Manufacturing process of medium-voltage fireproof cable for intelligent early warning communication

A fire-proof cable and manufacturing process technology, applied in cable/conductor manufacturing, insulation of conductors/cables, circuits, etc., can solve the problems of inability to monitor the temperature of the cable core, inability to perform load monitoring, fault alarm positioning and fire warning, etc. Achieve the effects of good thermal insulation and fire resistance, reduced optical fiber attenuation, and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

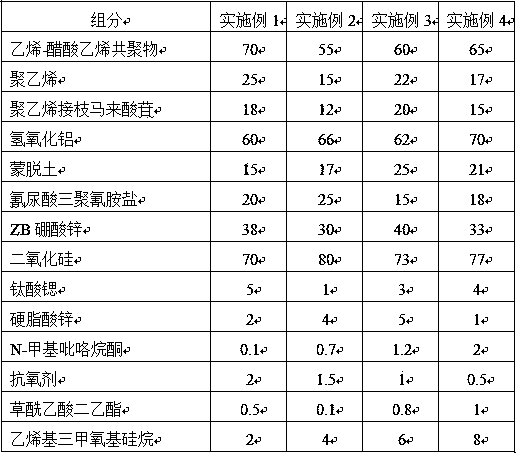

Embodiment 1~4

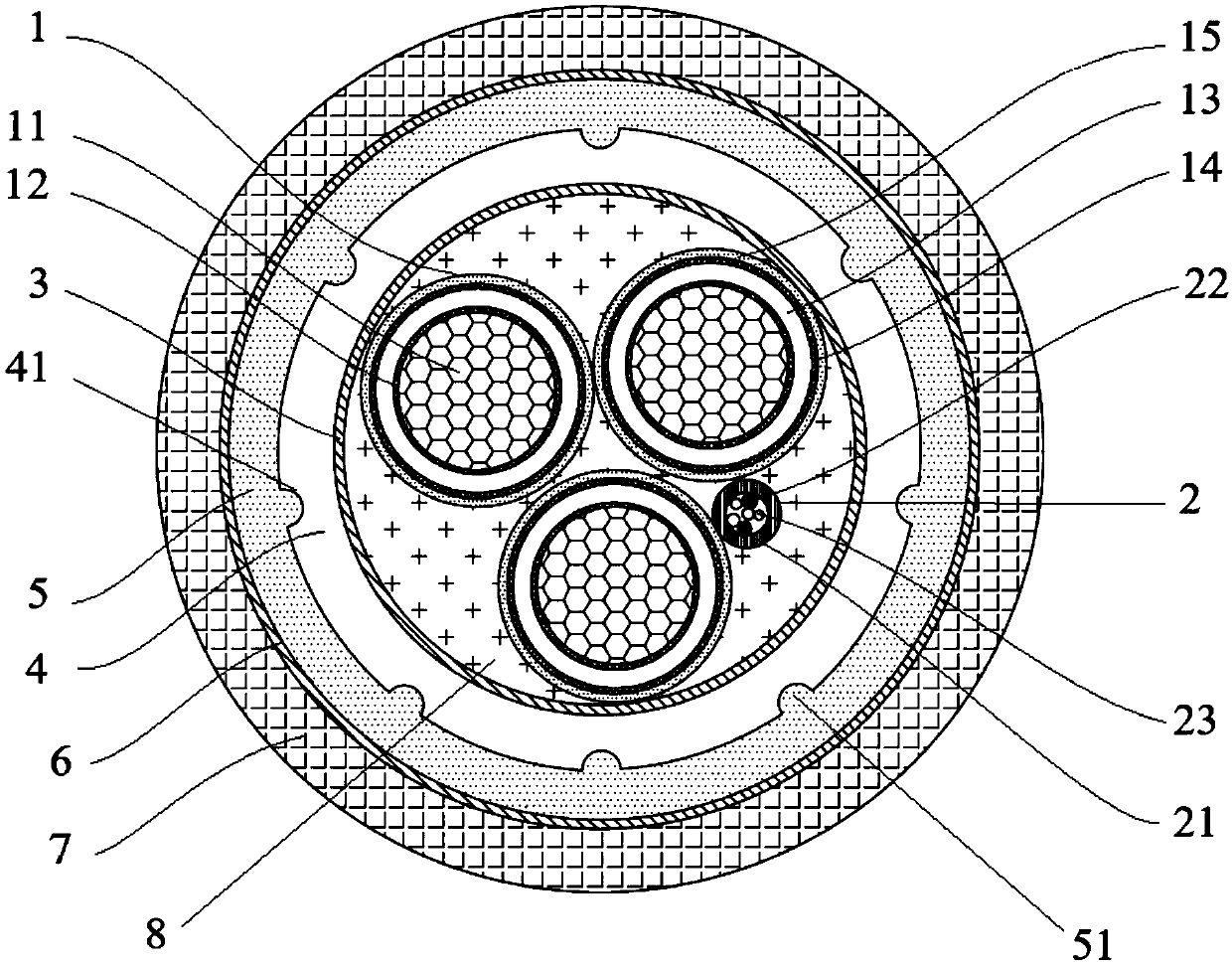

[0039] Embodiments 1 to 4: A manufacturing process of a medium-voltage fireproof cable for intelligent early warning communication. The medium voltage fireproof cable for intelligent early warning communication includes a power transmission unit 1 and an optical transmission unit 2. The power transmission unit 1 is composed of a copper conductor 11 , consisting of a conductor shielding layer 12, an insulating layer 13, an insulating shielding layer 14 coated on the outer surface of the copper conductor 11 from inside to outside, and a metal shielding layer 15 wrapped on the outer surface of the insulating shielding layer 14, the optical transmission unit 2 further includes a sheath 21 and a distributed temperature-sensing optical fiber 22 and a communication optical fiber 23 located inside the sheath 21;

[0040] A wrapping tape is wrapped around the power transmission unit 1 and the light transmission unit 2 to form a first wrapping layer 3, and a glass fiber filling rope 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com