Metal rubber honeycomb composite soft sandwich component preparation structure and method thereof

A technology of metal honeycomb core and metal rubber, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of material acoustic performance and mechanical performance degradation, vibration and noise reduction materials can not adapt to extreme environments, etc., to achieve excellent thermal protection effect, good shear strength and fatigue reliability, and the effect of reducing the influence of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

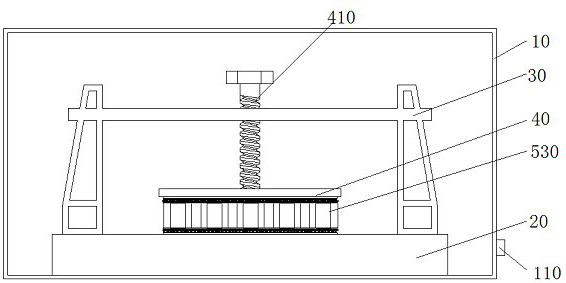

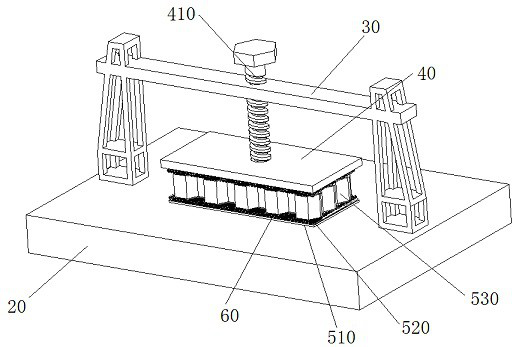

[0032] Such as Figure 1~5 As shown, the metal-rubber honeycomb composite soft sandwich member preparation structure includes a vacuum brazing furnace 10 and a fixture fixed in the vacuum brazing furnace, and the fixture includes a base 20 for placing a composite soft sandwich member and a fixing fixture. The bracket 30 on the base has a pressing plate 40 for pressing the composite soft sandwich member above the base, and an adjusting bolt 410 whose lower end can be in contact with the pressing plate is threaded on the bracket, and the side of the vacuum brazing furnace has Vent 110.

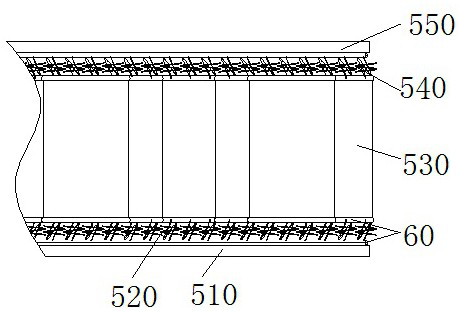

[0033] In this embodiment, the composite soft sandwich member includes a lower stainless steel skin 510 placed on the base, a lower metal rubber layer 520 on the upper part of the lower stainless steel skin, and a metal honeycomb core 530 above the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com