Patents

Literature

77results about How to "Anti-shock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

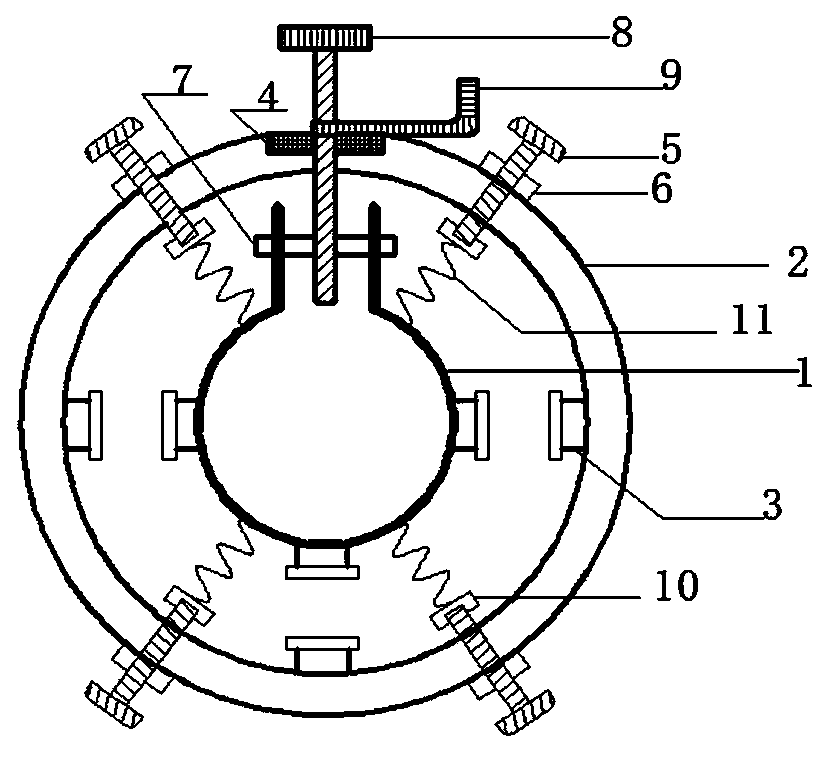

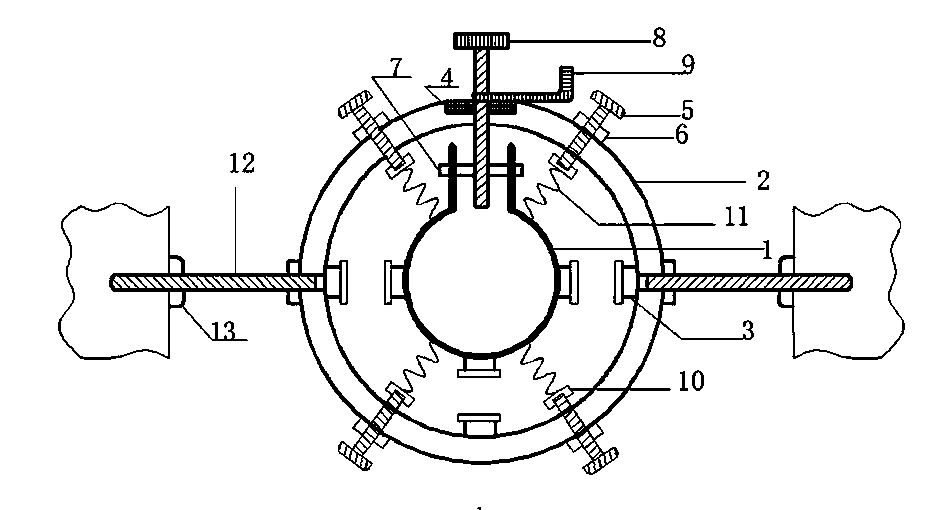

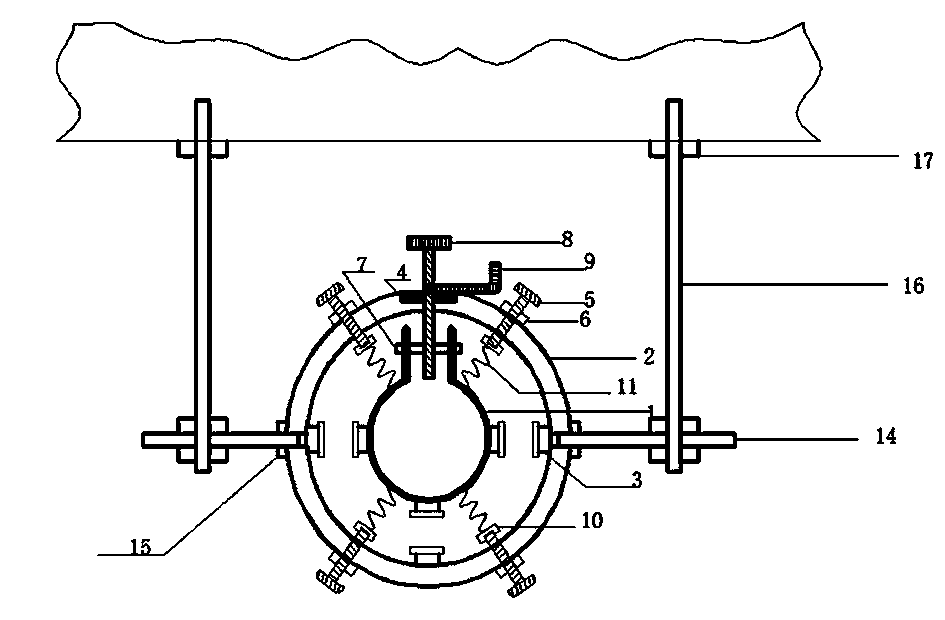

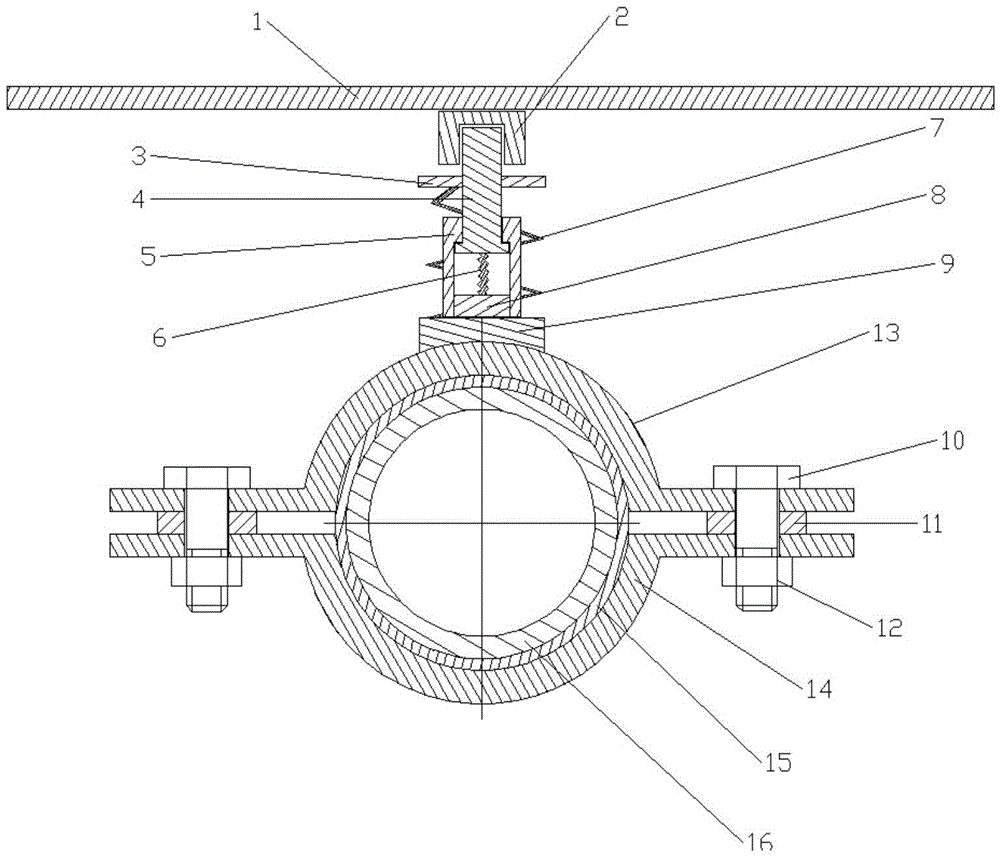

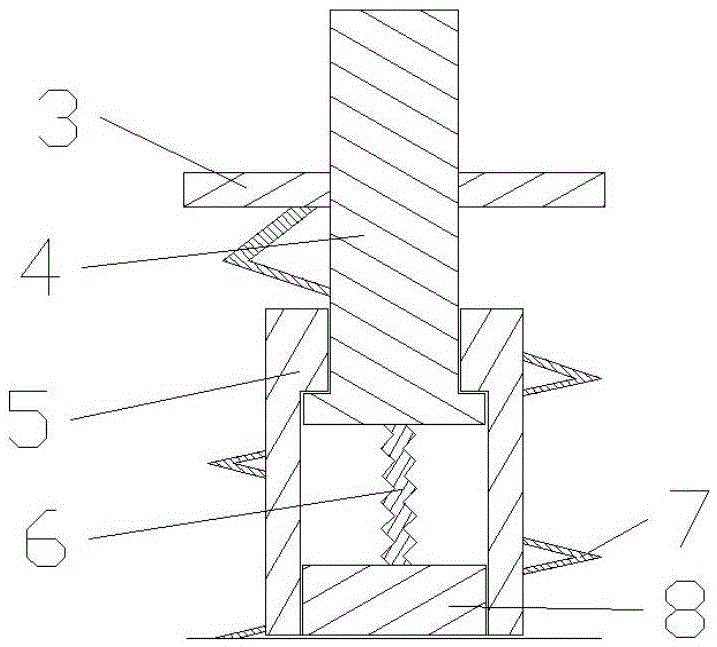

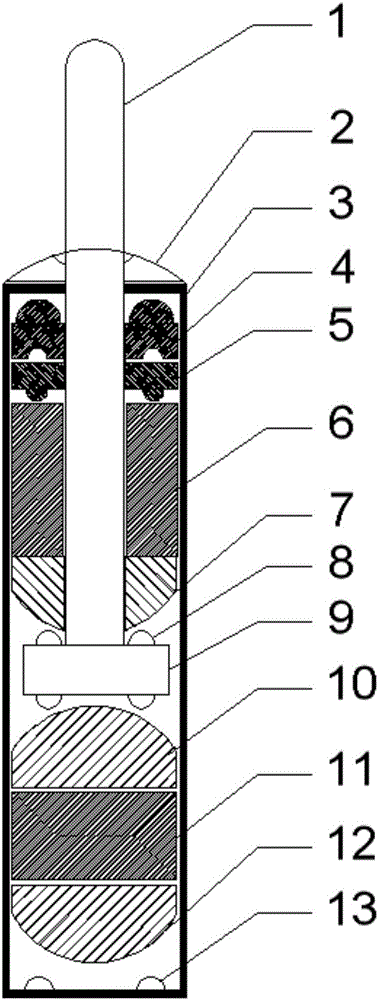

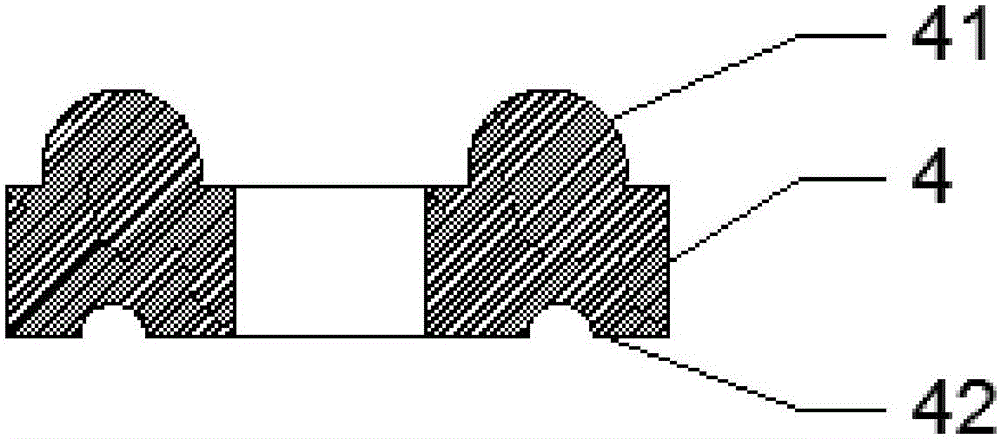

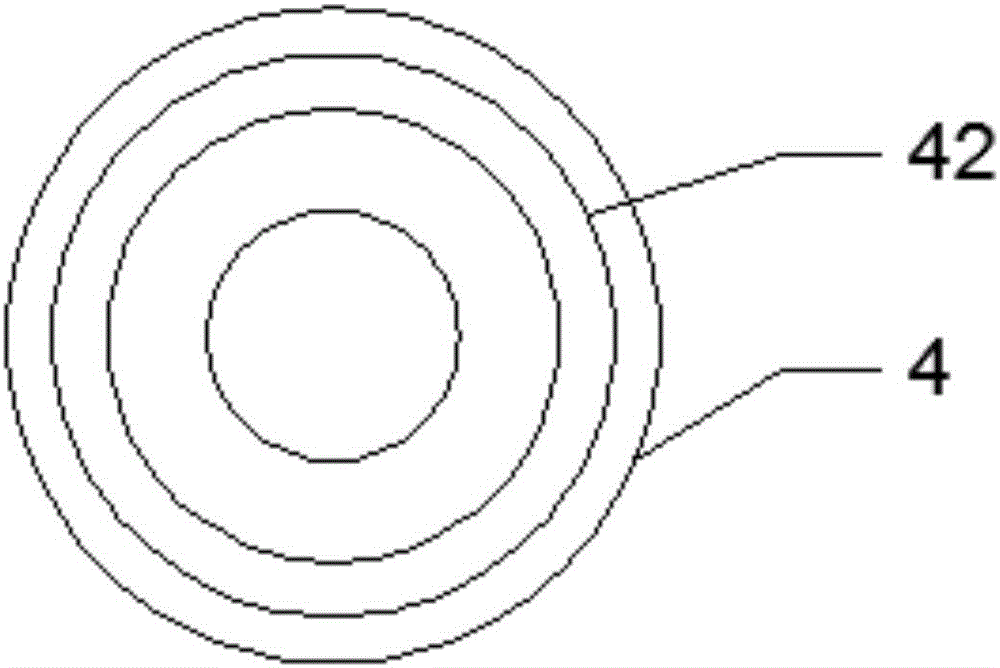

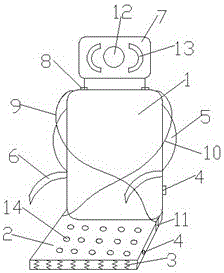

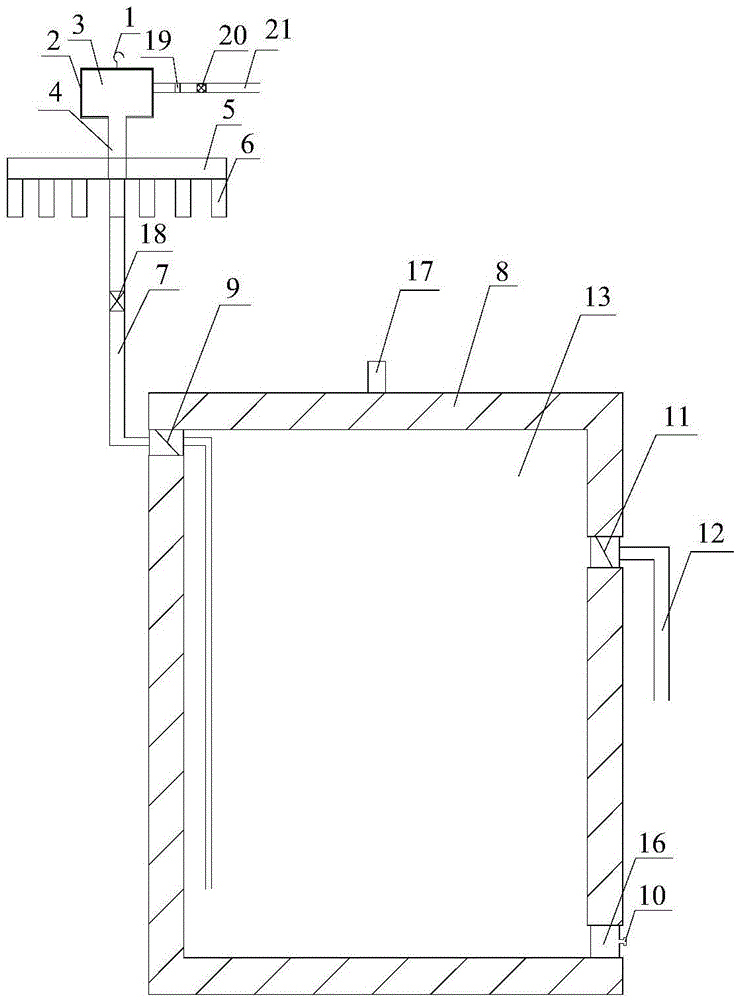

Adjustable ship pipeline shock resistance lantern ring device

InactiveCN103803033ATimely Limit OffsetLimit offsetVessel safetyPipe elementsFixed-functionRing device

The invention discloses an adjustable ship pipeline shock resistance lantern ring device which comprises a first adjusting ring covering a pipeline and a second ring arranged on the periphery of the first adjusting ring. The first adjusting ring is a non-closed ring and an allowance is reserved in a body of the first adjusting ring. The allowance of the ring body can be collected or released through an adjusting bolt and a connecting piece, and therefore the first adjusting ring can be used for pipelines with different diameters. The adjustable ship pipeline shock resistance lantern ring device is wide in application range and capable of reducing cost. When a casing pipe works normally, a pipeline system has the restraining function and the fixing function, when the pipeline system is shocked and vibration is generated, the pipeline is protected against large excursion, and the impact resistance of the ship pipeline is enhanced.

Owner:JIANGSU MARITIME INST +1

Method for preparing antibacterial filter material

The invention relates to a method for preparing an antibacterial filter material by utilizing biomass resources, and belongs to the technical field of air purification. The method provided by the invention comprises the following steps: mixing a surfactant, plant fibers and water to obtain mixed slurry; stirring the mixed slurry until the mixed slurry is foamy, thereby obtaining foam fibers; performing vacuum suction filtration on the foam fibers until a water line is not observed by naked eyes; and drying until moisture content is 10wt% or lower. According to the method, the biomass resources such as crop straw and market pulp which are existed in nature in large numbers are taken as main raw materials, and a novel biomass antibacterial filter material is prepared through a normal-temperature low-pressure mechanical stirring method; a raw material source is wide, and the raw materials can be naturally degraded and regenerated; and the preparation method is simple, is not high in equipment requirement, is relatively low in production cost, is good in product filter effect, is strong in bacteriostatic ability, has excellent characteristics of resisting impact and shock, absorbing noises and preventing moisture, insulating, preserving heat and the like, can be used for respirators, air purifiers, filter elements, and has a good market prospect.

Owner:烟台通润化工科技有限公司

Catalyst for preparing ethanol by acetic acid gas phase hydrogenation and preparation method thereof

InactiveCN102658165AImprove mechanical propertiesAnti-shockOrganic compound preparationHydroxy compound preparationCalcium silicatePlatinum

The invention discloses a catalyst for preparing ethanol by acetic acid gas phase hydrogenation and a preparation method thereof. The catalyst comprises active components, an auxiliary agent, and a carrier, wherein the active components comprise iron and tin; the auxiliary agent is one of platinum, palladium and ruthenium; the carrier is a composite carrier of alumina and titanium dioxide, or one or more of silica, alumina and calcium silicate; the weight of the active components is 1 to 20% of the total weight of the catalyst; and the weight of the auxiliary agent is 0.25 to 1% of the total weight of the catalyst. The preparation method of the catalyst comprises the following steps of 1, dissolving precursors of iron and tin in a solution of a water-soluble solvent, and loading the precursor solution on the selected carrier, 2, carrying out calcination in a muffle furnace, 3, preparing a precursor of platinum, palladium or ruthenium into an aqueous solution, dipping the catalyst precursor loaded with iron and tin into the aqueous solution, wherein the volume of the catalyst precursor is the same as that of the aqueous solution, standing, drying to constant weight in a muffle furnace, and carrying out calcination, and 4, carrying out reduction before catalyst use. The catalyst obtained by the preparation method has low precious metal content. Through the catalyst, products mainly comprise ethanol and ethyl acetate; reaction conditions are mild; and energy consumption is low.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Vibration-reducing anti-impact pipeline hanging rack

ActiveCN105650350AImprove vibration damping effectImprove impact resistancePipe supportsMechanical engineeringPiston rod

The invention discloses a vibration-reducing anti-impact pipeline hanging rack which comprises an upper pipe clamping body and a lower pipe clamping body. The upper pipe clamping body and the lower pipe clamping body are connected through bolts and nuts which are arranged at the clamping ends of the clamping bodies, a gasket is further arranged between the clamping ends of the upper pipe clamping body and the lower pipe clamping body, a base is arranged at the top of the upper pipe clamping body, a vibration-reducing cylinder provided with a vibration-reducing spring in the inside is fixedly connected to the base, a cylinder body of the vibration-reducing cylinder is fixedly connected with the base, the vibration-reducing spring is arranged between the cylinder body and a piston rod of the vibration-reducing cylinder, the piston rod is sleeved with a movable baffle, the outer side of the vibration-reducing cylinder is sleeved with an anti-impact spring, one end of the anti-impact spring is connected with the base, the other end of the anti-impact spring is connected with the movable baffle, and the top of the piston rod is fixedly connected with a machine body through a cap. The vibration-reducing anti-impact pipeline hanging rack can support a pipeline like other hanging racks during normal working, meanwhile can reduce small-amplitude vibration and can further make the advantages prominent when working in a severe environment suffering from a strong impact load.

Owner:江苏圣大中远电力科技有限公司

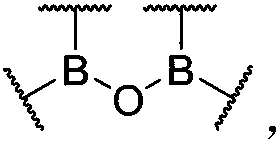

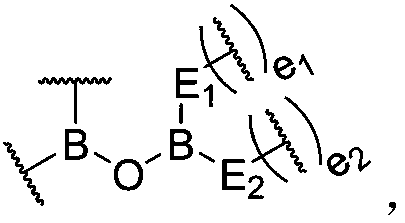

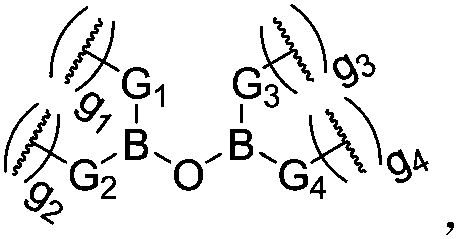

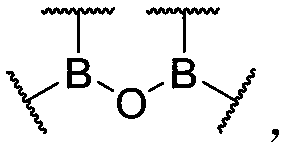

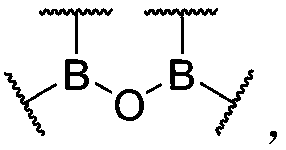

Dynamic polymer and application thereof

The invention discloses a dynamic polymer. The structure of the dynamic polymer contains dynamic covalent bonds and optional hydrogen bonds, wherein the dynamic covalent bonds are boron-oxygen-boron bonds which are composed of organic boron-oxygen-boron bonds, organic-inorganic boron-oxygen-boron bonds and inorganic boron-oxygen-boron bonds, or composed of organic boron-oxygen-boron bonds and organic-inorganic boron-oxygen-boron bonds, or composed of inorganic boron-oxygen-boron bonds and organic-inorganic boron-oxygen-boron bonds, or composed of organic-inorganic boron-oxygen-boron bonds; andall the inorganic boron-oxygen-boron bonds in the structure of the dynamic polymer are connected to the polymer via the organic-inorganic boron-oxygen-boron bonds and / or inorganic boron-oxygen-boronbonds. A plurality of the boron-oxygen-boron bonds and the optional hydrogen bonds in the structure of the dynamic polymer endow the dynamic polymer with good and hierarchical dynamic nature and allowthe dynamic polymer to have good toughness, buffering performance and self-repairing performance; and the dynamic polymer can be applied to fields like damping and buffering products, protection materials, sport protection materials, self-repairing materials, tough materials, stress-sensing materials, adhesives and sealing members.

Owner:厦门天策材料科技有限公司

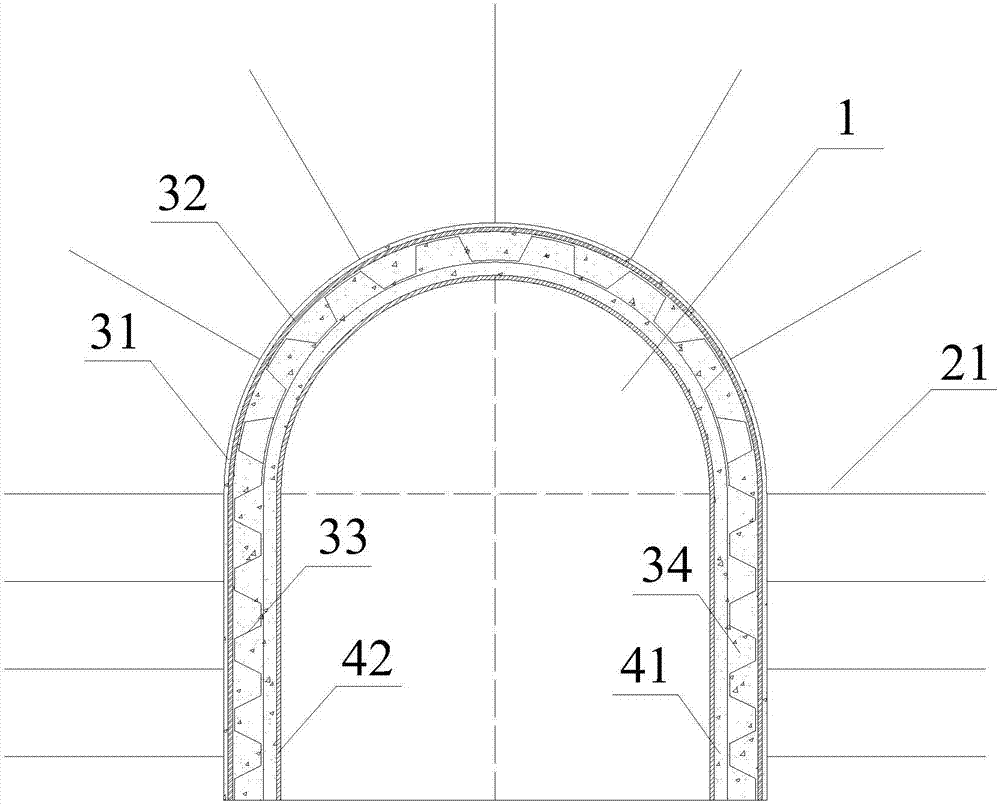

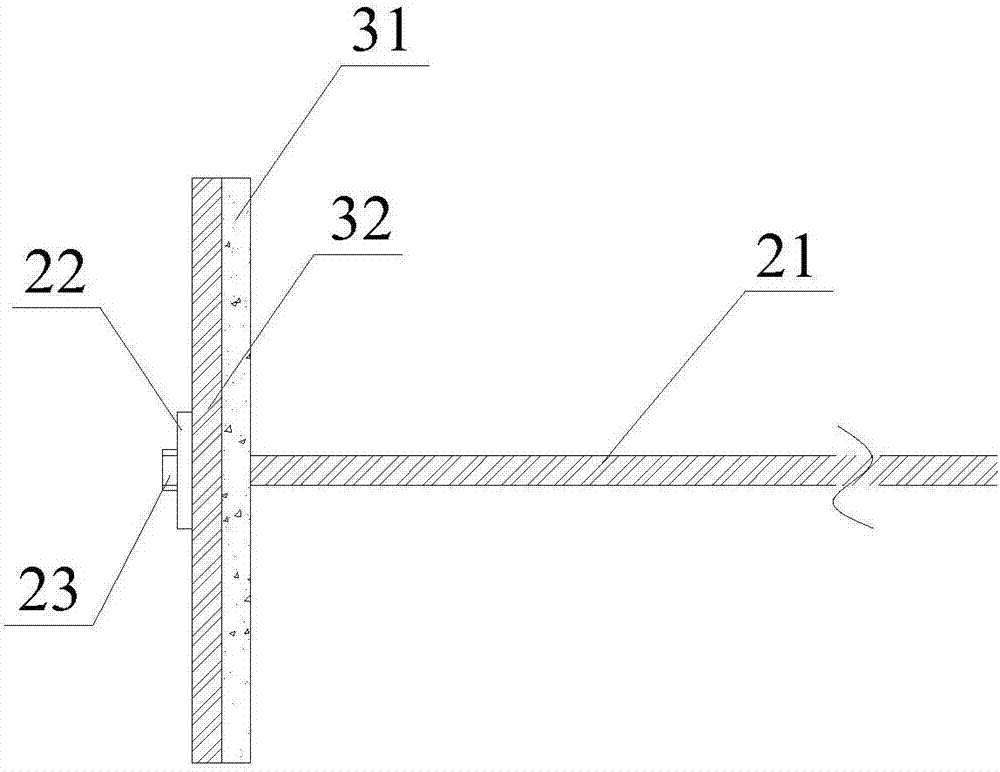

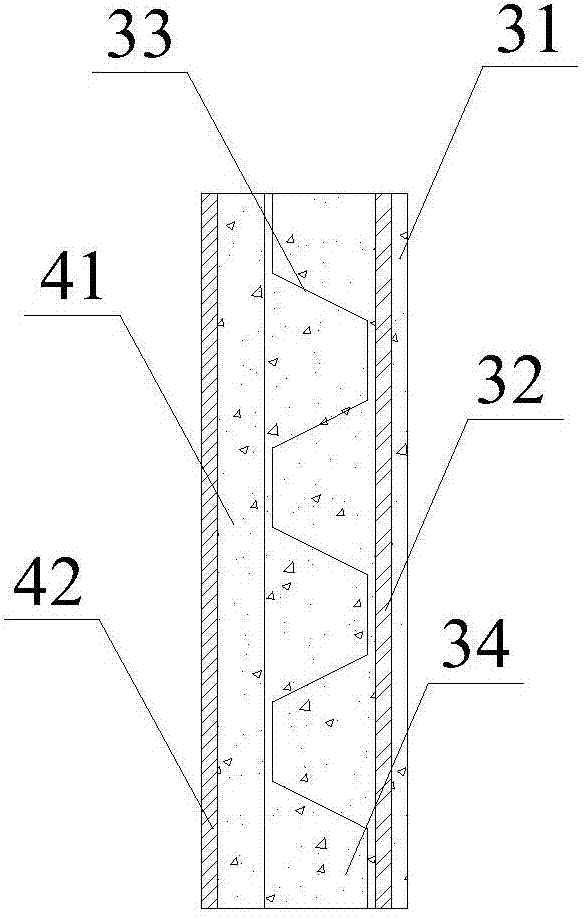

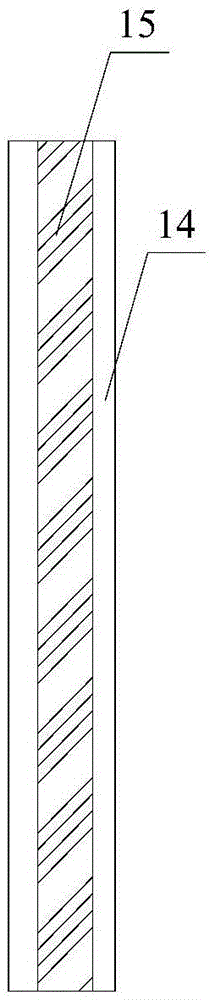

Deep high-ground-temperature roadway heat-insulation lining structure and construction method thereof

ActiveCN106988769ARealization of thermal insulation liningHigh strengthUnderground chambersTunnel liningInsulation layerArchitectural engineering

The invention discloses a deep high-ground-temperature roadway heat-insulation lining structure and a construction method thereof. The lining structure comprises a grouting heat-insulation ring, a primary lining heat-insulation layer and a secondary lining heat-insulation layer. Firstly, a heat-insulation grout material is injected through a hollow grouting anchor rod to form a grouting heat-insulation ring; the primary lining heat-insulation layer is distributed to form a primary support, wherein the primary lining heat-insulation layer comprises a first jet ceramsite concrete layer, a reinforcing mesh layer, a metal support and a second jet ceramsite concrete layer; after roadway deformation is stabilized, the secondary lining heat-insulation layer is constructed, and construction of the structure is completed, wherein the secondary lining heat-insulation layer comprises a third jet ceramsite concrete layer and a heat-insulation plate. By means of the structure and existing common support means and according to the current situation that deep mining high-temperature damage is severe, the stability of a roadway support structure is ensured by reasonably improving supporting materials and increasing the heat-insulation plates; by means of multiple heat-insulation measures, heat is effectively prevented from spreading into a roadway, and the application and popularization value is good.

Owner:ANHUI UNIV OF SCI & TECH

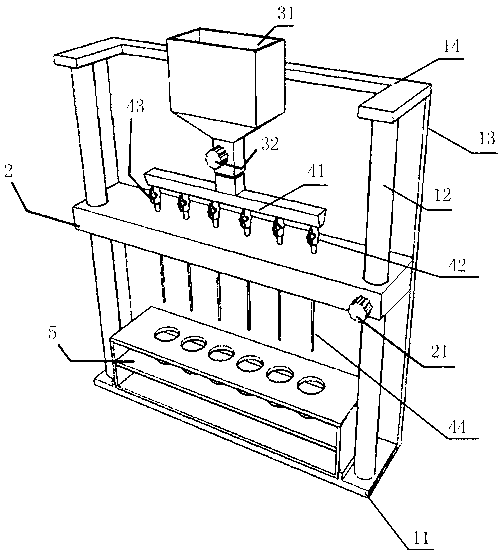

Multichannel liquid sample injector

The invention discloses a multichannel liquid sample injector which comprises a rack body, a lifting table and a sampling device, wherein the rack body comprises a bottom plate and a pair of support pillars which are symmetrically arranged on the bottom plate; the pair of support pillars respectively pass through holes formed in the lifting table, so that the lifting table can move up and down along the support pillars, and is fixed on the support pillars by lifting locking knobs arranged on the lifting table; the sampling device comprises a funnel-shaped liquid storage groove and an inverted T-shaped liquid discharge channel, wherein the top of the inverted T-shaped liquid discharge channel is communicated with a close up end of the liquid storage groove; a liquid discharge switch is arranged at the part of the liquid storage groove, which is close to the close up end; the bottom of the inverted T-shaped liquid discharge channel is provided with a plurality of sampling needles; and each sampling needle passes through the lifting table and is fixed on the lifting table. The multichannel liquid sample injector can be used for sampling liquid sample into multiple channels at the same time, thus being time-saving and labor-saving, reducing the error and the error probability, and being especially suitable for sampling liquid in a centrifuge tube; and two switches are arranged on the multichannel liquid sample injector, so that the liquid sampling flow speed is effectively controlled, and the different liquids are avoided being mixed when being added into the same tube.

Owner:启东市凯尔达电器有限公司

Steam distributor and moisture separator reheater

The invention relates to a steam distributor which comprises a steam channel entering from the bottom and diffused towards the periphery. A lower guide plate and an upper guide plate positioned above the lower guide plate enclose the steam channel, a dewatering channel connected with the lower guide plate and the upper guide plate is arranged in the steam channel, and the upper space of the upper guide plate is communicated with the peripheral space of the lower guide plate through the dewatering channel. Wet steam scouring prevention and guide functions are achieved, the dewatering channel collects condensed water formed by wet steam on the surface of the upper guide plate and drains the condensed water to the space between a lining plate on the periphery of the lower guide plate and a shell, so that the steam distributor can be directly fixed onto the shell, and great convenience is brought for mounting the steam distributor. The invention further relates to a moisture separator reheater. The steam distributor can be applied to steam distribution of the moisture separator reheater.

Owner:DONGFANG (GUANGZHOU) HEAVY MASCH CO LTD

Automobile brake lining

InactiveCN105202075AGood strengthExcellent wear resistanceOther chemical processesBraking membersBrake liningOxide

An automobile brake lining is prepared from, by weight, 14%-18% of ceramic fibers, 3%-6% of carbon fibers, 3%-7% of cellulose fibers, 8%-13% of aramid fibers, 8%-13% of modified phenolic resin, 2%-4% of aluminium oxide, 3%-5% of barium sulphide, 6%-9% of graphite, 4%-6% of zirconite, 8%-12% of quartz sand, 1%-2% of bauxite, 1%-2% of zinc oxide, 2%-4% of chemigum, 1%-4% of antimony sulfide, 7%-10% of friction powder and 6%-9% of nanometer silicon carbide. According to the automobile brake lining, a ceramic brake pad is kept to be stable in braking, low in noise and the like, the mechanical strength of the brake lining is further improved, and the service life of the brake lining is prolonged; meanwhile, recession and expansion of the high temperature can be avoided, and the automobile brake lining has the advantages of being good in braking performance and abrasion resistance, stable in braking, less in dust, moderate in hardness and good in high temperature recovery performance.

Owner:刘桂华

American ginseng tableting candy production method

InactiveCN105580952AImprove bioavailabilityUnique physical and chemical propertiesConfectionerySweetmeatsAdditive ingredientTableting

The present invention discloses an American ginseng tableting candy production method, which is characterized in that American ginseng powder is adopted as a main raw material, Chinese wolfberry powder, tuckahoe polysaccharides, an ophiopogon japonicus extract, corn starch and xylitol are matched, and mixing, ultrafine crushing, soft material preparation, granulation, tableting, testing and packaging are performed to prepare the American ginseng tableting candy. According to the present invention, the valuable resource compounding and the modern biotechnology are organically combined, the nutritional health value of the American ginseng and the characteristics and the advantages of the buccal eating of the candy are completely provided, and the American ginseng is prepared into the American ginseng tabletting candy with characteristics of rich nutrients, rich biological activity, easy absorption, easy easting, easy carrying and good taste, such that the American ginseng tabletting candy has a certain health effect, can provide a new approach for the multiple development of the American ginseng resources, and has wide market prospects.

Owner:WEIHAI XINYI BIOLOGICAL TECH

Dynamic polymer and application thereof

The invention discloses a dynamic polymer. The structure of the dynamic polymer contains dynamic covalent bonds and optional hydrogen bonds, wherein the dynamic covalent bonds are organic boron-oxygen-boron bonds; the structure of the dynamic polymer contains at least three organic boron-oxygen-boron bonds which realize connection without shared boron atoms; and the dynamic polymer has at least one glass-transition temperature no more than 25 DEG C. The dynamic covalent bonds and the optional hydrogen bonds have dynamic reversibility, so the dynamic polymer is endowed with good toughness, self-repairing performance, buffering performance and the like. The dynamic polymer is rich in structure and diversified in performance, has good regulability and can be applied to fields like buffer products, damping products, protection materials, sport protection materials, self-repairing materials, stress sensors, tough materials, adhesives and sealing materials.

Owner:厦门天策材料科技有限公司

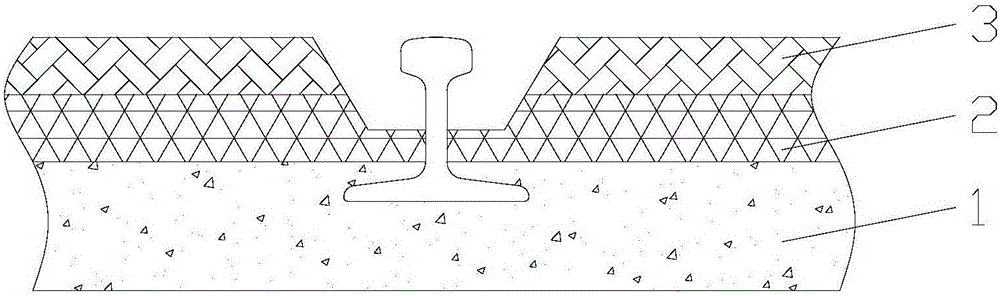

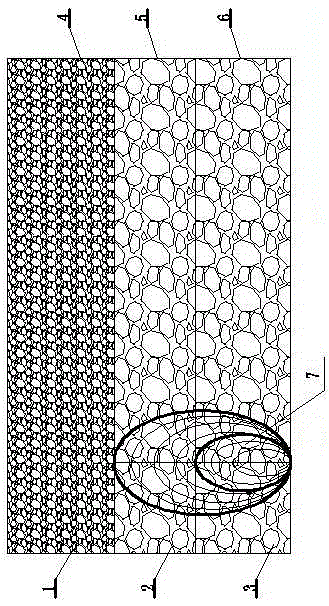

Tramcar basalt fiber composite road surface structure

InactiveCN106223158AExtended service lifeIncreased durabilityIn situ pavingsTemporary pavingsEnvironmental effectAsphalt mastic

Currently, a road surface structure in a tunnel is composed of conventional asphalt concrete and fracture-resistant concrete or steel fiber concrete. Primary causes of road surface damage comprise direct impact of repeated crushing of rubber wheels and external environmental effects, at best, cracks and tracks are generated, the riding comfort is affected, at worst, pits and grooves are generated, and the overall stability and safety of the road surface are threatened; and even traffic is delayed for a long time during later maintenance. To improve the fracture resistance and pressure resistance of the road surface, prolong the service life of the road surface and recover the road surface rapidly during later maintenance, the invention provides a tramcar basalt fiber composite road surface structure, and the tramcar basalt fiber composite road surface structure sequentially comprises a basalt fiber concrete base layer, a basalt fiber medium grain type asphalt concrete layer and a basalt fiber asphalt mastic gravel mixed aggregate layer from bottom to top.

Owner:中铁二院重庆勘察设计研究院有限责任公司 +1

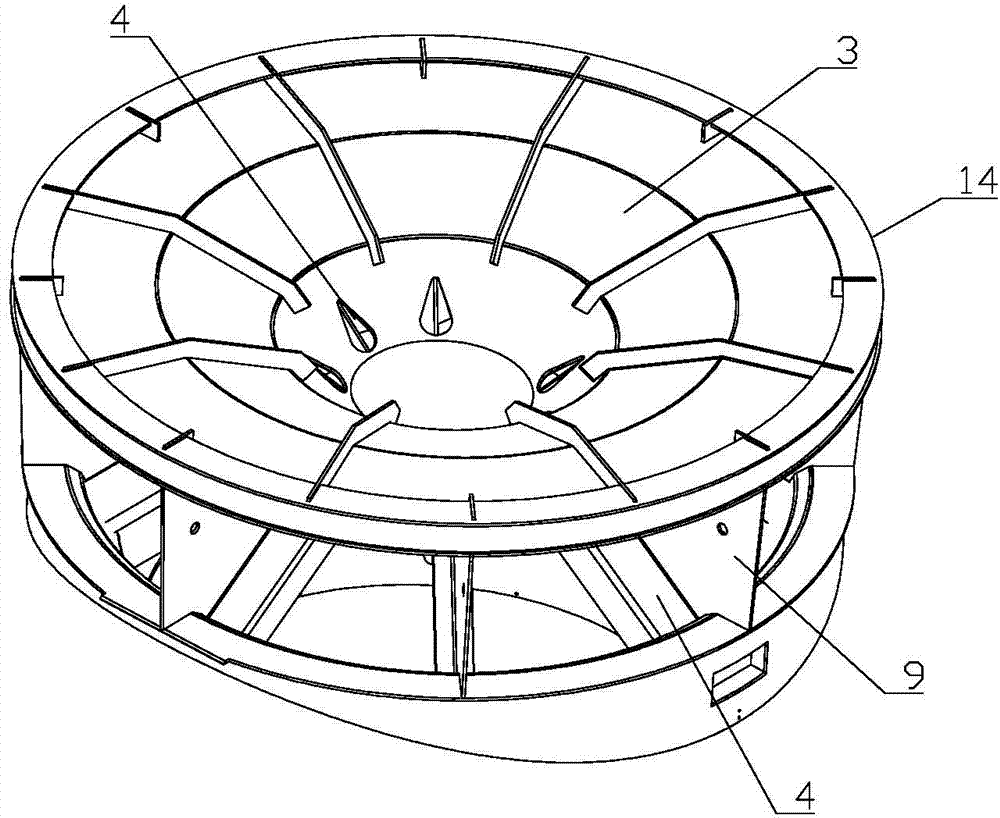

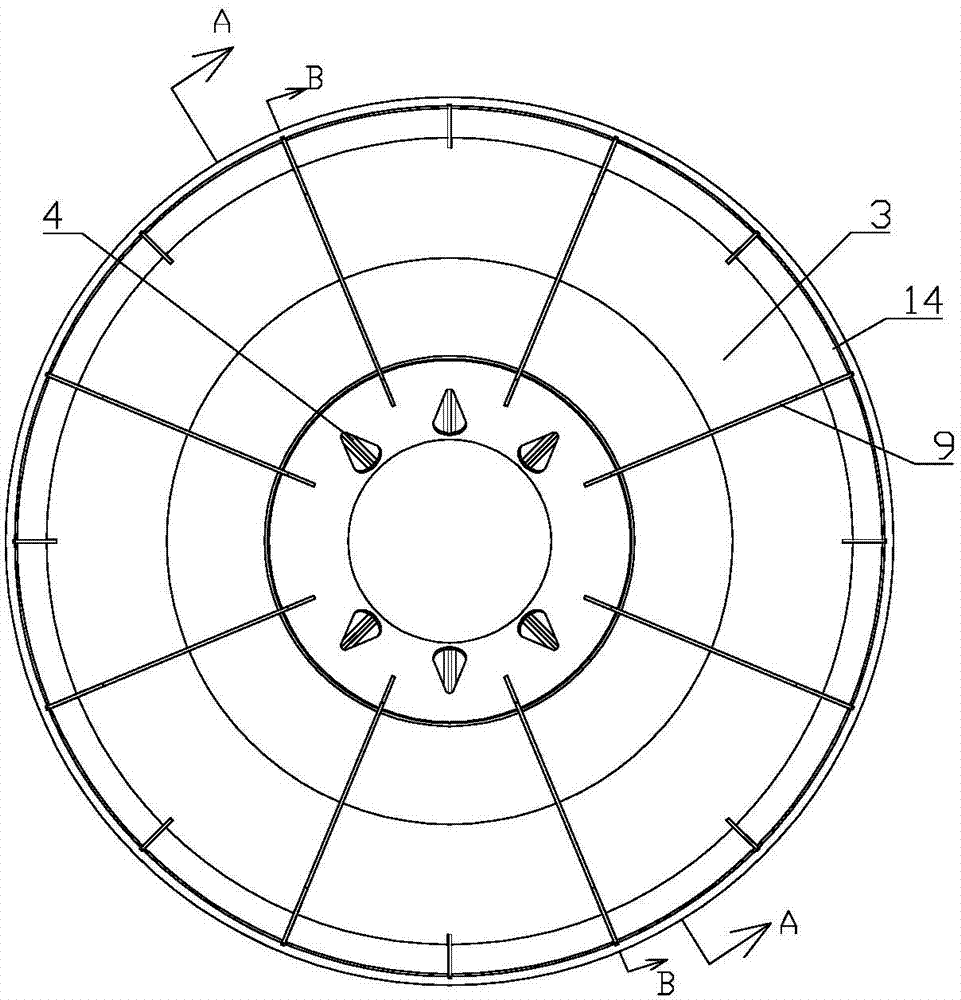

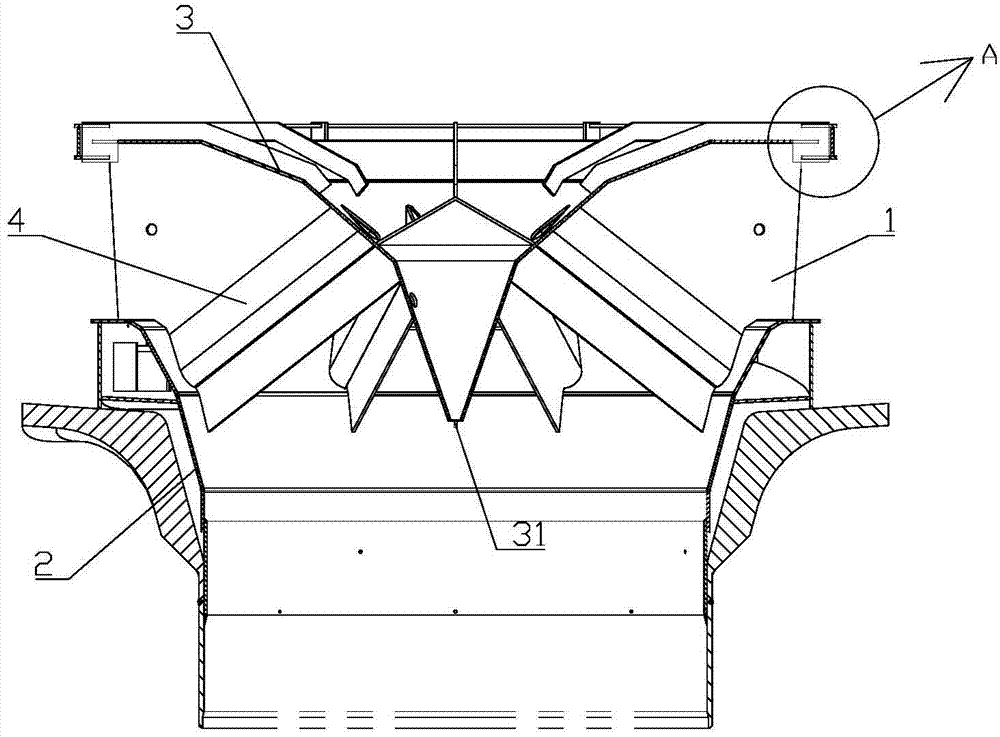

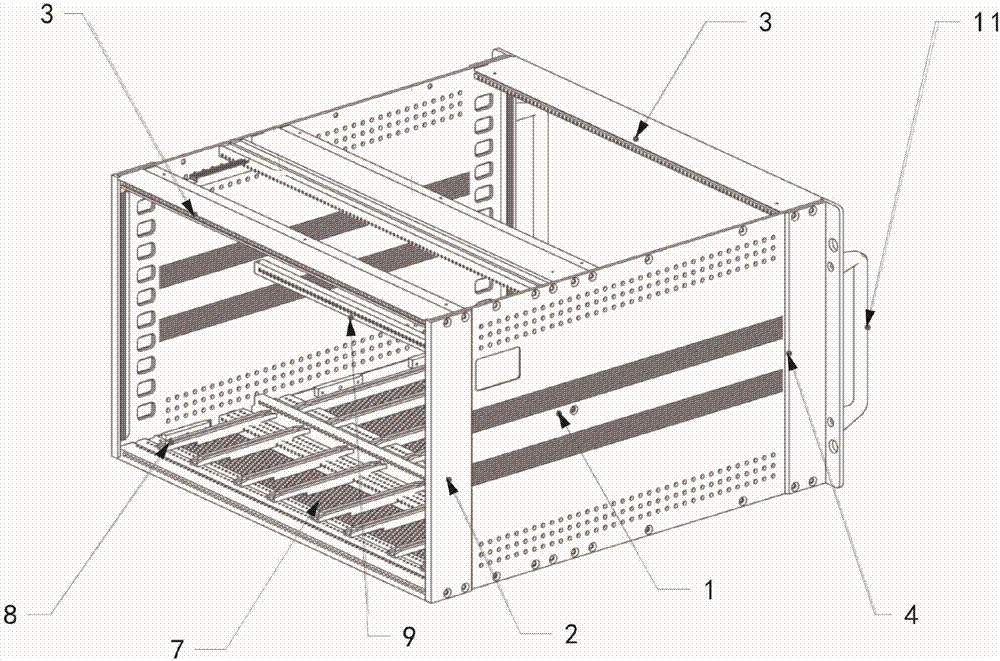

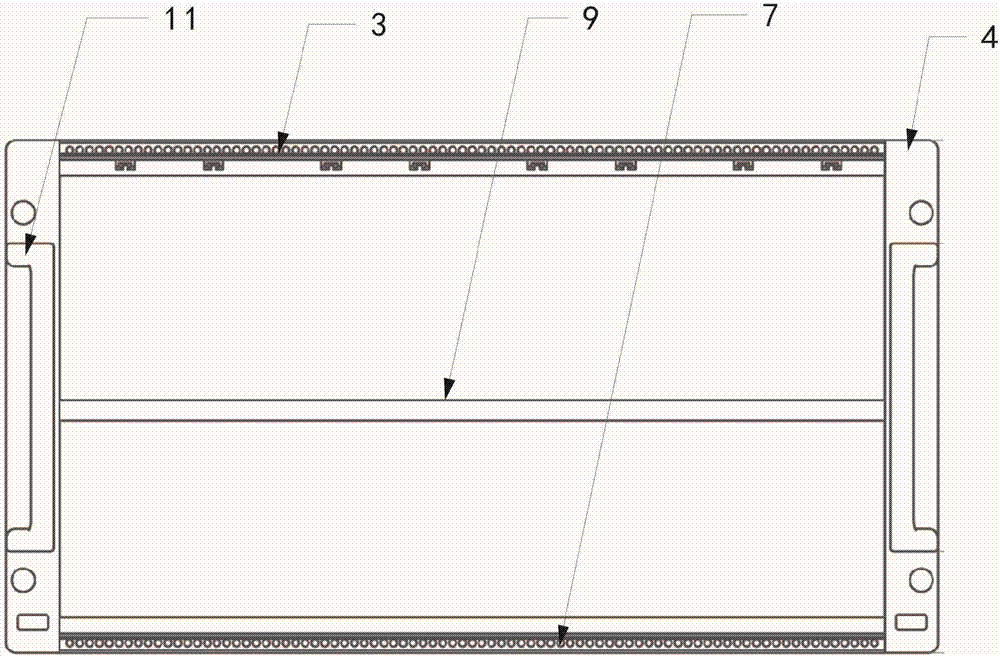

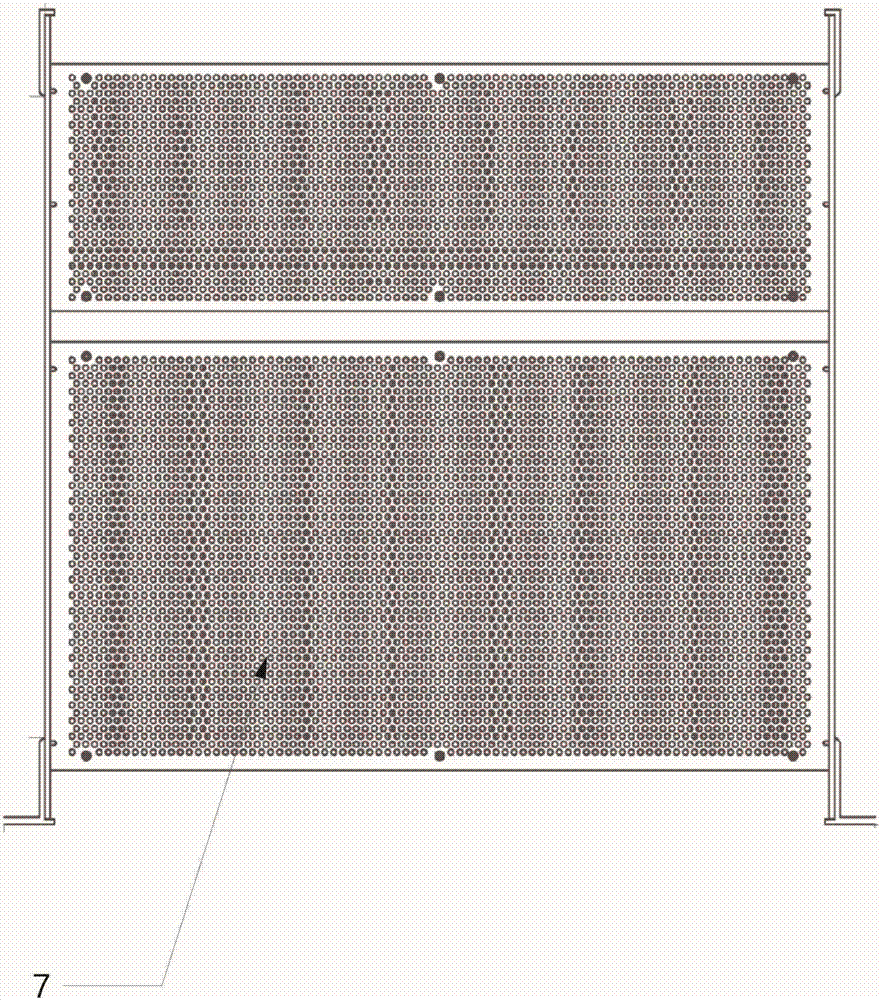

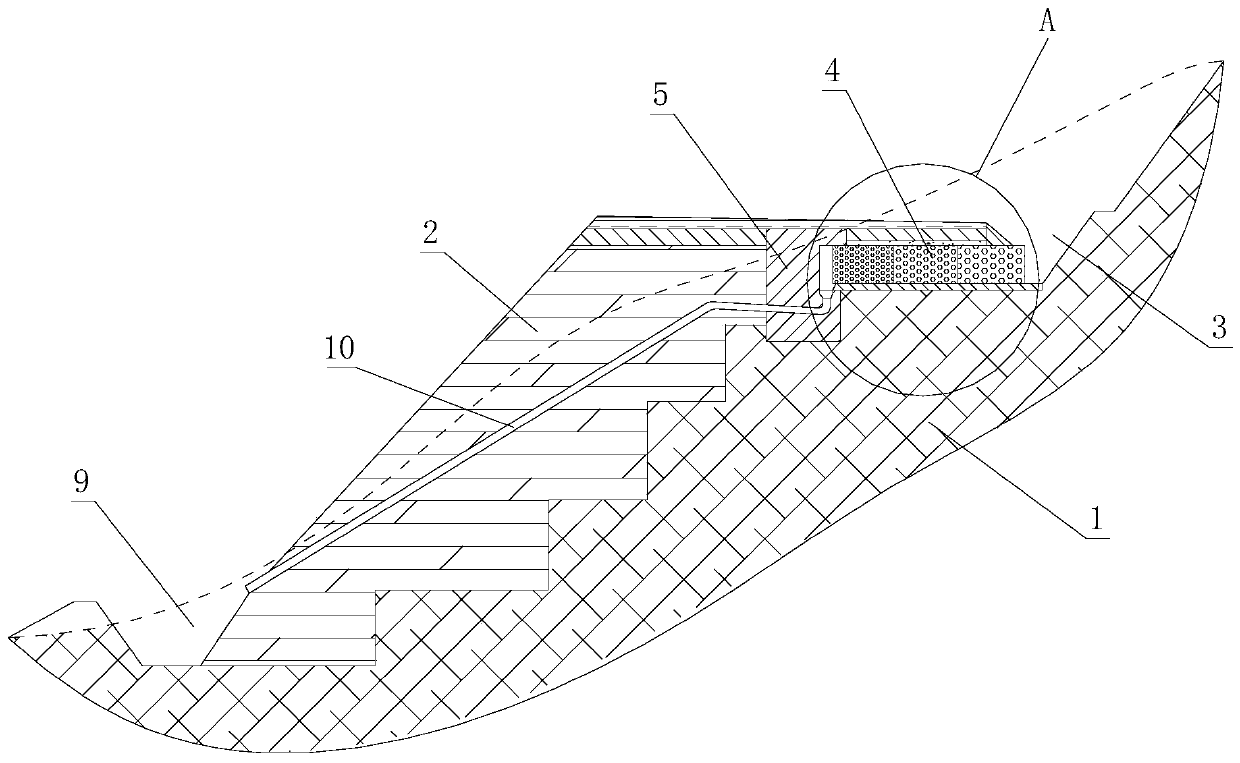

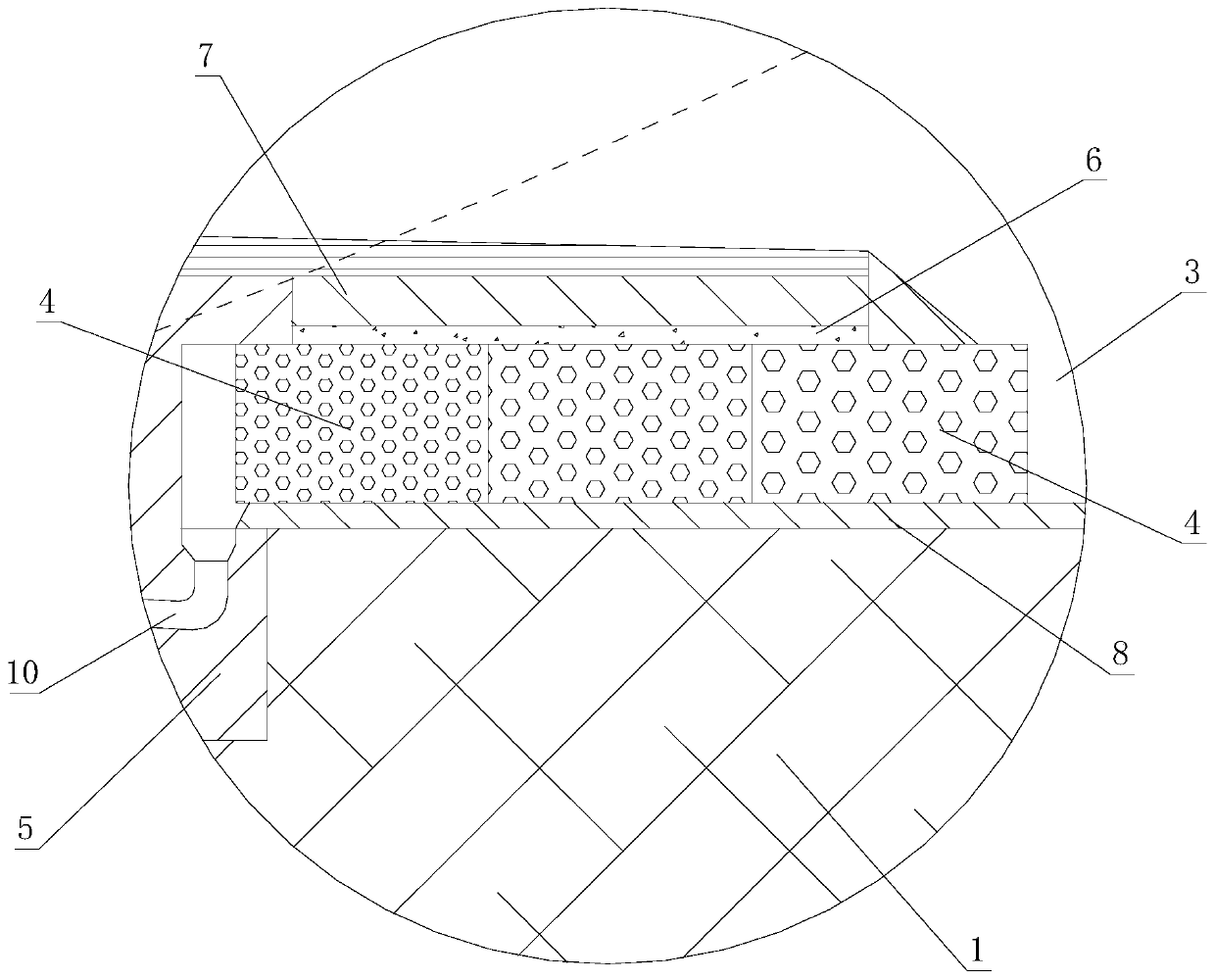

High-strength aviation impact-resistant anti-vibration shielding cabinet

PendingCN107484404AGuarantee continuityGuarantee the overall rigidityCasings/cabinets/drawers detailsEMI leakage reductionPhysicsEngineering

The invention discloses a high-strength aviation impact-resistant anti-vibration shielding cabinet, and relates to the technical field of aviation shielding cabinet equipment. The cabinet comprises two parallel side plates (1) and a rectangular frame (2), and the rectangular frame (2) is installed between the two parallel side plates (1) in a parallel manner. The rectangular frame (2) comprises a sealing cross beam (3) and a reinforcing vertical beam (4), which are connected through a riveting block to form the rectangular frame (2). The sealing cross beam (3) comprises a cross beam main body (31), and the cross beam main body (31) is provided with a circular bottom hole (32) for installing a steel wire thread sleeve, a flat hole (33) for installing a riveting block (5), a irregularly-shaped hole (34) for installing a nut bar (6), wherein the irregularly-shaped hole (34) is located at an inner side of the cross beam main body (31). The cabinet is advantageous in that the cabinet guarantees the overall strength of the cross beam main body (3) and the reinforcing vertical beam, and improves the work stability.

Owner:成都泵类应用技术研究所

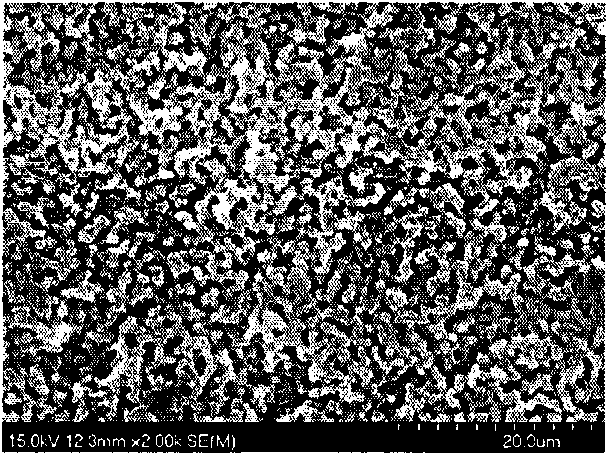

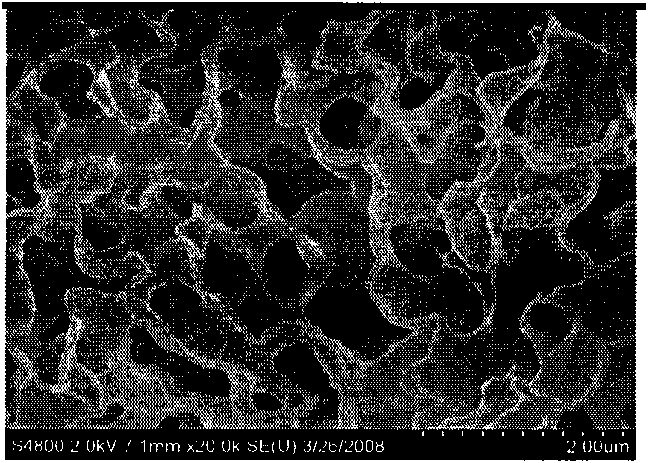

Preparation method for fuel cell compound proton exchange membrane enhanced by using SiO2 three-dimensional ultra-thin membrane

InactiveCN101931085AHigh mechanical strengthSolving Mechanical Stability IssuesCell component detailsCollectors/separatorsEpoxyDouble phase

The invention relates to a preparation method for a fuel cell compound proton exchange membrane enhanced by using an SiO2 three-dimensional ultra-thin membrane, comprising the following steps: polymerizing and splitting phase of the epoxy resin and the amine in the polyethylene glycol medium by a certain weight ratio at a certain temperature and obtaining the epoxy resin micro filtering membrane;performing the in situ hydrolysis to the tetraethoxysilane in the template pore channel of the epoxy resin micro filtering membrane, and forming the compound membrane of the three-dimensional SiO2 continuous phase coating epoxy resin; and removing the epoxy resin by high temperature calcination and forming the three-dimensional SiO2 ultra-thin micro pore membrane; and then casting the perfluorinated sulfonic resin solution with a certain amount on the three-dimensional SiO2 ultra-thin micro pore membrane, and heating and volatilizing the solvent; heating under the vacuum atmosphere, and obtaining the compound proton exchange membrane enhanced by using an SiO2 ultra-thin micro pore membrane after washing with de-ionized water. The compound membrane has the structure that the SiO2 and the perfluorinated sulfonic resin are in two-phase continuous interpenetrating polymer network; the SiO2 content is high; the side stability and mechanical performance in wet and dry states are good; and the invention has the characteristics of high moisture holding capability, high-temperature resistance and cell work efficiency at high temperature.

Owner:NINGBO UNIV

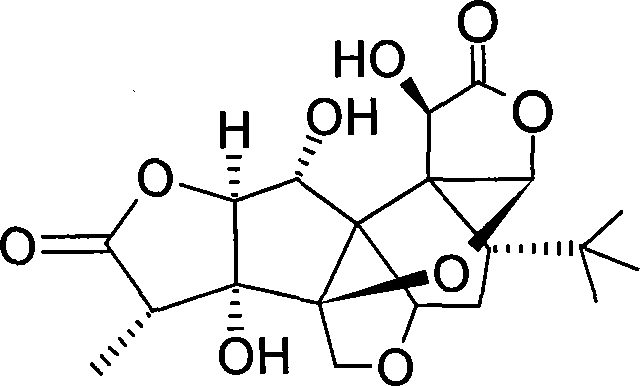

Ginkgolide B powder injection and its preparation method

InactiveCN101053554ASolve insolubleAnti-allergicOrganic active ingredientsPowder deliveryMANNITOL/SORBITOLMedicine

The invention discloses a Ginkgolide B powder injection, which is characterized in that: it is a powder injection consisting of main medcine and pharmacological acceptable filter aid, excipient and stabilizer. Said main medicine is Ginkgolide B, and filter aid is meglumine, and excipient is mannitol or dextran 40, and stabilizer is EDTA-2Na or EDTA-CaNa. The weight ratio is: Ginkgolide B:EDTA-2Na or EDTA-CaNa:mannitol or dextran 40 = 1:0.5-3:0.01-2:1-20. The preparation solves the problems such as Ginkgolide B indissolvable problem, redissolve clarity and stability.

Owner:HAINAN SIHUAN PHARMA +2

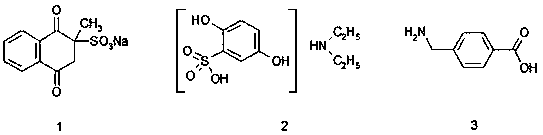

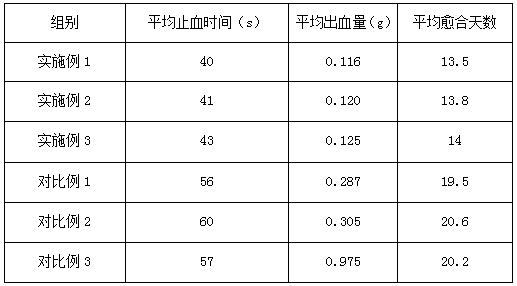

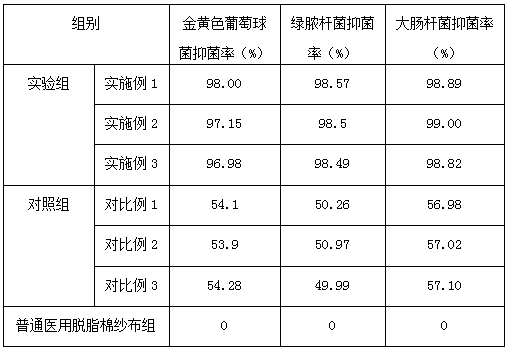

Antibacterial medical hemostasis absorbent cotton gauze and preparation method thereof

InactiveCN108478848APrevent agglutinationAntiarrhythmicAbsorbent padsBandagesEscherichia coliDeep wounds

The invention provides antibacterial medical hemostasis absorbent cotton gauze, which consists of medicine dressing and a tissue material carrying the medicine dressing, wherein the medicine dressingis prepared from traditional Chinese medicine and western medicine; the tissue material carrying the medicine dressing is blended by scleroprotein fiber and cotton fiber. The hemostasis and the antibacterial effects are integrated; the obvious effects are achieved on abnormal bleeding in operations of lung, liver, pancreas, adrenal gland and the like, the bleeding except for obstetrics departmentand postpartum hemorrhage, urinary tract bleeding and the like; in addition, the antibacterial medical hemostasis absorbent cotton gauze can be used under the conditions of great and deep wound and great bleeding quantity; the hemostasis is fast; the wound surface wound recovery is facilitated; meanwhile, the antibacterial spectrum is wide; the sterilization power is strong; the action is fast; the effectiveness can also be achieved on pseudomonas aeruginosa, klebsiella, escherichia coli, enterobacter, staphylococcus, mycoplasma and chlamydia; in addition, good effects are achieved on trimethoprim drug resistant bacteria, penicillin drug resistant staphylococcus aureus andtylosin or tiamulin drug resistant mycoplasma.

Owner:代清燕

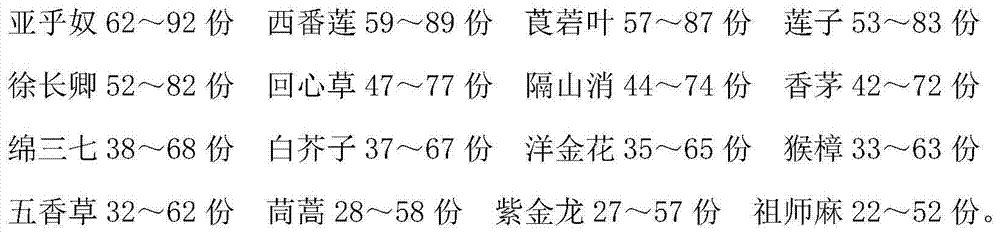

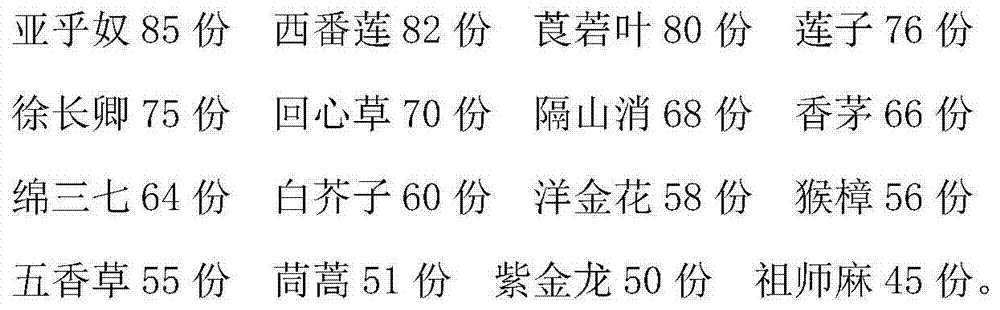

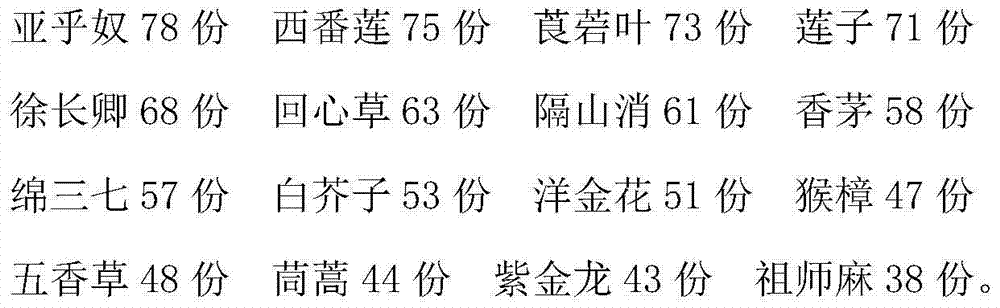

Traditional Chinese medicinal preparation for treating pre-operative anesthesia and preparation method of traditional Chinese medicinal preparation

InactiveCN104758690AAnalgesicHeat-clearing and detoxifyingAnaestheticsPlant ingredientsModern medicineSide effect

The invention discloses a traditional Chinese medicinal preparation for treating pre-operative anesthesia and a preparation method of traditional Chinese medicinal preparation, and belongs to the field of traditional Chinese medicine. Active ingredients of the traditional Chinese medicinal preparation consist of the following raw materials: common cissampelos herb, passion flower, hembane leaf, lotus seed, paniculate swallowwort root, rhodobryum roseum, radix cynanchi, cymbopogon, himalayan eriosema root, semen brassicae, hindu datura flower, cinnamomum bodinieri, suchow mosla herb, crowndaisy chrysanthemum, dactylicapnos root and girald daphne bark. The traditional Chinese medicinal preparation disclosed by the invention, since the selected medicinal materials are appropriately combined in accordance with the theories of traditional Chinese medicine and modern medicine, has functions of relieving and alleviating pain, clearing away heat and toxic materials, anesthetizing and tranquilizing, and resisting shock, and the traditional Chinese medicinal preparation is quick to take effect, short in duration, high in anesthesia efficiency, good in absorption effect and free from adverse as well as toxic and side effects; and the traditional Chinese medicinal preparation has a quite significant anesthesia effect in clinical practice, and is suitable for wide popularization and application.

Owner:宋修响

Preparation method of nitrile rubber composite metal plate

InactiveCN104816529AGood oil resistanceIncrease elasticityLaminationLamination apparatusPolymer scienceStearic acid

The invention discloses a preparation method of a nitrile rubber composite metal plate. Raw materials of a recovery processing technology comprise nitrile rubber, zinc oxide, stearic acid, sublimated sulfur, carbon black, dibutyl phthalate, butyl acetate, bentonite, Chemlok and hexadecyl trimethyl ammonium bromide. The preparation method comprises the following steps: (1) crushing the nitrile rubber, wherein a beaker of 1000ml is taken out, 100g of the nitrile rubber is weighed on an electronic balance, the weighed nitrile rubber is cut into small blocks, and the small blocks are put into a high-speed universal crusher to be crushed; (2) stirring and dissolving the nitrile rubber, dissolving the nitrile rubber with 500ml of butyl acetate, electrically stirring the dissolved nitrile rubber at the rotational speed of 70r / min in the process of dissolving, and stirring the nitrile rubber for several hours until masterbatch is uniform.

Owner:ANHUI TONGFENG RUBBER & PLASTIC IND

Lucid ganoderma and America ginseng capsule

InactiveCN104825514AImprove microcirculationIncrease supplyNervous disorderDigestive systemMedicineSecretion

The invention relates to a lucid ganoderma and America ginseng capsule, and belongs to the technical field of health product. The provided capsule is composed of a capsule shell and contents encapsulated in the capsule shell, wherein the contents are composed of the following raw materials in percentage by weight: 30 to 65% of lucid ganoderma extract, 20 to 50% of American ginseng extract, 10 to 30% of microcrystalline cellulose, and 0.5 to 2.5% of magnesium stearate. The capsule has the advantages of scientific formula and no side or toxic effect, and has the functions of relieving fatigue, preventing aging, boosting qi, tranquilizing, refreshing the spirit, improving memory, regulating internal secretion, strengthening human immunity, and improving the cardiovascular state.

Owner:SHANDONG SHENGHAI HEALTH PROD CO LTD

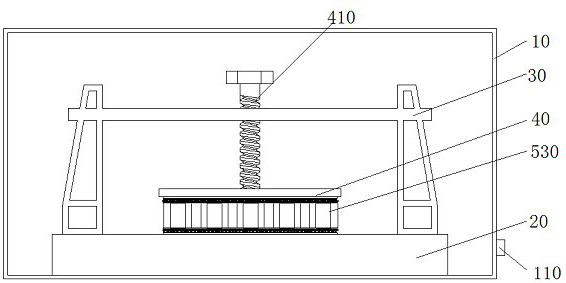

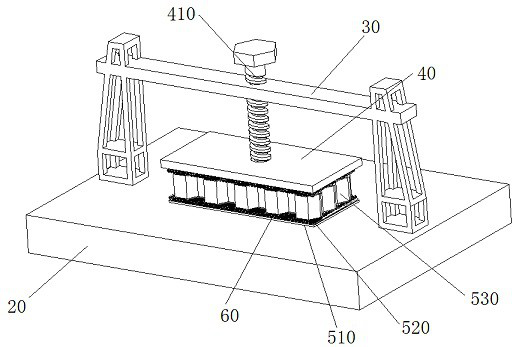

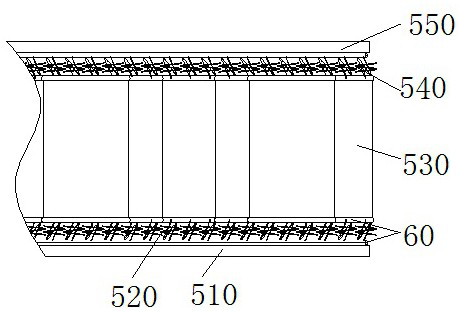

Metal rubber honeycomb composite soft sandwich component preparation structure and method thereof

PendingCN111715961AImprove sound absorption performancePlay the role of crushing energy absorptionLayered productsSound producing devicesMetal rubberEnergy absorption

The invention provides a metal rubber honeycomb composite soft sandwich component preparation structure and a method thereof. The metal rubber honeycomb composite soft sandwich component preparation structure includes a vacuum brazing furnace and a tooling fixture, the tooling fixture comprises a base and a support fixed to the base, a pressure plate is arranged above the base, and the support ismatched with an adjusting bolt in a threaded mode. The designed metal soft sandwich structure part is metal skin, the middle layer is a metal honeycomb core, metal rubber is clamped between the metalskin and the middle layer metal honeycomb core, under complex dynamic load, the elastic porous metal rubber mainly has the effect of damping vibration reduction, and a metal honeycomb core structure in the middle plays the role of impact resistance and energy absorption; and in addition, the metal soft sandwich structure further has the structural characteristics of light weight structure, sound absorption and thermal protection and the like. The preparation device is used for realizing the metallurgical and solid interface combination of an interface of the metal soft sandwich structure partunder the vacuum hot pressing brazing technology, and the comprehensive mechanical properties and environmental adaptability of the whole structure part are improved.

Owner:FUZHOU UNIV

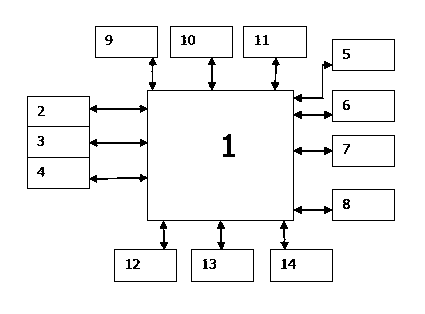

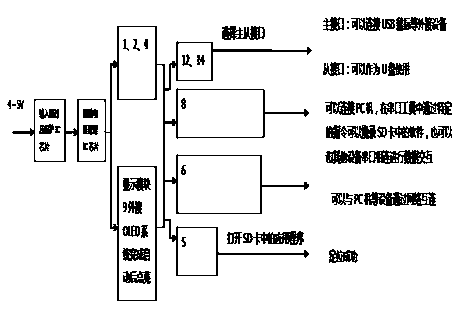

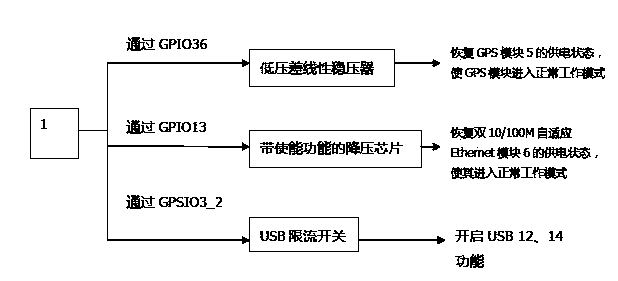

Interactive portable satellite communication control method

InactiveCN103365806AGood shock resistance and drop resistanceEasy to handleElectric digital data processingTerminal equipmentCommunication control

The invention discloses an interactive portable satellite communication control method aiming at defects of the prior art. The interactive portable satellite communication control method supports various communication modes and synchronously supports the latest WINCE operating system and the Android operating system. The satellite communication control method is implemented through the following 14 parts: a CPU (Central Processing Unit) (1), a DDR (2), an extensible large capacity NANDFLASH (3), a NANDFLASH (4), a GPS (Global Position System) module (5), a double 10 / 100 M self-adaptive Ethernet module (6), a customizable audio coder-decode (7), TTL converting RS232 serial interface module (8), a display module (9), a keyboard module (10), a power management module (11), a USB-HOST (12), a SD-Socket (13) and a USB-OTG (14), wherein the CPU (1) controls other 13 parts through respective IO interfaces and interactively connected with the 13 parts. The interactive portable satellite communication control method provided by the invention is designed at the aim of special environment, various communication modes are supported through external connection and utilization of hand-held terminal equipment synchronously, and the interactive portable satellite communication control method is suitable for various application scenes and severe environment.

Owner:NANJING DANAO TECH +2

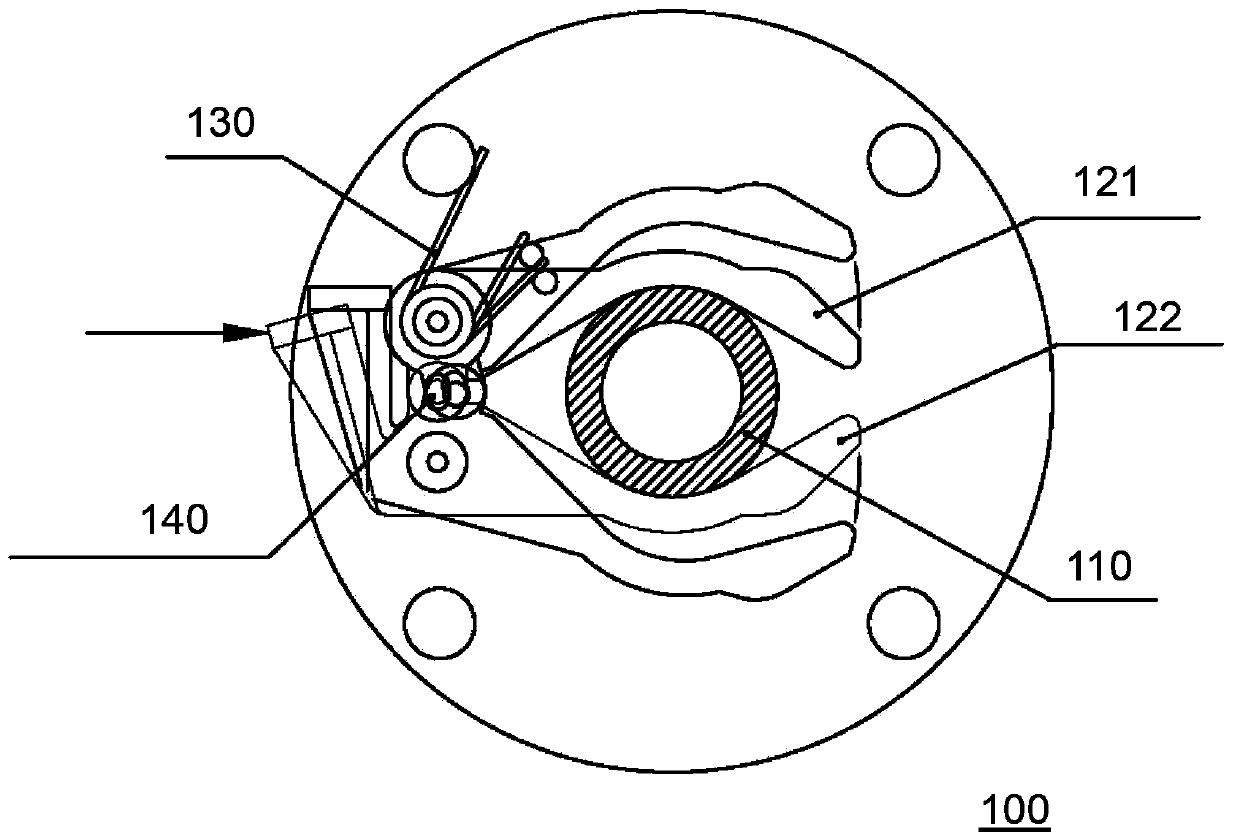

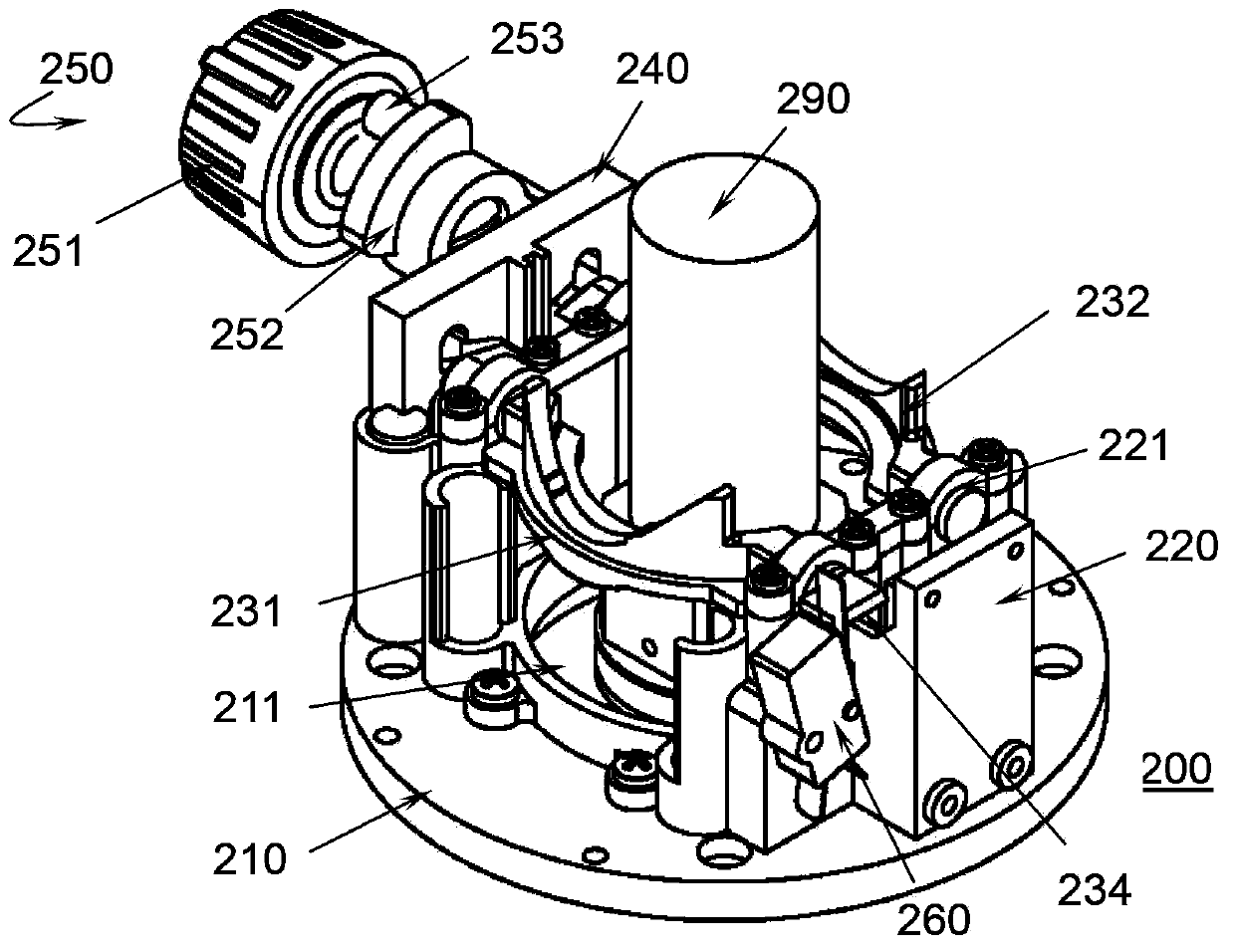

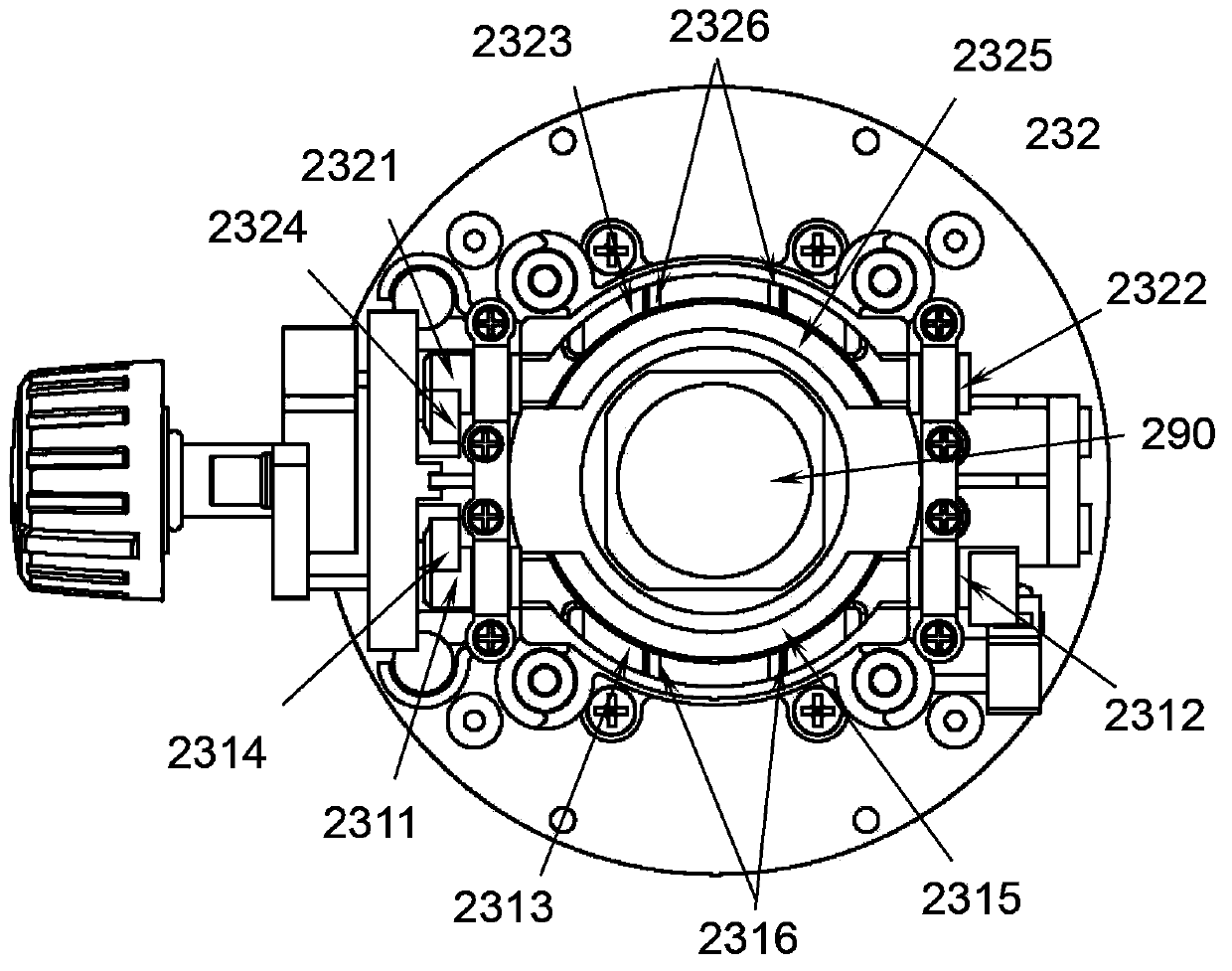

Locking device and laser alignment instrument with same

ActiveCN103967884AImprove stabilityImprove reliabilitySurveying instrumentsFriction grip releasable fasteningsMechanical engineeringLaser

The invention discloses a locking device for a laser alignment instrument. The locking device comprises a base, a support, a first locking sheet, a second locking sheet and a driving device. A center hole is formed in the base, and an activity range of a center swing rod of the laser alignment instrument is defined by the center hole; the support is upwardly arranged from the base around the center swing rod, the first locking sheet and the second locking sheet are oppositely arranged around the center swing rod, and each locking sheet comprises a first end shaft, a second end shaft and a clamping portion, and each first end shaft and the corresponding second end shaft are coaxial with each other and are respectively pivotally connected with the support; the clamping portions are used for clamping the center swing rod; the driving device is used for driving the first locking sheet and the second locking sheet; when the driving device is switched on, the clamping portion of the first locking sheet and the clamping portion of the second locking sheet respectively rotate towards the center swing rod until the clamping portions reach locking positions, so that the center swing rod can be locked; when the driving device is switched off, the clamping portion of the first locking sheet and the clamping portion of the second locking sheet respectively rotate from the locking positions and reach releasing positions, so that the center swing rod can be released.

Owner:CHANGZHOU HUADA KEJIE OPTO ELECTRO INSTR

Plant polysaccharide protective washing solution

InactiveCN104721222AProtect biological activityInhibit bacterial growthHydroxy compound active ingredientsAntisepticsSodium carboxymethylcelluloseCellulose

The invention relates to a plant polysaccharide protective washing solution taking calcium-modified sodium carboxymethylcellulose as a main component. The plant polysaccharide protective washing solution comprises the following components: 0.3%-3% by weight of calcium-modified sodium carboxymethylcellulose, and 0.01%-0.1% by weight of a pH buffer substance and physiological saline, wherein the pH value of the plant polysaccharide protective washing solution is 6.5-7.5. The plant polysaccharide protective washing solution provided by the invention has the effects of performing surgical flushing, preventing adhesion and promoting wound healing, simultaneously has a hemostatic function and is good in stability and difficult to degrade.

Owner:SHIJIAZHUANG YISHENGTANG MEDICAL SUPPLIES

Automotive shock resisting rubber damper

PendingCN106763477AIncrease buffer distanceAnti-shockSpringsNon-rotating vibration suppressionEngineeringImpact effect

The invention discloses an automotive shock resisting rubber damper. A first rubber block is arranged on the lower side of a top cover; a second rubber block is arranged on the lower side of the first rubber block; a first sliding block is arranged on the lower side of the second rubber block; a third rubber block is arranged on the lower side of the first sliding block; a movable block is fixedly connected with the lower end of a piston rod; a first semicircular ring is fixedly connected with each of upper and lower surfaces of the movable block; a fourth rubber block is arranged on the lower side of the movable block; a second sliding block is arranged on the lower side of the fourth rubber block; and a fifth rubber block is arranged on the lower side of the second sliding block. Compared the automotive shock resisting rubber damper, disclosed by the invention, with the prior art, the fourth rubber block and the fifth rubber block arranged to be hemispheric provide a dot-to-plane deformation manner to weaken the impact effect, and the arranged second sliding block can provide displacement to lengthen the buffer distance so as to resist impact.

Owner:安徽德耐孚汽车减震科技技术有限公司

Hierarchical covering layer control method for open-pit-to-underground mine

InactiveCN105350967AImprove targetingEasy to set upUnderground miningSurface miningOverburdenControl layer

The invention discloses a hierarchical covering layer control method for an open-pit-to-underground mine. According to a hierarchical covering layer control theory, an overall downward moving layer which is stable in structure serves as a leakage balancing layer, a flowing layer serves as a covering layer loss control layer, the overall downward moving layer is located on the upper portion of the flowing layer, and the flowing layer is connected with an ore layer; the thickness of the leakage balancing layer is determined according to the drainage reservoir balance conditions and the air leakage control requirements; the loss control layer is determined according to the height of a drawing ellipsoid; the total thickness of the covering layer is the sum of the thickness of the leakage balancing layer and the thickness of the loss control layer. Accordingly, the structural adjustment pertinence of the covering layer can be improved by combining the actual requirements, and establishment and improvement of the covering layer system theory are facilitated; by establishing a determining method for the thickness of the leakage balancing layer and the thickness of the loss control layer, the reasonable thickness of the covering layer is determined; meanwhile, the overall downward moving layer and the flowing layer jointly achieve the effects of preventing and relieving rock blast hazards, preventing cold and keeping warm and have the functions of preventing water permeating, debris flow, air leakage, depletion and the rock blast hazards, preventing cold and keeping warm.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Compound genticin-micronomicin injection, preparing method and use thereof

InactiveCN101015561AImprove immunityRelative weight gainOrganic active ingredientsPharmaceutical delivery mechanismMicronomicinCurative effect

The invention discloses an injection of compound micironomicin sulfate, its preparation method and application. the injection comprises (by weight part) micironomicin sulfate injection 1-20, chlorpheniramine maleate 0.1-1, and dexamethasone sodium phosphate 0.01-1. the preparation method comprises heating 50% water for injection to 40-50deg.C, dissolving each components, regulating pH to 3.5-6.5 with hydrochloric acid or sodium hydroxide, and adding water for injection to 1000. The invention has the advantages of rational formulation, reduced drugfastness, and shortened withholding period. It can enhance therapeutic effect, improve swinish immunity, increase swinish body weight; and can be used for treating mycoplasmal pneumonia of pig.

Owner:TIANJIN SHENGJI GRP CO LTD

Child safety seat

InactiveCN106183911APrevent fallingPlay a role of buffer protectionArm restsChild seatsCompression deviceEngineering

The invention relates to a child safety seat. The child safety seat comprises a seat body and a safety belt, wherein the seat body comprises a backrest and a seat cushion, the backrest and the seat cushion are filled with pearl wool and respectively provided with an elastic buffer element, a compression device is arranged at the outer side of the backrest and the seat cushion and used for controlling the elasticity of the elastic buffer element, arc protection side wings are respectively arranged at the upper two sides of the backrest, movable handrails are respectively arranged at the lower two sides of the backrest, the backrest comprises a head pillow, the head pillow is installed above the backrest in a sliding manner, the head pillow is controlled and locked at a preselected height by virtue of a lock catch device, the safety belt comprises a main belt and an auxiliary belt which are respectively arranged at the left side and the right side of the backrest, and two sides of the seat cushion are provided with a groove buckle corresponding to the safety belt.

Owner:朱秀琴

Mountain area highway subgrade and construction method

PendingCN110172884AAnti-shockImprove drainage capacityGround-workSewerage structuresMountainous terrainRoad surface

The invention relates to the technical field of landscape architecture, in particular to a mountain area highway subgrade. According to the technical scheme, the mountain area highway subgrade comprises a cut subgrade and a fill subgrade, a main drainage ditch is constructed at the joint of the cut subgrade and a mountain body, a plurality of gabion mesh cages are arranged at the top end of the cut subgrade, the gabion mesh cages are arranged form the inner of the main drainage ditch to the cut subgrade, a concrete bridge is longitudinally constructed on the side, directly opposite to the fillsubgrade, of the top end of the cut subgrade, the concrete bridge is higher than the top surfaces of the gabion mesh cages and the fill subgrade, a water-proof layer is paved on the top surfaces of the gabion mesh cages, the top surface of the fill subgrade, and the top surface of the concrete bridge and the top surface of the water-proof layer are used for paving a pavement structure layer. According to the mountain area highway subgrade, the structural strength of the subgrade is ensured, meanwhile the effective drainage section area of the drainage ditch is enlarged, the characteristics ofhigh drainage capacity and reliable drainage are achieved, and the subgrade safety can be guaranteed for a long time.

Owner:CITIC GUOAN CONSTR GRP CO LTD

Composition containing radix notoginseng stem and leaf extract as well as preparation method, preparation and application thereof

InactiveCN108096391AImprove microcirculationImprove immunityMetabolism disorderImmunological disordersGrape seedGINSENG EXTRACT

The invention discloses a composition containing a radix notoginseng stem and leaf extract as well as a preparation method, a preparation and application thereof. The composition comprises the following raw materials in parts by weight: 40-70 parts of a radix notoginseng stem and leaf extract, 8-20 parts of a green tea extract, 1-5 parts of a ginseng extract and 1-5 parts of a grape seed ultrafinepowder. The composition disclosed by the invention has the significant effects of promoting blood circulation to remove blood stasis, reducing lipid, reducing blood pressure, diminishing swelling, relieving pain, improving micro-circulation and enhancing immunity, adopts a material optimization formula capable of cooling blood, promoting blood circulation to remove blood stasis, enhancing metabolism and resisting oxidation, and protects blood vessels and hearts, enhances the immunity and accelerates the fat metabolism while treating cardiovascular diseases.

Owner:CHUXIONG BAICAOLING PHARMA DEV

Glass window with underground water circulating in hollow cavity

InactiveCN105464538ANoise-proofWith natural light transmissionUnits with parallel planesDiseaseInlet valve

The invention discloses a glass window with underground water circulating in a hollow cavity. The glass window comprises hollow glass, and also comprises a water inlet pipe which is communicated with the hollow cavity of the hollow glass through a water inlet valve, and a drain pipe which is communicated with the hollow cavity of the hollow glass through a drain valve. The water inlet pipe is connected with an underground water supply pipe through a main pipe. The tail end of the drain pipe is communicated with an outdoor sewer line. The main pipe is provided with a plurality of branch pipes communicated with the main pipe. The branch pipes are connected with the water inlet pipe. The glass window has functions of noise prevention, low radiation, natural light transmitting, pressure resistance and vibration prevention, self-explosion resistance, and external impact prevention. The window also has functions of heating in winter and refrigerating in summer, and objectives of saving energy and reducing emission, being green and environmentally friendly, and eliminating air-condition diseases are achieved. The glass window satisfies requirements of efficient, healthy, comfortable, and safe.

Owner:HUBEI SHALLPHA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com