Cast-in-situ steel mesh frame sandwich heat-insulating shear wall and construction method thereof

A technology of steel wire grid and shear wall, which is applied in the direction of insulation, walls, floors, etc., and can solve the problems of steel wire damage, large stretching deformation of steel wire, cracking and damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

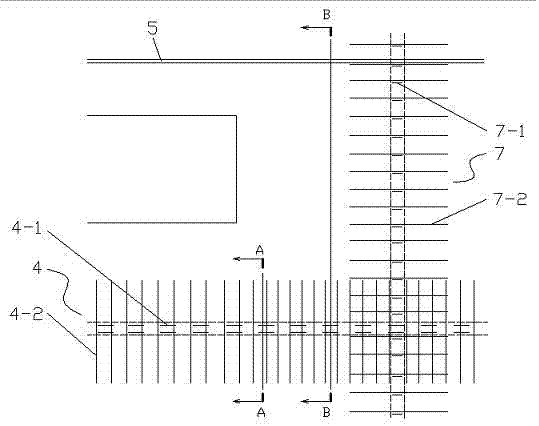

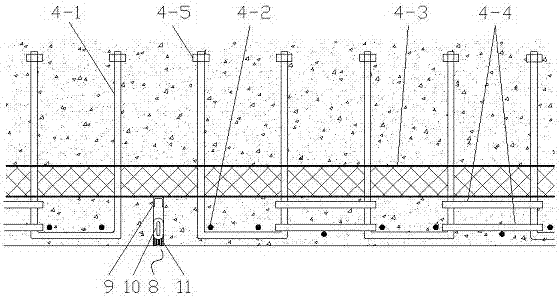

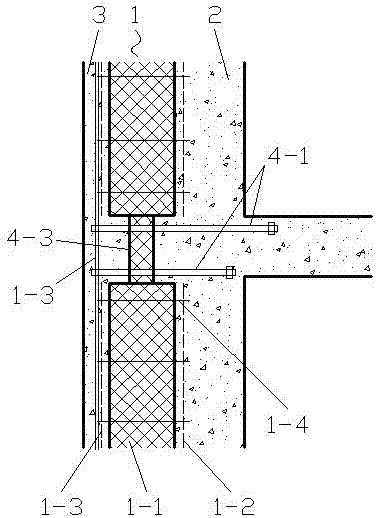

[0027] The invention provides a cast-in-place steel wire grid sandwich insulation shear wall, such as Figure 1-5As shown, it includes a steel wire grid sandwich insulation board 1 and cast-in-situ concrete inner leaf walls 2 and outer leaf walls 3 consolidated on both sides of the steel wire grid sandwich insulation board. The steel wire grid sandwich insulation board includes a heat preservation board 1-1, an inner steel wire mesh 1-2 and an outer steel wire mesh 1-3 respectively located on the inner and outer sides of the heat preservation board, and several wire meshes passing through the heat preservation board. And the abdominal wires 1-4 connected between the inner and outer wire meshes are welded, and the abdominal wires are perpendicular to the inner and outer wire meshes. The steel wire grid sandwich insulation board with abdominal wire perpendicular to the steel wire mesh is used, and the small triangular units are replaced by rectangular units. The expansion and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com