Full-automatic plastic bag arranging and binding system

A fully automatic, plastic bag technology, applied in the parts of strapping machinery, paper product packaging, packaging, etc., can solve the problems of inconvenient movement, large size of strapping machines, and troublesome strapping of plastic bags.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

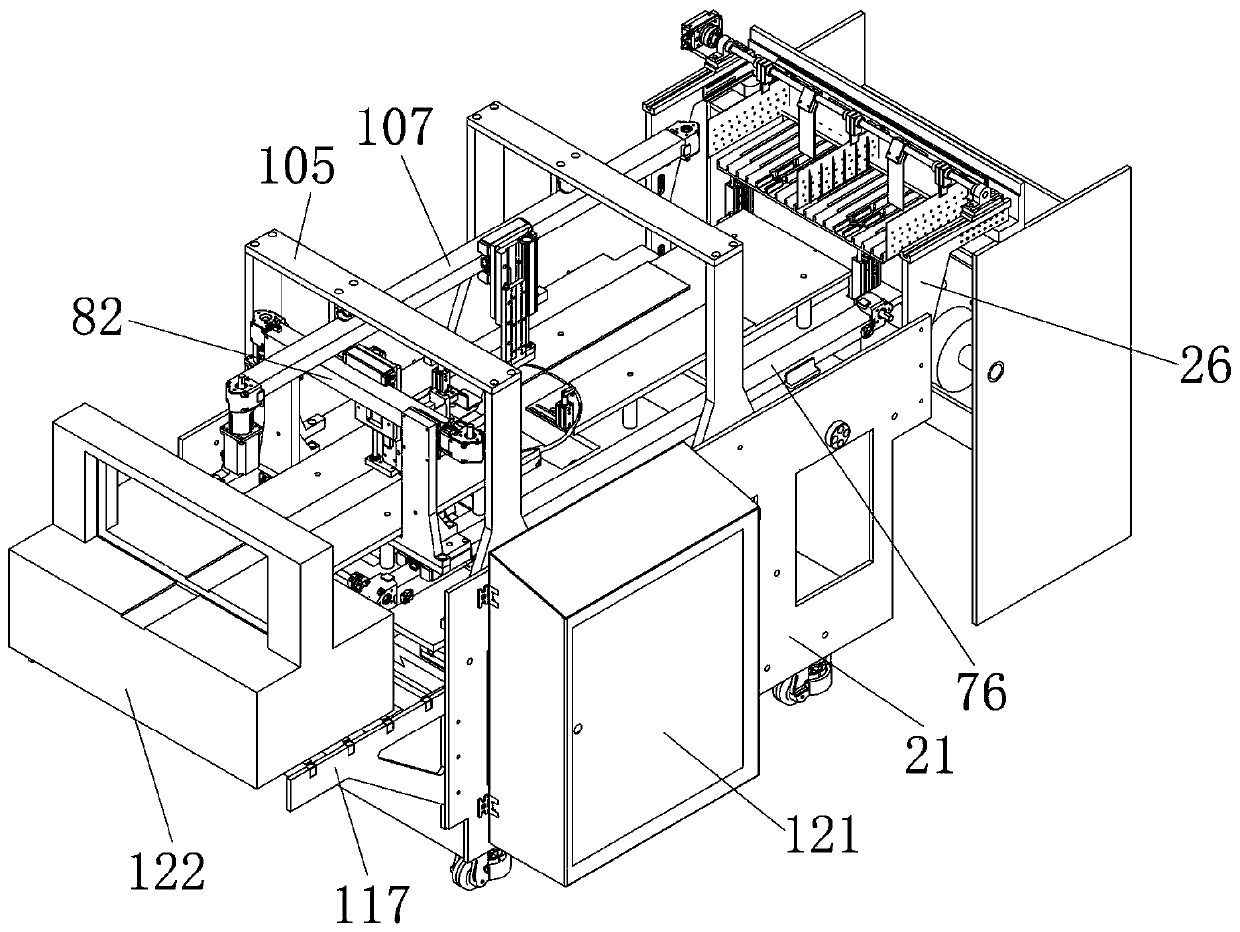

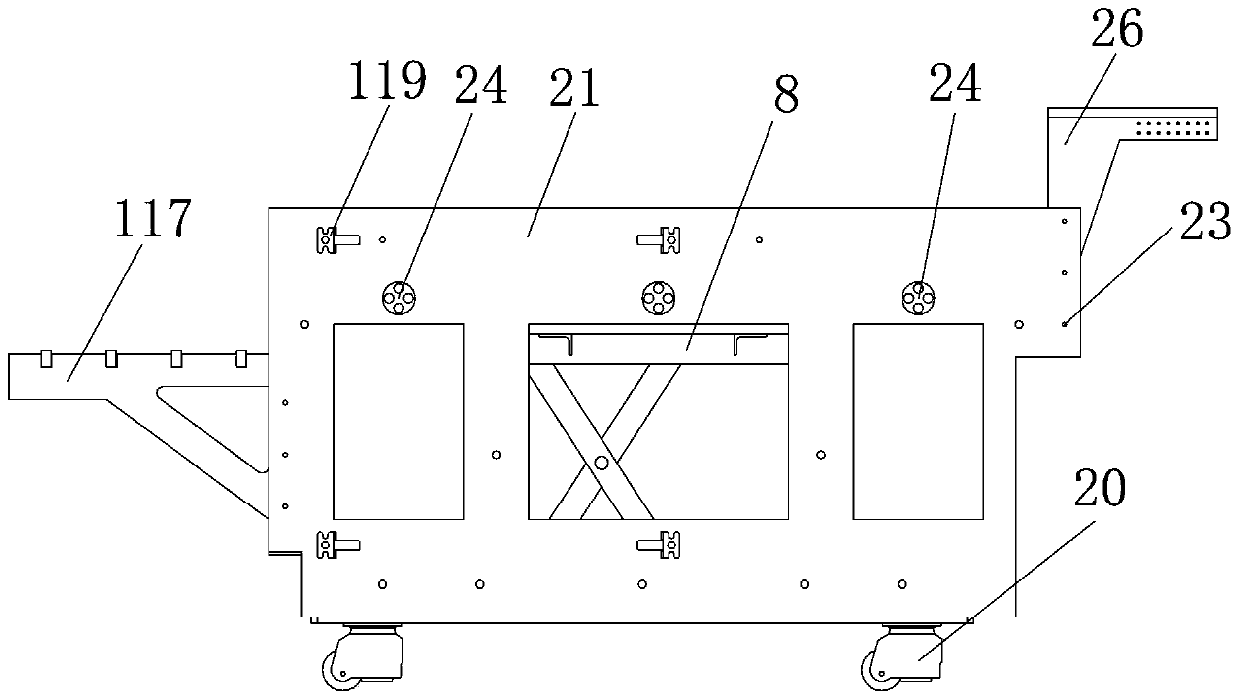

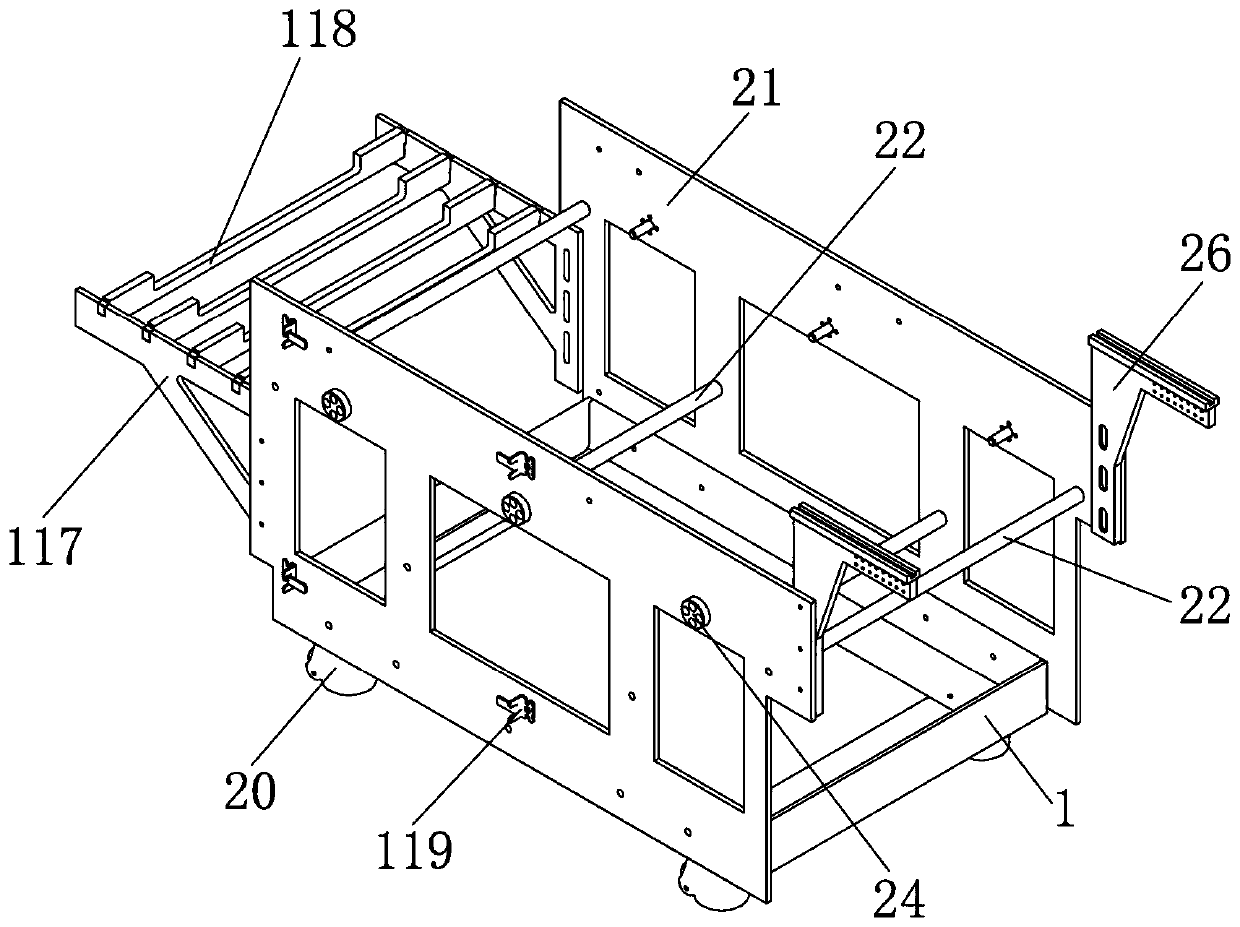

[0071] Embodiment: a kind of plastic bag automatic finishing and binding system, such as Figure 1-Figure 26 As shown, it includes a main body frame, a trough mechanism, a fork stop mechanism, a clamping mechanism, a transfer mechanism, a push mechanism, a strapping machine and an electric control cabinet. , transfer mechanism, pushing mechanism, strapping machine and electric control cabinet are all set on the main frame;

[0072] The main body frame includes a base, the bottom of the inner cavity of the base is fixedly installed with a first drive motor, the output end of the first drive motor is installed with a first threaded rod, and the surface of the first threaded rod is threadedly connected with a slide Platform, the bottom of the sliding platform is fixed with a sliding platform slide plate, and the two ends of the sliding platform sliding plate are respectively slidably connected with the two sides of the base; the sliding platform is slidably connected with a lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com