Production method for basalt fiber materials

A technology of basalt fiber and production method, which is applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of basalt fiber filament mechanical properties, thermal insulation and fireproof performance are not ideal, and achieve good heat insulation and fireproof performance, large hydrophobicity, mechanical The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take the raw material by the following parts by weight:

[0027] Basalt ore 115 parts,

[0028] 25 parts limestone,

[0029] 40 parts of coke;

[0030] Among them, the basalt ore is composed of the following chemical substances in weight percentage: SiO 2 46%, Al 2 o 3 17%, CaO12.3%, MgO12%, FeO.Fe 2 o 3 10%, TiO 2 2.0%, MnO0.7%; basalt ore with a particle size of 60-180mm accounts for 80% of its total weight; coke with a particle size of 20-120mm accounts for 80% of its total weight; limestone with a particle size of 20-80mm accounts for 90% of its total weight; the calorific value of coke is 7000Kcal / Kg, the strength M60 is 97%, and the fixed carbon accounts for 95% of the weight percentage of coke.

[0031] production method

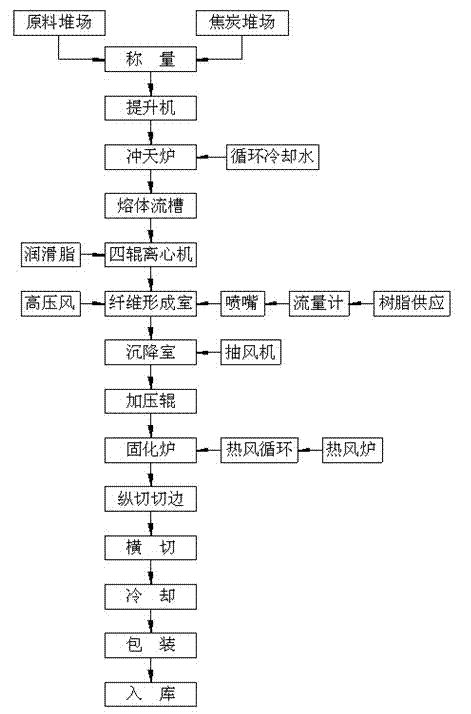

[0032] The production method of the basalt fiber material of the present embodiment, see figure 1 Production process flow chart, including the following steps:

[0033] 1) Mixing of raw materials: mixing the above-mentioned raw mate...

Embodiment 2

[0039] Take the raw material by the following parts by weight:

[0040] Basalt Ore 100 parts,

[0041] 5 parts limestone,

[0042] 30 parts of coke;

[0043] Among them, the basalt ore is composed of the following chemical substances in weight percentage: SiO 2 54%, Al 2 o 3 14.3%, CaO13%, MgO6%, FeO.Fe 2 o 3 8.4%, TiO 2 2.0%, MnO0.4%, loss on ignition 1.9%; basalt ore with a particle size of 60-180mm accounts for 90% of its total weight; coke with a particle size of 20-120mm accounts for 90% of its total weight; particle size is The 20-80mm limestone accounts for 93% of its total weight; the calorific value of coke is 8000Kcal / Kg, the strength M60 is 98%, and the fixed carbon accounts for 96% by weight of coke.

[0044] In addition to containing 80 parts by weight of water-soluble phenolic resin, 20 parts by weight of silane, 20 parts by weight of silicone oil, 5 parts by weight of ammonia water, 5 parts by weight of urea, 1 part by weight of dustproof oil, and 1 Th...

Embodiment 3

[0046] Take the raw material by the following parts by weight:

[0047] Basalt Ore 130 parts,

[0048] 30 parts limestone,

[0049] 50 parts of coke;

[0050] Among them, the basalt ore is composed of the following chemical substances in weight percentage: SiO 2 53%, Al 2 o 316%, CaO8%, MgO9.4%, FeO.Fe 2 o 3 10%, TiO 2 1.6%, MnO0.5%, loss on ignition 1.5%; basalt ore with a particle size of 60-180mm accounts for 90% of its total weight; coke with a particle size of 20-120mm accounts for 90% of its total weight; particle size is The 20-80mm limestone accounts for 93% of its total weight; the calorific value of coke is 8500Kcal / Kg, the strength M60 is 98%, and the fixed carbon accounts for 96% by weight of coke.

[0051] In addition to containing 50 parts by weight of water-soluble phenolic resin, 10 parts by weight of silane, 15 parts by weight of silicone oil, 3 parts by weight of ammonia water, 3 parts by weight of urea, 3 parts by weight of dustproof oil, and The pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com