Fireproof ultraviolet-ray-resistant multi-core optical cable

A UV-resistant and optical cable technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of high replacement and maintenance costs of optical cables, harm to the environment and human health, aging and cracking of the outer sheath of optical cables, etc., achieve good heat insulation and fire prevention measures, and prolong service life , good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

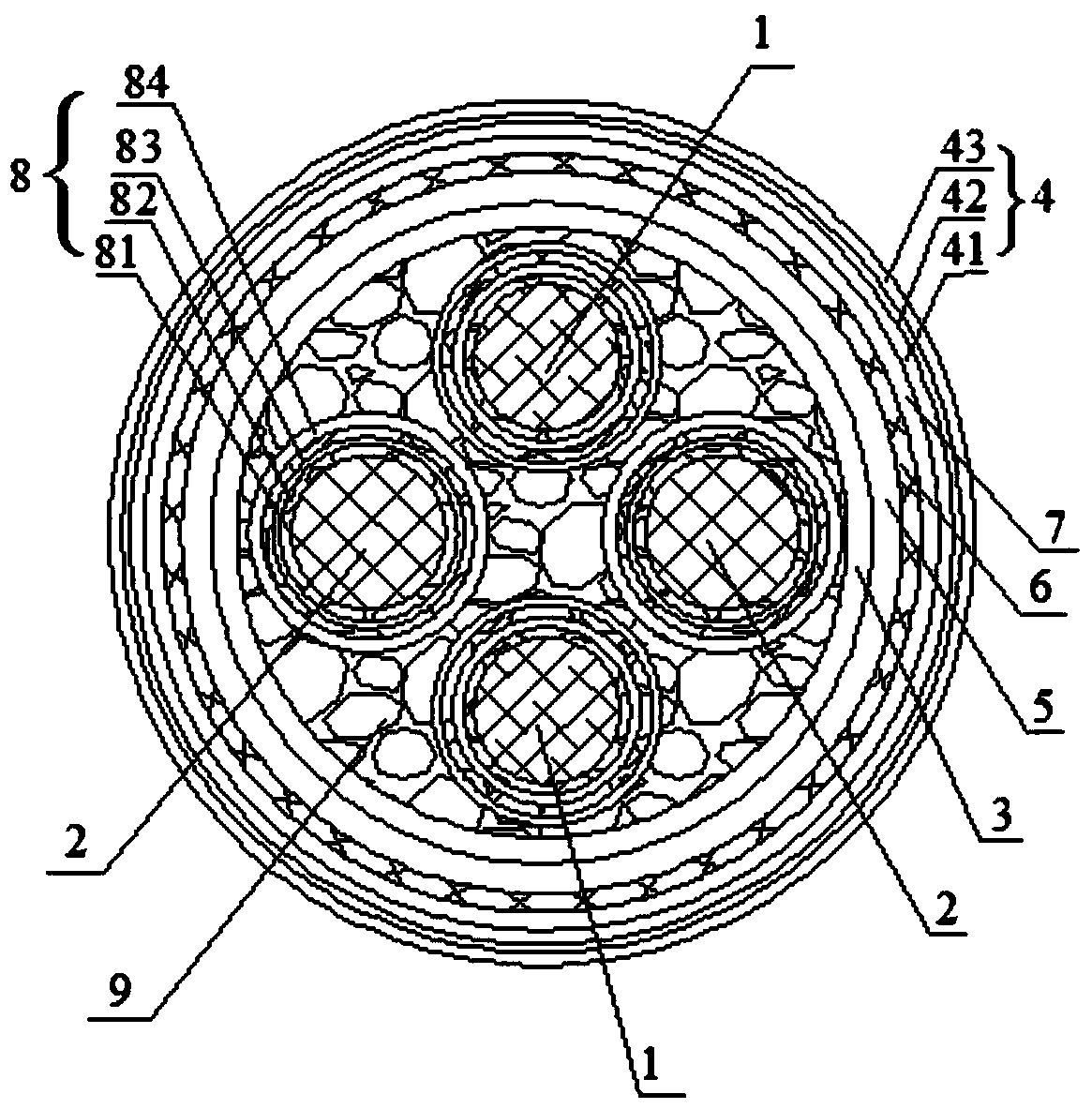

[0024] see figure 1 As shown, the present embodiment provides a fire-proof and UV-resistant multi-core optical cable, including two optical cable cores 1 and two carbon fiber composite mandrels 2 arranged inside, an outer shielding layer 3 and an outer insulating layer 4 arranged outside . Between the outer insulating layer 4 and the outer shielding layer 3, a metal pipe 5, a fiber sleeve 6, and a metal braided mesh 7 are arranged. The outer insulating layer 4 includes a first polytetrafluoroethylene layer 41, a ceramic silicone rubber Layer 42, high flame-retardant halogen-free polyethylene layer 43. The metal pipe 5 is a metal spiral pipe, a metal seamless pipe or a metal nodular pipe.

[0025] The outer side of the optical cable core 1 and the carbon fiber composite mandrel 2 is provided with an inner protective layer 8, and the inner protective layer 8 includes a second polytetrafluoroethylene layer 81, a silicon nitride ceramic layer 82, an inner shielding layer 83, Th...

Embodiment 2

[0029] The difference between the fire-proof and ultraviolet-resistant multi-core optical cable of this embodiment and the embodiment 1 is that 16 wt % of calcium hypophosphite is added to the low flame-retardant halogen-free polyethylene layer 84 . 22wt% polysiloxane flame retardant is added to the high flame-retardant halogen-free polyethylene layer 43 .

[0030] The fire-proof and ultraviolet-resistant multi-core optical cable of this embodiment has a UV-resistant fastness of 850 hours after testing, a thermal conductivity of 0.092W / Mk, and a fire-resistant grade that has reached the A-level standard of GB12666.6. Medium burning over 90min.

Embodiment 3

[0032] The difference between the fire-proof and ultraviolet-resistant multi-core optical cable of this embodiment and the embodiment 1 is that 18wt% of hypophosphite is added to the low flame-retardant halogen-free polyethylene layer 84 . 26wt% polysiloxane flame retardant is added to the high flame-retardant halogen-free polyethylene layer 43 .

[0033] The fire-resistant and ultraviolet-resistant multi-core optical cable of this embodiment has a UV-resistant fastness of 847 hours after testing, a thermal conductivity of 0.088W / Mk, and a fire-resistant grade that has reached the A-level standard of GB12666.6. Medium burning over 90min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com