Low-smoke halogen-free heat-insulating fireproof cable material used for fire-resistant cable, and preparation method and application thereof

A technology of fire-resistant cables and fire-resistant cables, applied in the field of refractory materials, can solve problems such as lack of fire-proof effects, complicated laying operations, and large bending radius, and achieve good heat insulation and fire-proof effects, normal operation protection, and good processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

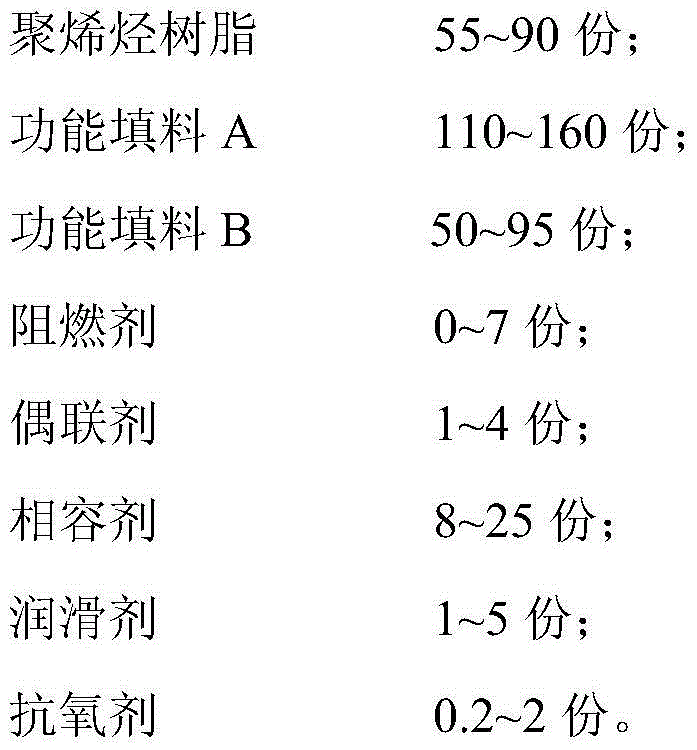

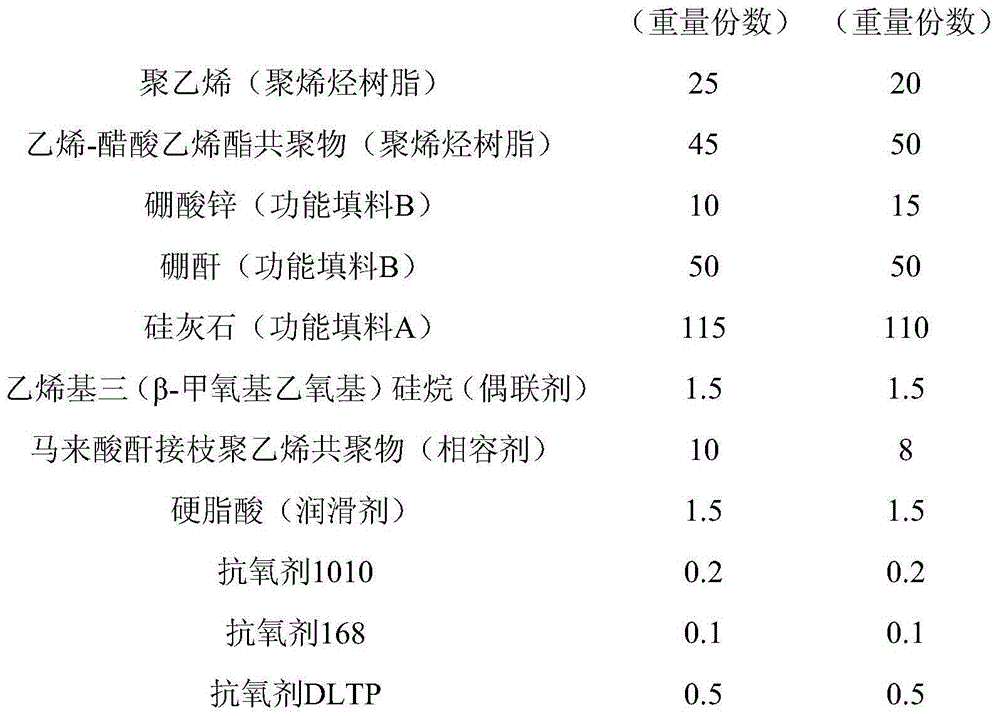

[0054] A low-smoke, halogen-free, heat-insulating and fire-resistant cable material for fire-resistant cables. The raw material components are: polyethylene, ethylene-vinyl acetate copolymer, zinc borate, boric anhydride, wollastonite, vinyl tris(β-methoxy Ethoxy) silane, maleic anhydride grafted polyethylene copolymer, stearic acid, antioxidant DLTP. Its specific formula is shown in Table 1, and the properties of the obtained low-smoke, halogen-free, heat-insulating and fire-resistant cable material for fire-resistant cables are shown in Table 5.

[0055] The preparation method is as follows: firstly graft polyethylene, ethylene-vinyl acetate copolymer, zinc borate, boric anhydride, wollastonite, vinyl tris(β-methoxyethoxy)silane, maleic anhydride to polyethylene The copolymer, stearic acid, and antioxidant DLTP are mixed and fed into the internal mixer for kneading. When the temperature of the material is 145-155°C, the material is discharged and fed into the single-screw or...

Embodiment 2

[0057] A low-smoke, halogen-free, heat-insulating and fire-resistant cable material for fire-resistant cables, the raw material components of which are the same as in Example 1. Its specific formula is shown in Table 1, and the properties of the obtained low-smoke, halogen-free, heat-insulating and fire-resistant cable material for fire-resistant cables are shown in Table 5.

[0058] Its preparation method is identical with embodiment 1.

[0059] Table 1

[0060]

[0061]

Embodiment 3

[0063] A low-smoke, halogen-free, heat-insulating and fire-resistant cable material for fire-resistant cables. The raw material components are: polyethylene, ethylene-vinyl acetate copolymer, ethylene-α-octene copolymer, glass powder, zinc borate, kaolin, silicon Limestone, Vinyl Tris(β-Methoxyethoxy) Silane, Maleic Anhydride Grafted Polyethylene Copolymer, Magnesium Stearate, Antioxidant 1010. Its specific formula is shown in Table 2, and the properties of the obtained low-smoke, halogen-free, heat-insulating and fire-resistant cable material for fire-resistant cables are shown in Table 5.

[0064] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com