A street lamp installation device and installation method thereof

A technology for installing devices and street lamps, which is applied to hoisting devices, hoisting devices, towers, etc., can solve the problems of dangerous construction process and unstable structure, and achieve the effect of improving safety, ensuring stability and uniform force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

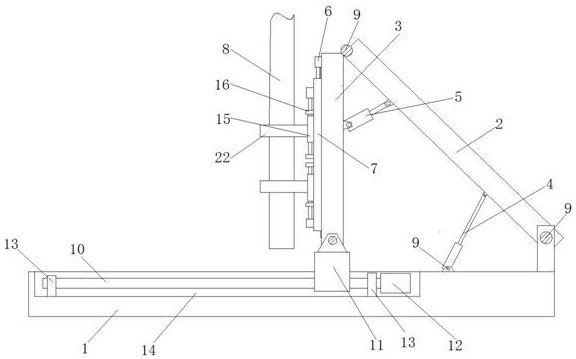

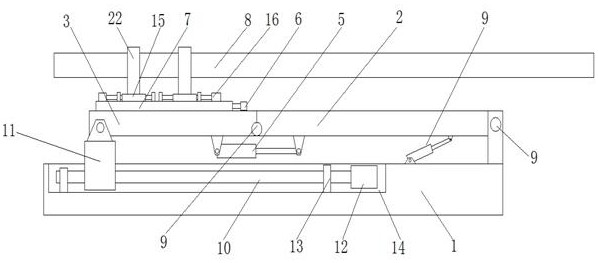

[0043] A street lamp installation device, including a base 1, a support I2, a support II3, a driving device I and a driving device II, the base 1 is in a "concave" shape, one end of the support I2 is hinged to the base 1, and the support I2 The other end of the drive device I is hinged to one end of the support member II3, one end of the drive device I is hinged to the base 1, and the other end is hinged to the support member I2, the drive device I can drive the support member I2 to rotate, and the two ends of the drive device II are respectively connected to the support Part I2 and support part II3 are hinged, and the driving device II can drive support part I2 and support part II3 to rotate around the hinge between support part I2 and support part II3, and a guide device is provided at the other end of support part II3 , the guiding device is in contact with the base 1, the guiding device can slide along the base 1, a sliding plate 7 is installed on the support member II3, th...

Embodiment 2

[0061] This embodiment is basically the same as Embodiment 1, the difference is that the driving devices I, II and III are pneumatic driving devices.

[0062] Wherein, the driving device IV can also be a pneumatic or hydraulic driving device. In actual use, the air cylinder or hydraulic cylinder is fixed on the base 1, and then the movable end of the air cylinder or hydraulic cylinder is connected to the guide device, that is, it is connected to the straight line Bearings are connected.

Embodiment 3

[0064] This embodiment is basically the same as Embodiment 1, the difference is that the guide device includes guide rails and rollers, the guide rails are installed on the base 1, the rollers are installed at the end of the support member II3, and the rollers can be Roll on rails.

[0065] In this way, the roller is connected to the lead screw nut 11; in actual use, the rotating shaft 9 of the roller can be extended and then connected to the lead screw nut 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com