Bulk part bagging and bundling device for logistics and using method of bulk part bagging and bundling device

A strapping device and a technology for loose parts, which are applied in the directions of packaging, transportation packaging, transportation and packaging, etc., to achieve the effect of ensuring practicality and accuracy, and facilitating bundling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

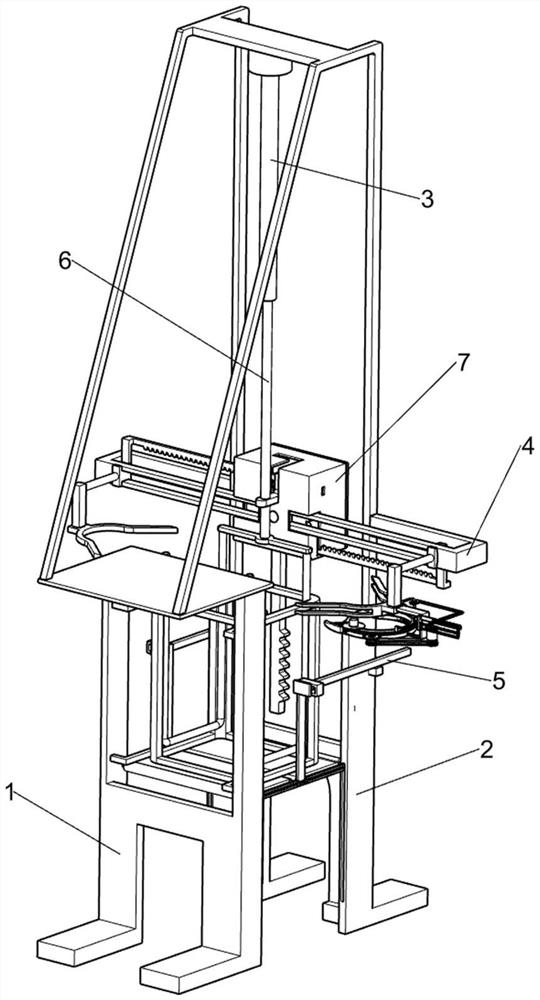

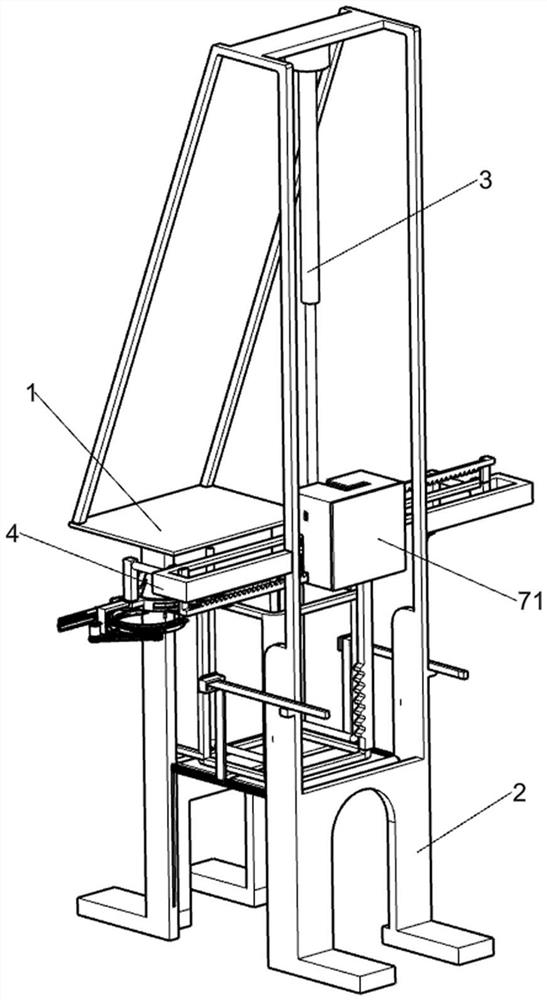

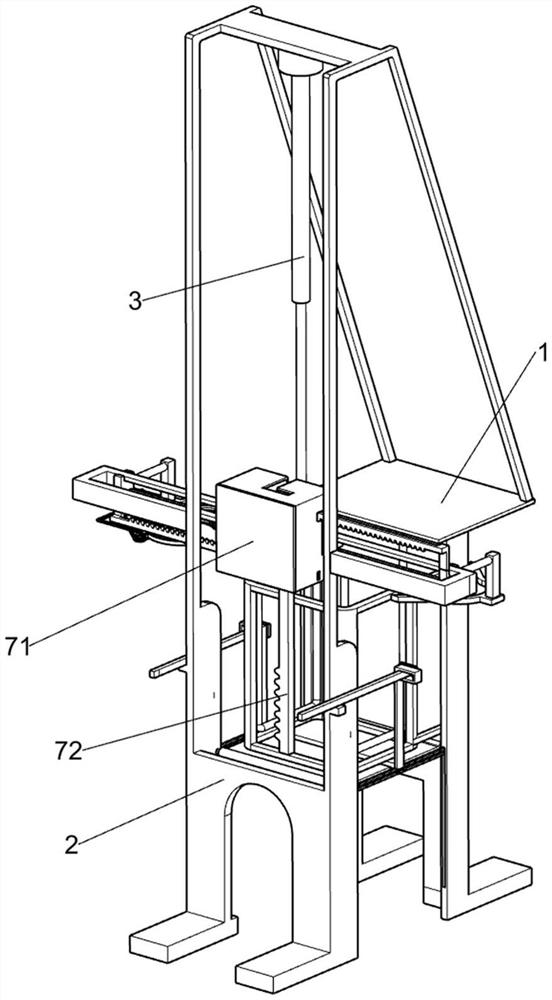

[0062] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 As shown, this embodiment proposes a bulk bagging and binding device for logistics and its use method, including a front seat 1, a rear mounting seat 2, an electric push rod 3, a fixed guide groove seat 4, and a support assembly 5 , socket expansion assembly 6 and opposite clamping assembly 7, the front seat 1 is fixedly installed with the rear mounting seat 2, and the upper part of the rear mounting seat 2 is fixedly installed with an electric push rod 3 for telescopic drive, and the rear mounting seat 2 The middle part is fixedly installed with a fixed guide groove seat 4, the support assembly 5 is arranged on the front seat 1 and the rear installation seat 2, the socket expansion assembly 6 is arranged on the telescopic shaft of the electric push rod 3, and the socket expansion assembly 6 For stretching th...

Embodiment 2

[0067] The scheme in embodiment 1 is further introduced below in conjunction with specific working methods, see the following description for details:

[0068] Such as Figure 12 , Figure 13 , Figure 14 , Figure 15 and Figure 16 As shown, as a preferred embodiment, on the basis of the above method, further, it also includes a tape sealing bag assembly 8, and the right side of the clamping frame one 77 is fixedly connected with the tape sealing bag assembly 8, and the tape sealing bag assembly 8 is used. For bundling the opening of the packaging bag, the adhesive tape bag sealing assembly 8 includes a fixed support plate 81, a fixed tripod 82, a bidirectional servo motor 83, a transmission shaft 84, a transmission gear 85, a transmission tooth belt 86, an overrunning clutch 87, and a rotating gear 88, fixed arc groove seat 89, arc sliding frame 810, fixed arc ring gear 811, adhesive tape placement seat 812, fixed oblique bar 813, fixed special-shaped support plate 814 a...

Embodiment 3

[0072] The schemes in Embodiment 1 and Embodiment 2 are further introduced below in conjunction with specific working methods, see the following description for details:

[0073] Specifically, according to Figure 18 As shown, the bulk bagging and binding device used in this logistics and its use method are at work: when bulk goods need to be packaged, the staff will place the packaging bag on the fixed limit frame 63, and the staff will manually control the electric push rod 3 elongation, the extension of the electric push rod 3 drives the fixed plate 61 and the fixed U-shaped spreading rod 62 to move downward, so that the fixed U-shaped spreading rod 62 will stretch the packaging bag, and then the external conveying equipment will pass the bulk goods through the front The seat 1 is transported into the packaging bag, and the movable support plate 51 supports the packaging bag and the goods. Simultaneously, the electric push rod 3 can drive the special-shaped fixed seat 64 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com