Device used for assisting bi-directional bundling of aluminum ingot stack automatic bundling machine

A technology of bundling machines and aluminum ingots, which is applied to the parts and components of bundling machines, can solve the problems of high labor costs, single direction of fully automatic bundling devices, and low efficiency, so as to improve bundling efficiency, save labor costs and The effect of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

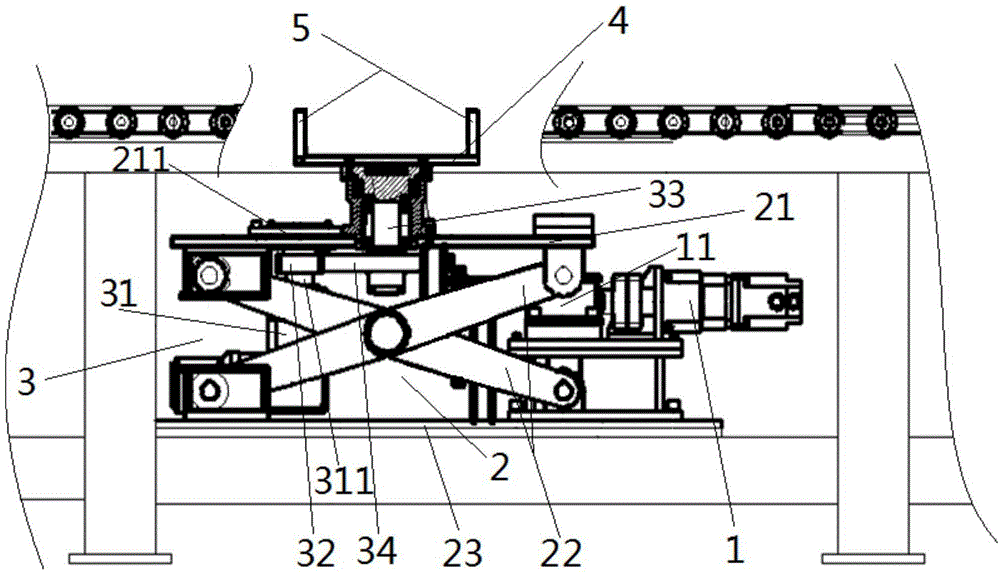

[0017] Such as figure 1 As shown, a device for assisting the two-way bundling of an automatic bundling machine for aluminum ingot stacks includes an elevator 1 , a scissor support 2 , a rotating mechanism 3 , a top plate 4 and a bracket 5 .

[0018] The elevator 1 is arranged under the upper seat plate 21 in the scissors support 2 to adjust the distance between the upper seat plate 21 and the lower seat plate 23, and the lifting rod 11 of the elevator 1 is hinged with the bottom of the upper seat plate 21 to avoid wear and noise , while improving the synchronization of equipment operation. The bracket 5 is arranged on the top board 4 , and the vertical axis of symmetry of the bracket 5 passes through the geometric center of the top board 4 .

[0019] The scissors support 2 includes two seat plates and the shear plate 22. The lower seat plate 23 of the seat plates of the scissors support 2 is arranged below the conveyor chain at the packaging position of the aluminum ingot con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com