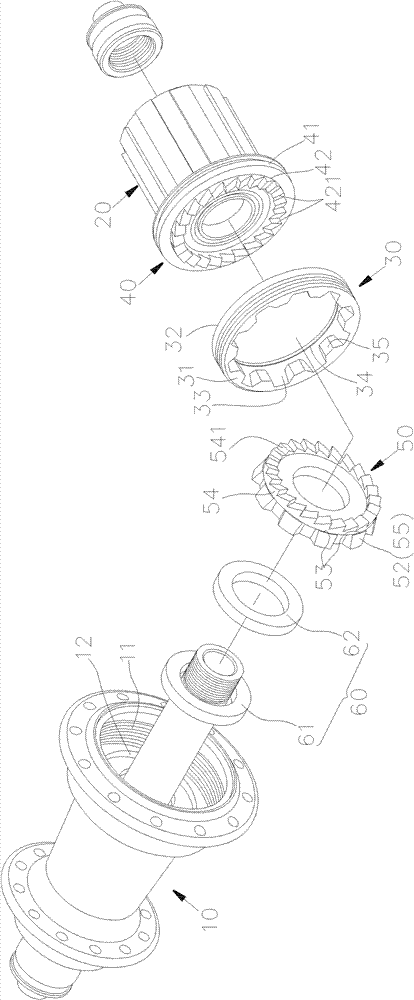

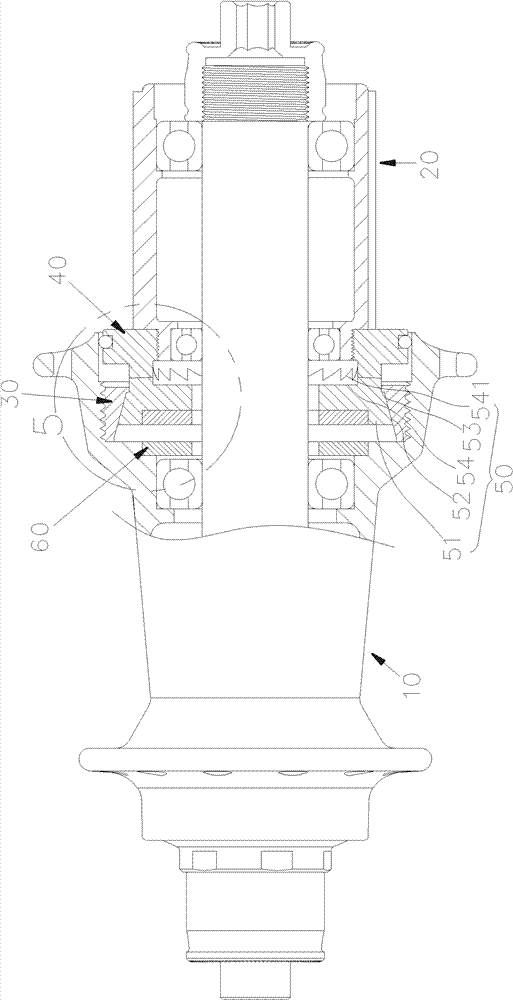

[0035] First please refer to Figure 1-3 As shown, the ratchet wheel of a bicycle hub provided by the present invention is located between the hub seat 10 and a sleeve seat 20, and includes: a stop ring 30 and a driving group located in the hub seat 10 40 , a driven group 50 disposed in the stop ring 30 , and a magnetic group 60 between each driven group 50 and the hub seat 10 .

[0036] The hub seat 10 is a hollow seat body, one end surface of which is recessed with a set of joint grooves 11 with a preset depth;

[0037] The sleeve seat 20 is hollow and cylindrical, and one end thereof is provided with a connecting portion 21 with a smaller outer diameter.

[0038] The stop ring 30 is a hollow ring that is screwed in the assembly groove 11, and its two side edges are respectively set as a set of end faces 31 and a free end face 32; the stop ring 30 is provided with a preset taper An oblique cone inner hole 33 is a penetrating inner diameter hole tapered from the set end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com