Binding device for tobacco leaf-covering bag

A bundling device and tobacco technology, applied in horticulture, gardening methods, botanical equipment and methods, etc., can solve the problems of low bundling efficiency, difficulty in guaranteeing bundling quality, easy damage to tobacco, etc., and achieve high bundling efficiency, simple and reliable mechanical structure , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

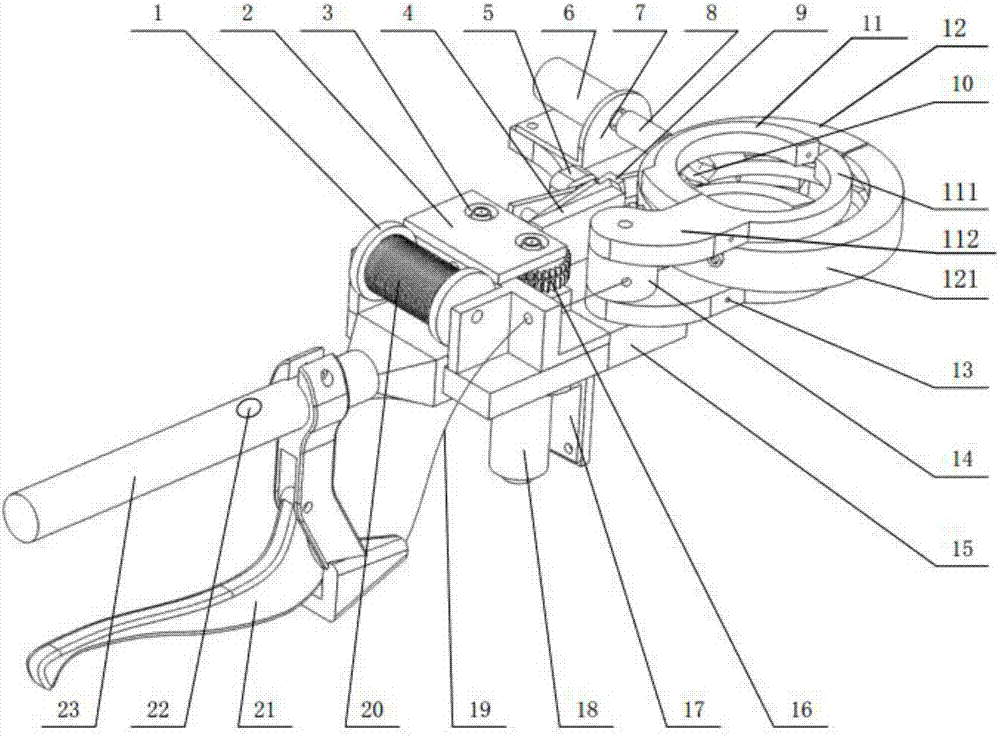

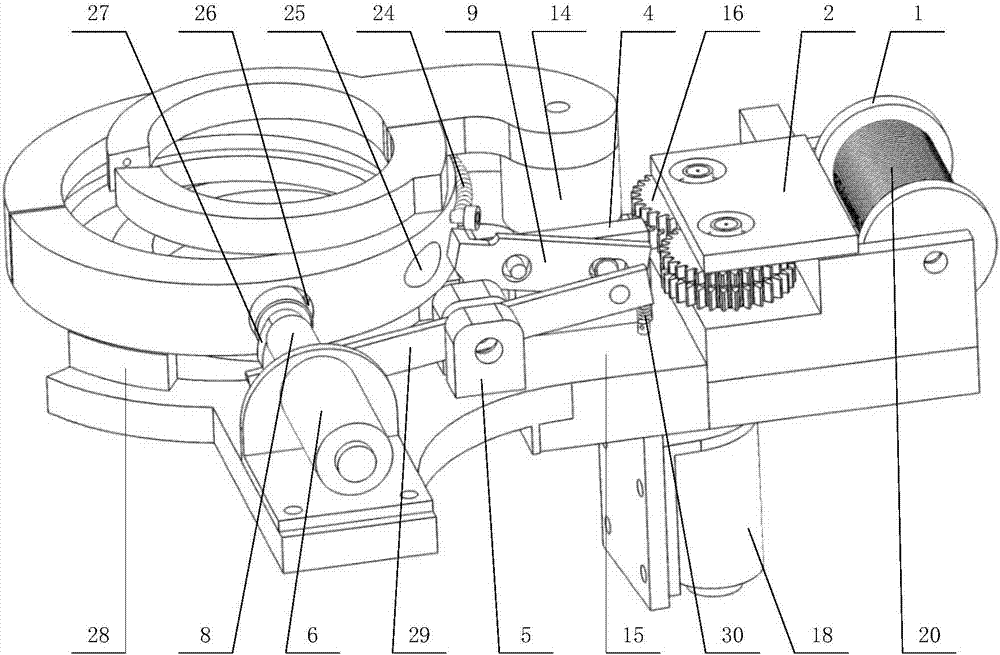

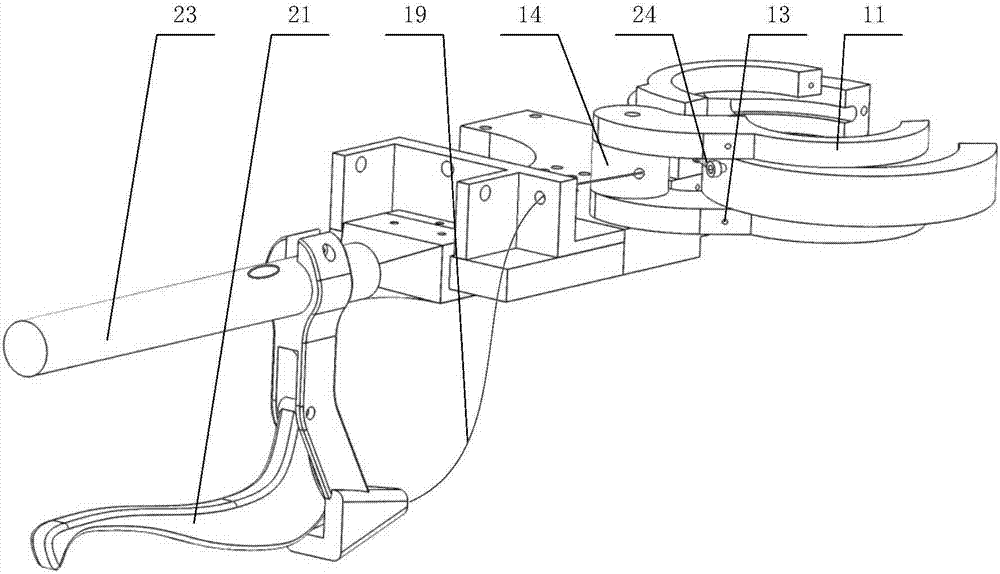

[0032] Such as figure 1 The shown tobacco leaf bag binding device includes a support base plate 15 and a leaf bag shrinking system installed on the support base plate 15, a wire feeding system, a wire cutting system and a wire stranding system. Wherein, the supporting bottom plate 15 is a structural frame for installing and fixing various components, which can be made of ABS plastic.

[0033] Each system is described in detail below:

[0034] The leaf bag shrinking system comprises a shrinking mechanism for tightening the seal of the leaf bag and a winding mechanism for wrapping the binding wire 20 around the seal of the leaf bag after tightening; the wire feeding system uses The binding wire 20 is transported to the winding position of the winding mechanism; the wire cutting system is used to cut off the binding wire 20 part entering the winding device; The binding wire 20 is used to realize the binding of the tobacco leaf bag.

[0035] This application tightens the seal o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com