An electromechanical heat insulation and fire protection device

A technology of protection device and fire protection device, which is applied in the direction of thermal insulation protection of pipelines, pipeline protection, heat preservation, etc., can solve problems such as unfavorable use, easy occurrence of danger, etc., and achieves long service life, convenient installation, and good thermal insulation and fire resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

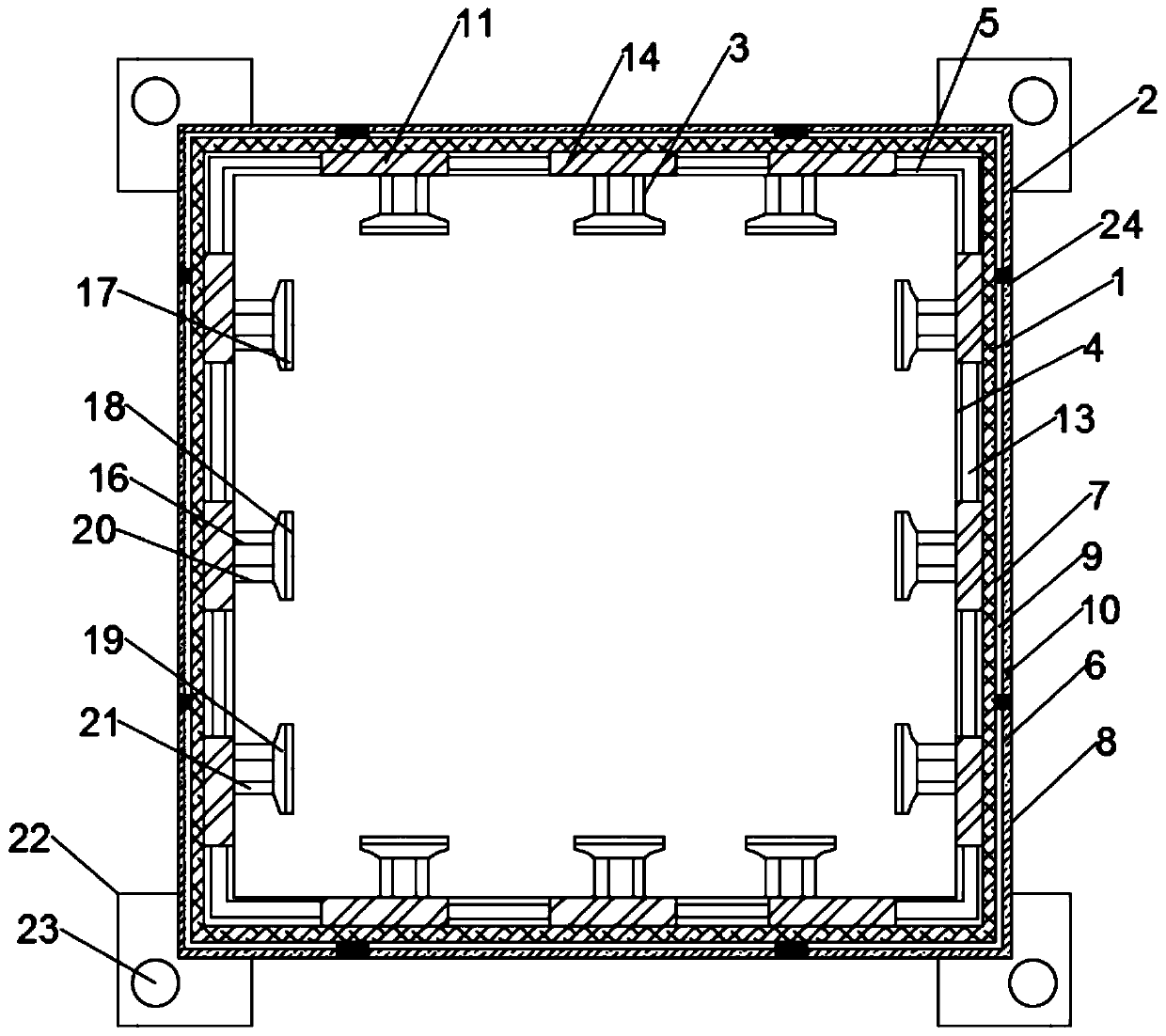

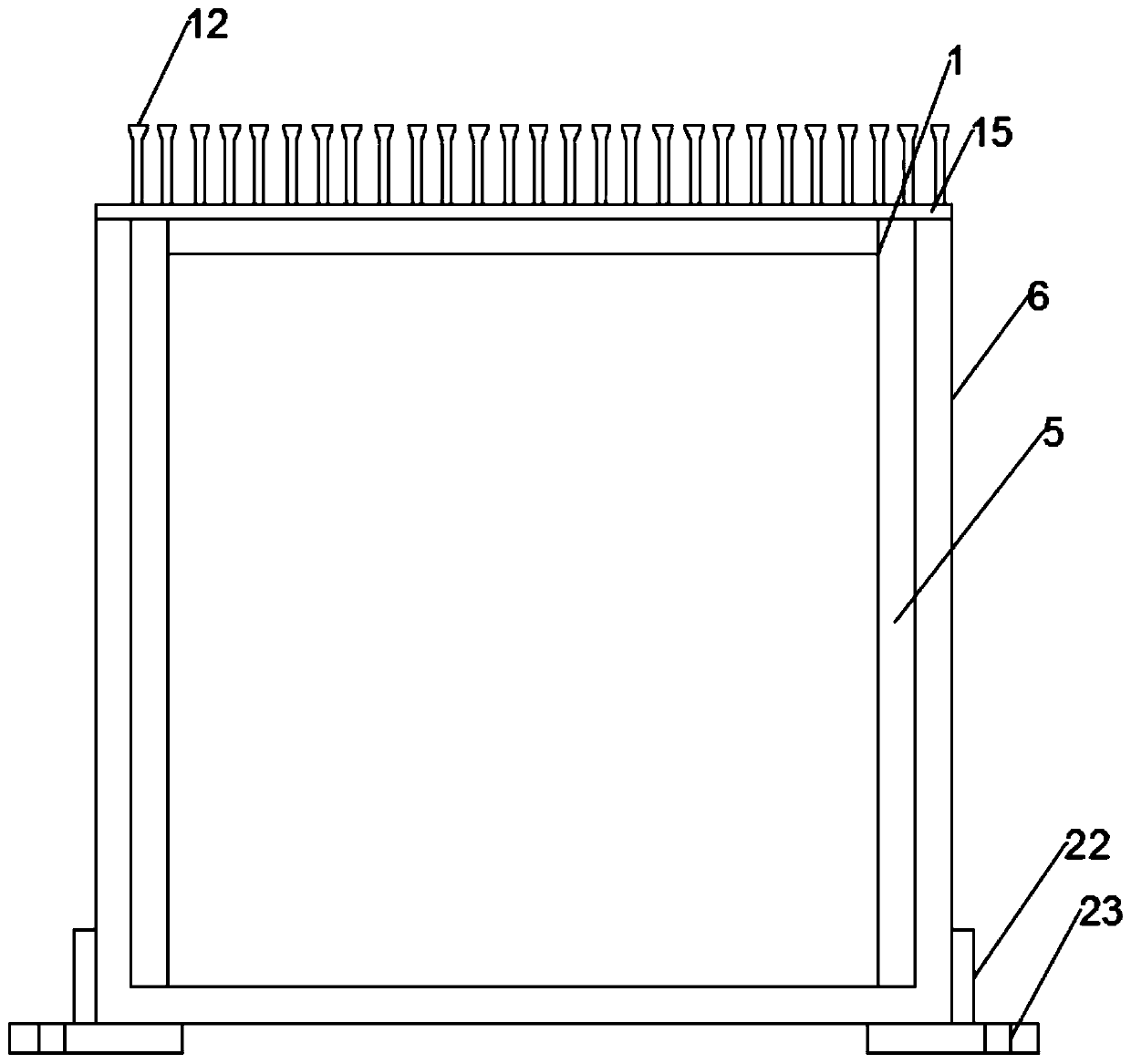

[0015] see figure 1 , figure 2 , the present invention provides a technical solution: an electromechanical heat insulation and fire protection device, characterized in that it includes a protective shell 1, a mounting frame 2, a buffer frame 3 and a protective device 4, and the protective shell 1 is fixedly installed on the mounting frame 2 On the surface, the protective device 4 includes a heat insulation device 5 and a fireproof device 6, the heat insulation device 5 is arranged inside the protective shell 1, the fireproof device 6 is arranged outside the protective shell 1, and the fireproof device 6 includes a fireproof layer 7 and a heat insulation layer 8, the fireproof layer 7 includes a fireproof board 9 and an aluminum alloy board 10, and the fireproof board 9 and the aluminum alloy board 10 are connected together through a flame retardant strip 24, and the heat insulation layer 8 Evenly arranged on the surface of the fireproof layer 7, the heat insulation device 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com