Patents

Literature

55results about How to "Improve bearing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

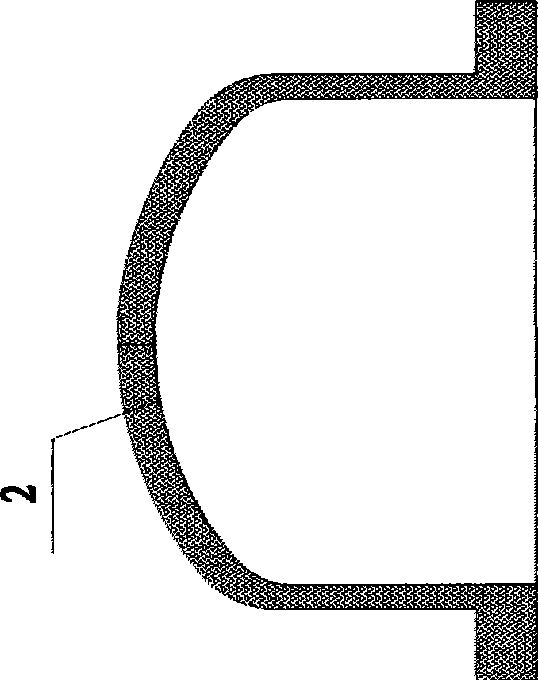

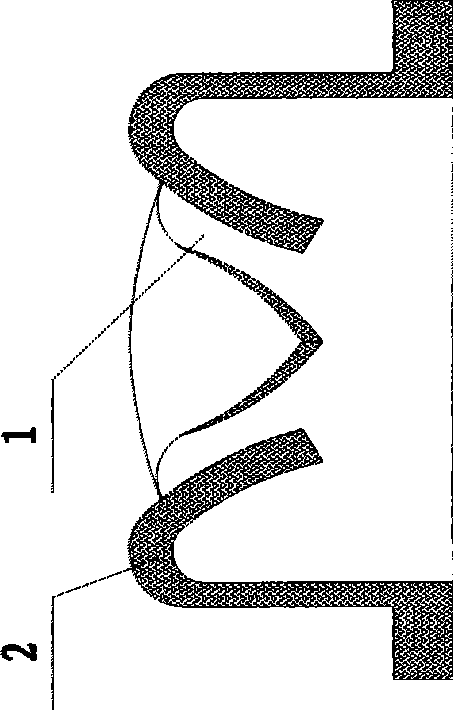

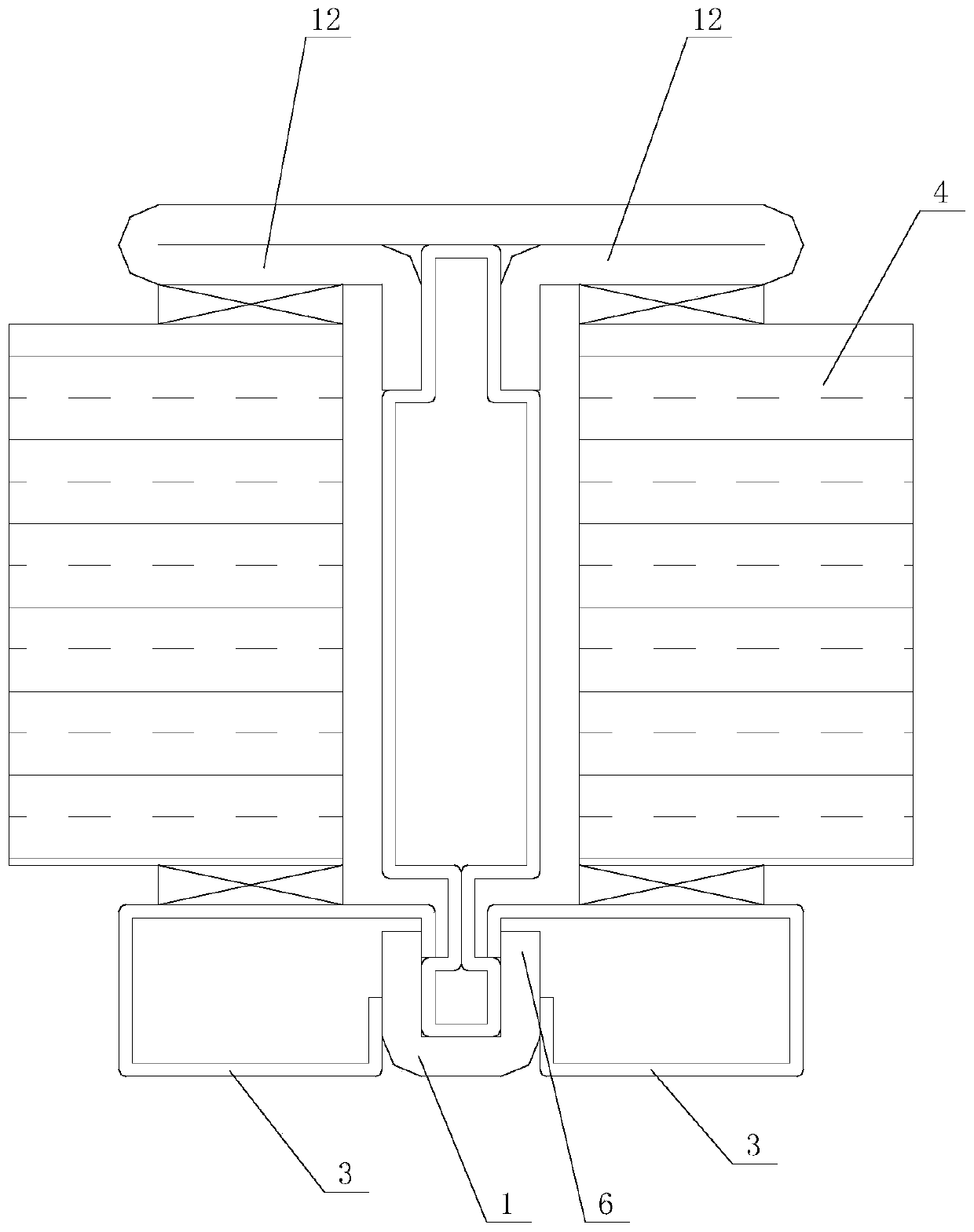

Multipurpose thimbleshaped valve respiration valve

The invention discloses a multipurpose cap-shape valve respiratory valve, comprising a valve seat, a valve core and a fixed sleeve; the valve core is of cap shape and made of elastic rubber; the cap rim of the valve core is fixed between the valve seat and the fixed sleeve; the cap body is sheathed in the central hole of the valve seat or the fixed sleeve; furthermore, the top of the cap of the valve core is provided with at least two lancings so that at least one valve clack is formed at the top of the cap. the lancings are distributed all around in a radial pattern from the axle center projected at the top of the cap to form a taper angle shape valve clack, or a C shape, V shape, U shape or opening polygon shape valve clack to cause the end part projected at the top of the cap to form a flip-shell valve clack or cause the lateral side projected at the top of the cap to form at least two valve clacks. The invention has the advantages of simple structure, few faults, long service life, low manufacturing cost, multiple functions and extensive usage, is favorable for environment protection, and has good social and economical benefits.

Owner:刘景福

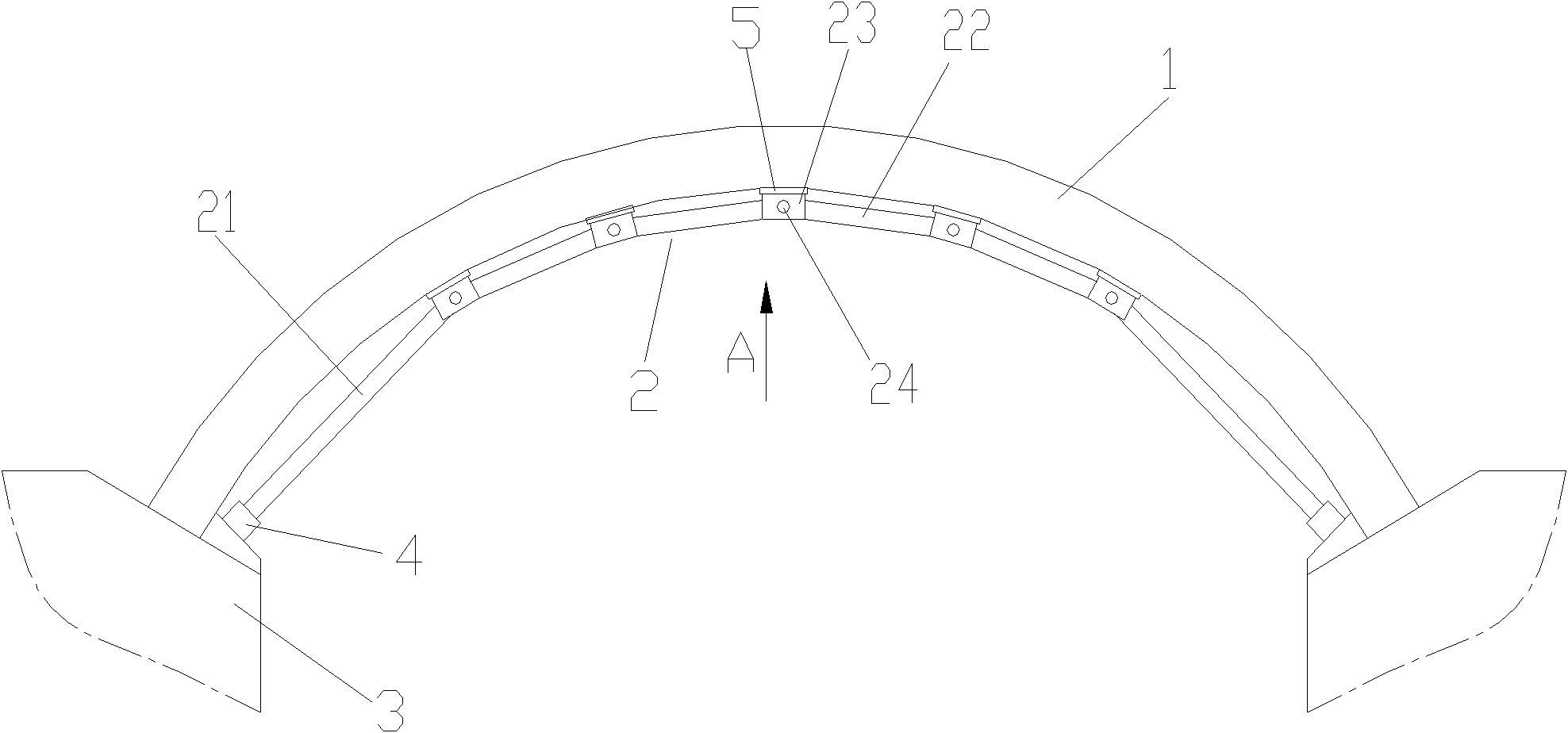

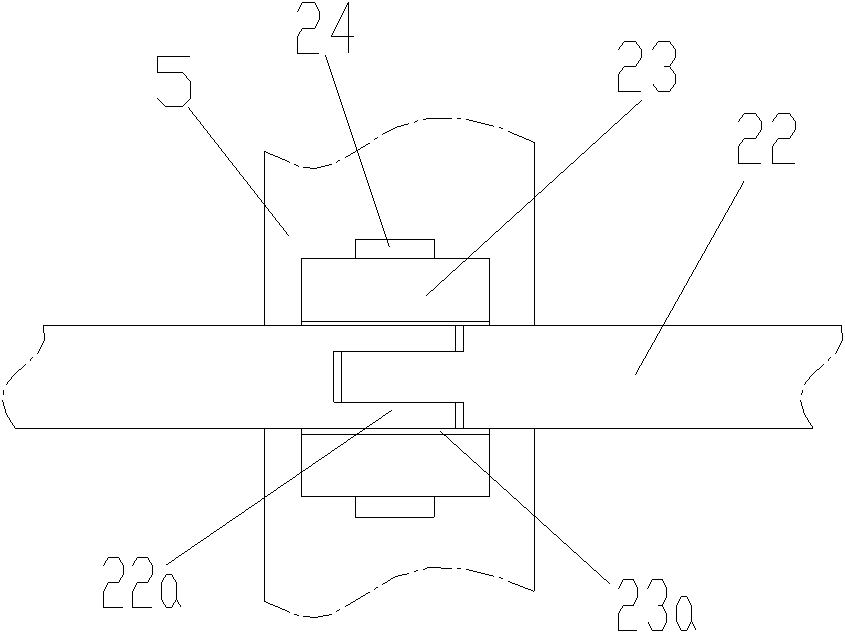

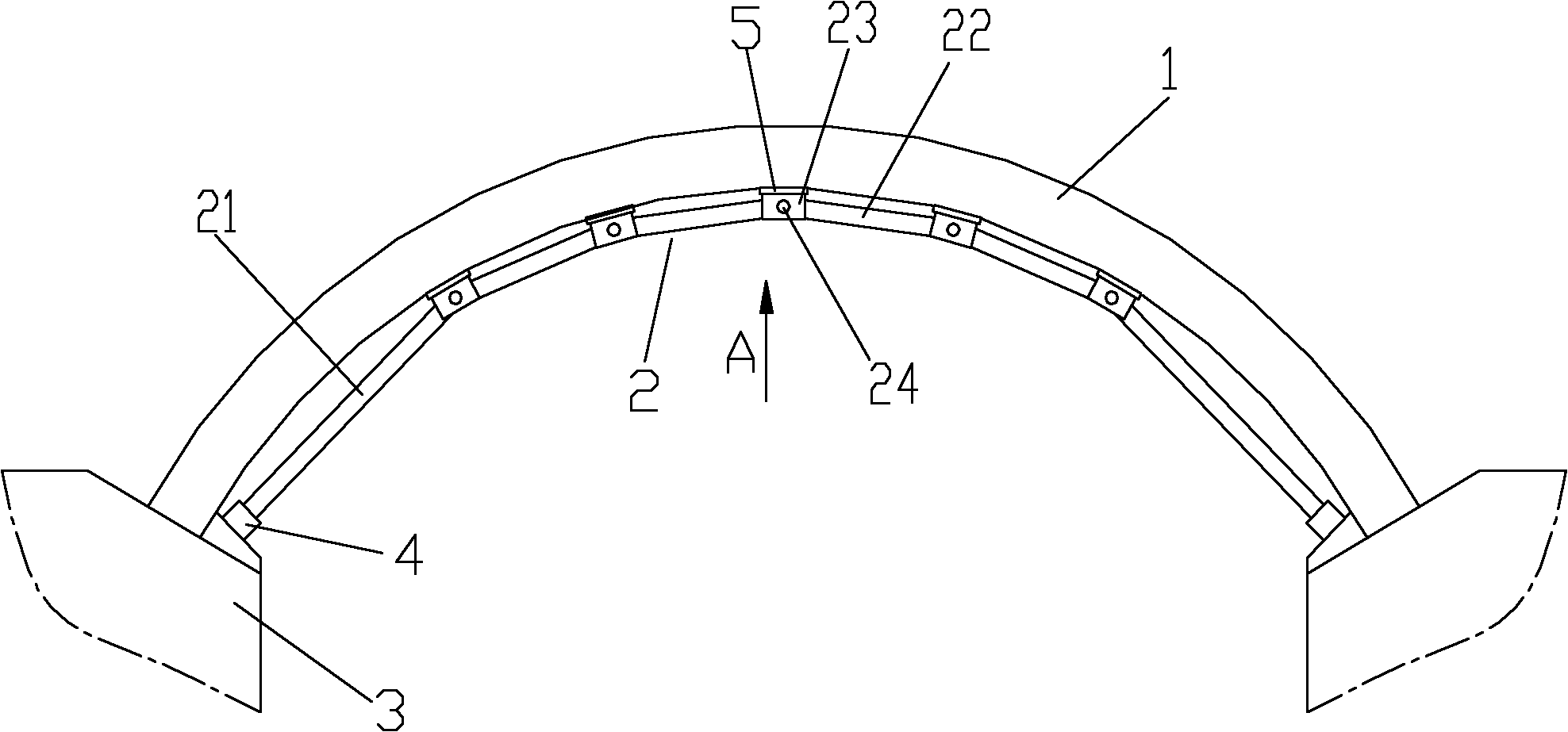

Reinforced combined arch ring for arch bridge

InactiveCN102425103ASimple component formFast and easy to transport and installBridge structural detailsBridge erection/assemblyLoad carryingBending moment

The invention discloses a reinforced combined arch ring for a arch bridge, comprising a main arch ring and a mansard hinge arch positioned at the lower part of the main arch ring, wherein adjacent hinged load-carrying rods are hinged to a load-carrying piece; compressive prestress is applied to the load-carrying rods at two ends of the mansard hinge arch; the load-carrying pieces are distributed at the lower part of the main arch ring, tightly propped against the lower surface of the load-carrying positive bending moment part of the main arch ring, and naturally separated with one another. The reinforced combined arch ring for the arch bridge is simple in structure, and convenient to install and transport; force magnitude and direction of prestressing applied to the main arch ring by each load-carrying piece at the hinge point are specific and can be flexibly adjusted according to requirements; the original constant load internal force distribution of the original main arch ring can be effectively modified without adding the load of the original structure; the special requirement on inner force adjustment at different sections of the main arch ring can be adapted well; and the components of the compressive prestress mansard hinge arch are detectable, maintainable and replaceable when in use, therefore, technical convenience is provided for maintenance management in the usage period of the arch ridge, the durability of the arch bridge can be effectively improved, and the service life of the arch bridge can be prolonged.

Owner:CHONGQING JIAOTONG UNIVERSITY

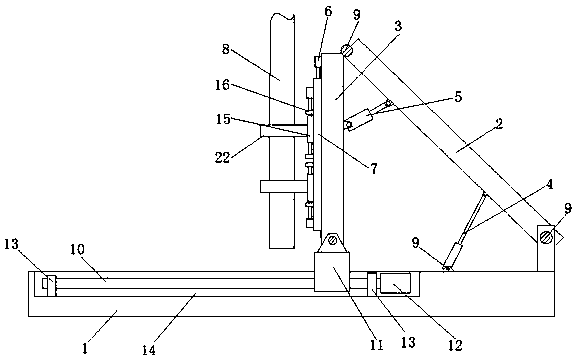

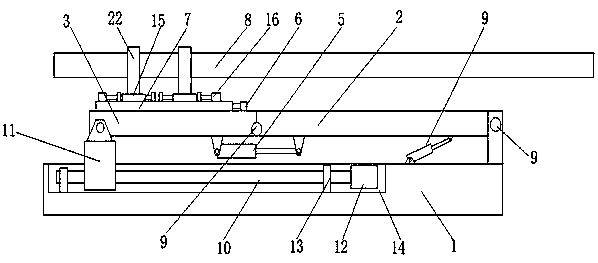

Mounting device and mounting method of street lamp

Owner:华体智城系统集成有限公司

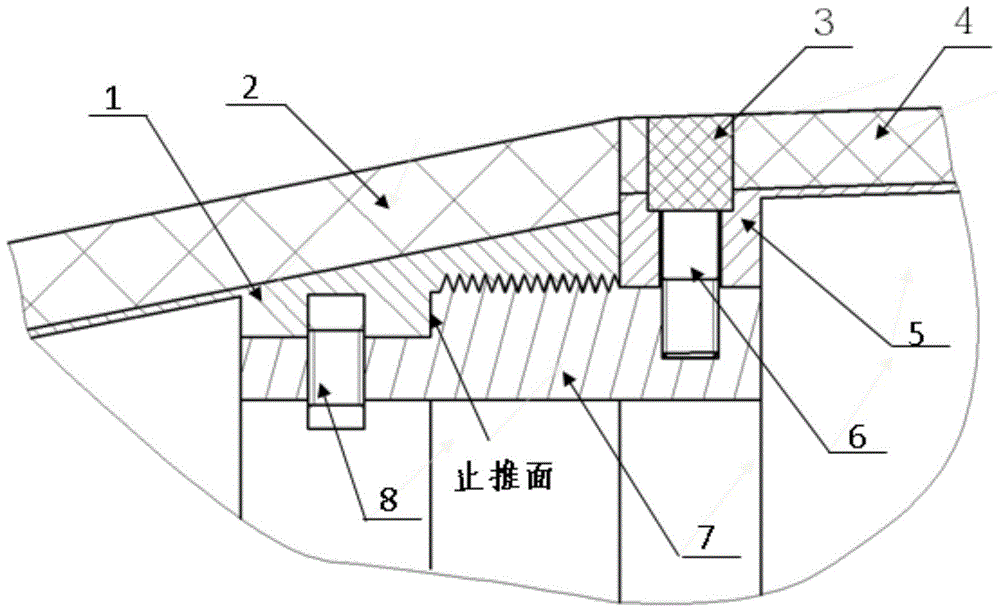

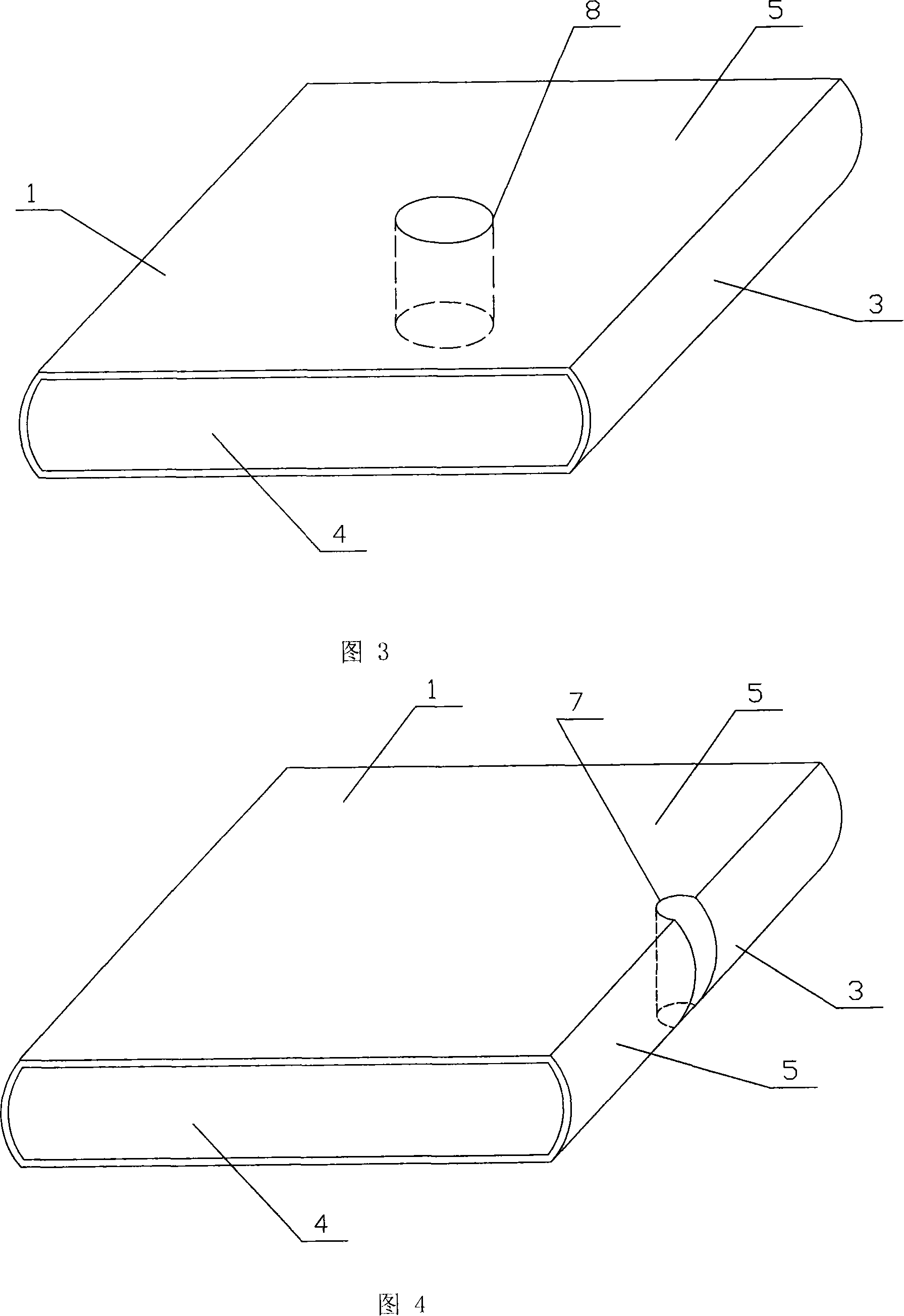

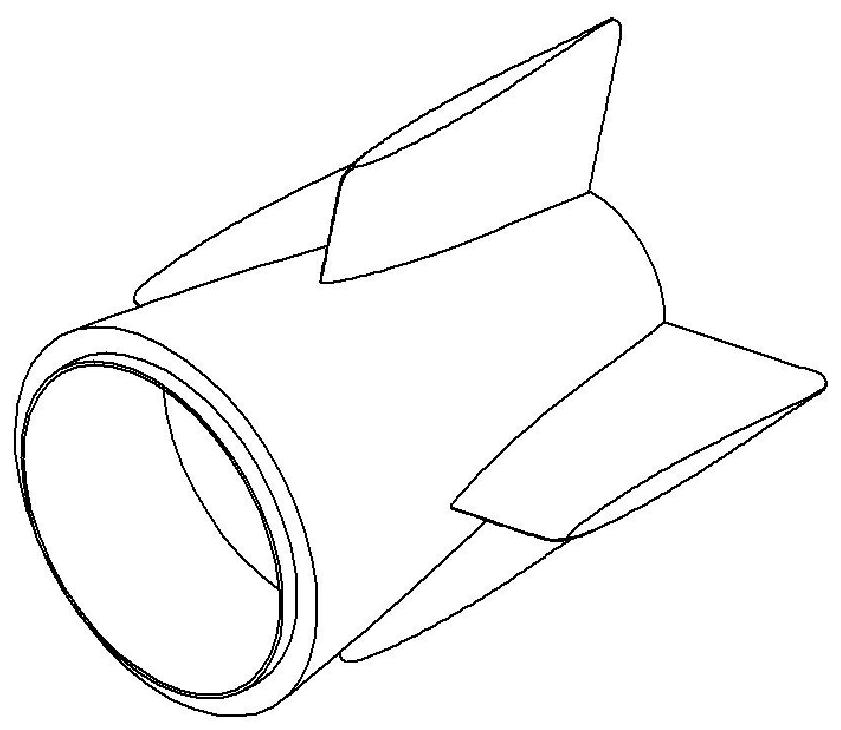

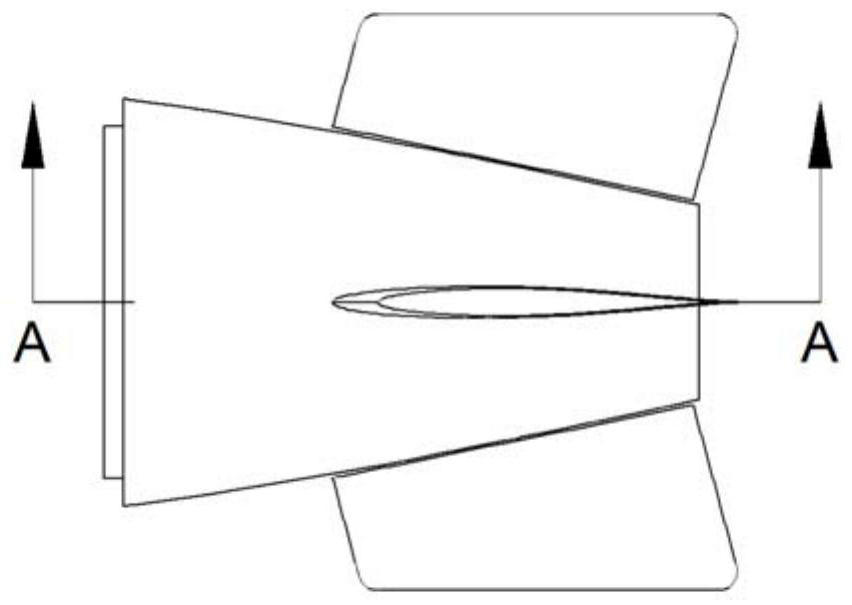

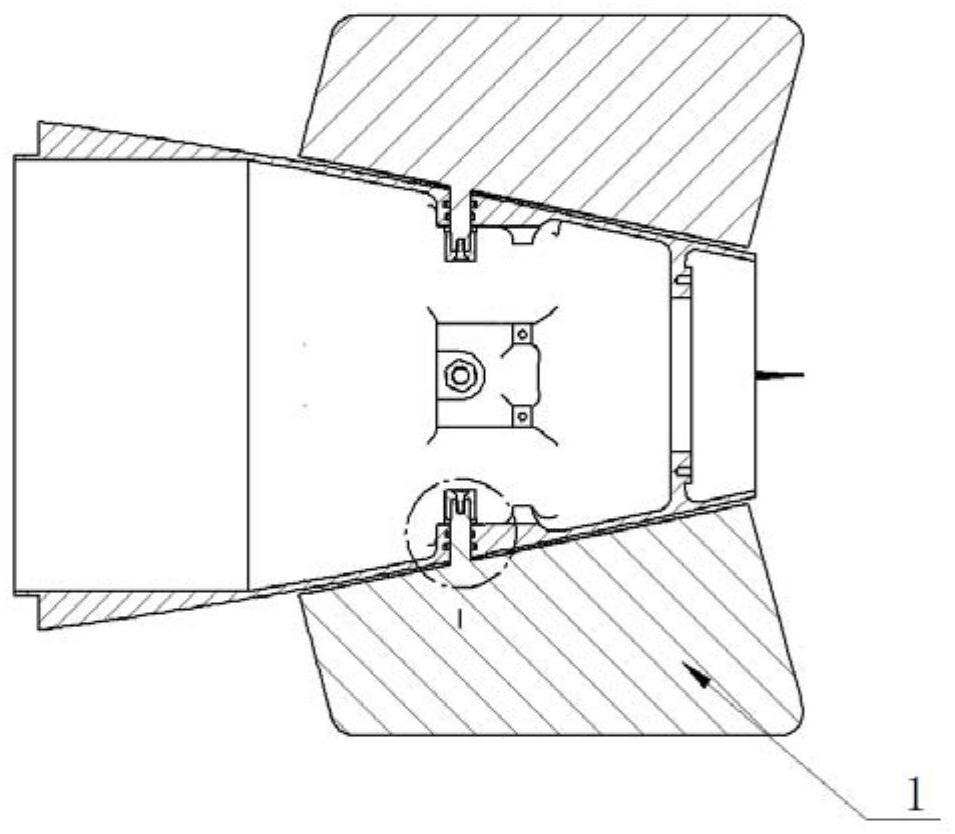

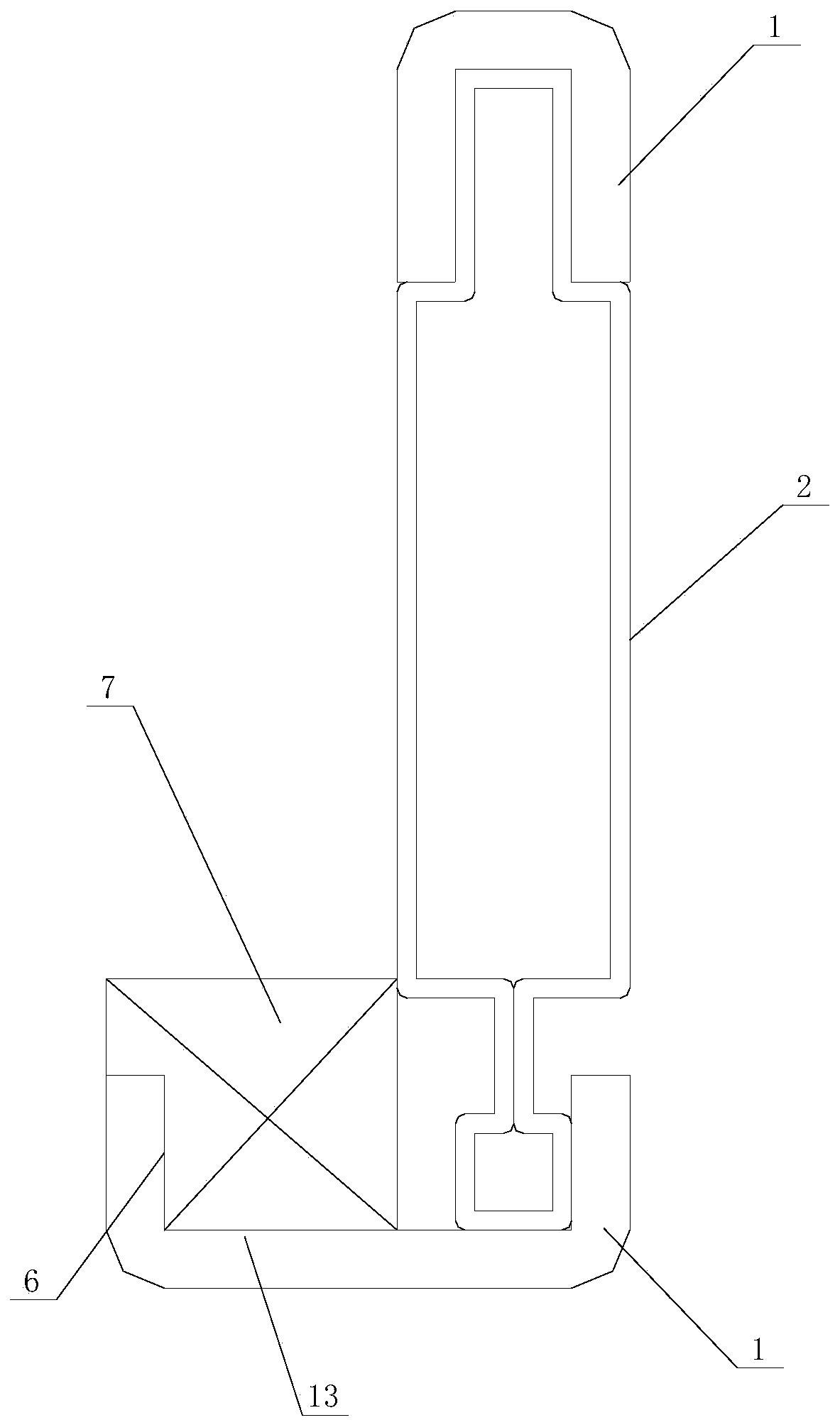

Special-shape missile bay section connecting structure for sectional fairing deploying

InactiveCN104567561AImprove bearing effectSimple manufacturing processSelf-propelled projectilesManufacturing technologyFlight vehicle

The invention relates to the technical field of special-shape aircraft bay connecting section, and particularly discloses a special-shape missile bay section connecting structure for sectional fairing deploying. The special-shape missile bay section connecting structure comprises a guide bay metal shell, a warhead bay metal shell and a bay body adapter ring, wherein the bay body adapter ring is of a step-shaped cylinder structure, and is fixedly connected with the guide bay metal shell through a thread structure, the left cylinder wall of the bay body adapter ring and the guide bay metal shell are fixedly connected through an anti-loosening pin, the warhead bay metal shell is matched with the end surface of the guide bay metal shell, the inner wall of the warhead bay metal shell is matched with the right cylinder wall of the bay body adapter ring, and the warhead bay metal shell and the bay body adapter ring are fixedly connected through a connecting pin. The special-shape missile bay section connecting structure has the advantages that the problems of failure of loosening prevention of bay section large threads and the nonuniform butting surface of the special-shape bay body are solved; compared with the flap type quick connecting, the bearing property of the butting surface is good, the gap of the butting surface is avoided, and the implementation of manufacturing technology is easy.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

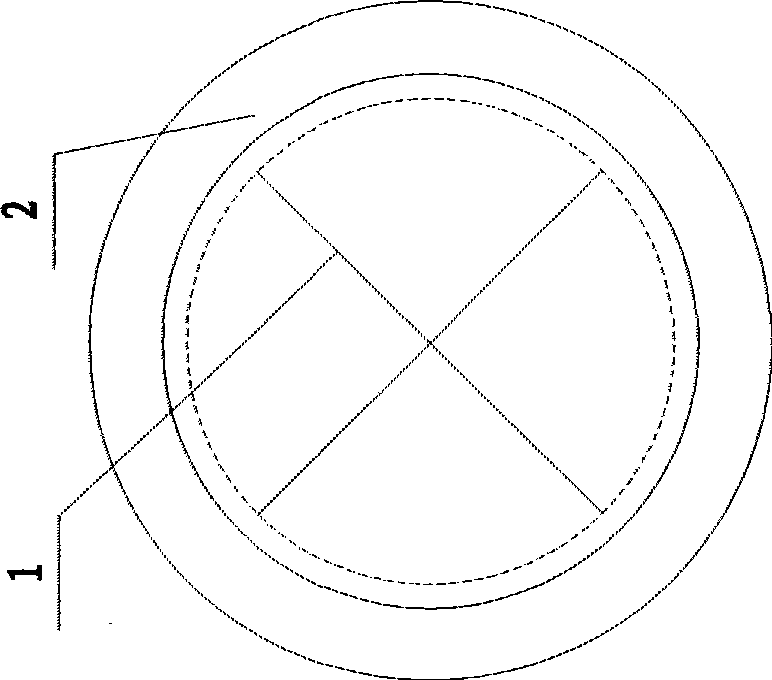

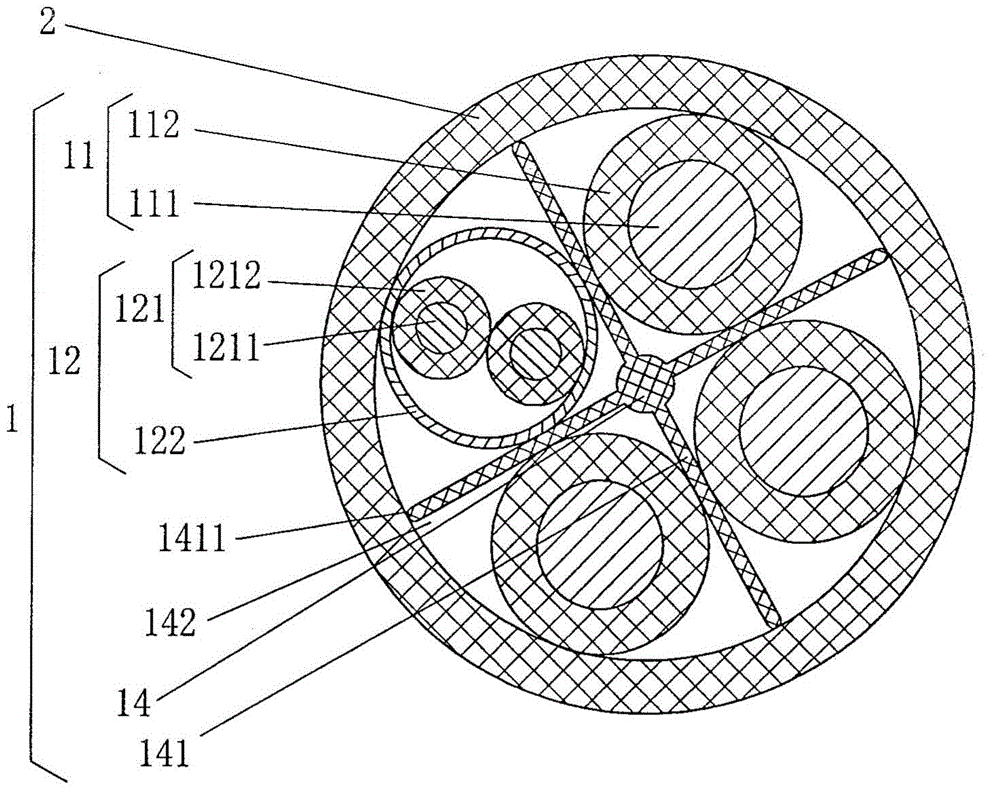

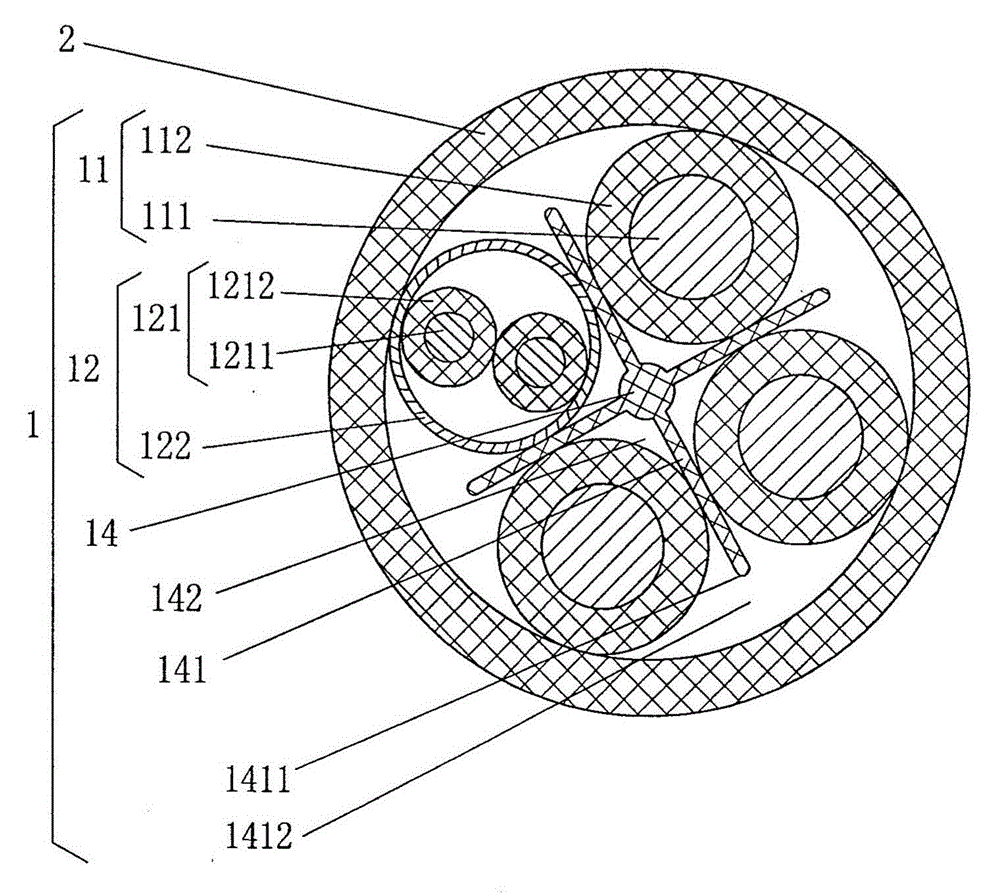

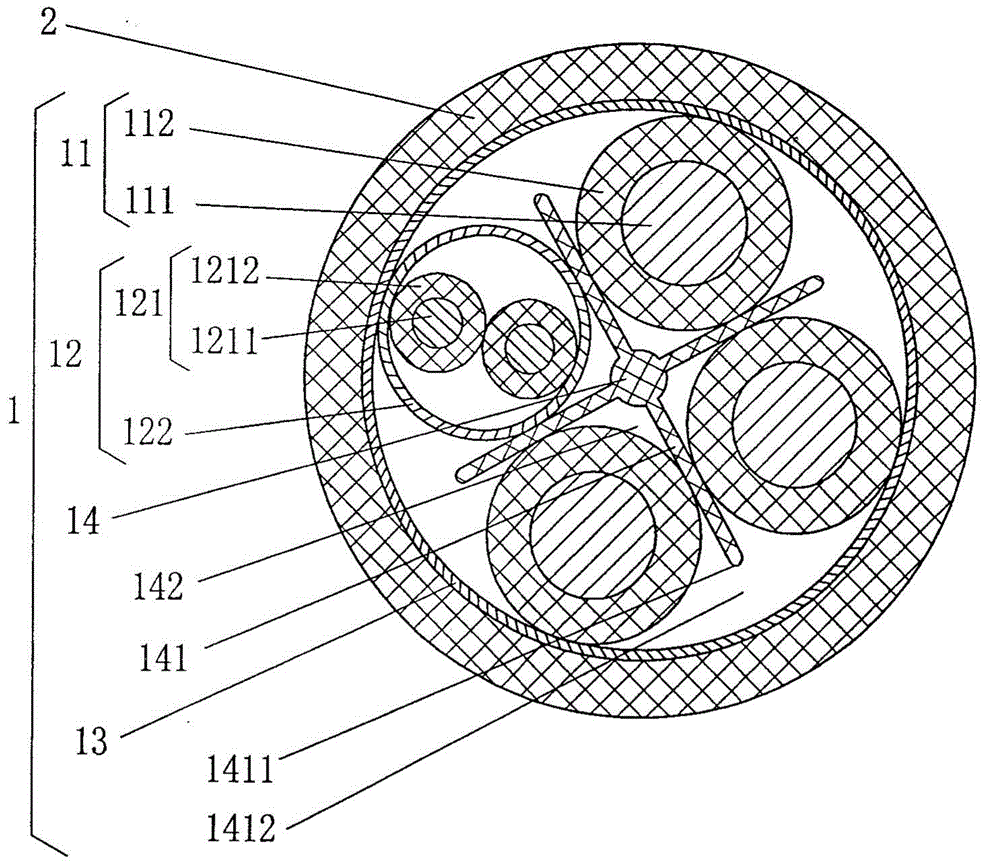

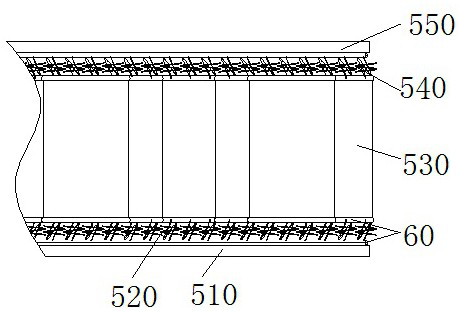

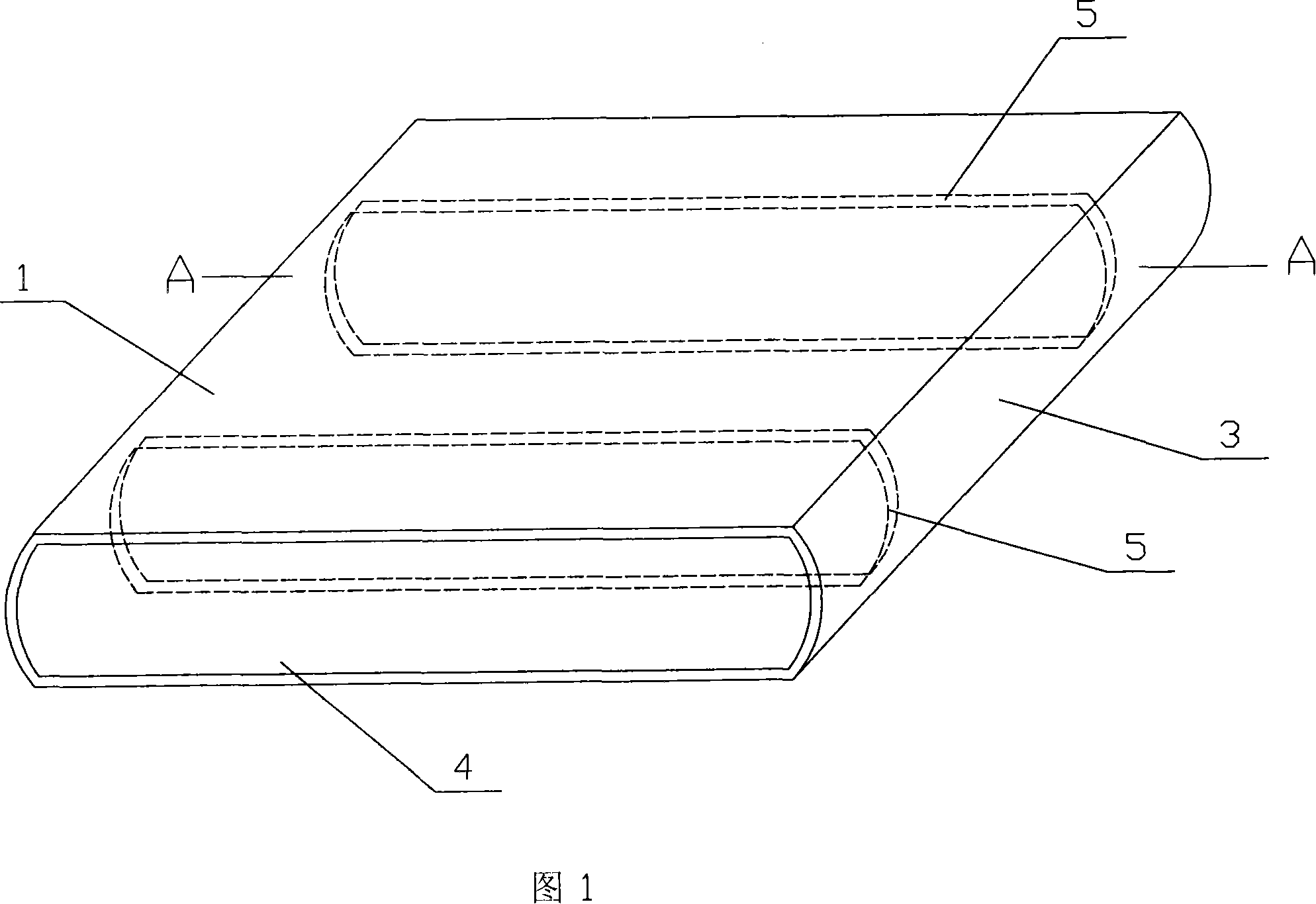

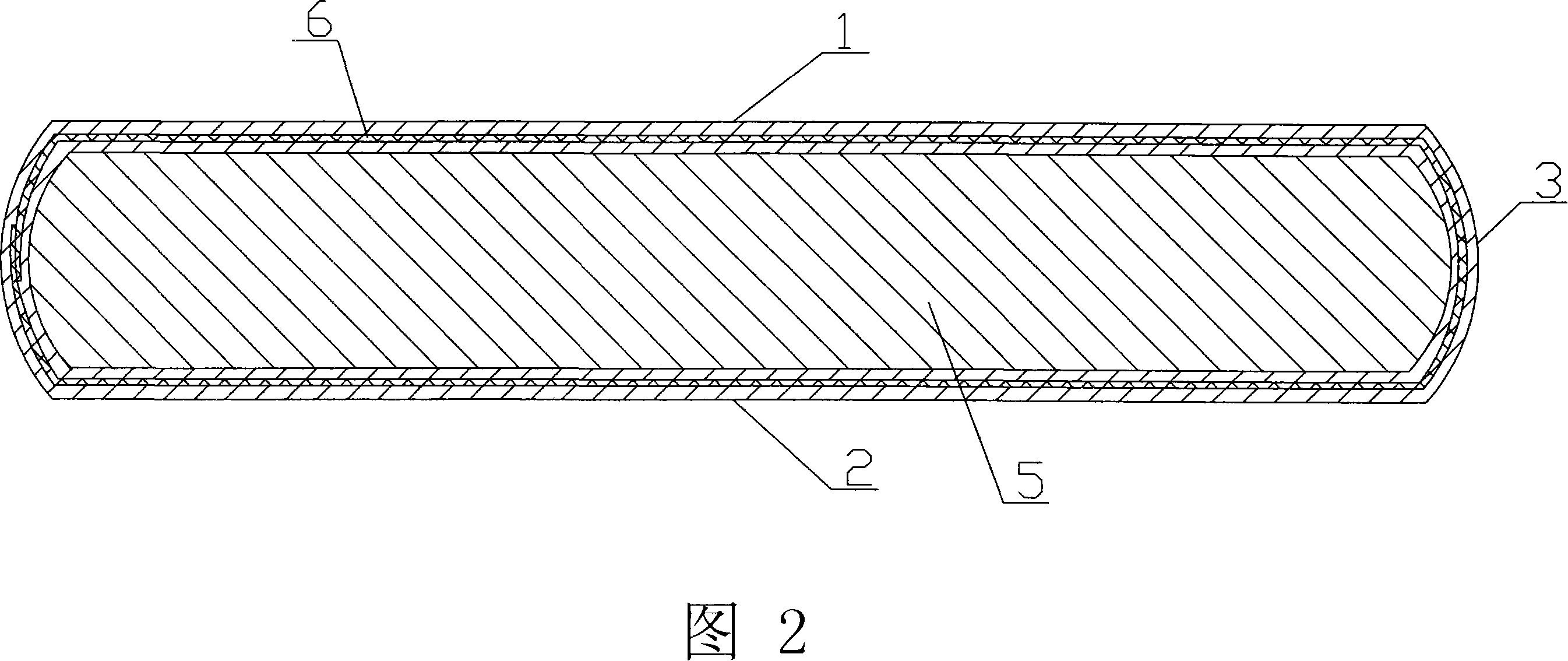

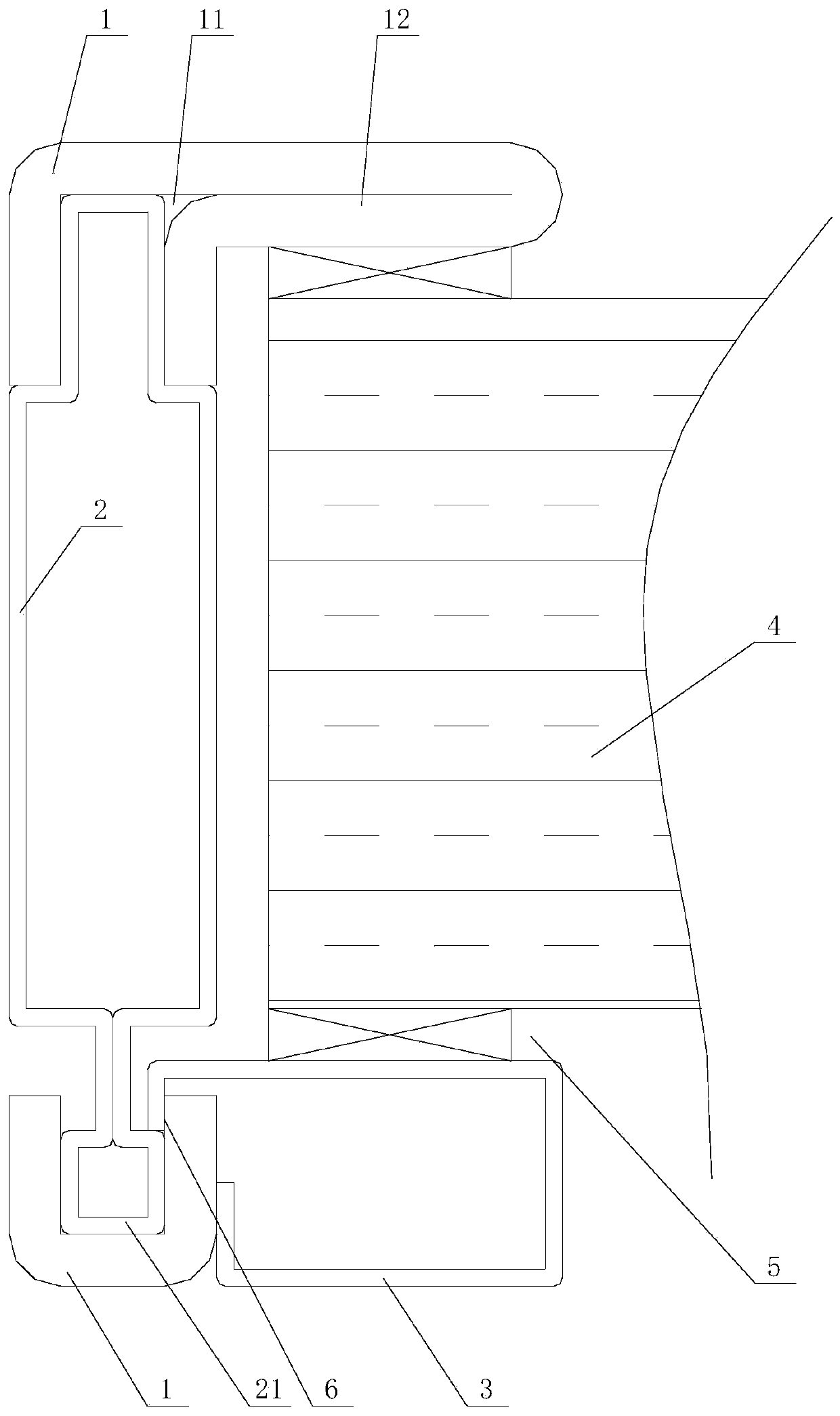

Cable for charging facility of electric automobile

InactiveCN105006292AImprove bearing effectGood flexibilityPower cablesFlexible cablesStructural engineeringElectric cables

The invention provides a cable for a charging facility of an electric automobile, and belongs to the field of wires and cables. The cable comprises a cable core and a sheath layer positioned at the outside of the cable core, the cable core comprises power lines and a signal line pair, and the power lines and the signal line pair are positioned in the sheath layer. The cable is characterized in that the cable core also comprises a cable core support skeleton, the cable core support skeleton is positioned in the sheath layer with the power lines and the signal line pair, the cable core support skeleton is provided with a group of support skeleton wings, the group of support skeleton swings are distributed in a radiation manner in the direction of the cross section of the cable core support skeleton and extend towards the length direction of the cable core support skeleton, each two adjacent support skeleton wings form a totally-closed or semi-closed conducting wire separating chamber whose cross section is in a sector shape, and the power lines and the signal line pair, which are respectively separated by the support skeleton wings, are distributed in the conducting wire separating chambers. According to the cable, the service lifetime of the cable is extended, and the softness, the flexibility, and the lightness effect of the cable can still be well reflected.

Owner:3Q WIRE & CABLE

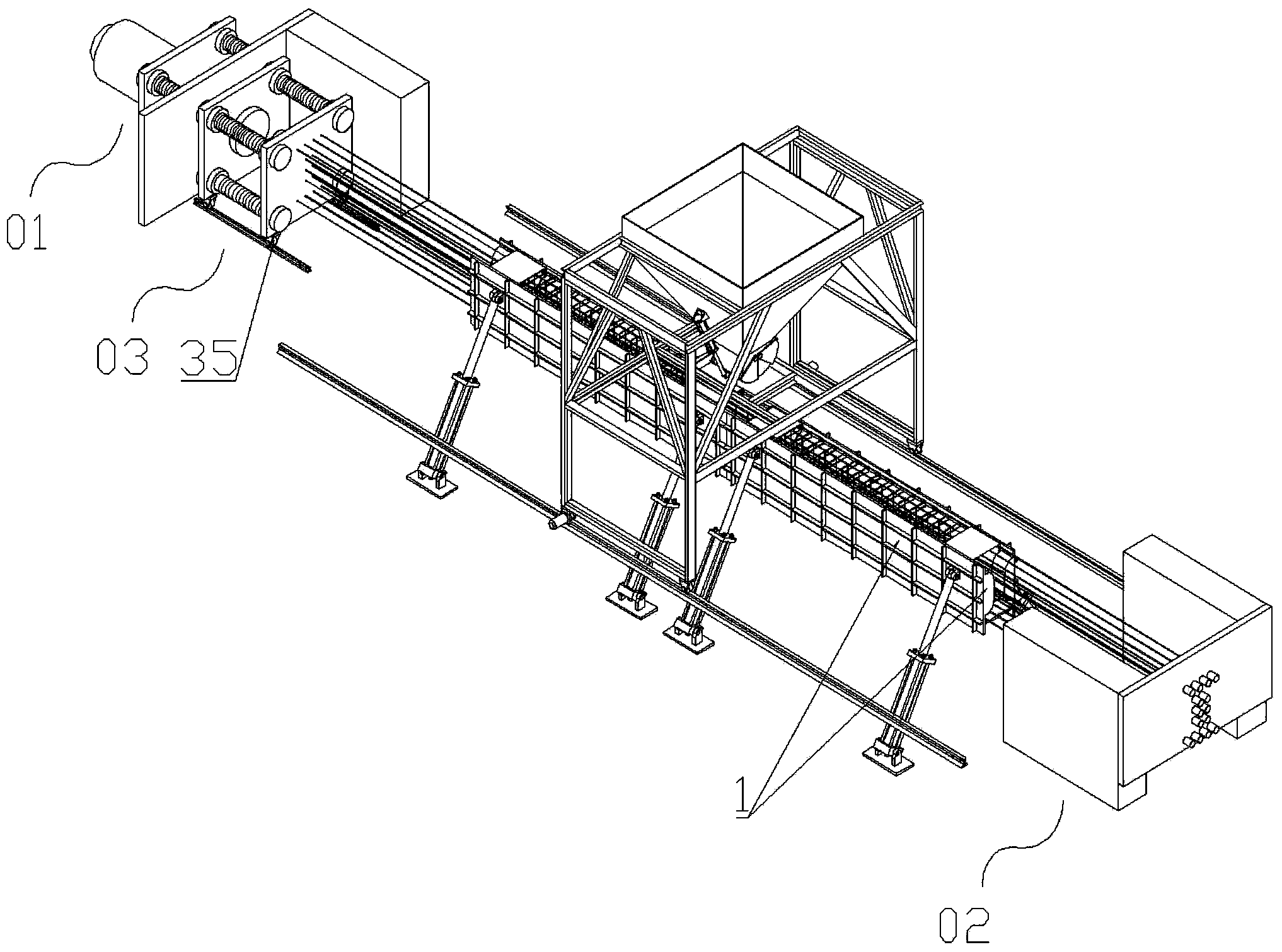

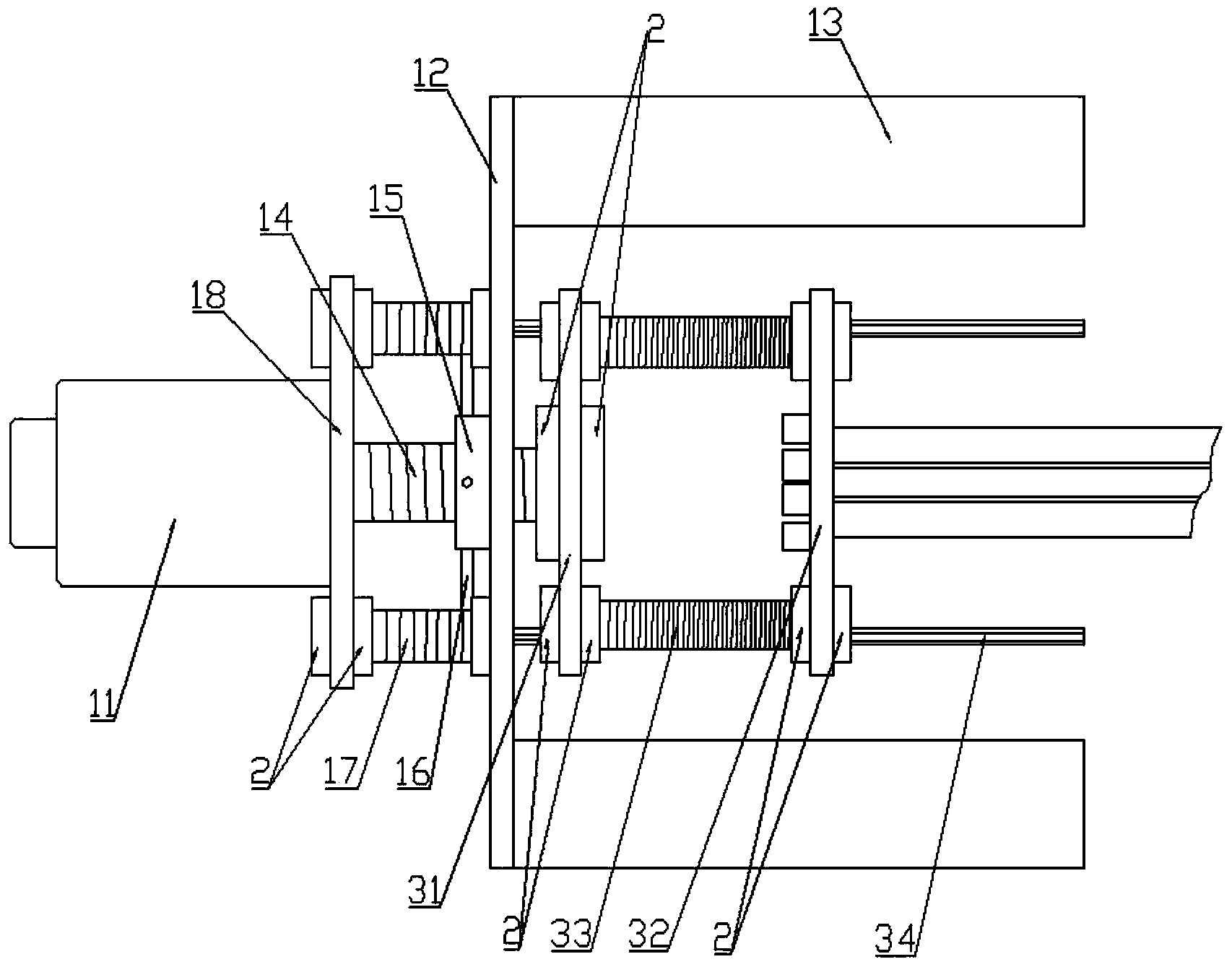

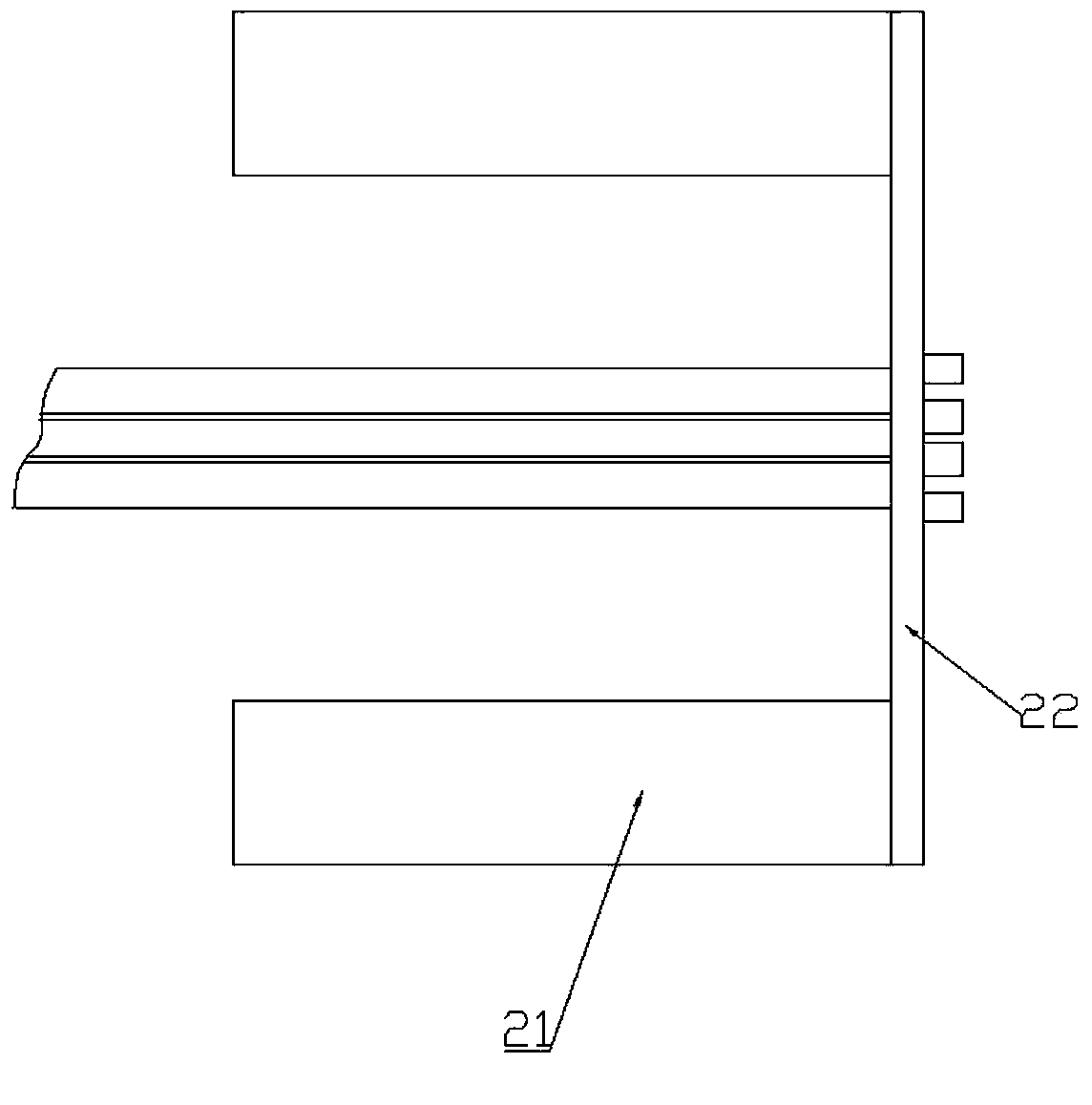

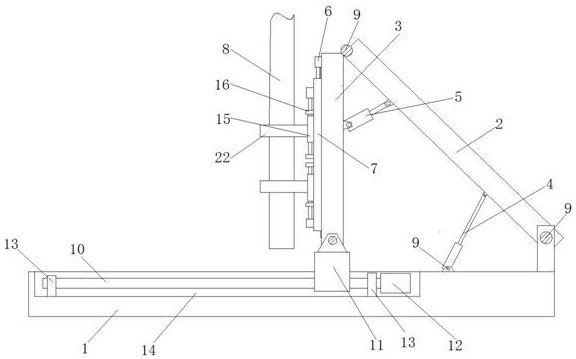

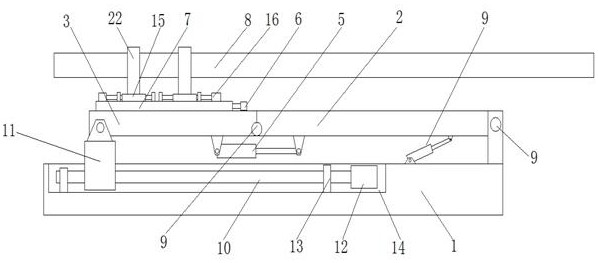

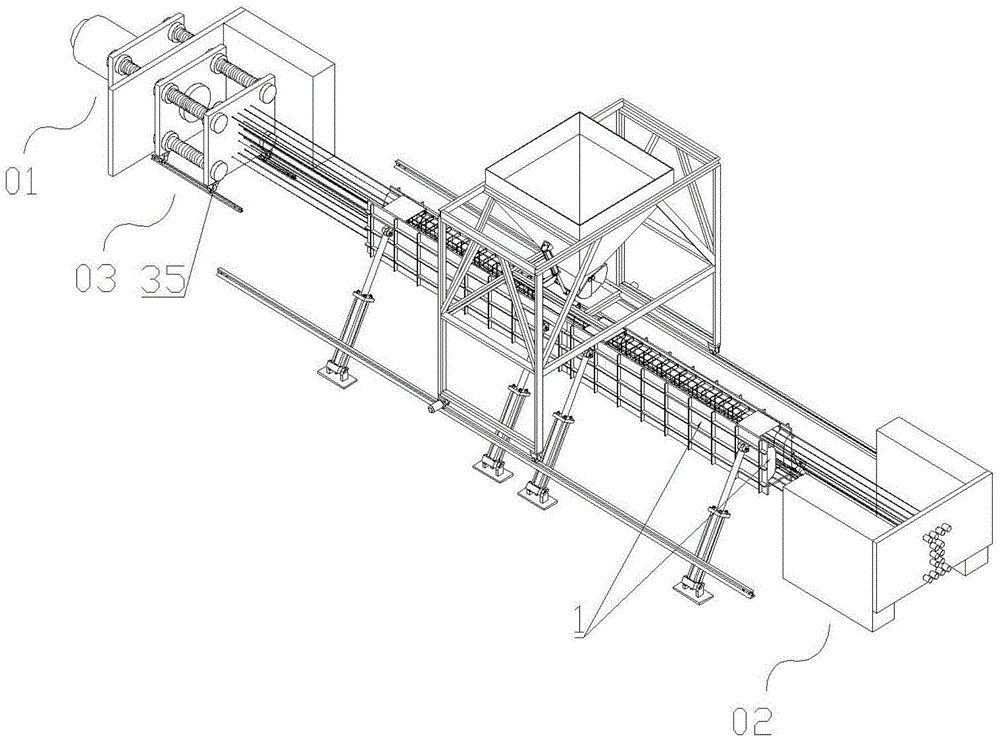

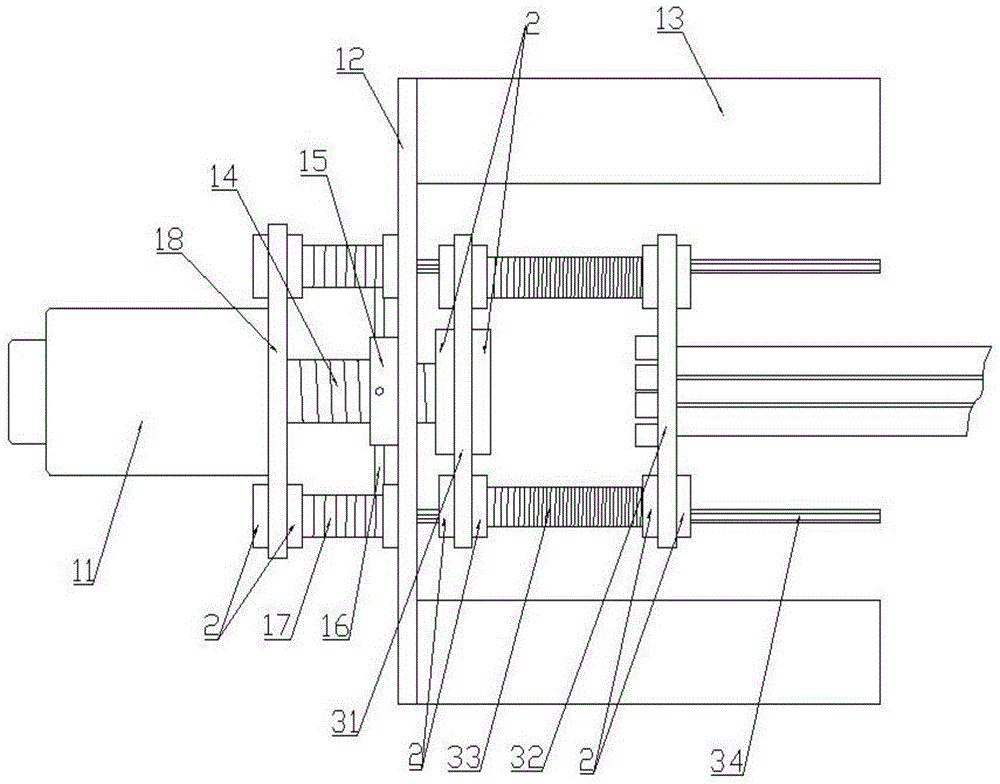

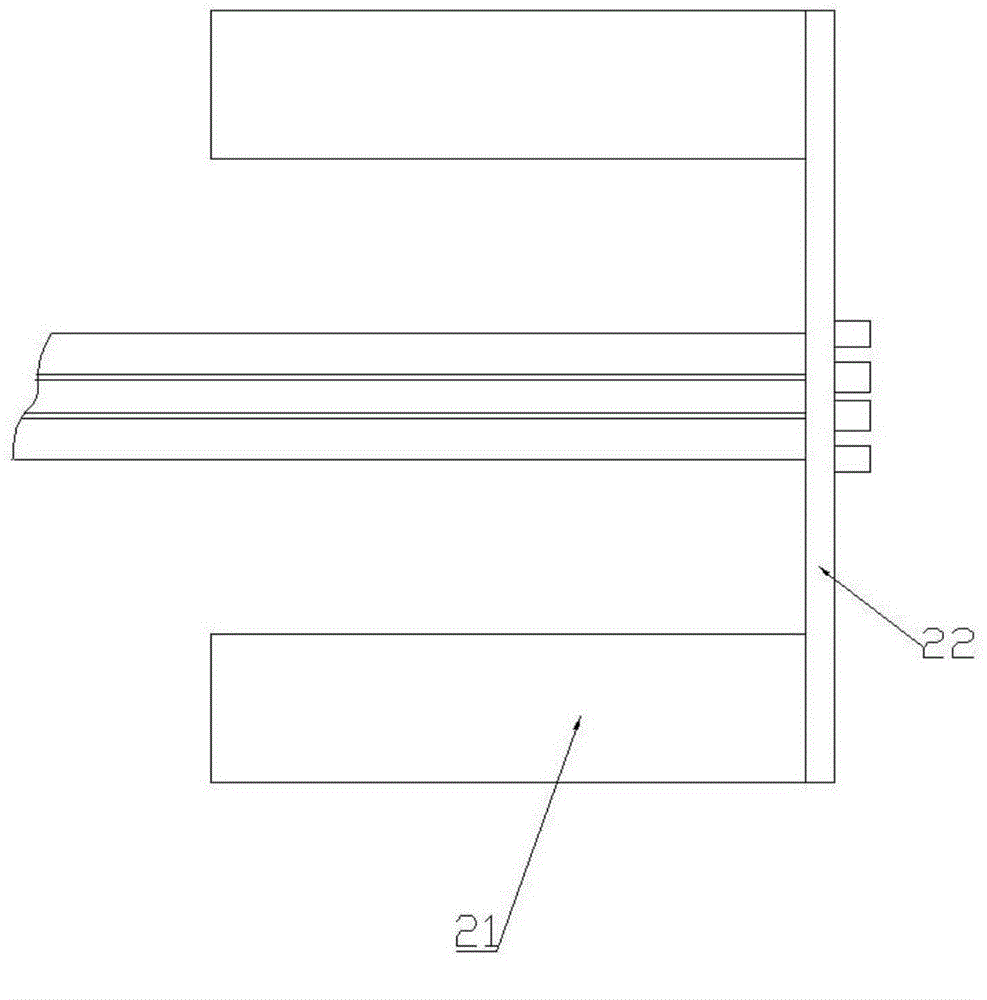

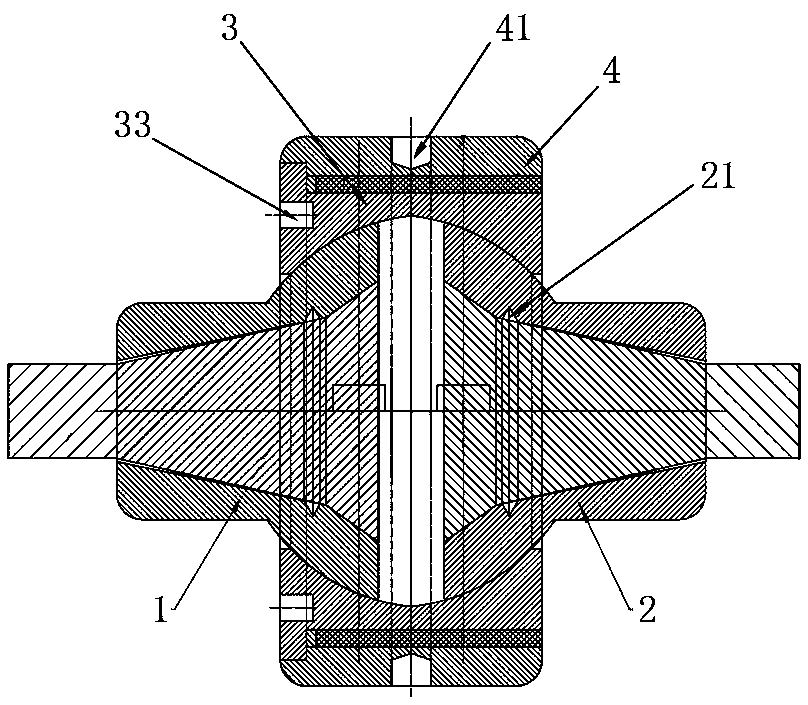

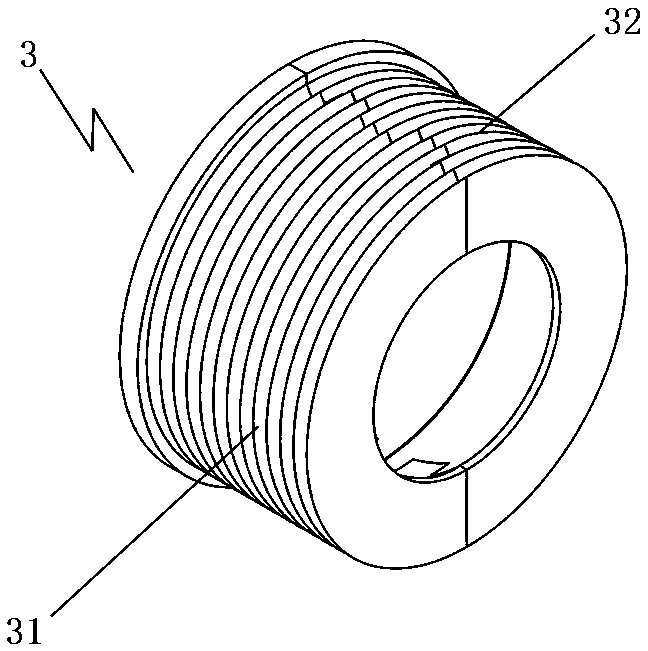

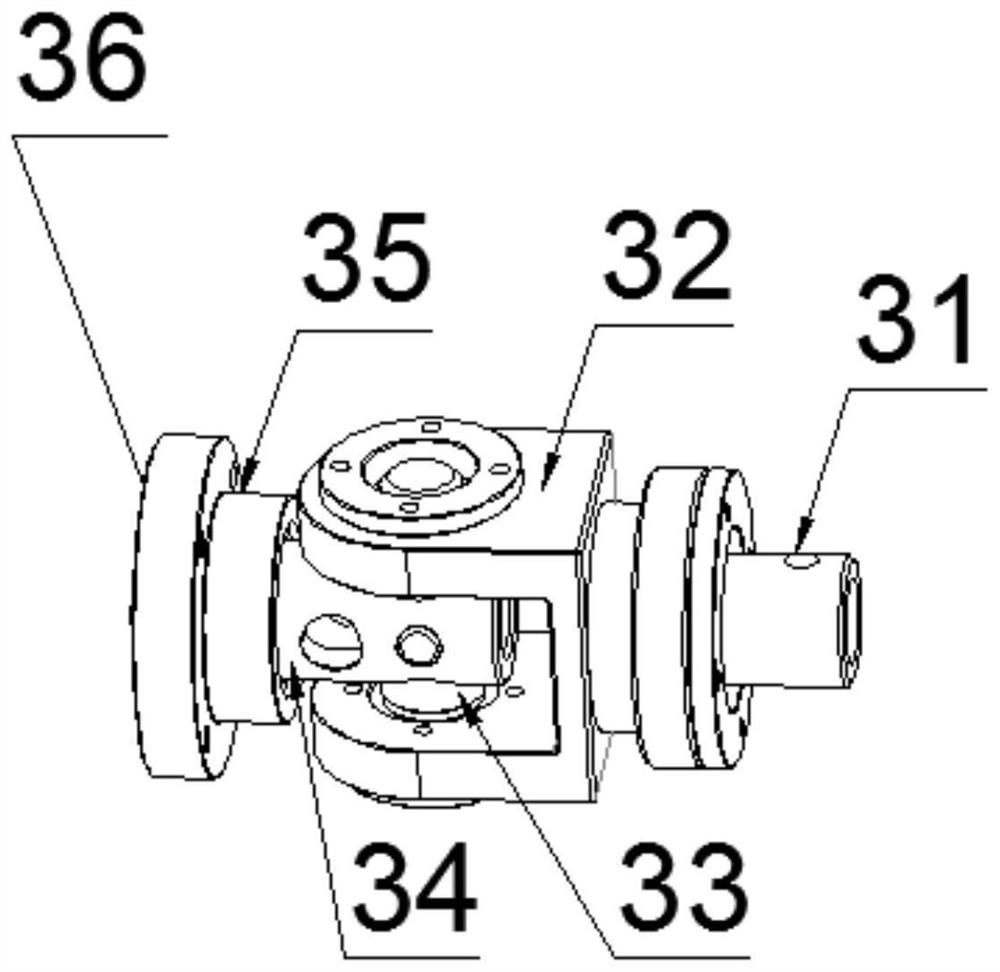

Supporting pile tensioning device

The invention discloses a supporting pile tensioning device. The supporting pile tensioning device comprises a tensioning drive mechanism (01), a locking mechanism (02) and a pretensioning mechanism (03), wherein the locking mechanism (02) is used for locking prestressed tendons at the rear ends of pile molds (1), and the pretensioning mechanism (03) is used for pretensioning prestressed tendons at the front ends of the pile molds (1); the pretensioning mechanism (03) comprises a connecting plate (31), a front anchor plate (32) and a plurality of connecting rods (33) which are used for connecting the front anchor plate (32) and the connecting plate (31), a drive output rod (14) of the tensioning drive mechanism (01) is connected with the connecting plate (31), and the prestressed tendons at the front ends of the pile molds (1) are anchored on the front anchor plate (32). The supporting pile tensioning device can be used for tensioning solid supporting piles and is compact and reasonable in overall structure and reliable in tensioning.

Owner:俞晓东

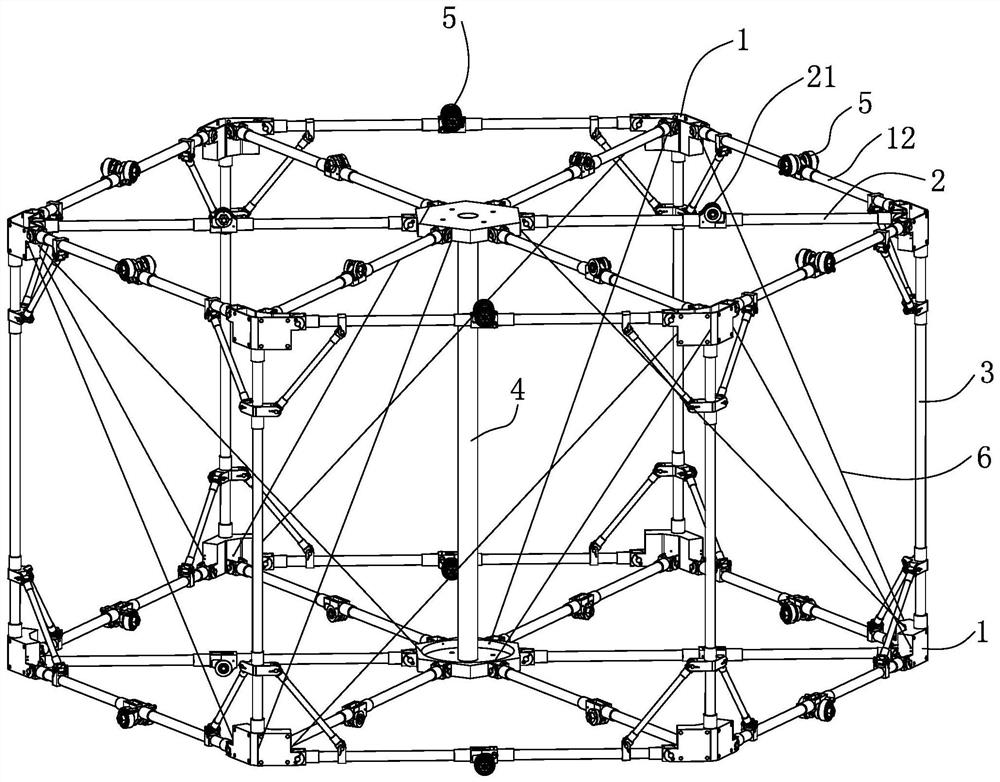

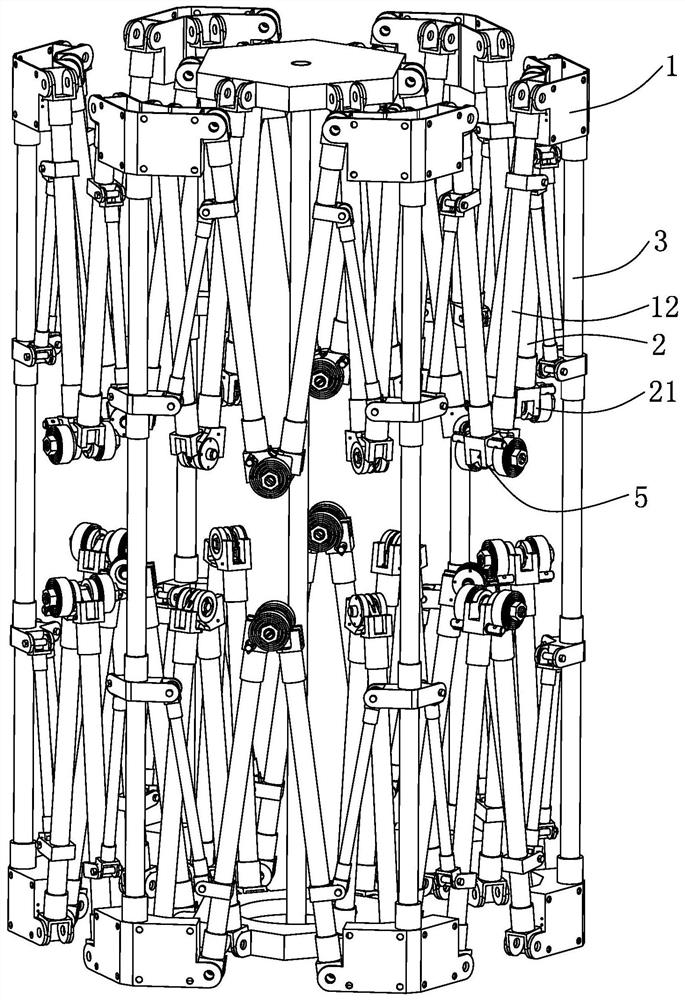

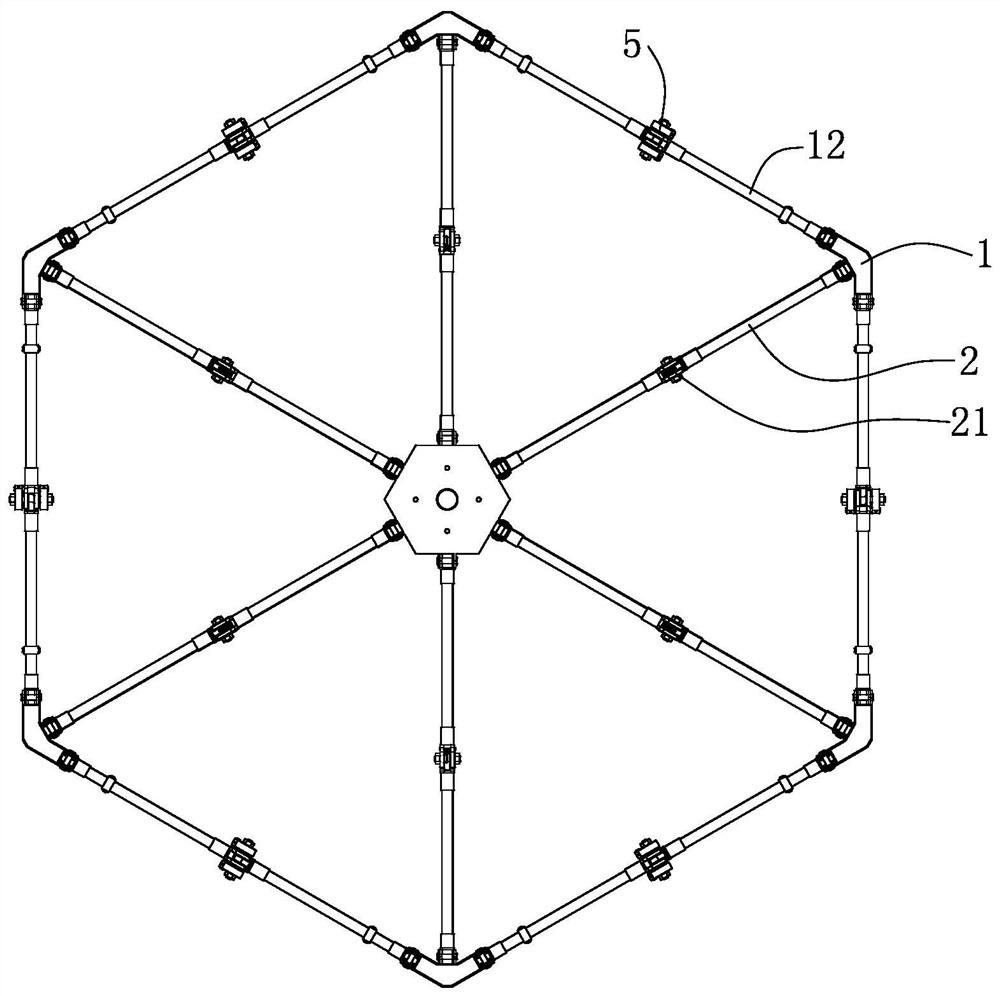

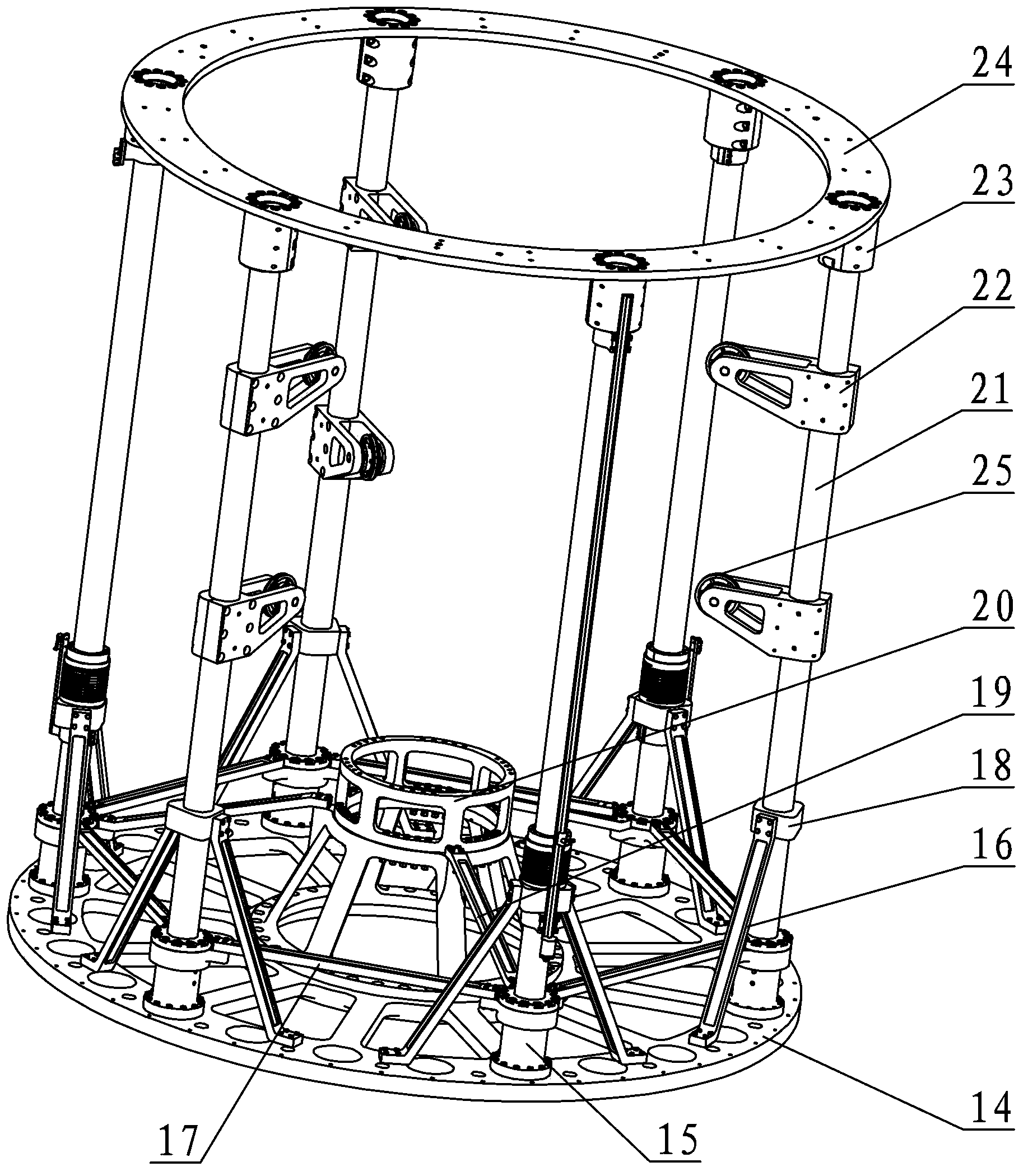

Spatially deployable prism unit for in-orbit assembly

InactiveCN112319855APrevent unlockingImprove stabilityCosmonautic vehiclesCosmonautic partsButt jointSpatial structure

The invention discloses a space deployable prism unit for on-orbit assembly. The space deployable prism unit comprises a synchronizing mechanism, an inner cross rod, an outer vertical rod and a central vertical rod, a plurality of synchronizing mechanisms are connected end to end to form an upper ring and a lower ring, the adjacent synchronizing mechanisms in the same ring are folded, unfolded andlimited through connected volute spring hinges, the two rings are connected through outer vertical rods rotationally connected with the synchronizing mechanisms to form a regular hexagonal prism unit, and a center vertical rod is arranged in the center of the regular hexagonal prism unit. The central vertical rod is rotatably connected with the synchronizing mechanisms through foldable inner transverse rods to form a regular hexagonal prism folding and unfolding unit, the three synchronizing mechanisms arranged in the upper ring at intervals are connected with the two obliquely-opposite synchronizing mechanisms in the lower ring through inhaul cables respectively, and the three synchronizing mechanisms arranged in the upper ring at intervals are connected with the lower end of the centralvertical rod through inhaul cables. The deployable prism units are large in folding-unfolding ratio, good in force bearing performance, reliable, stable and good in symmetry, and the connecting rigidity of on-orbit butt joint of the space structure assembling unit can be improved.

Owner:HARBIN INST OF TECH

A street lamp installation device and installation method thereof

ActiveCN110182737BEasy to holdStable supportLifting devicesTowersStructural engineeringMechanical engineering

Owner:华体智城系统集成有限公司

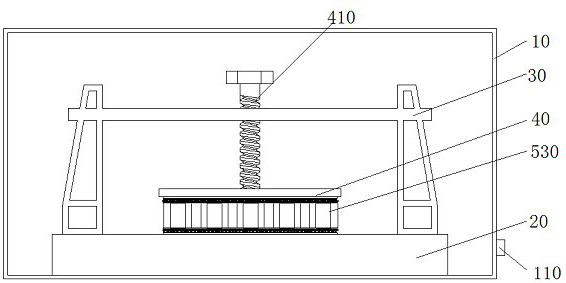

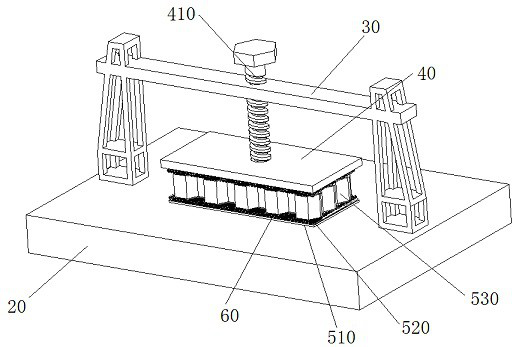

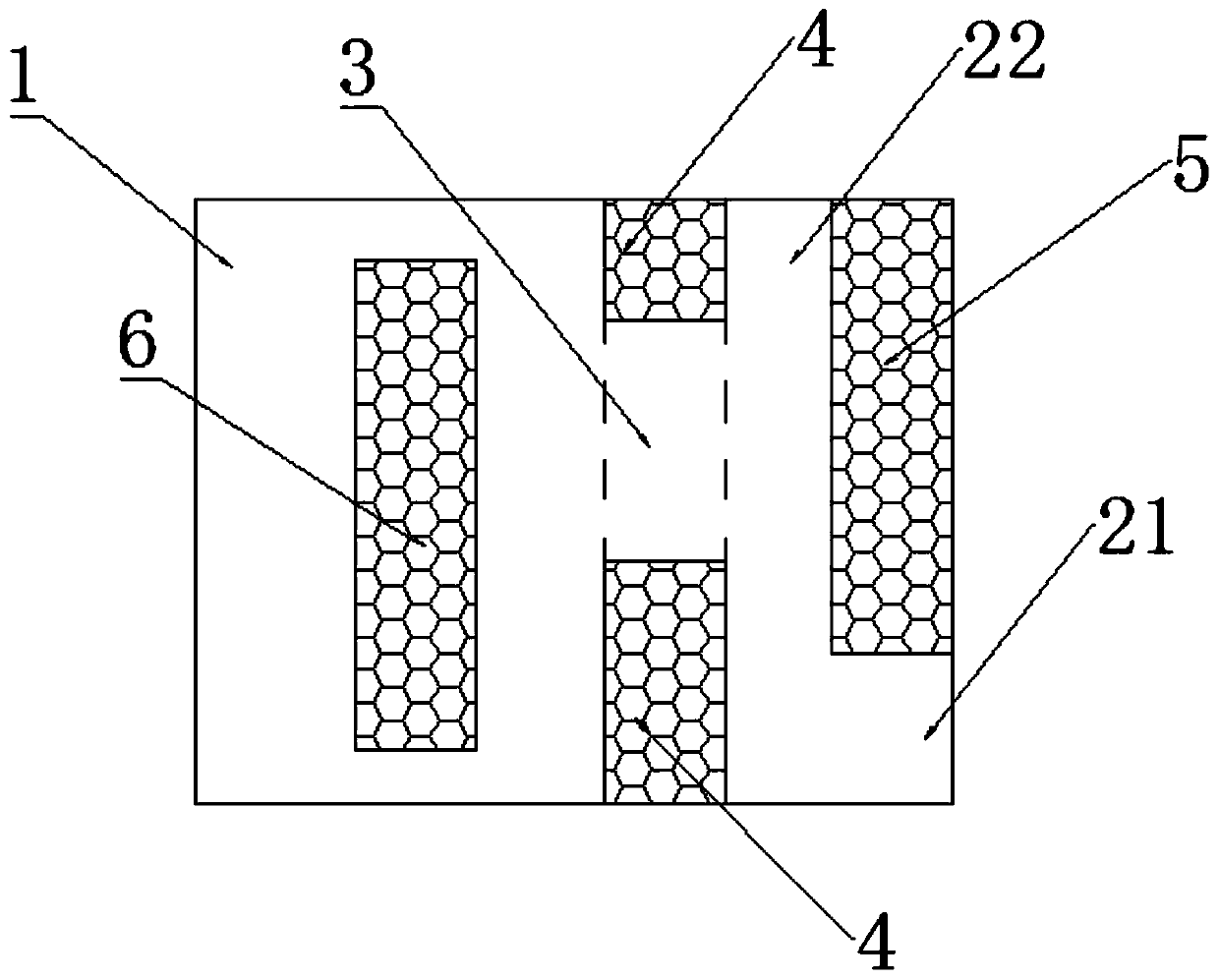

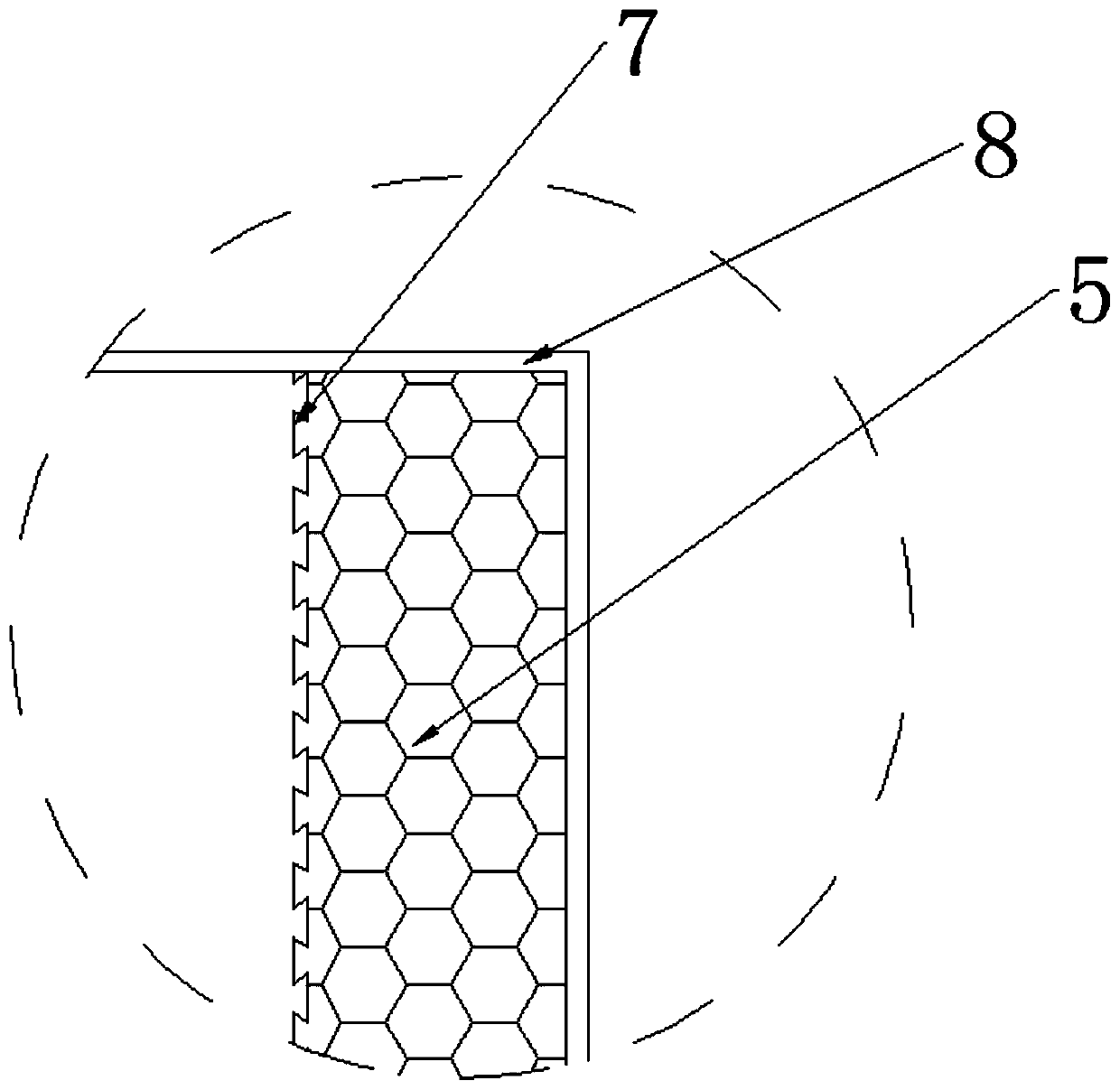

Metal rubber honeycomb composite soft sandwich component preparation structure and method thereof

PendingCN111715961AImprove sound absorption performancePlay the role of crushing energy absorptionLayered productsSound producing devicesMetal rubberEnergy absorption

The invention provides a metal rubber honeycomb composite soft sandwich component preparation structure and a method thereof. The metal rubber honeycomb composite soft sandwich component preparation structure includes a vacuum brazing furnace and a tooling fixture, the tooling fixture comprises a base and a support fixed to the base, a pressure plate is arranged above the base, and the support ismatched with an adjusting bolt in a threaded mode. The designed metal soft sandwich structure part is metal skin, the middle layer is a metal honeycomb core, metal rubber is clamped between the metalskin and the middle layer metal honeycomb core, under complex dynamic load, the elastic porous metal rubber mainly has the effect of damping vibration reduction, and a metal honeycomb core structure in the middle plays the role of impact resistance and energy absorption; and in addition, the metal soft sandwich structure further has the structural characteristics of light weight structure, sound absorption and thermal protection and the like. The preparation device is used for realizing the metallurgical and solid interface combination of an interface of the metal soft sandwich structure partunder the vacuum hot pressing brazing technology, and the comprehensive mechanical properties and environmental adaptability of the whole structure part are improved.

Owner:FUZHOU UNIV

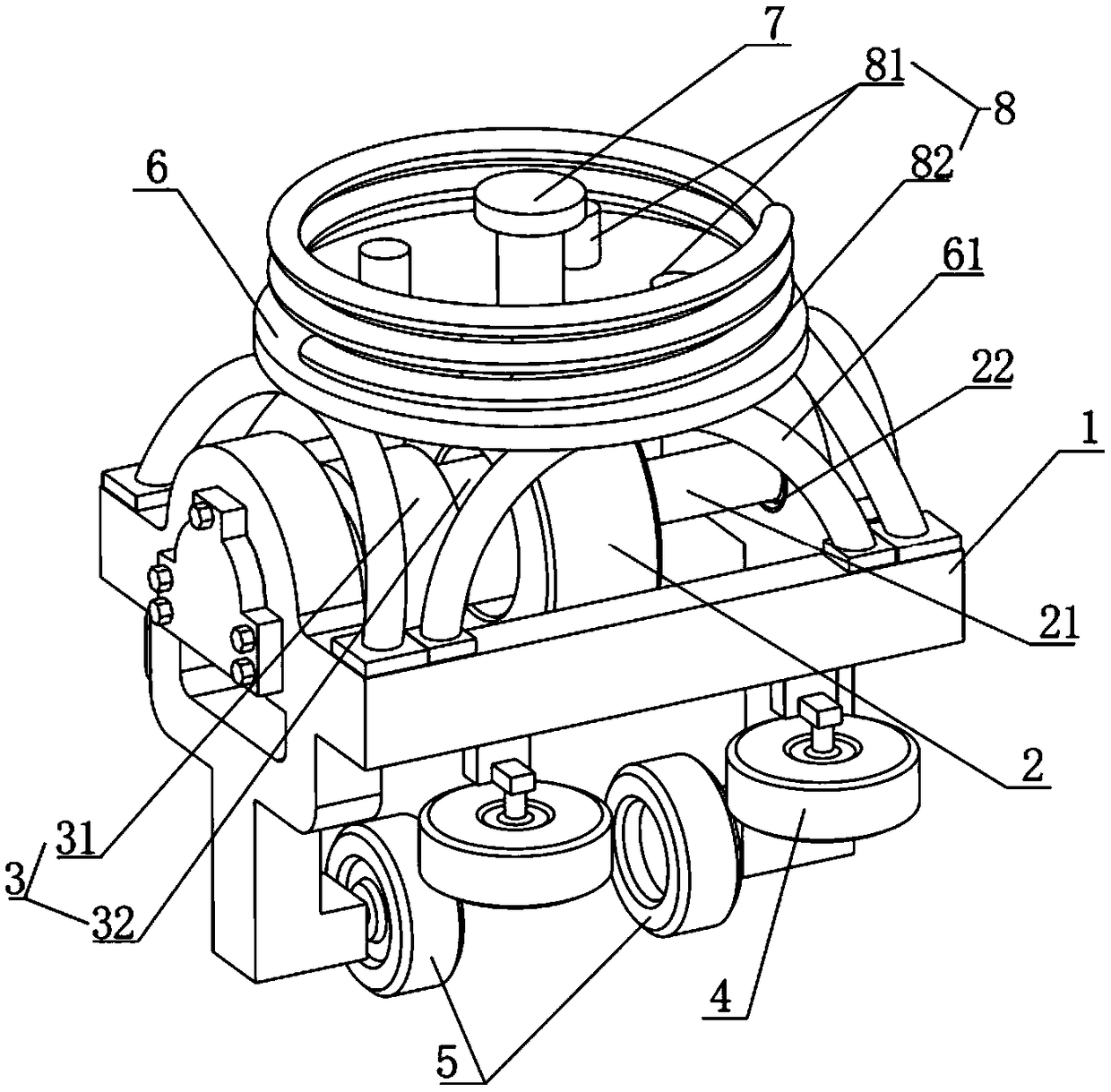

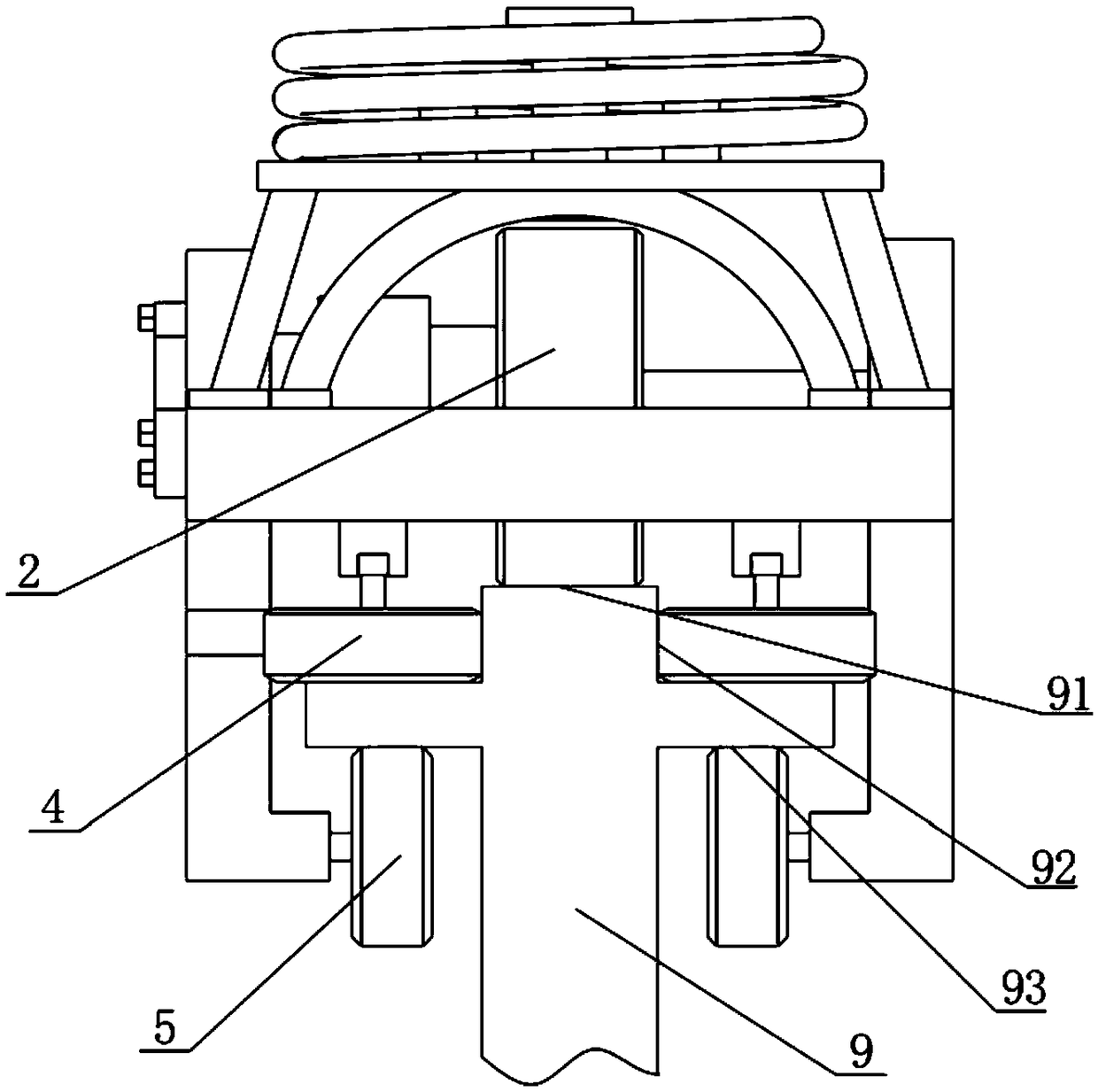

Simple straddle monorail train bogie

PendingCN109080655AAffect the service lifeKeep it steadyElectric motor propulsion transmissionDraw-gearBogieAgricultural engineering

The invention provides a simple straddle-type monorail train bogie, which relates to the technical field of straddle-type monorail train systems, comprising a frame and a traveling wheel rotatably connected to the middle part of the frame through a rotating shaft, wherein a driving brake integrated device is installed on the rotating shaft, and two sides of the traveling wheel are provided with aguide wheel and a stabilizing wheel; A support plate is fixedly connected with that upper end of the frame, a traction column for connecting with the vehicle body is fixedly connected with the supportplate, and a shock absorbing device is also arranged on the support plate. The invention solves the problem that the volume of the monorail train bogie in the prior art is too large and the cost is high, which is not suitable for the small monorail train.

Owner:SOUTHWEST JIAOTONG UNIV

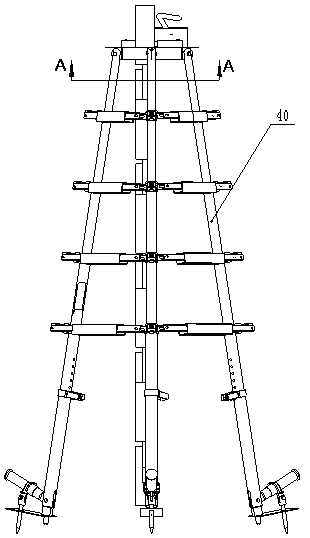

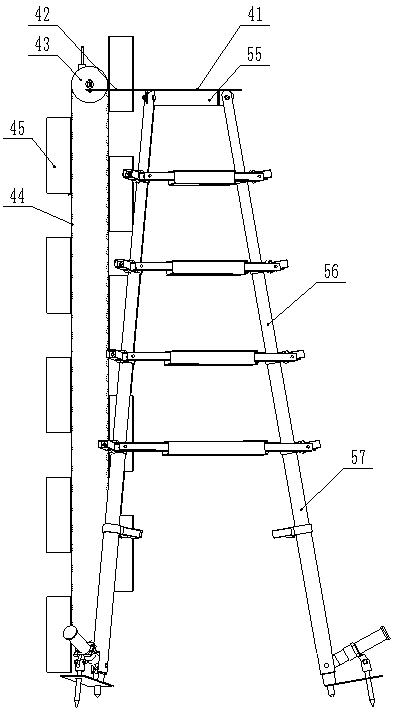

Fruit picking ladder

InactiveCN109197139AImprove tensile strengthImprove bearing effectPicking devicesLaddersLocking mechanismEngineering

The present invention discloses a fruit picking ladder. The fruit picking ladder comprises a picking ladder body. The lower end of the picking ladder body is provided with a fixed mechanism and configured to fixedly connect with the ground; one side of the picking ladder body is provided with a vertical transporter configured to vertically transport the fruits to the ground; the vertical transporter comprises a carrying plate horizontally fixed on the picking ladder body, a section of impending installation plate is extended outwards and is formed at one end of the carrying plate, the installation plate is provided with a vertically rotatable gear, one side, in the axial direction, of the gear on the installation plate is provided with a locking mechanism configured to restrict rotation ofthe gear; a whole annular transmission gear belt is wound on the gear, and one end, far away from the gear, of the transmission gear belt is extended downwards is located at the upper portion of thelower end face of the picking ladder body at intervals. The fruit picking ladder can better transport the picked fruits to the ground from the high altitude and can better ensure the integrity of thefruits.

Owner:YANGTZE NORMAL UNIVERSITY

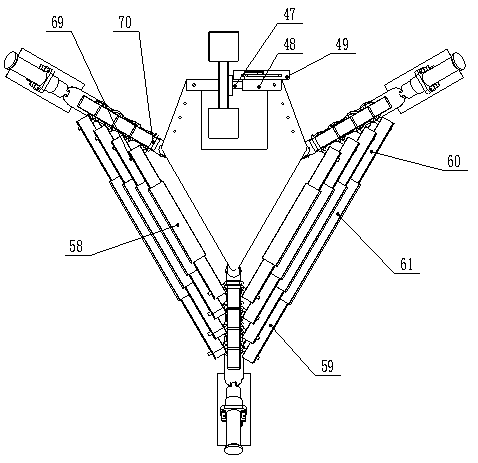

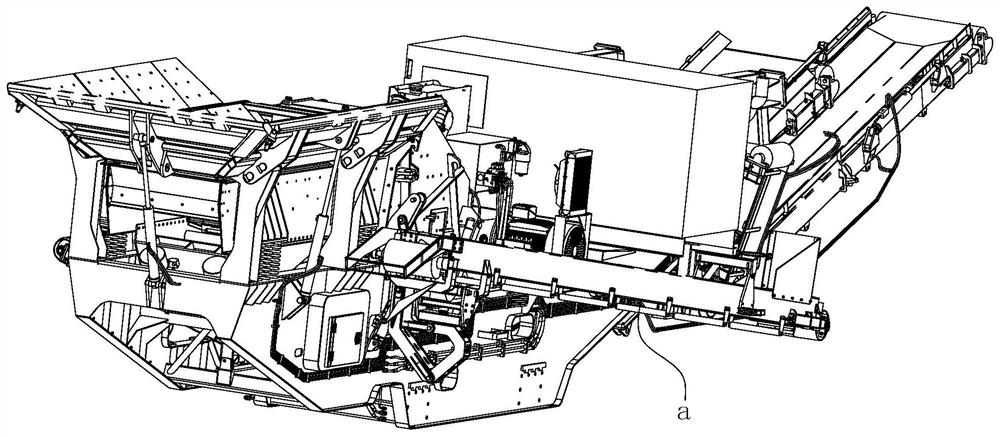

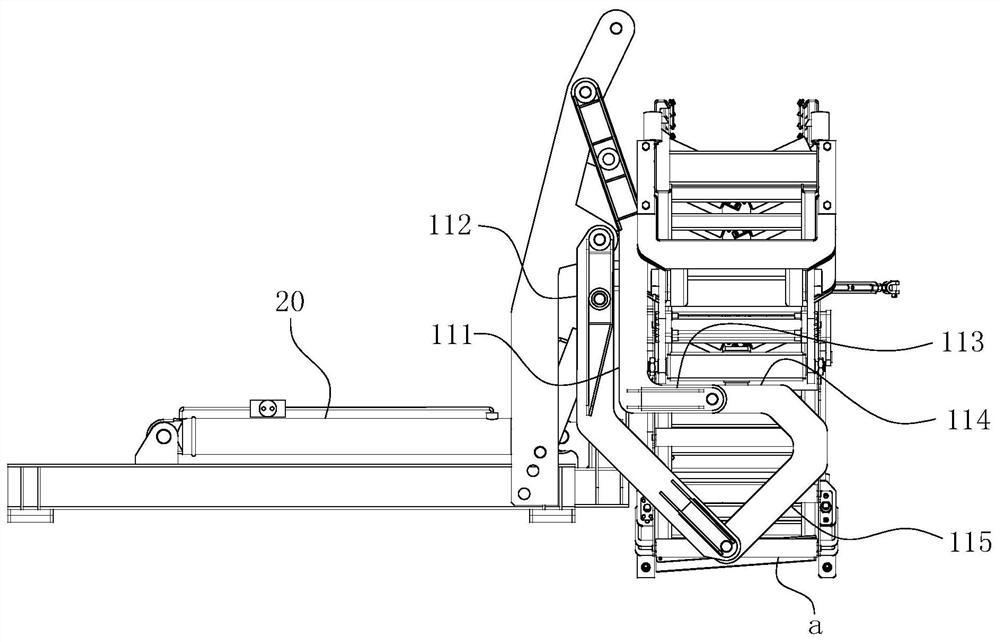

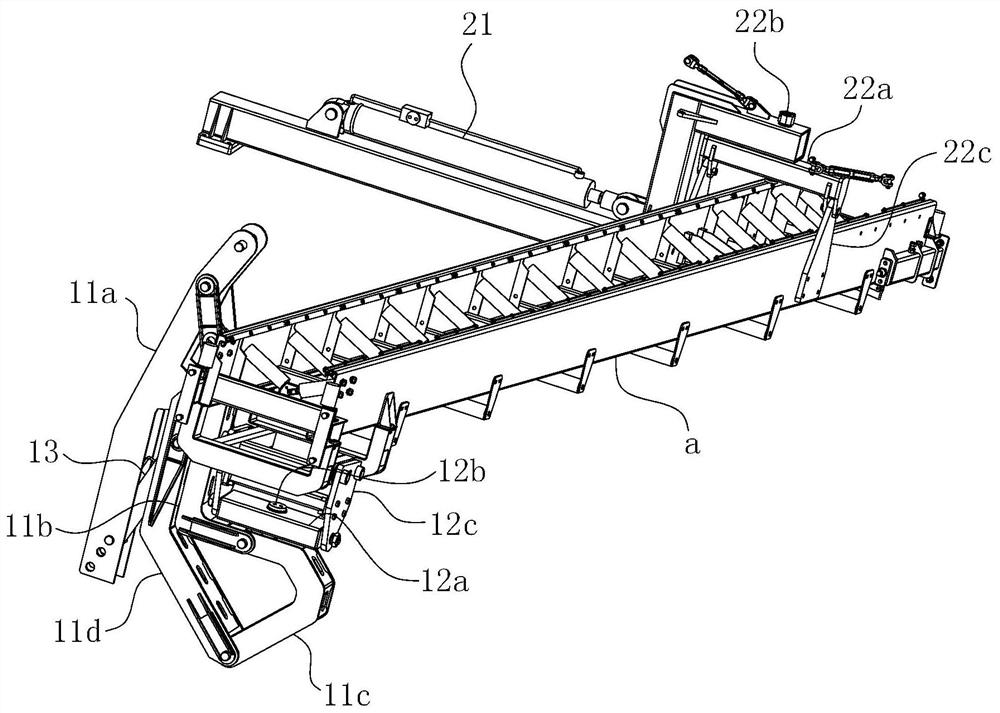

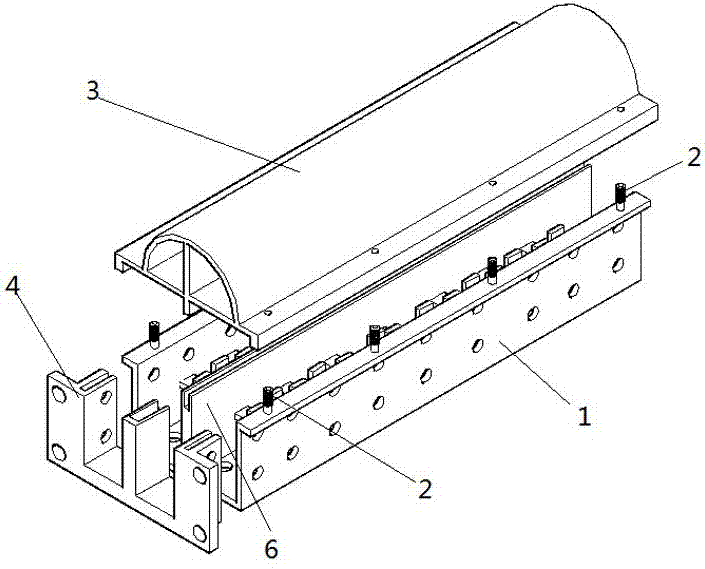

Returning extensible system used for impact crusher

PendingCN112024052ARealize online foldingRealize functionGrain treatmentsStructural engineeringMechanical engineering

The invention belongs to the technical field of crushers, and particularly relates to a returning extensible system used for an impact crusher. The returning extensible system used for the impact crusher comprises a tail-end telescopic device which is arranged at the tail end of a returning transmission rack and has a telescopic function, and a head-end lifting device which is located at the headend of the returning transmission rack and has a lifting function; the head-end lifting device comprises a four-bar linkage jacking assembly, and a head supporting assembly which is used for being connected with the four-bar linkage jacking assembly and the returning transmission rack; and the tail-end telescopic device comprises a telescopic cylinder fixed to a car body, and a tail supporting assembly which is used for being connected with the telescopic cylinder and the returning transmission rack. By means of the returning extensible system used for the impact crusher, online folding and storage and lifting functions of the returning transmission rack can be achieved, so that the efficiency of transportation work of the impact crusher is effectively improved.

Owner:安徽赛美特矿机有限公司

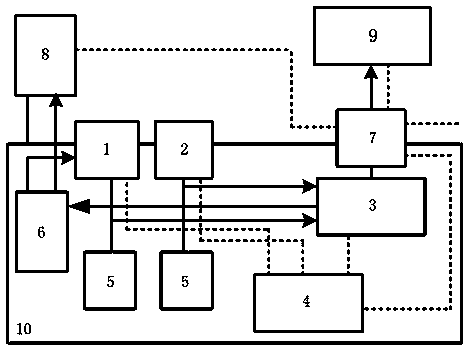

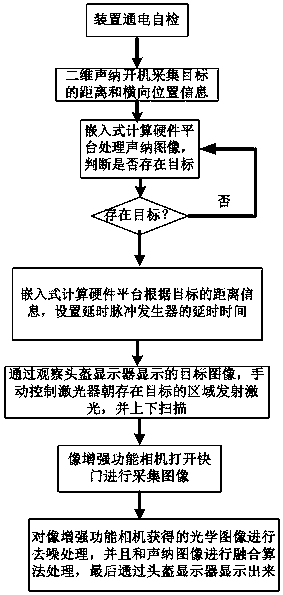

A fusion imaging device of two-dimensional sonar and laser distance gating imaging equipment

PendingCN109788163AReduce the effect of stray lightImprove Optical Imaging QualityTelevision system detailsColor television detailsImaging qualityDisplay device

The invention provides a fusion imaging device of two-dimensional sonar and laser distance gating imaging equipment. The fusion imaging device is characterized by comprising a sealed cabin, an image function enhancing camera, two-dimensional multi-beam sonar equipment, a watertight plug, a lithium battery, an embedded computing hardware platform, a short pulse laser, a helmet display and a two-dimensional adjusting frame. The method has the advantages that 1) the influence of underwater backward scattered light is effectively reduced by adopting laser distance gating imaging equipment, and theoptical imaging quality is greatly improved; 2) a two-dimensional adjusting frame is arranged to facilitate adjustment of view field center positions of the image function enhancing camera and the two-dimensional multi-beam sonar equipment, and a diver can manually remotely control the light beam emitting direction of the auxiliary laser light source, so that an optical image can be convenientlyand rapidly obtained after the acoustic image obtains the position of a target; 3) the structure is simple and practical and can be used as a guiding and collision device for underwater divers, and 4)the overall structure is good in bearing performance and water tightness and high in engineering application feasibility.

Owner:南京砺剑光电技术研究院有限公司

Cavity polyhedron filling block and method of processing the same

ActiveCN101109202AHigh strengthImprove integrityFloorsCeramic shaping apparatusEngineeringMechanical engineering

The invention discloses a hollow polyhedral filling block and the processing method for the block. The top, sides and bottom of the filling block are an non-circular tube that is formed integrally, the top and the bottom of the tube are plane or convex arc, the side of the tube is slant, crestal plane, convex arc or a combination of convex arc at upper and a slant at lower; in the cavity of the tube, a prefabricated support for mating with the top is or not provided; the two ends of the tube are provided with prefabricated end boards. In the invention, the top, sides and bottom of the filling block are a tube that is formed integrally, the block is of high integrality, good force bearing capability; the top, side and bottom of the tube can be formed integrally by a monoblock dabber mesh held by gelled material, unlike prior thin-wall box that is overlapped and connected by a plurality of dabber; the invention is of better integrality and strength.

Owner:HENAN WUJIAN CONSTR GRP

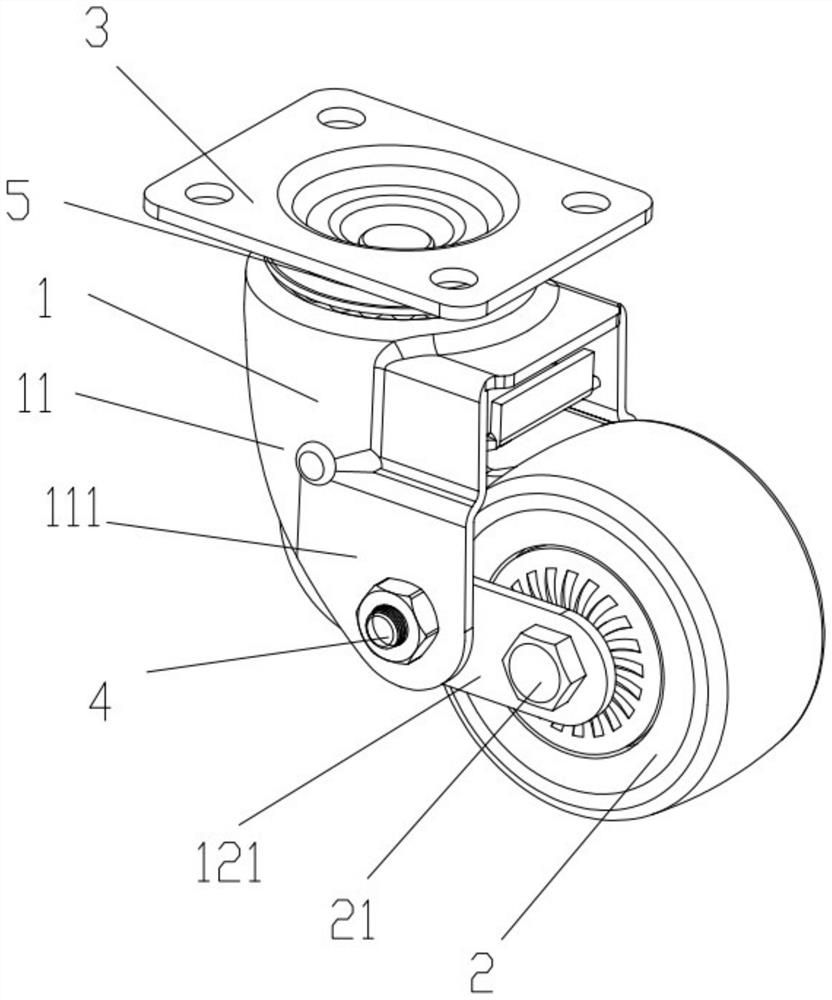

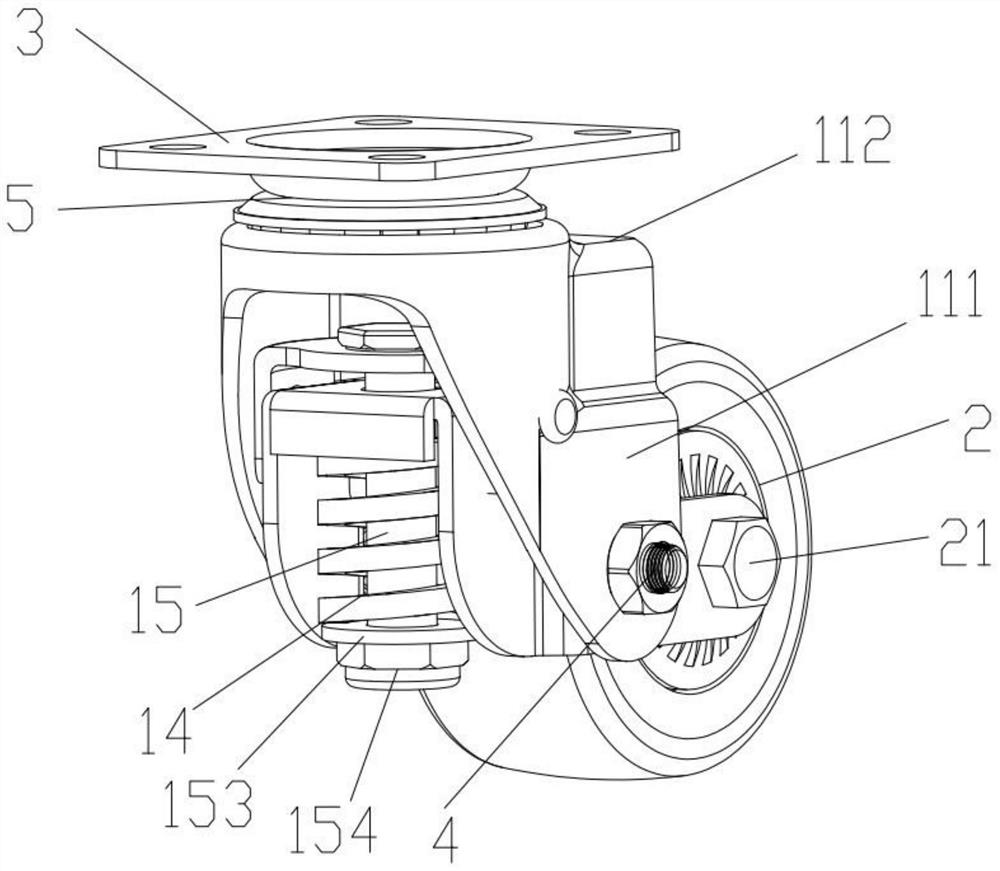

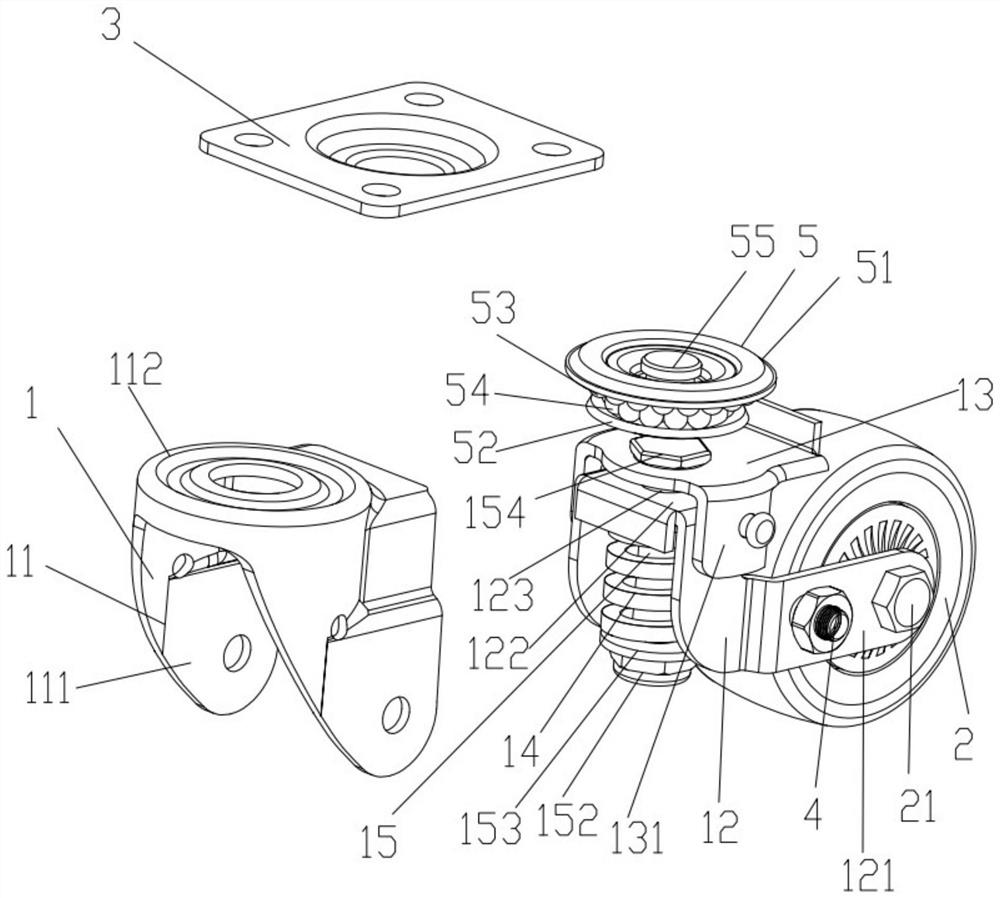

Vibration reduction type trundle

The invention relates to the technical field of trundles, and particularly relates to a vibration reduction type trundle which comprises a trundle support, a wheel installed on the lower portion of the trundle support and a mounting structure arranged on the upper portion of the trundle support and used for being connected with bearing equipment, the trundle support comprises a support body, a vibration reduction frame, a fixing frame, at least one set of spring and a fixing rod, and the vibration reduction frame is of an integrally-formed structure; according to the vibration reduction type trundle, a lever principle vibration reduction mechanism is formed by matching the support body, the vibration reduction frame and the spring and the vibration reduction effect is better; and the pressing plate on the vibration reduction frame downwards abuts against the upper end of the spring, the structural strength is high, the force bearing performance is good, the stability and the durabilityare better, the occupied space of the structural design in the longitudinal space is small, the longitudinal swing space of the vibration reduction frame is large, the bearing piece is connected to the lower end of the fixing rod in a threaded mode, and disassembly and assembly are convenient.

Owner:广州新兴金属有限公司

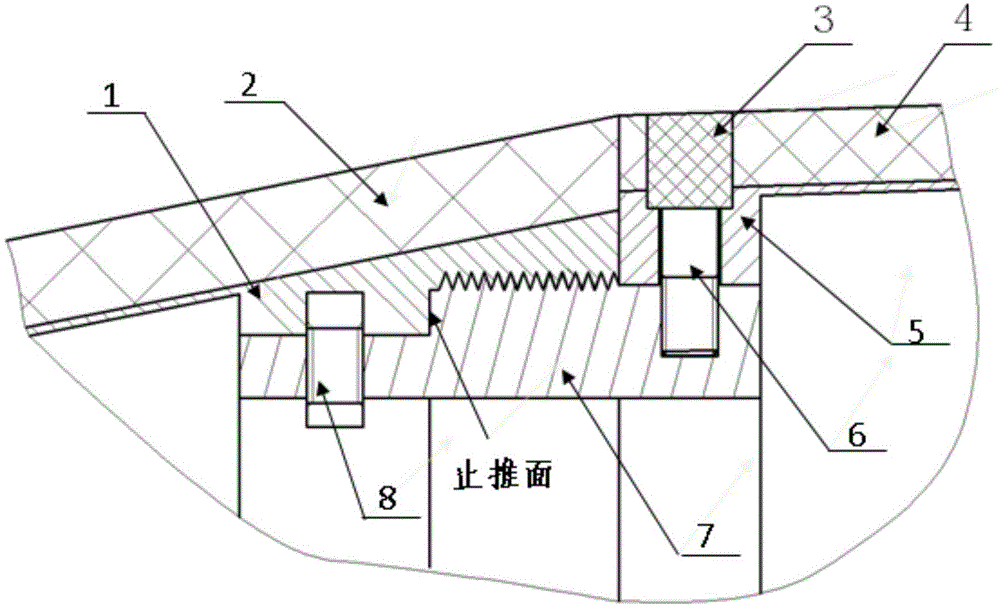

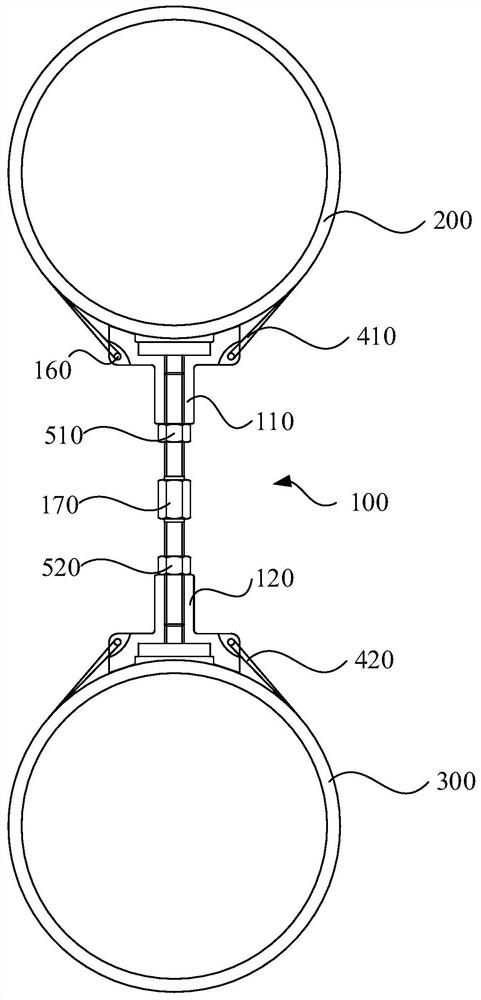

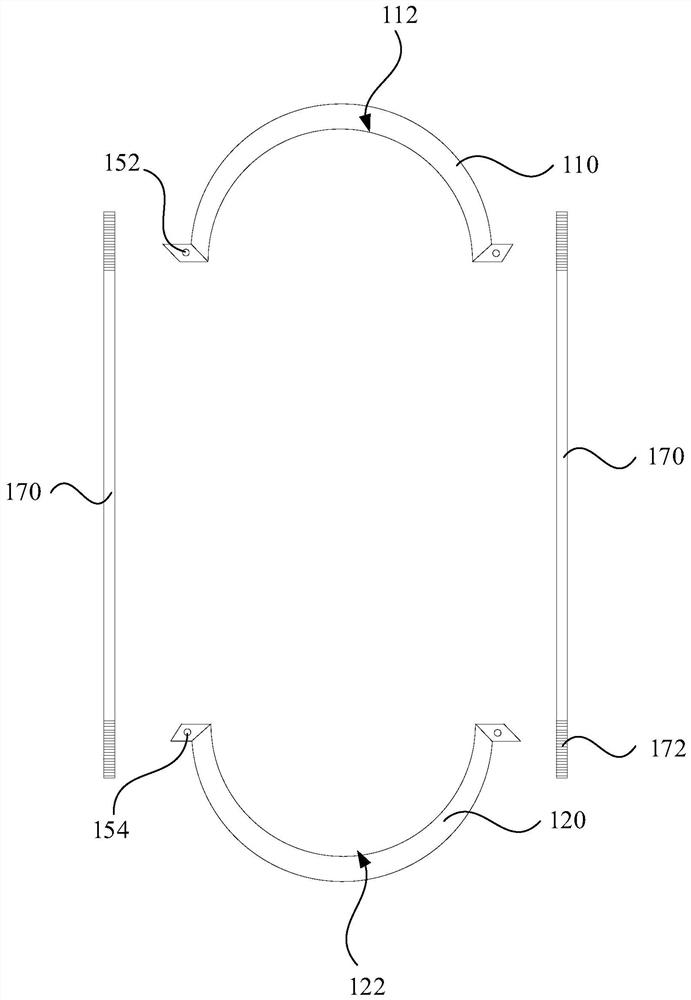

Conveniently-disassembled mounting structure in small rudder cabin

InactiveCN111634410ACompact structureSimple processingSteering ruddersAircraft controlStructural engineeringMechanical engineering

The invention discloses a convenient-to-disassemble mounting structure in a small rudder cabin. The convenient-to-disassemble mounting structure comprises a rudder blade, a rudder shaft, a shell, a lubricating gasket, a rudder shaft sleeve, a steering engine, a rotating Glyd ring and an O-shaped sealing ring, wherein a lower end surface of the rudder shaft is fixedly connected with the rudder blade and sequentially penetrates through the shell, the lubricating gasket and the rudder shaft sleeve from bottom to top, the rudder blade is tightly attached to the shell, a lubricating and sealing ring structure is installed on the rudder shaft and matched with a rudder shaft hole and a sealing groove in the shell, lubricating and sealing of the rudder shaft are guaranteed, the lubricating gasketis located between the rudder shaft sleeve and the shell and used for reducing friction between the rudder shaft sleeve and the shell, a polygonal prism is arranged at a tail end of the rudder shaft and matched with a polygonal inner hole of the rudder shaft sleeve, the rudder shaft sleeve and the rudder shaft are fixed through sunk screws, the diameter of the rudder shaft sleeve is larger than that of the rudder shaft hole in the shell, and the rudder shaft is prevented from disengaging from the shell. The small-sized rudder cabin inner mounting structure is advantaged in that the rudder shaft can be quickly disassembled and assembled in a narrow space, positioning is accurate, and stability and strength reliability in the use process are ensured.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

A connection structure of special-shaped missile compartment suitable for split-flap ejection

InactiveCN104567561BImprove bearing effectSimple manufacturing processSelf-propelled projectilesManufacturing technologyMissile

The invention relates to the technical field of special-shape aircraft bay connecting section, and particularly discloses a special-shape missile bay section connecting structure for sectional fairing deploying. The special-shape missile bay section connecting structure comprises a guide bay metal shell, a warhead bay metal shell and a bay body adapter ring, wherein the bay body adapter ring is of a step-shaped cylinder structure, and is fixedly connected with the guide bay metal shell through a thread structure, the left cylinder wall of the bay body adapter ring and the guide bay metal shell are fixedly connected through an anti-loosening pin, the warhead bay metal shell is matched with the end surface of the guide bay metal shell, the inner wall of the warhead bay metal shell is matched with the right cylinder wall of the bay body adapter ring, and the warhead bay metal shell and the bay body adapter ring are fixedly connected through a connecting pin. The special-shape missile bay section connecting structure has the advantages that the problems of failure of loosening prevention of bay section large threads and the nonuniform butting surface of the special-shape bay body are solved; compared with the flap type quick connecting, the bearing property of the butting surface is good, the gap of the butting surface is avoided, and the implementation of manufacturing technology is easy.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

Support pile tensioning device

Owner:俞晓东

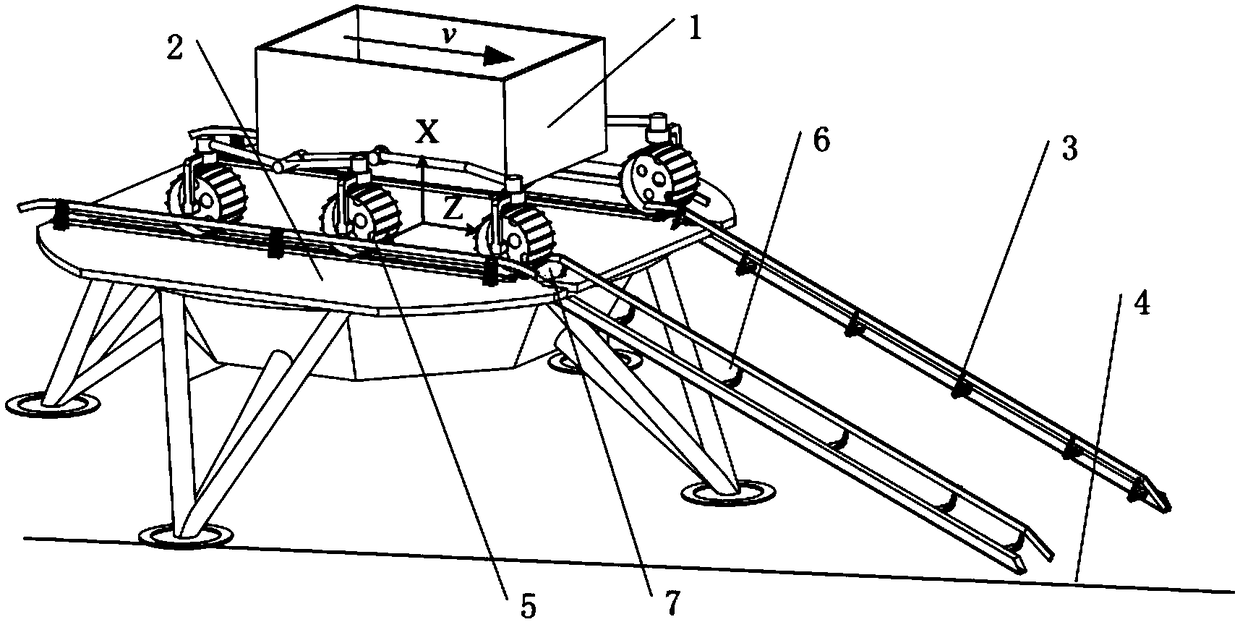

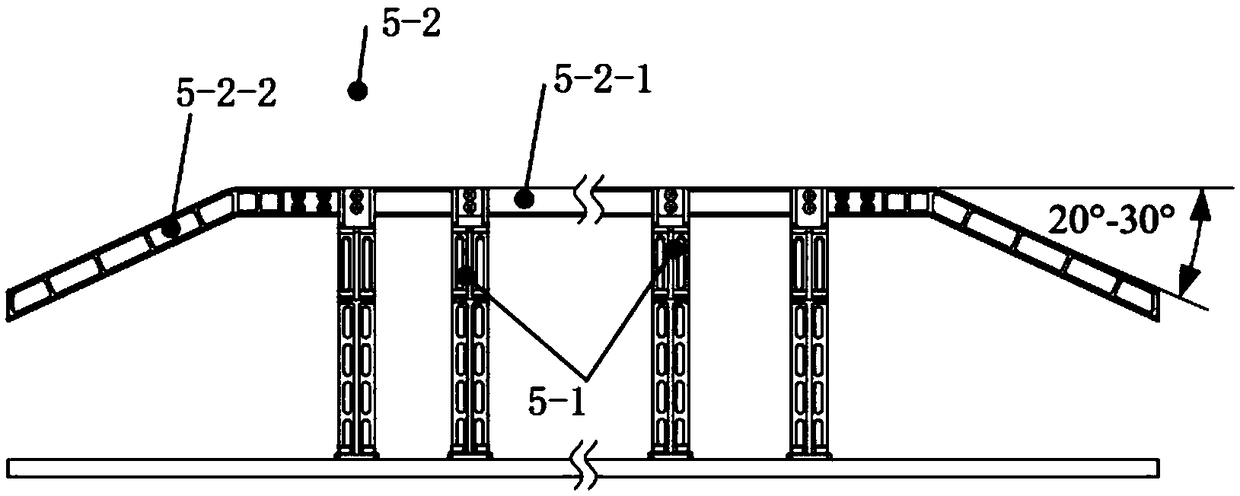

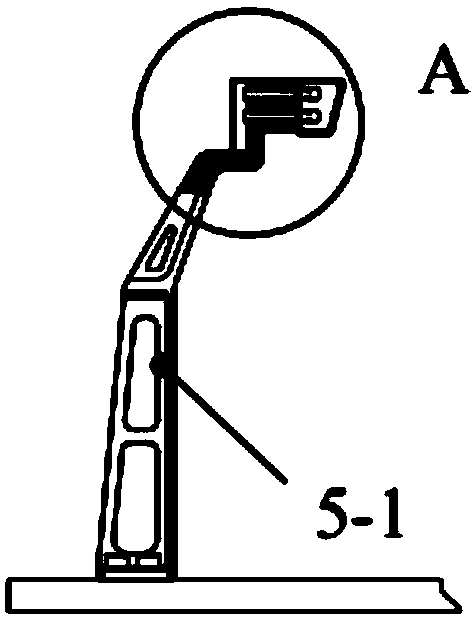

A safety fence for transferring the ramp of a planetary vehicle

ActiveCN109050974APrevent rolloverPrevent side slipExtraterrestrial carsMarine engineeringPlanetarium

The invention provides a safety fence for transferring a ramp of a planetary vehicle, including platform rails and ramp rails, Platform guardrails are arranged in pairs, the ramp rails are arranged inpairs, When the planetarium is moved, on the landing platform, The wheels are shielded by the platform rails, on the ramp ladder, The wheels are protected by ramp rails, A platform guard includes a platform rim and a plurality of platform support seats, A plurality of platform supports support platform flange, the platform flange comprises a straight flange and a bent flange, the ramp guard comprises a ramp flange and a plurality of ramp supports, the ramp supports support ramp flange, the ramp flange comprises a long straight flange and an outer swing flange, and a wheel transition guide section is arranged at the intersection of the platform fence and the ramp fence on the same side. As that star vehicle is transfer from the mesa of the landing platform to the ground, the invention canprevent the star vehicle from being found to roll sideways and slipping sideways, ensure the smooth transition and transfer from the platform to the ramp ladder surface, and independently correct andguide the attitude of a plurality of wheels of the star vehicle.

Owner:HARBIN INST OF TECH

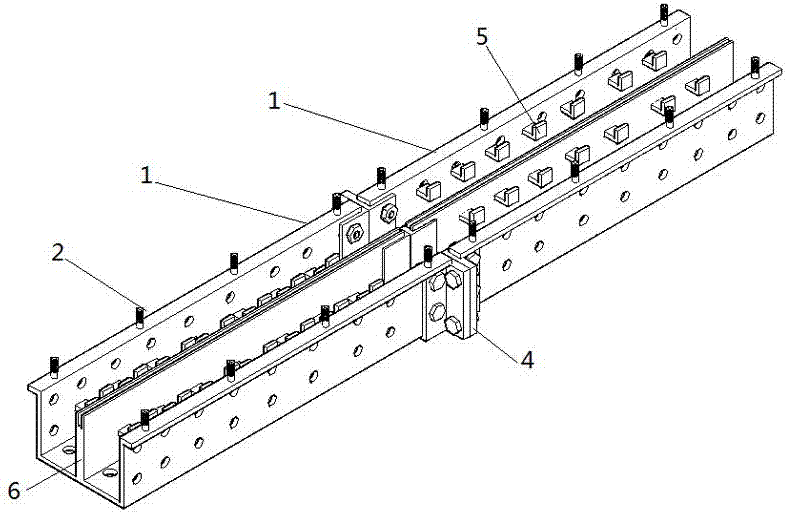

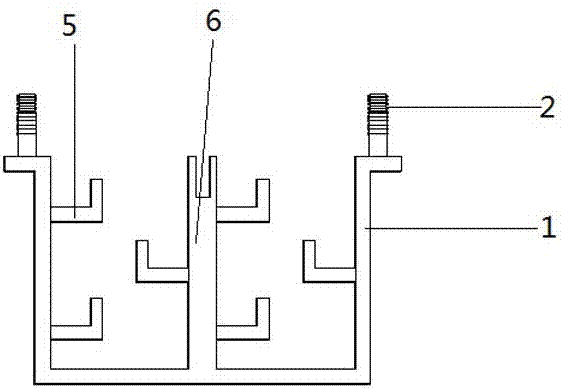

Wire duct structure for electrical operation

InactiveCN107086514AImprove bearing effectGood resistance to extrusion deformationElectrical apparatusWire gaugeFixed frame

A wire duct structure for electrical operation comprises a wire duck body, fixing bolts, a top cover, connecting plugs, cable fixing frames and an intermediate separator plate. The connecting plugs sleeve the front and rear ends of the wire duck body and are fixedly connected with the wire duck body through fastening screws. The cable fixing frames are welded to the inner wall of the wire duck body. The intermediate separator plate is welded to the top of the bottom plate of the wire duck body and is located on the center line of the bottom plate. The wire duct structure for electrical operation is provided with the cable fixing frames. Cables are placed on three cable fixing frames so as to be separated from one another. Thus, electrical accidents, such as short circuit and the like, caused by a case that sharply increased heat and over-high temperature melt the insulating layers of the cables because the cables are gathered together. In addition, the cable fixing frames can prevent the cables from being wound around each other and causing internal confusion of the wire duck body and difficulty in determination of power transmission direction of the cables, ensures regular cables in the wire duck body, and provides convenience for operations such as cable replacement in the future.

Owner:CHANGYI CHUANGTONG ELECTRONICS TECH CO LTD

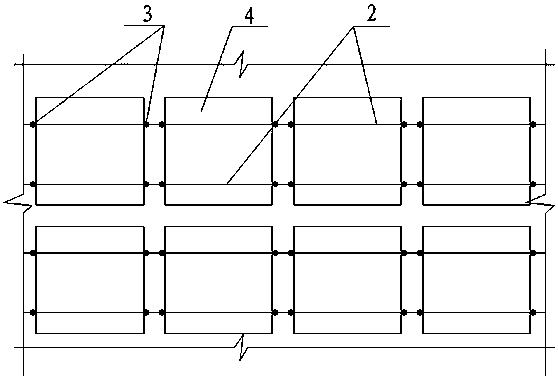

Combined frame system

PendingCN110080437AImprove stabilitySmall sizeWallsEngineeringElectrical and Electronics engineering

The invention discloses a combined frame system, including a plurality of frames, and the frames are connected in a surrounding mode to form a frame system. Each frame comprises a weak-rigidity middleconnecting piece and a pair of strong-rigidity outer frameworks, the weak-rigidity middle connecting piece is located between the pair of strong-rigidity outer frameworks and fixedly connected with the two strong-rigidity outer frameworks, buckling positions are formed on the weak-rigidity middle connecting piece or the strong-rigidity outer frameworks, and pressing strips or sealing rubber strips are buckled at the buckling positions. The frame system has the advantages of being simple and reliable in structure, low in cost, convenient to install, high in strength, thin and attractive.

Owner:HUNAN JIANZHI CURTAIN WALL INSTALLATION DESIGN CO LTD +1

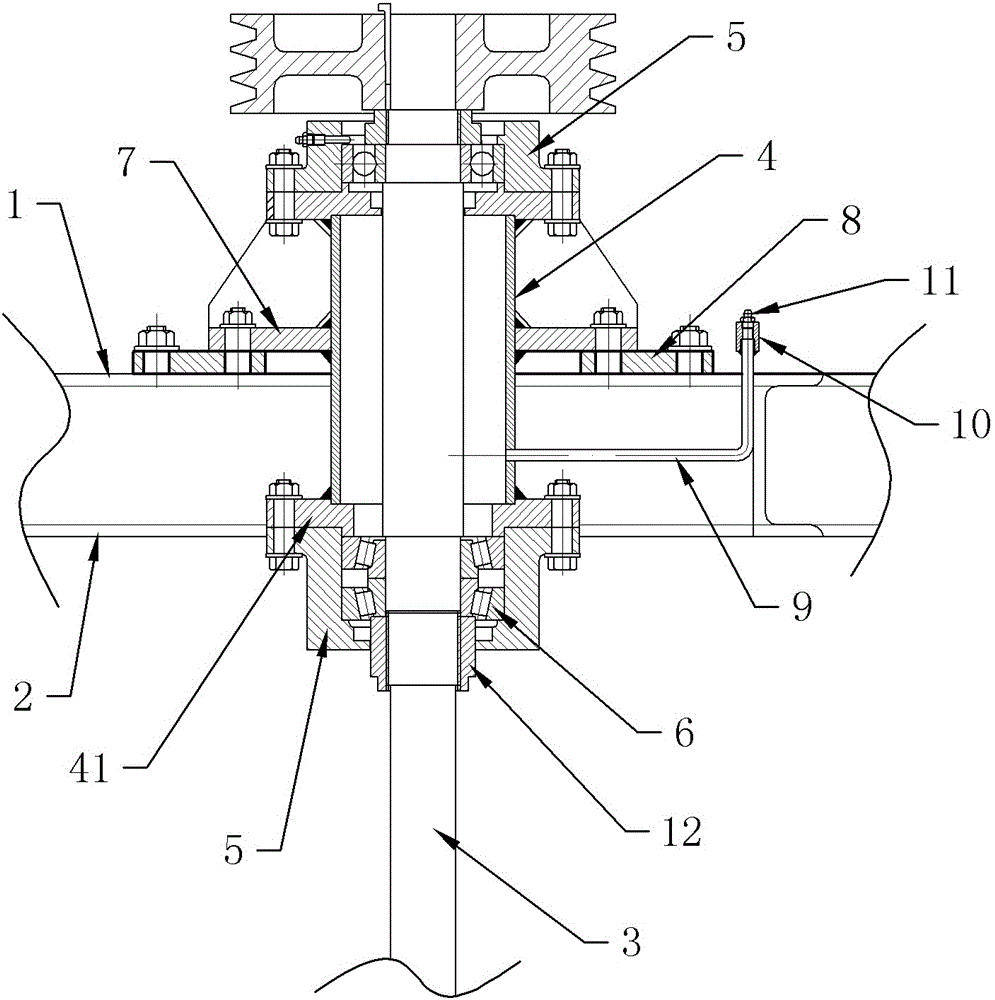

Stirring shaft mounting structure of stirring device

The invention discloses a stirring shaft mounting structure of a stirring device. The stirring shaft mounting structure comprises a stirring shaft and a stirring barrel, and also comprises a supporting seat, bearing seats and a connecting cylinder with two ends provided with flange discs, the stirring barrel is provided with a first mounting plate and a second mounting plate which are arranged up and down, the connecting cylinder penetrates through the first mounting plate and the second mounting plate, the supporting seat is connected to the first mounting plate, the upper end and the lower end of the connecting cylinder are respectively in flange connection with the bearing seats, the bearing seat at the upper end of the connecting cylinder is connected to the supporting seat, the stirring shaft penetrates through the connecting cylinder and the bearing seats, the stirring shaft is connected with the bearing seats through bearings, and the bearing close to the second mounting plate is a tapered roller bearing. The connecting structure in the above scheme realizes firm mounting of the stirring shaft.

Owner:CHONGQING YUKUNLONG METALLURGICAL MATERIAL CO LTD

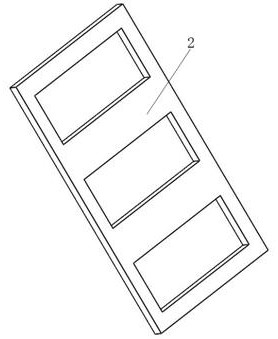

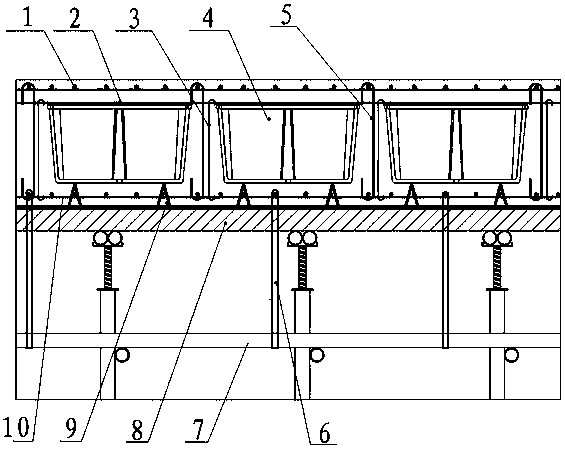

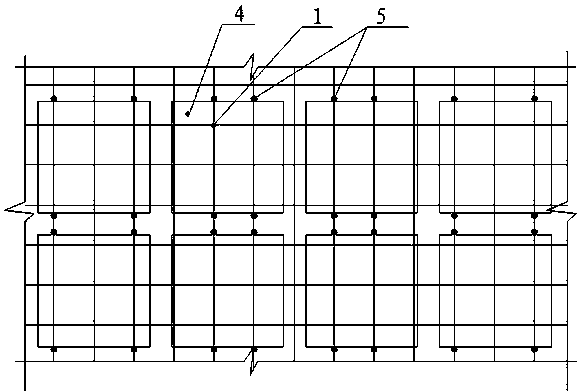

Thin-wall square box rib-free and accurate positioning hollow floor construction method

InactiveCN111058561AReduce buoyancy effectsFloating range is reducedFloorsForms/shuttering/falseworksRebarMechanical engineering

The invention relates to construction methods, in particular to a thin-wall square box rib-free and accurate positioning hollow floor construction method. The problem that displacement is caused due to application of a thin-wall square box to a top board of a garage is solved. The construction method includes the steps that a form board support is built; a floor form board is fixed to the form board support; board lower steel bars and hidden beam steel bars are tied; anti-floating iron wires are arranged; the upper ends of the anti-floating iron wires are connected with the lower steel bars, and the lower ends of the anti-floating iron wires are connected with the form board support; a thin-wall square box is placed in a determined position; anti-floating steel bars are arranged above thethin-wall square box; tension bars are disposed between the anti-floating steel bars and the board lower steel bars; positioning steel bars are installed on the two sides of the thin-wall square box;the lower ends of the positioning steel bars are connected with the board lower steel bars; board upper steel bars are installed; the positioning steel bars are connected with the board upper steel bars; and finally concrete pouring is performed. Through the scheme, the thin-wall box can be tied to the steel bars in the top board of the garage and is completely fixed, displacement in the horizontal direction and the vertical direction cannot occur, the structural distribution is uniform, the stress is balanced, and the force-bearing effect is good.

Owner:CHINA SHANXI SIJIAN GRP

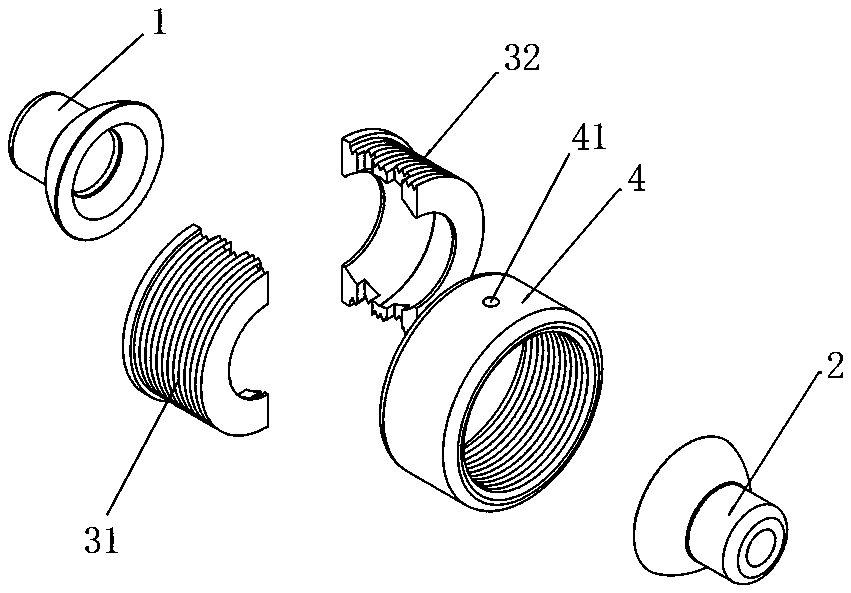

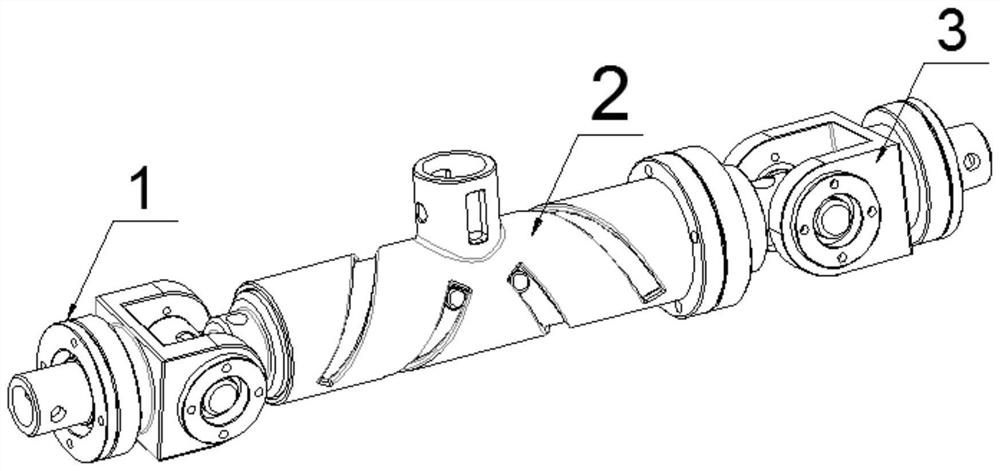

Plug disc type steel rope joint for material conveying, application method and steel rope plug disc system for conveying

InactiveCN108278328ASimple structureEasy to operateRopes and cables for vehicles/pulleyTextile cablesEngineeringMechanical engineering

The invention discloses a plug disc type steel rope joint for material conveying. The plug disc type steel rope joint comprises a left connecting part, a right connecting part, an inner clamping sleeve and an outer hoop sleeve, wherein the left connecting part and the right connecting part are axial pieces, and are provided with conical inner cavities for inserting in steel ropes; small-port endsof the conical inner cavities are the tail end of the left connecting part, and large-port ends are the front end of the left connecting part; the outer side peripheral surface of the front end is a curved surface; the inner clamping sleeve consists of two or multiple inner clamping sleeve part bodies capable of axially assembling as a cylindrical sleeve body; the left end of the assembled cylindrical sleeve body sleeves the front end of the left connecting part, and the right end sleeves the front end of the right connecting part; the middle part is hollowed, so that a gap is formed between the front end surface of the left connecting part and the front end surface of the right connecting part; an inner sleeve surface of the left end of the assembled cylindrical sleeve body is a curved surface closed with the front end curved surface of the left connecting part, and an inner sleeve surface of the right end is a curved surface closed with the front end spherical surface of the right connecting part; and the outer hoop sleeve sleeves the closed inner clamping sleeve in an axial limiting mode.

Owner:CANGZHOU YONGGAO FARMING MACHINERY TECH CO LTD

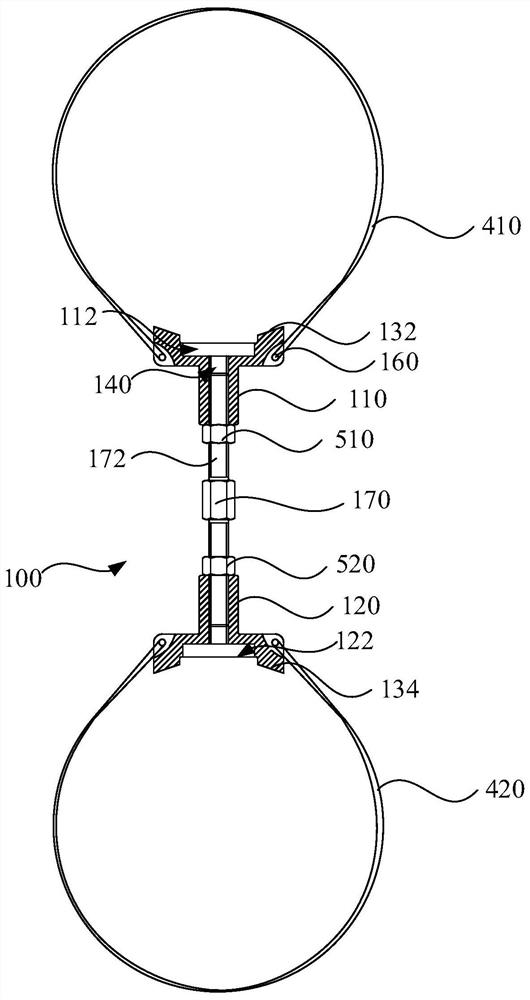

Satellite support and carrier rocket

PendingCN112722338AReduce volumeReduce assembly processCosmonautic vehiclesCosmonautic component separationClassical mechanicsRocket

The invention relates to the technical field of aerospace, and in particular relates to a satellite support and a carrier rocket. The satellite support comprises a first force bearing structure on which a satellite is arranged, a second force bearing structure which is arranged on the outer side of the first force bearing structure and is suitable for being connected with a control cabin of the carrier rocket, and a connecting structure which is arranged between the first force bearing structure and the second force bearing structure, and the two ends of the connecting structure are connected with the first force bearing structure and the second force bearing structure respectively; the first force bearing structure, the second force bearing structure and the connecting structure are integrally formed. The first force bearing structure, the second force bearing structure and the connecting structure of the satellite support are integrally formed, so that the satellite support only comprises a necessary main body structure, other connecting structures for connecting the main body structure do not need to be additionally arranged, the number of parts is reduced as much as possible, the overall size of the satellite support is reduced, and overall assembling procedures are reduced; the assembly is simple, the weight of the satellite support is reduced, and the overall carrying capacity of the carrier rocket is improved.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD +1

Supporting tool for tubular bus maintenance

ActiveCN113206475AEnsure connection stabilityReasonable force structureCable installation apparatusStructural engineeringMechanical engineering

The invention discloses a supporting tool for tubular bus maintenance. The supporting tool comprises a supporting assembly. The supporting assembly comprises a first supporting piece and a second supporting piece which are connected with each other; and one end of the first supporting piece is provided with a first groove used for being matched with an upper-layer tubular bus support, the other end of the first supporting piece is connected with one end of the second supporting piece, and the other end of the second supporting piece is provided with a second groove used for being matched with a lower-layer tubular bus support. When the upper-layer tubular bus is overhauled, the second supporting piece is fixed to the lower-layer tubular bus through the second groove, then the first supporting piece is connected to the fracture of the upper-layer tubular bus through the first groove, and stable supporting of the upper-layer tubular bus is formed. When the lower-layer tubular bus is overhauled, the first supporting piece is fixed to the upper-layer tubular bus through the first groove, then the second supporting piece is connected to the fracture of the lower-layer tubular bus through the second groove, and stable supporting of the lower-layer tubular bus is formed. The problem of different supports of the overlapped tubular bus bars in the maintenance process can be solved, and the safety and reliability of the site can be effectively improved.

Owner:QUJING BUREAU OF SUPERVOLTAGE POWER TRANSMISSION CHINA SOUTHERN POWER GRID

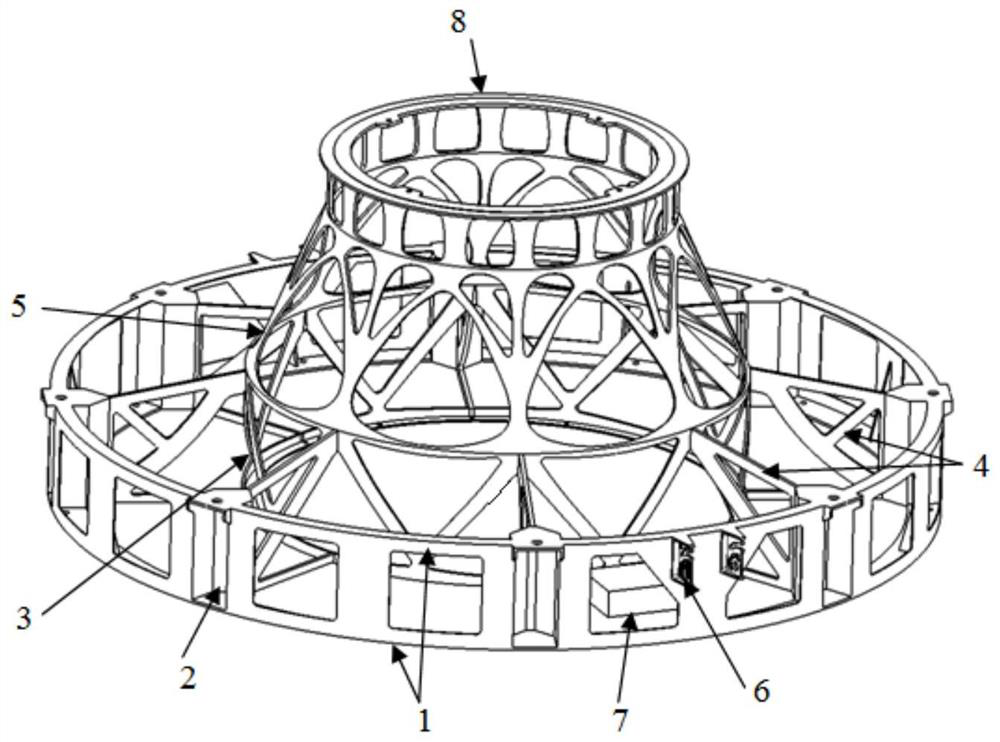

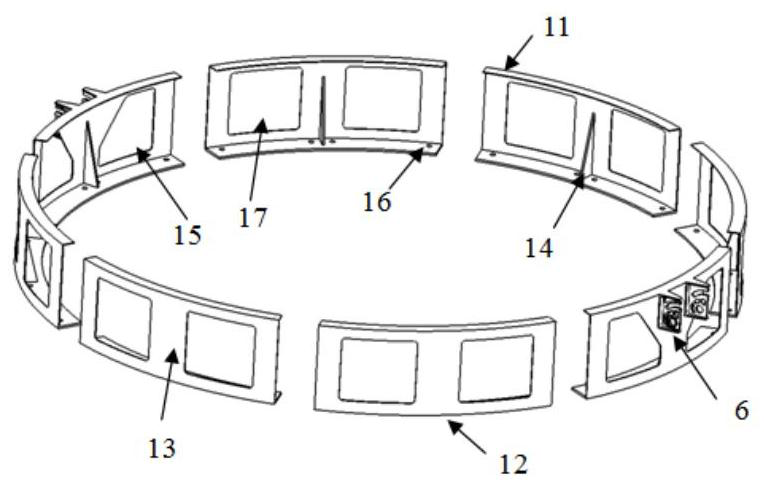

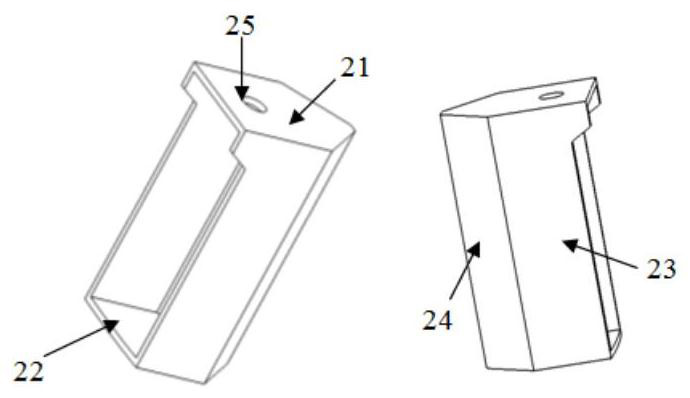

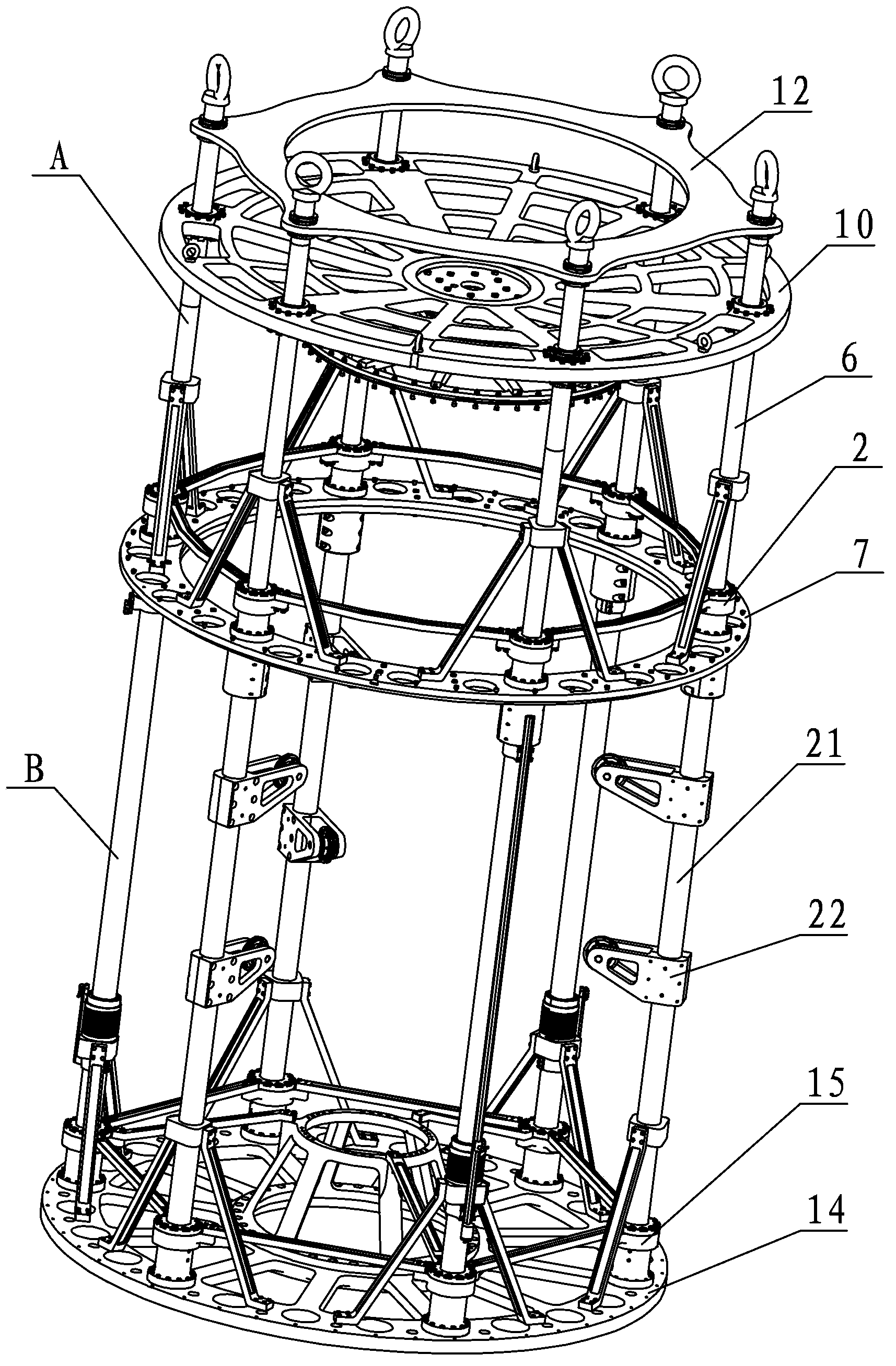

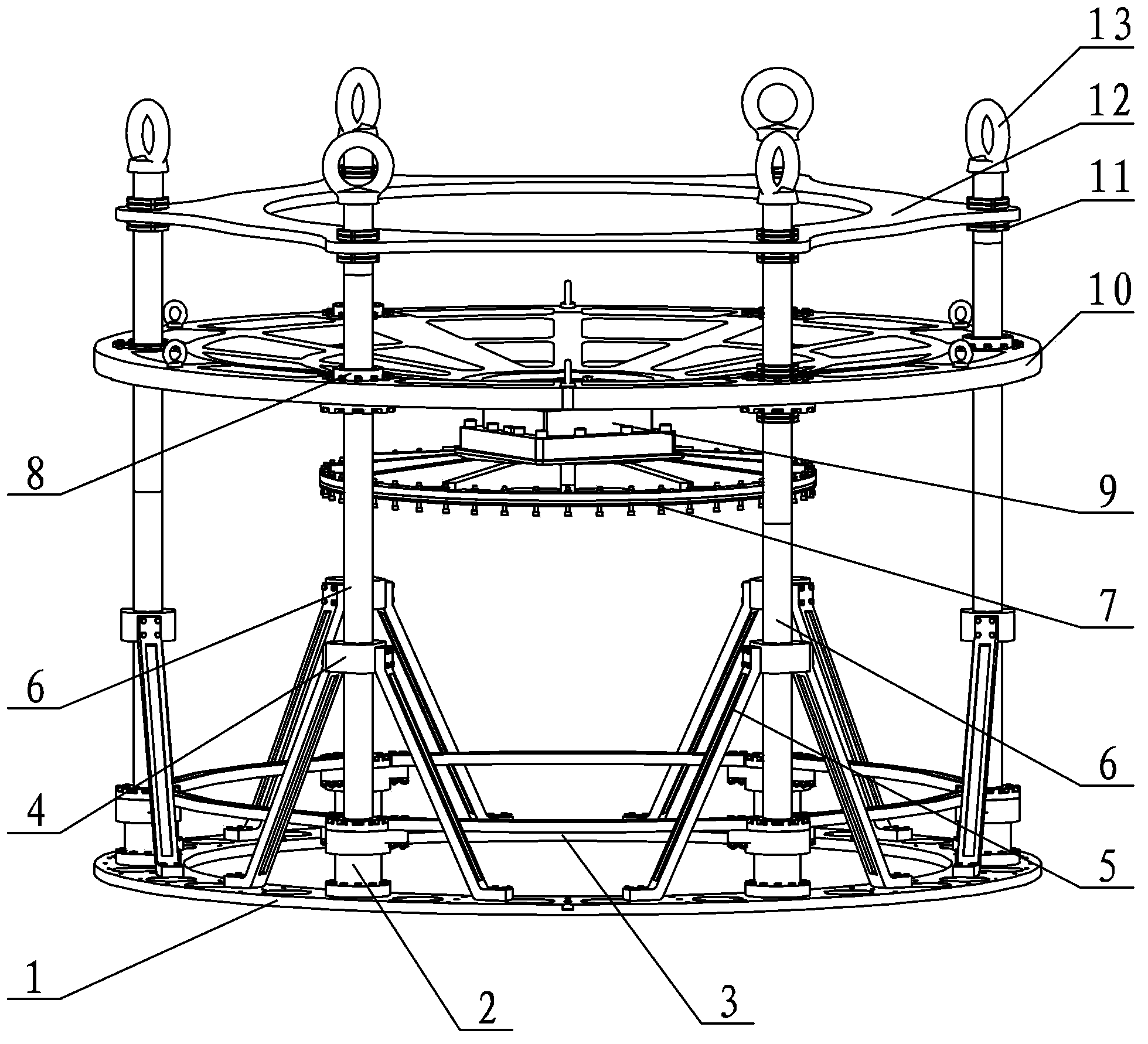

Large-scale split installation mouse cage type bearing framework

ActiveCN103398268ASolve structural installation difficultiesReduce the difficulty of operationMachine framesEngineeringForce sensor

Owner:HARBIN INST OF TECH

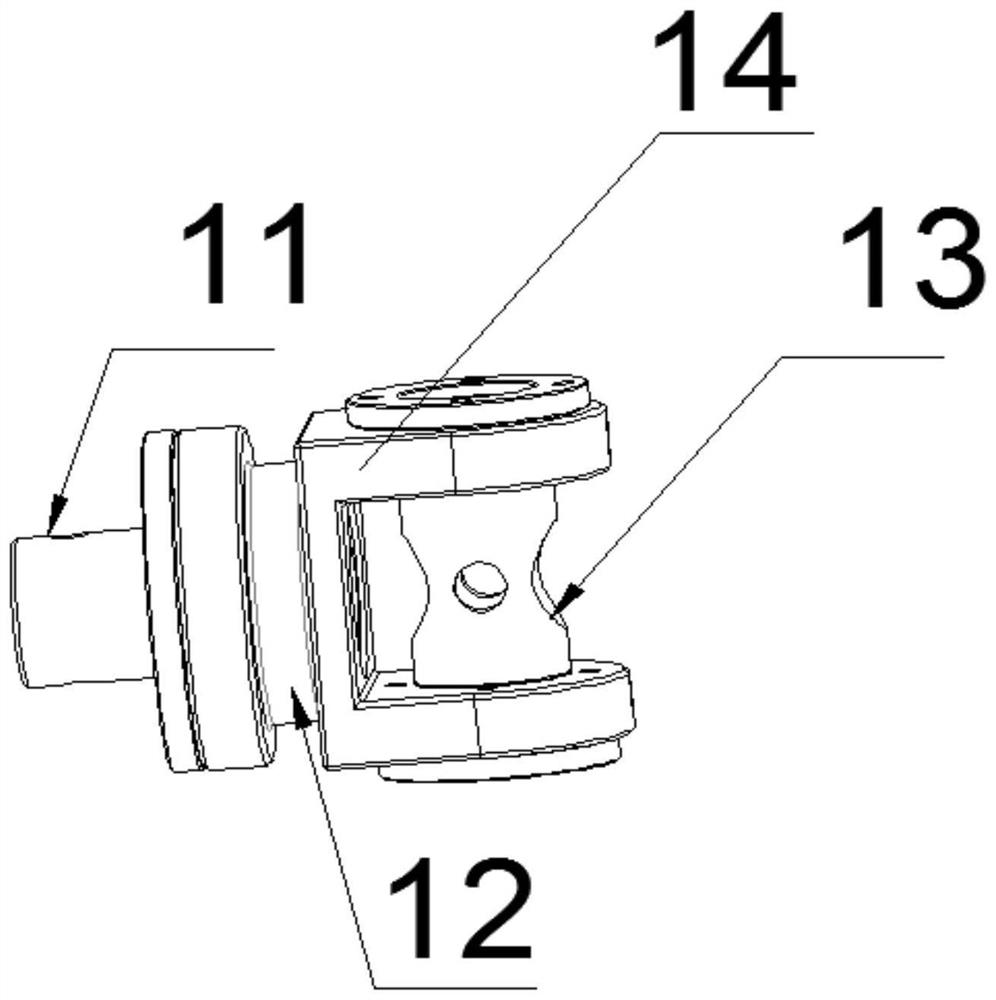

Mechanical arm tail end executing device

ActiveCN112847417ALarge range of motionCompact structureGripping headsClassical mechanicsStructural engineering

The invention discloses a mechanical arm tail end executing device. The mechanical arm tail end executing device comprises a hooke joint, a spherical hinge joint and a connecting sleeve. The hooke joint and the spherical hinge joint are installed at the left end and the right end of the connecting sleeve correspondingly. The connecting sleeve comprises a hooke joint side connecting rod, a spherical hinge side connecting rod, a first fastening flange, a supporting sleeve and a middle connecting rod. The hooke joint side connecting rod and the spherical hinge side connecting rod are installed at the left end and the right end of the supporting sleeve correspondingly. The middle of the supporting sleeve is hollow. A plurality of through holes are formed in the supporting sleeve. The middle connecting rod is installed in the supporting sleeve. The first fastening flange is fixed to the right wall of the spherical hinge side connecting rod. A connecting pipe is arranged in the middle of the top end of the supporting sleeve. The mechanical arm tail end executing device is compact in structure, small in occupied space, wide in movement range, flexible in movement and capable of achieving the six-freedom-degree movement function of the tail end of the executing device.

Owner:洛阳尚奇机器人科技有限公司

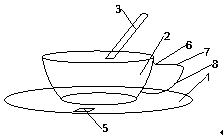

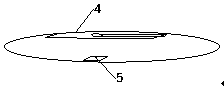

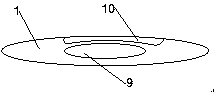

Glass heat insulation mute coffee cup

The invention relates to a glass heat insulation mute coffee cup. The glass heat insulation mute coffee cup comprises a coffee tray, a coffee cup, a coffee spoon, a mute spacer and an anti-skid gasket; the mute spacer is placed on the surface of one side of the upper part of the coffee tray; the anti-skid gasket is arranged on the surface of the other side of the coffee tray; the coffee cup is placed and connected to the surface of the upper part of the coffee tray; the surface of one side of the coffee spoon is placed inside the coffee cup; a cup handle on the coffee cup comprises a force bearing arc rod, a slave force cup handle bracket and a master force cup handle bracket; one end of the force bearing arc rod is fixedly connected to the surface of the upper part of the coffee cup; oneend of the force bearing arc rod is fixedly connected to the surface of one end of the slave force cup handle bracket; the surface of the other end of the slave force cup handle bracket is fixedly connected to the surface of one end of the master force cup handle bracket; and the surface of the other end of the master force cup handle bracket is fixedly connected to the surface of the coffee cup.

Owner:江苏瑞泰玻璃制品有限公司

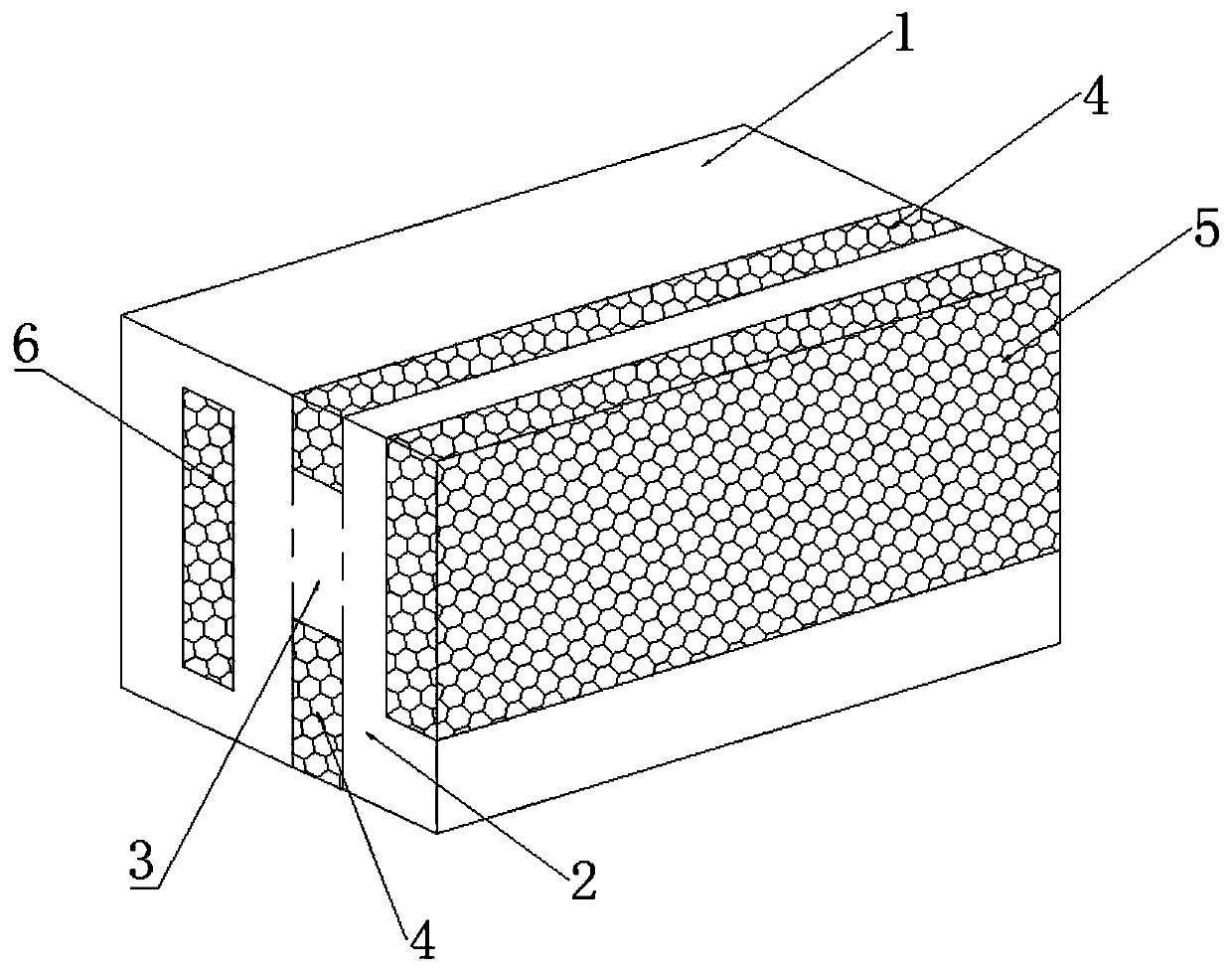

Compound type ribbed one-side thermal insulation block

ActiveCN110374251AReduce heat exchangeReduce crackingConstruction materialWallsThermal insulationEngineering

The invention discloses a compound type ribbed one-side thermal insulation block. The one-side thermal insulation block comprises a block body, a connecting rib, an overhanging rib, an inter-rib thermal insulation material and an outer thermal insulation material; the block body, the connecting rib and the overhanging rib are of an integral structure; the cross section of the overhanging rib is inan L shape; the overhanging rib includes an upright part and an overhanging part located at the lower end of the upright part and extends out to the outer side; the upright part of the overhanging rib is connected with the block body through the connecting rib; the upper edge and the lower edge of the connecting rib are filled between the upright part and the block body through the inter-rib thermal insulation material; the outer side of the overhanging rib is provided with the outer thermal insulation material; the overhanging part bears the bottom part of the outer thermal insulation material; and the outer thermal insulation material and a cold and heat bridge thermal insulation layer are located on the same layer and are identical in thickness. The one-side thermal insulation block iscapable of reducing cracks brought to an outer wall by shrinkage and expansion of different materials under temperature variation.

Owner:安徽铭能保温科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com