Patents

Literature

30results about How to "Smooth alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

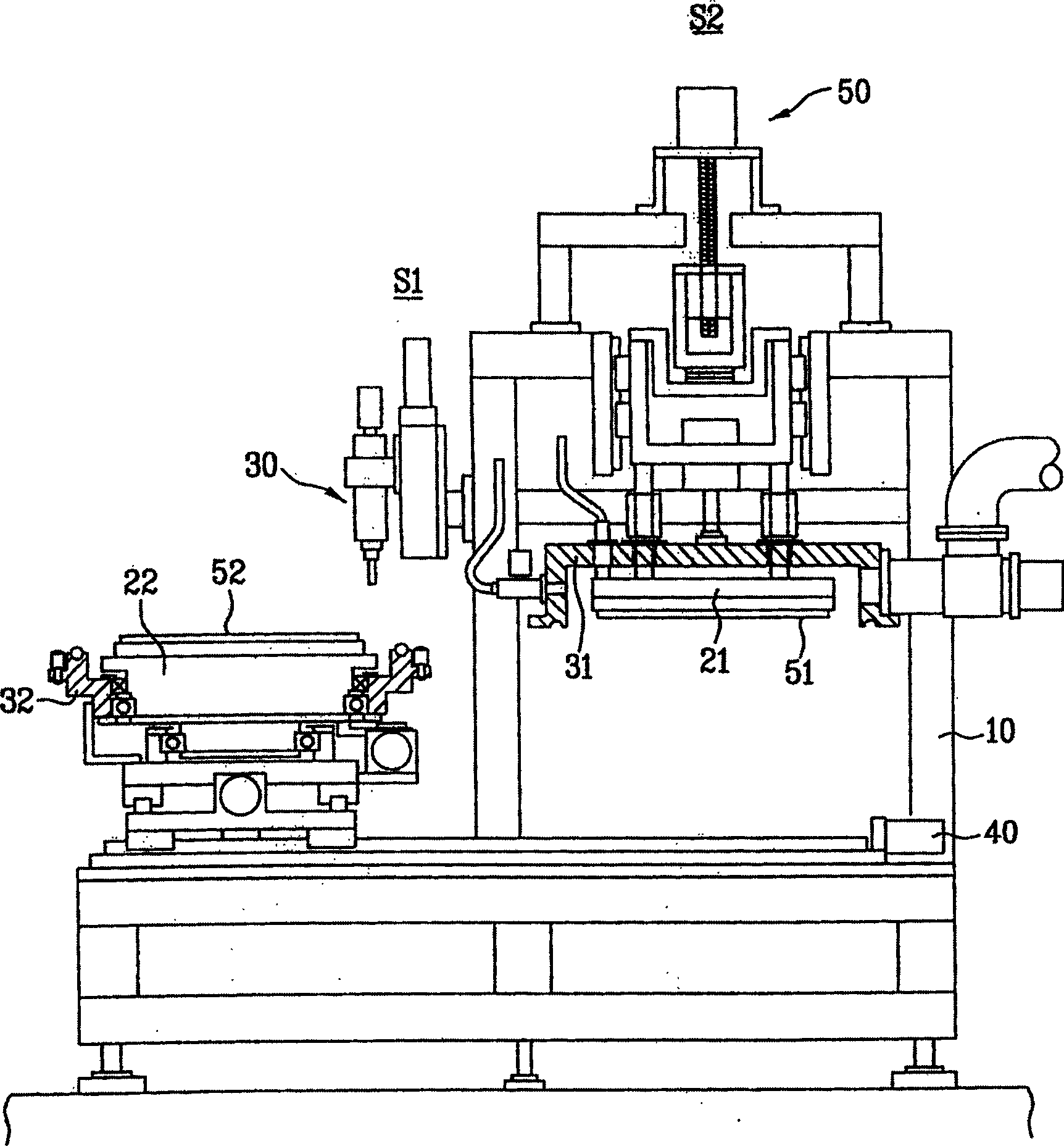

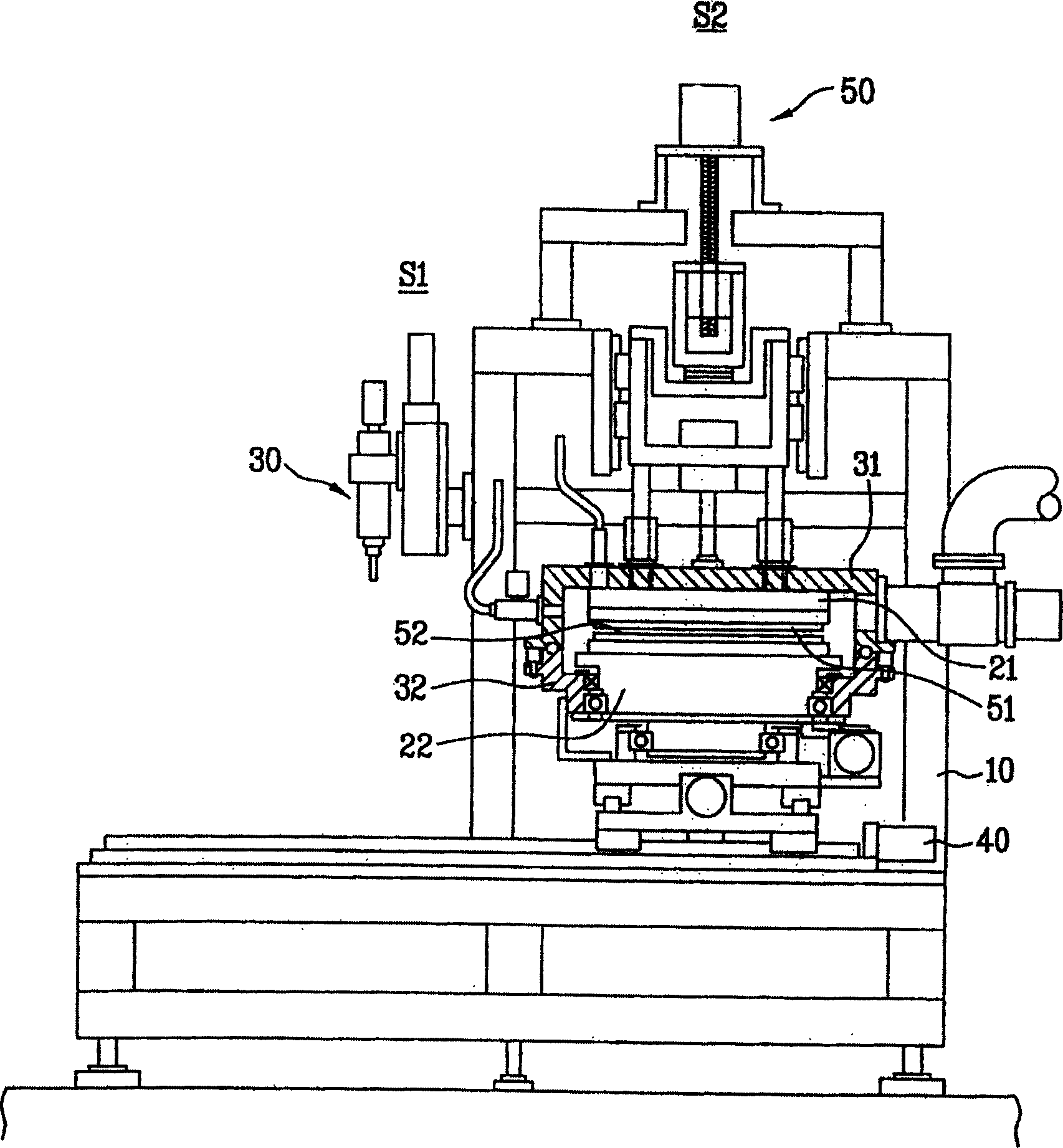

Device and method for fabricating liquid-crystal display device

InactiveCN1504795ASimplify the layout processSimple structureStatic indicating devicesAdhesivesInterior spaceLiquid-crystal display

Owner:LG DISPLAY CO LTD

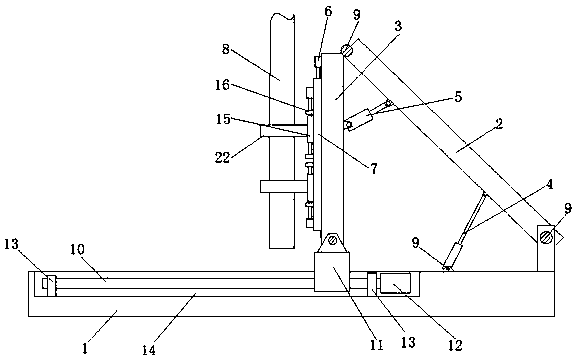

Mounting device and mounting method of street lamp

Owner:华体智城系统集成有限公司

Bicolor die sliding block structure and sliding block core pulling mechanism

The invention discloses a bicolor die sliding block structure. The bicolor die sliding block structure comprises a sliding block body, an extending platform and a telescopic buckle mechanism. The extending platform comprises a guiding-in hole which is in a long bar shape. The telescopic buckle structure comprises a buckle. The buckle comprises a buckle body and an extending arm. A containing space partly containing the side wall of an inclined guide pillar is formed between the extending arm and the buckle body. The side wall of the inclined guide pillar abuts against the extending arm. The inclined guide pillar drives the extending arm so as to achieve the side core pulling action. The invention further discloses a sliding block core pulling mechanism. The sliding block core pulling mechanism comprises the inclined guide pillar and the bicolor die sliding block structure. The bicolor die sliding block structure is connected to a rear die in a sliding manner, and the inclined guide pillar is fixed to a front die. The inclined guide pillar is guided in the extending platform from the guiding-in hole. By means of the technical scheme, it can be ensured that in the second-time injection molding process of a bicolor die, the inclined guide pillar can be accurately aligned with the guiding-in hole.

Owner:SHENZHEN SILVER BASIS TECH

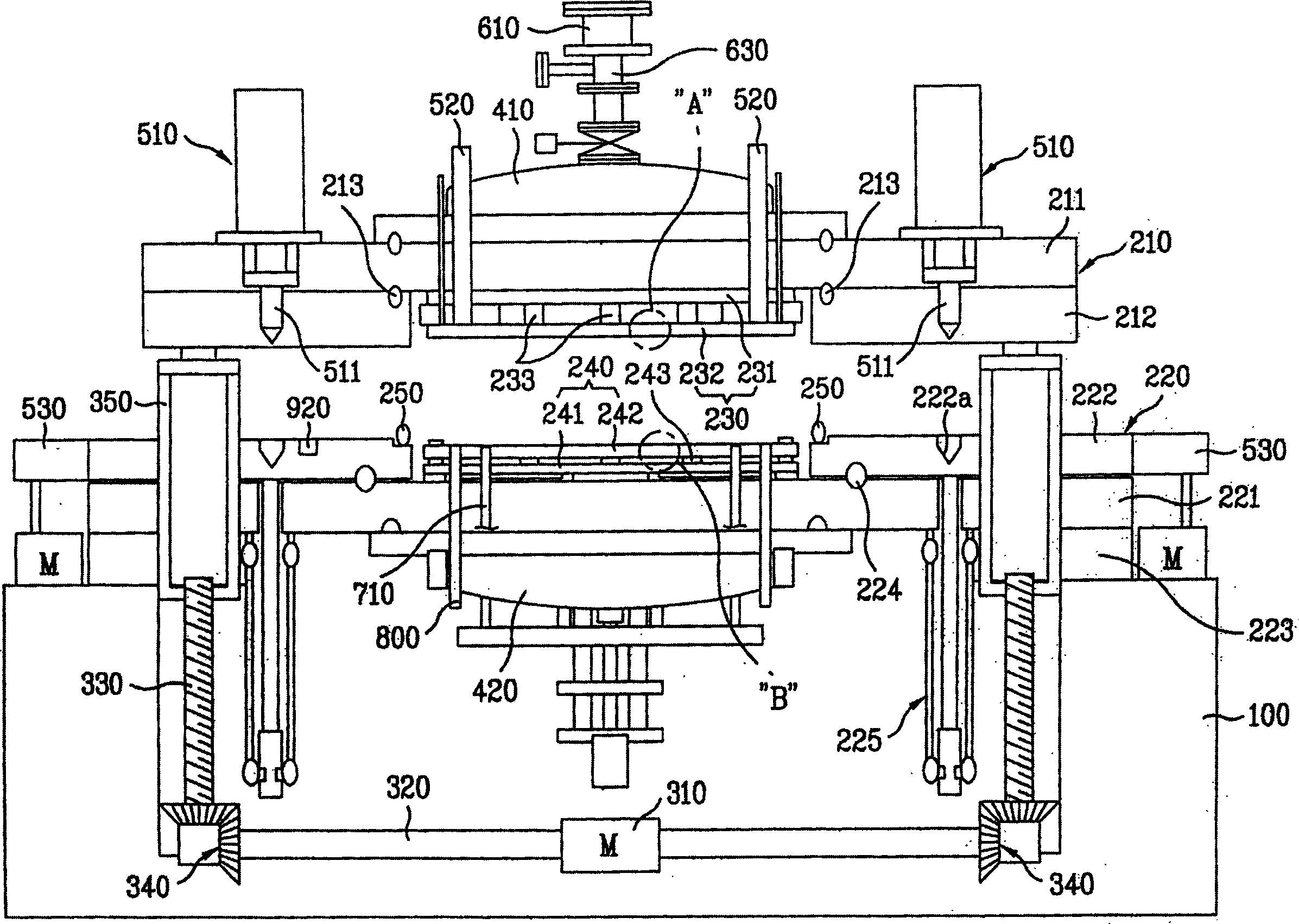

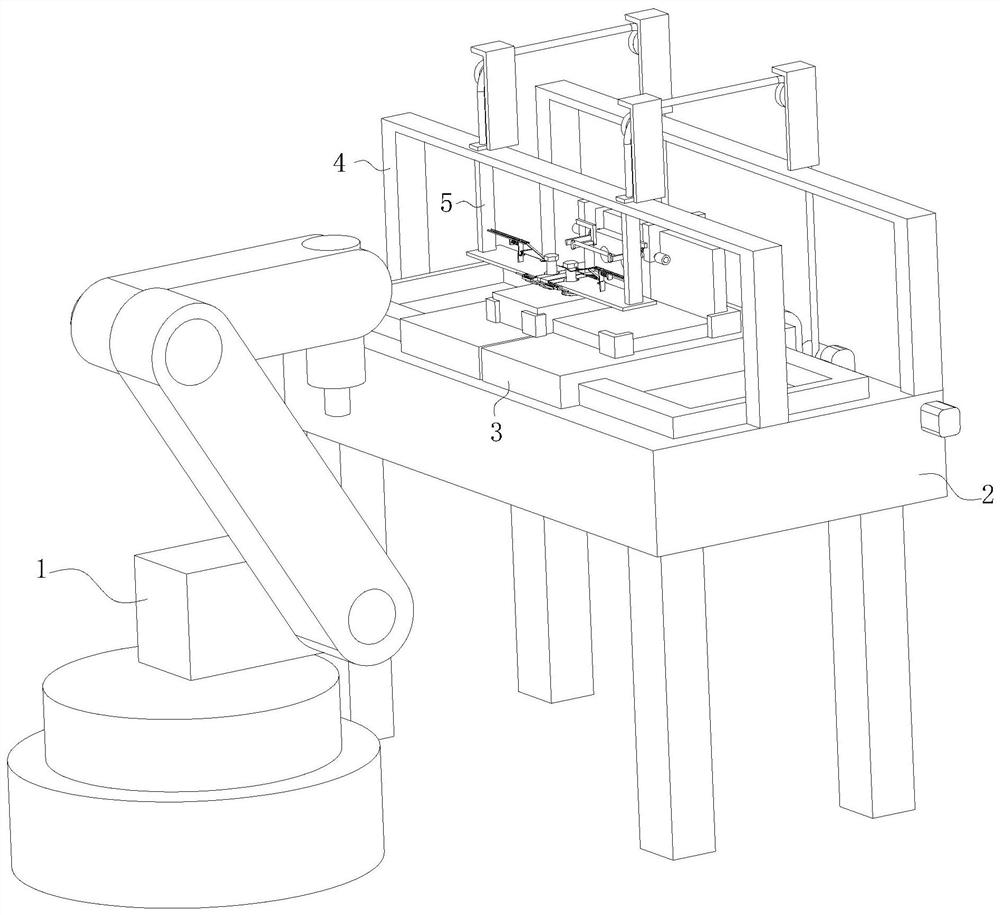

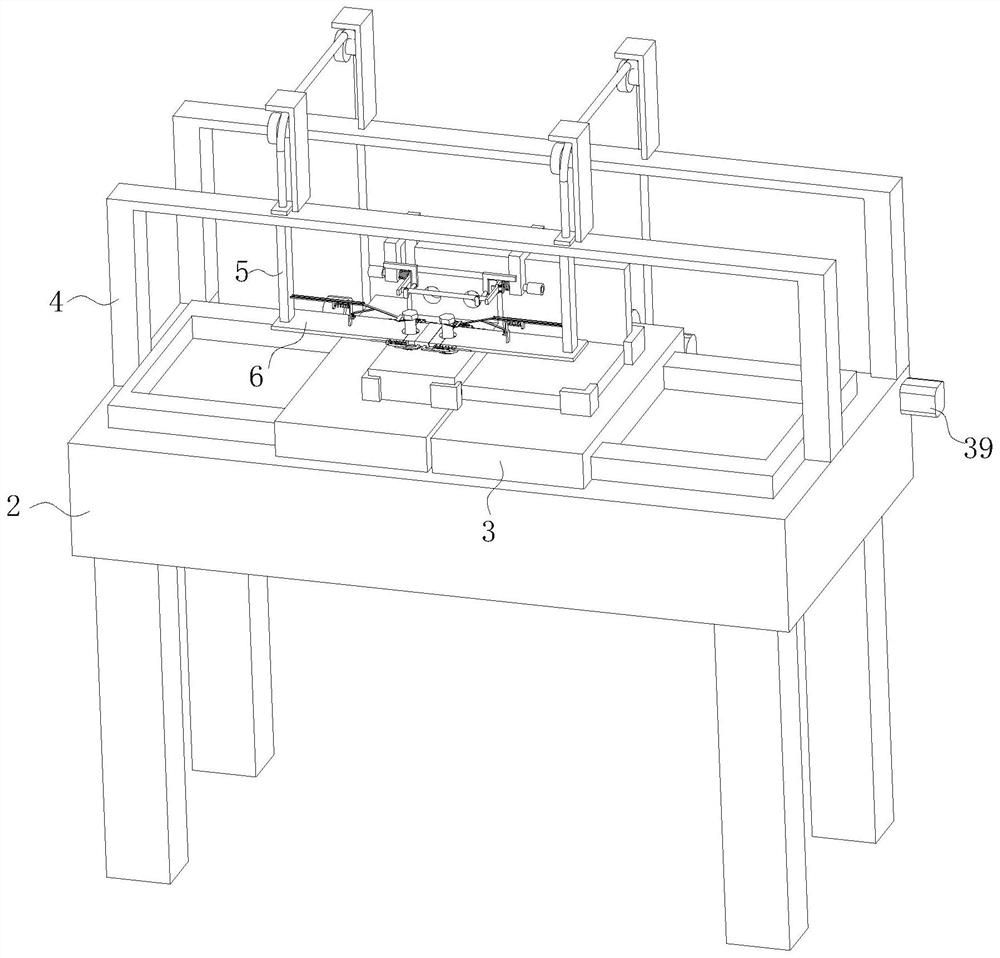

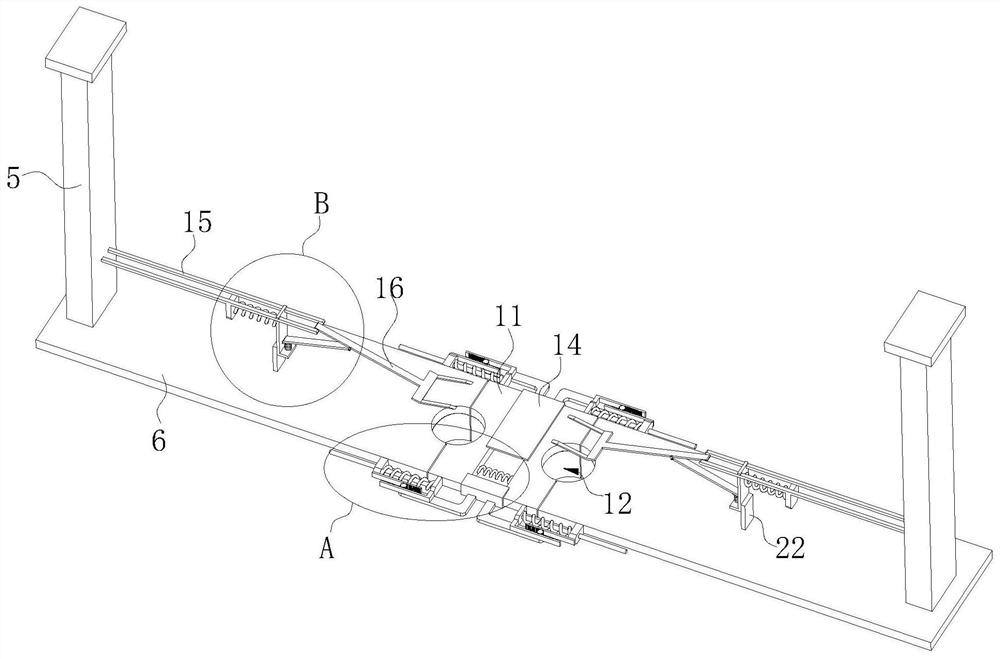

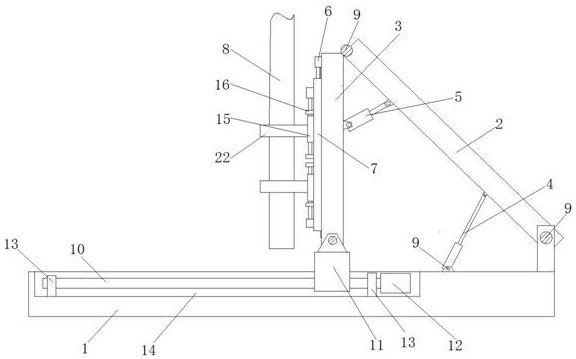

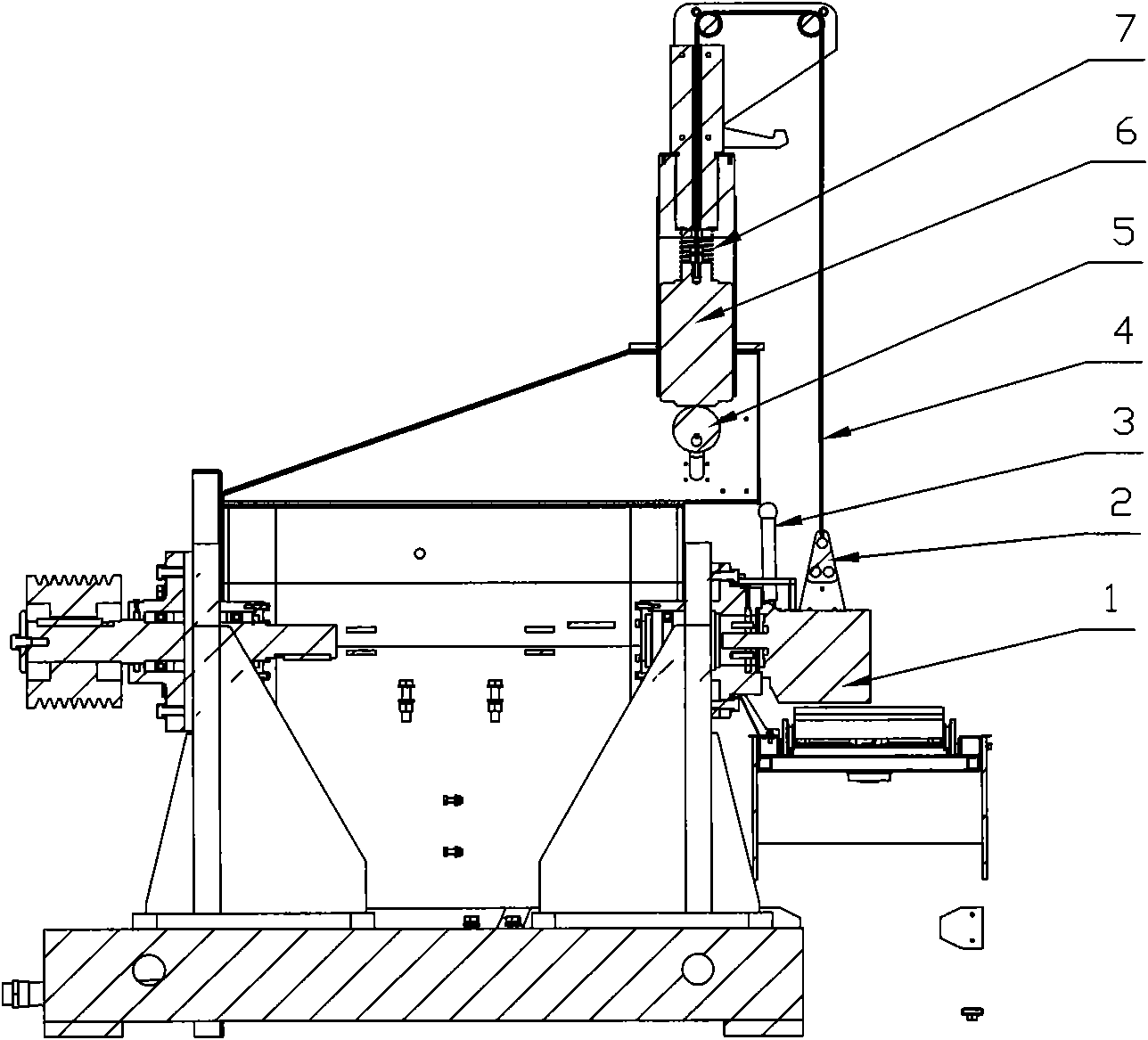

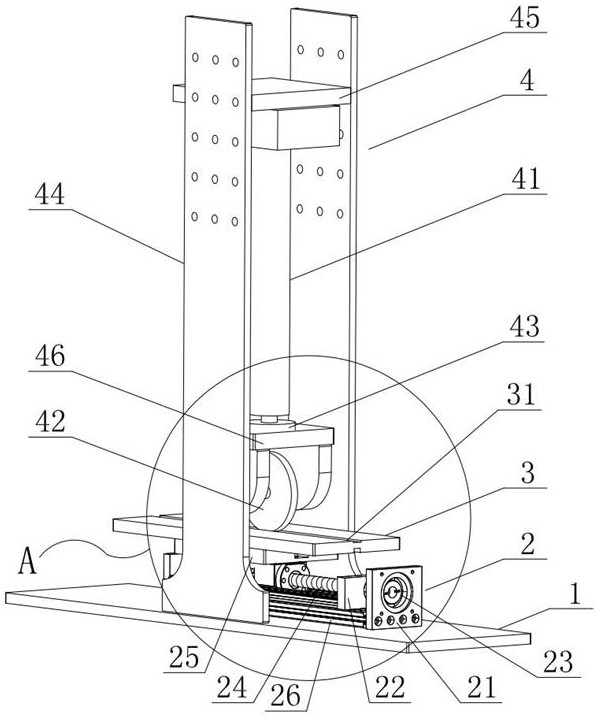

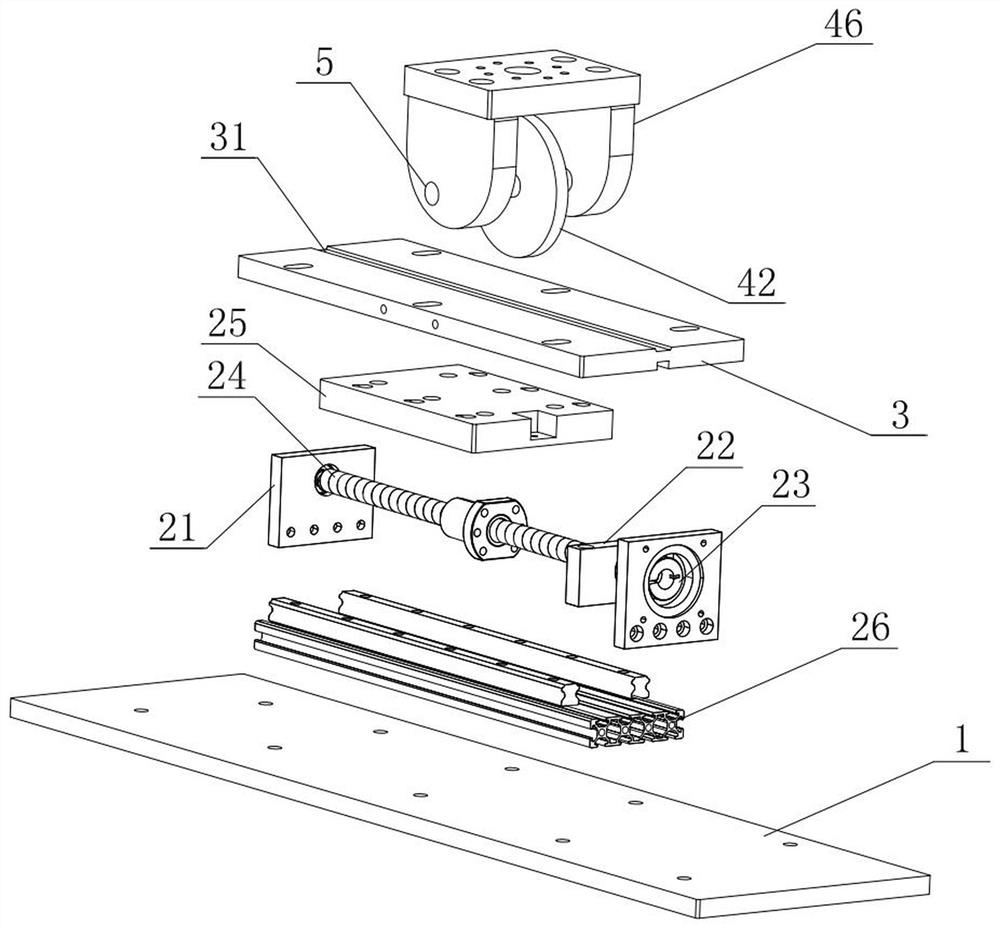

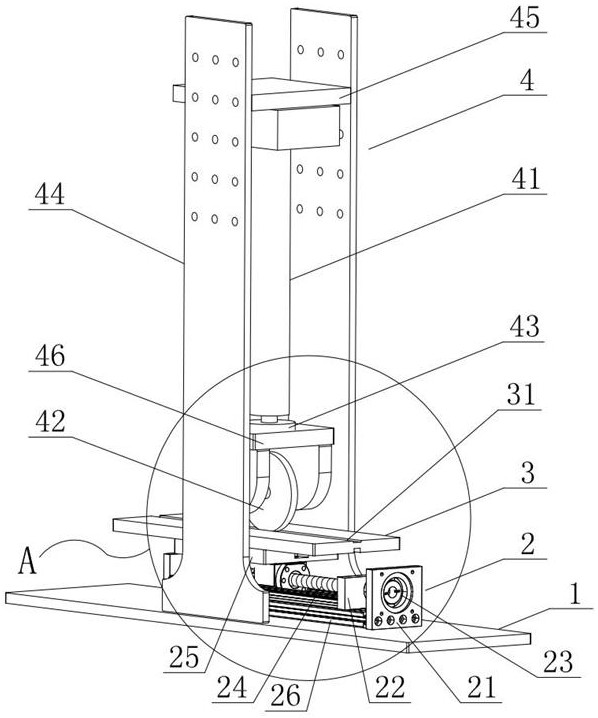

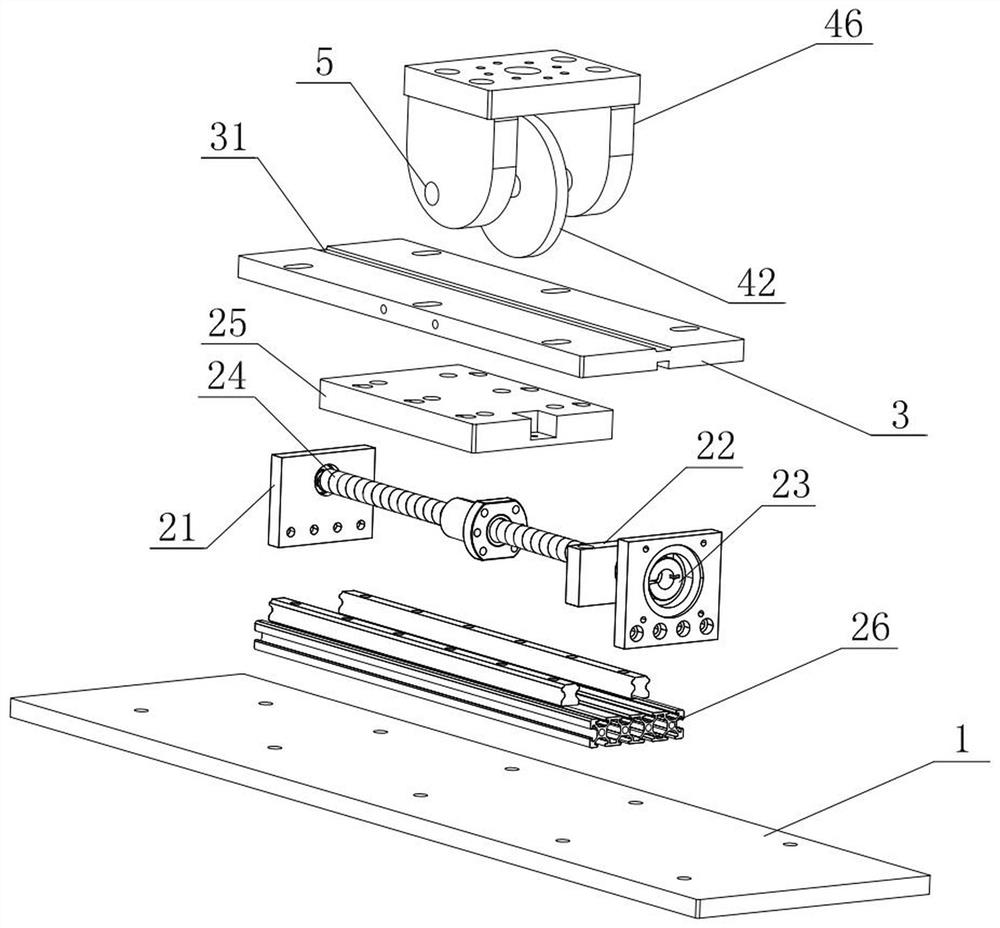

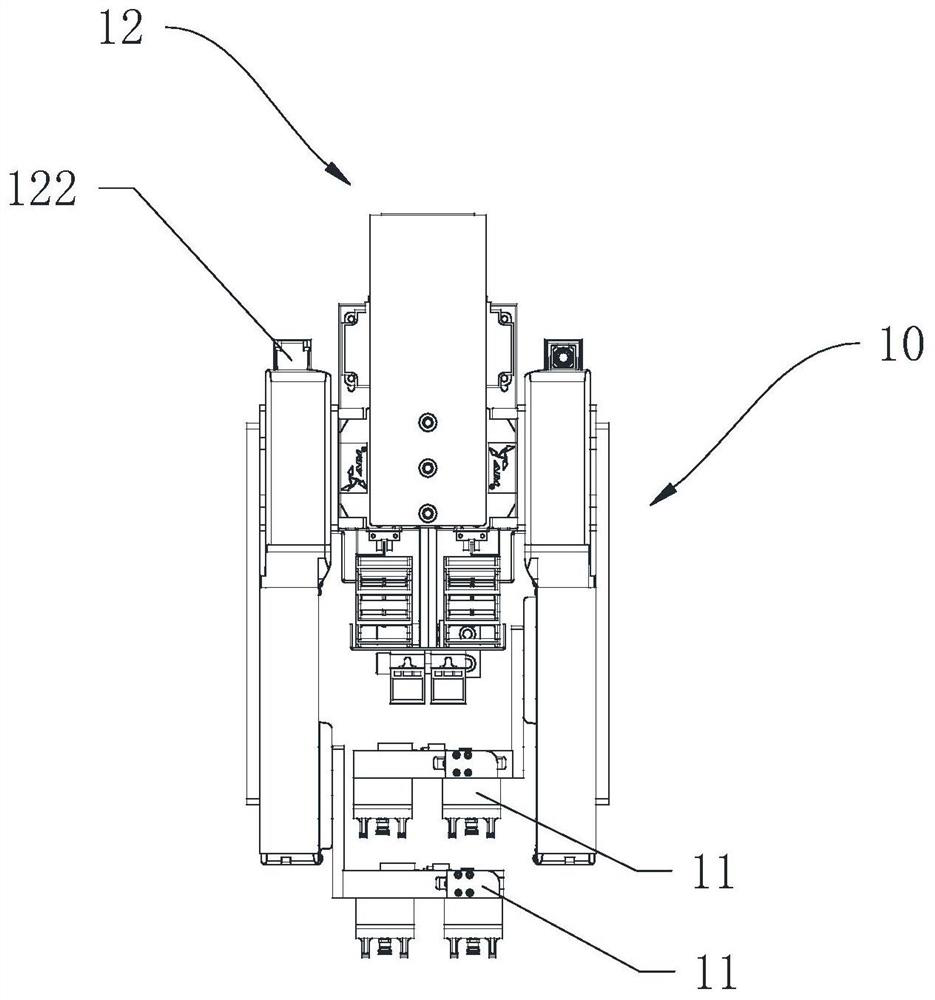

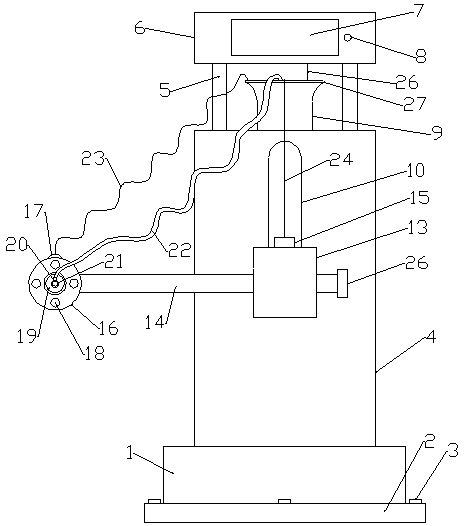

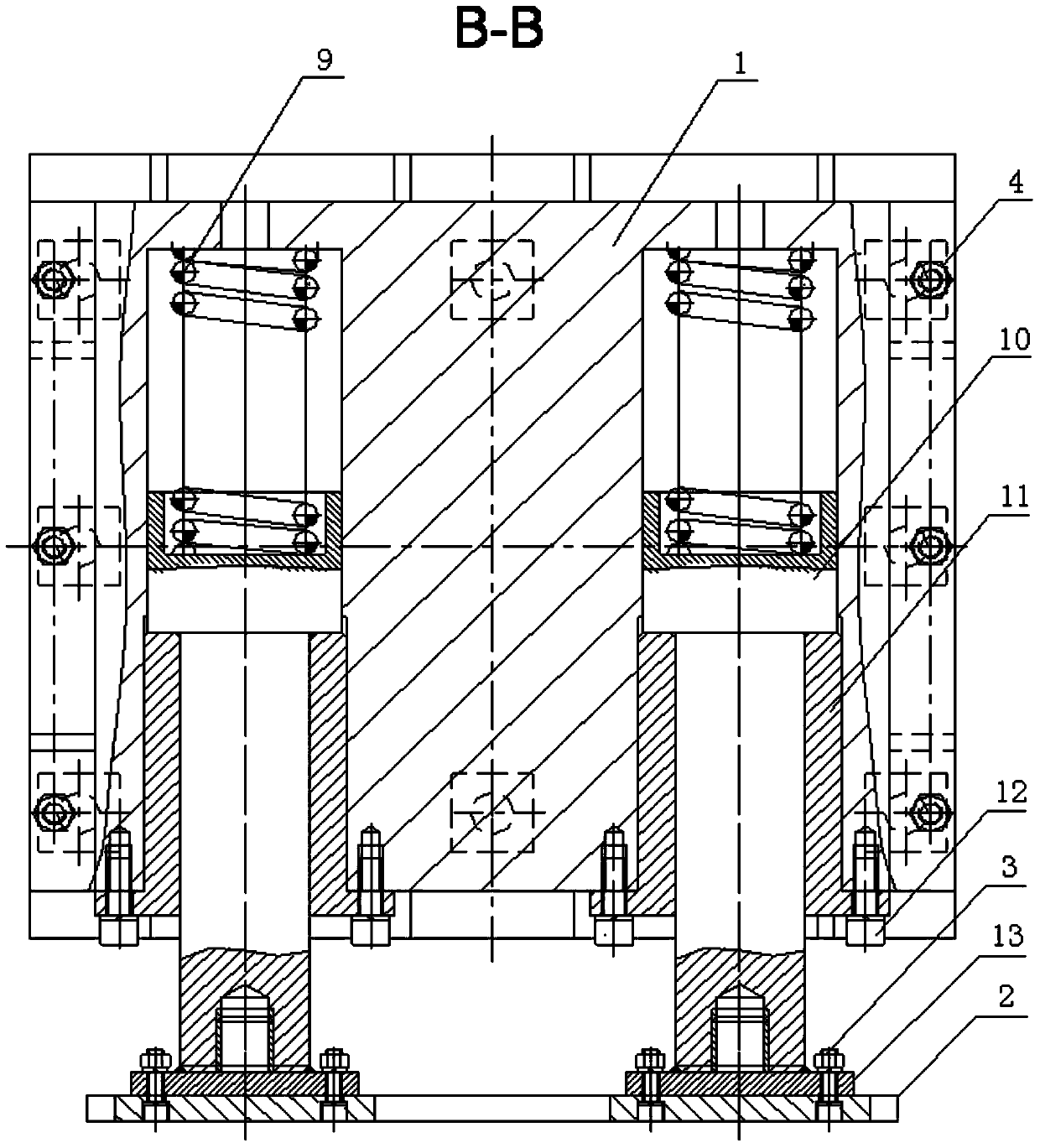

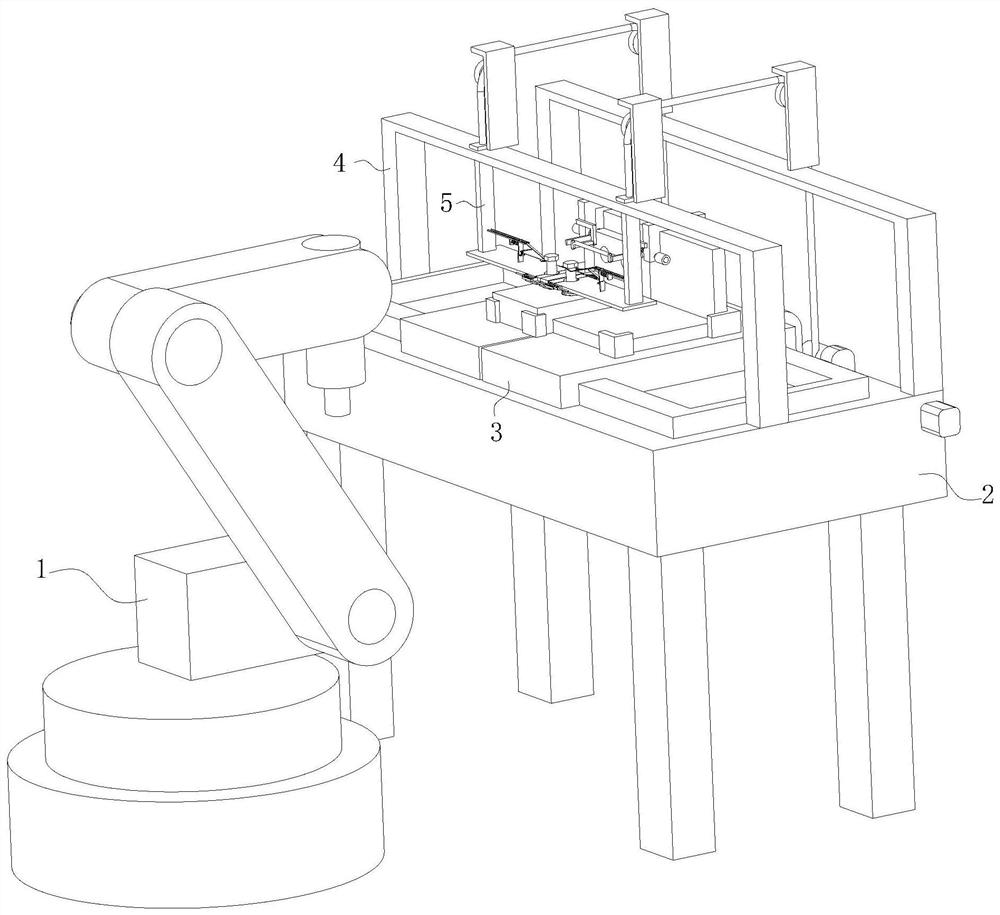

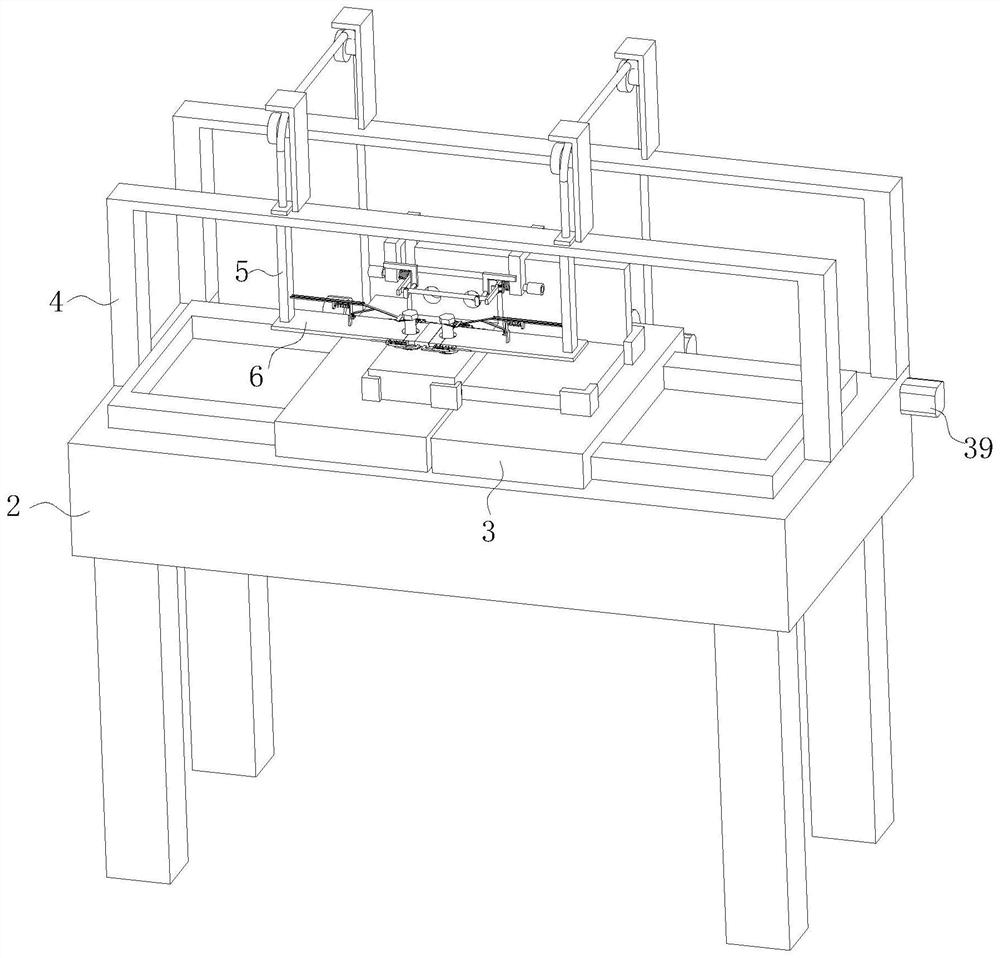

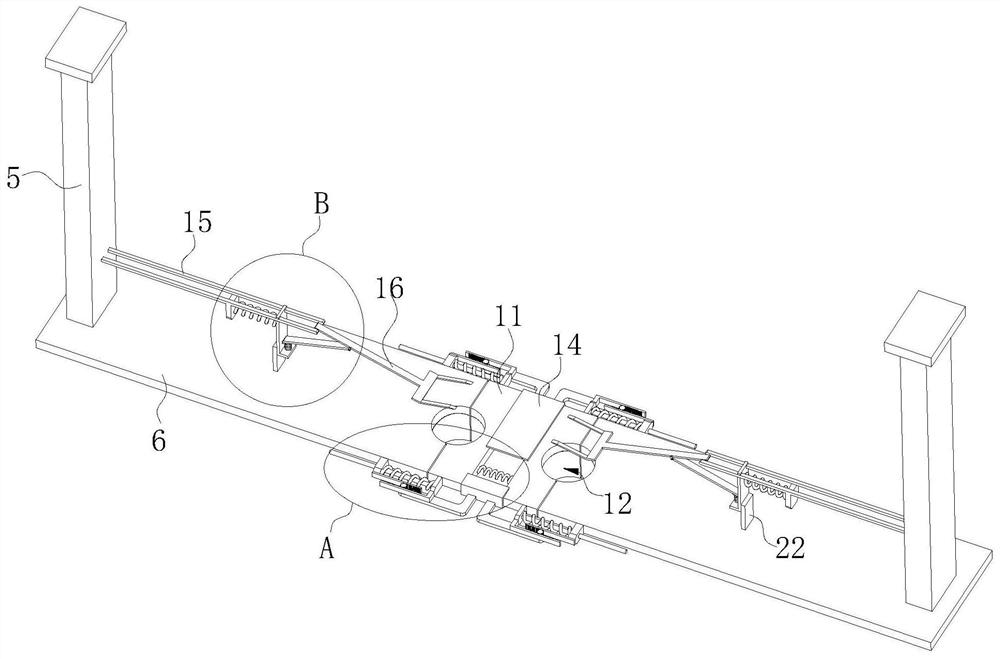

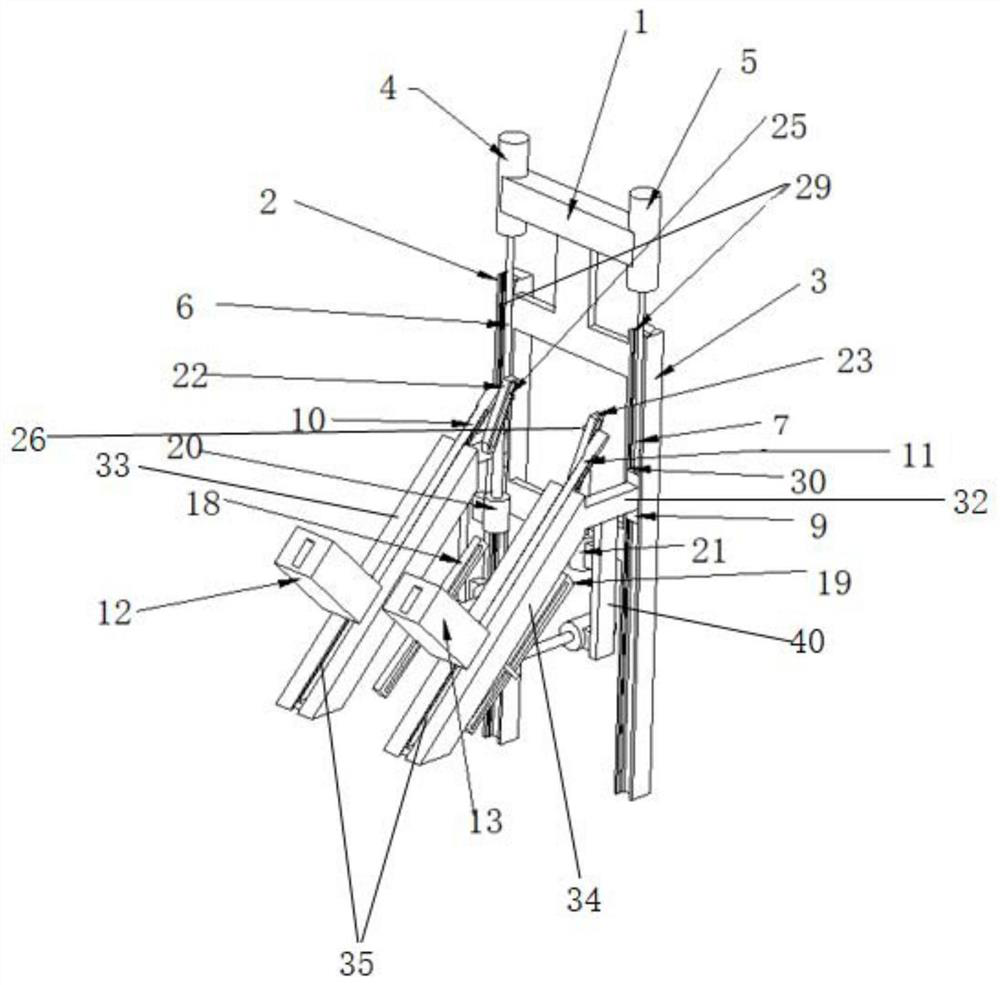

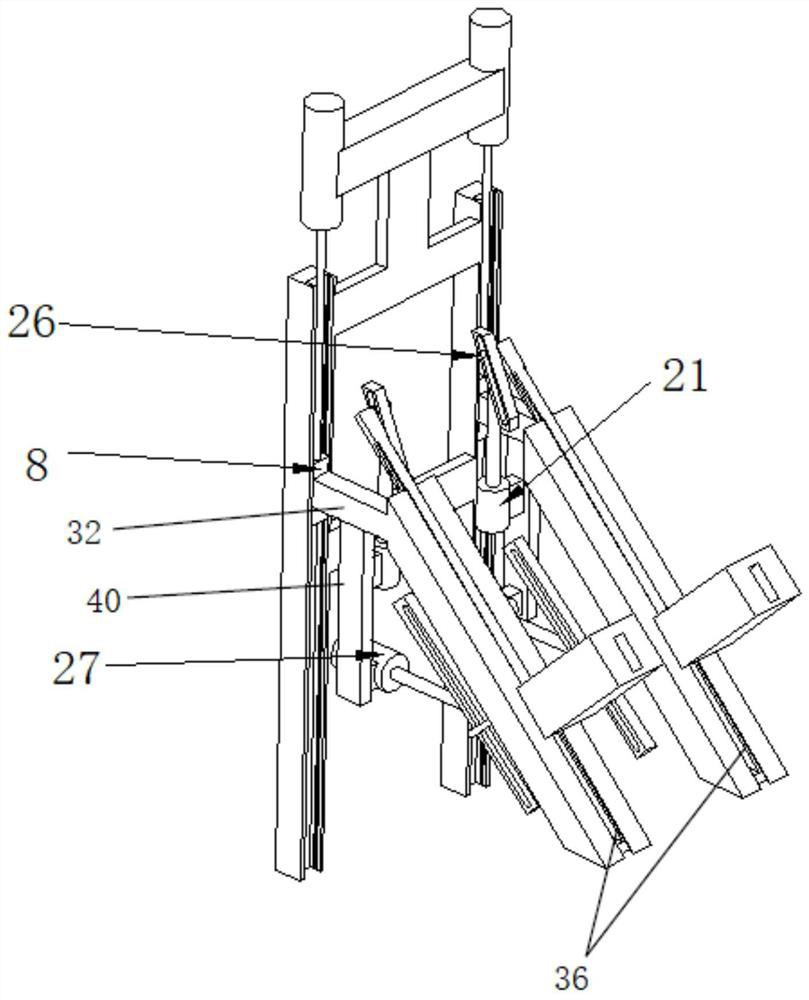

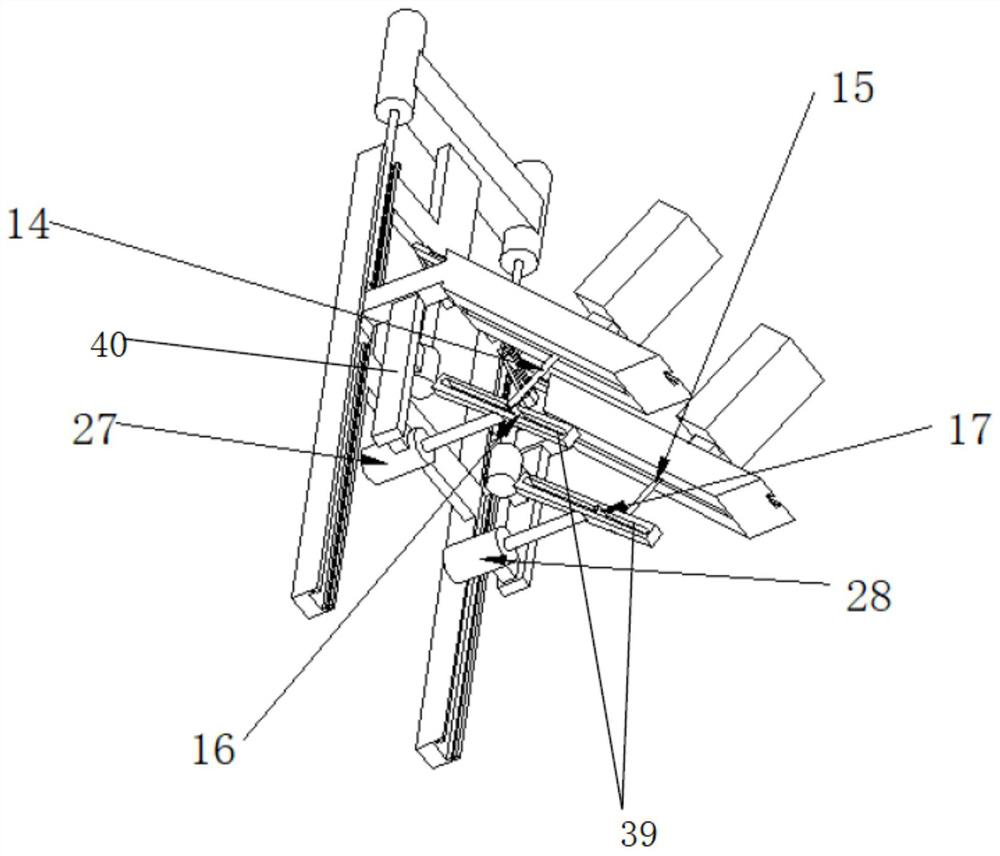

Precise six-degree-of-freedom assembly robot

InactiveCN113182832AEnsure safetyAvoid workpiece damageMetal working apparatusControl engineeringStructural engineering

The invention discloses a precise six-degree-of-freedom assembly robot, and belongs to the technical field of six-degree-of-freedom assembly robots. The precise six-degree-of-freedom assembly robot comprises a six-axis robot and an assembly table, wherein the six-axis robot is located on the front side of the assembly table; two symmetrically-arranged shelving plates are slidably connected to the top of the assembly table; and a driving mechanism used for driving the two shelving plates to move towards the middle of the assembly table simultaneously is connected to the top of the assembly table. When the six-axis robot is used for fastening a bolt every time, the bolt is guided through a through groove formed by a first connecting plate and a second connecting plate, so that the bolt can be smoothly aligned with a threaded hole of a workpiece every time, the bolt does not need to be clamped by the six-axis robot for thread fastening, the situation that the bolt cannot be aligned with the threaded hole of the workpiece and the workpiece is damaged due to track change caused by deviation or fixing looseness in operation of the six-axis robot is avoided, and the working safety is guaranteed.

Owner:北京瓢虫星球信息技术有限公司

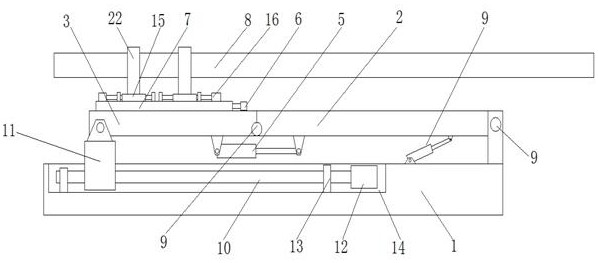

A street lamp installation device and installation method thereof

ActiveCN110182737BEasy to holdStable supportLifting devicesTowersStructural engineeringMechanical engineering

Owner:华体智城系统集成有限公司

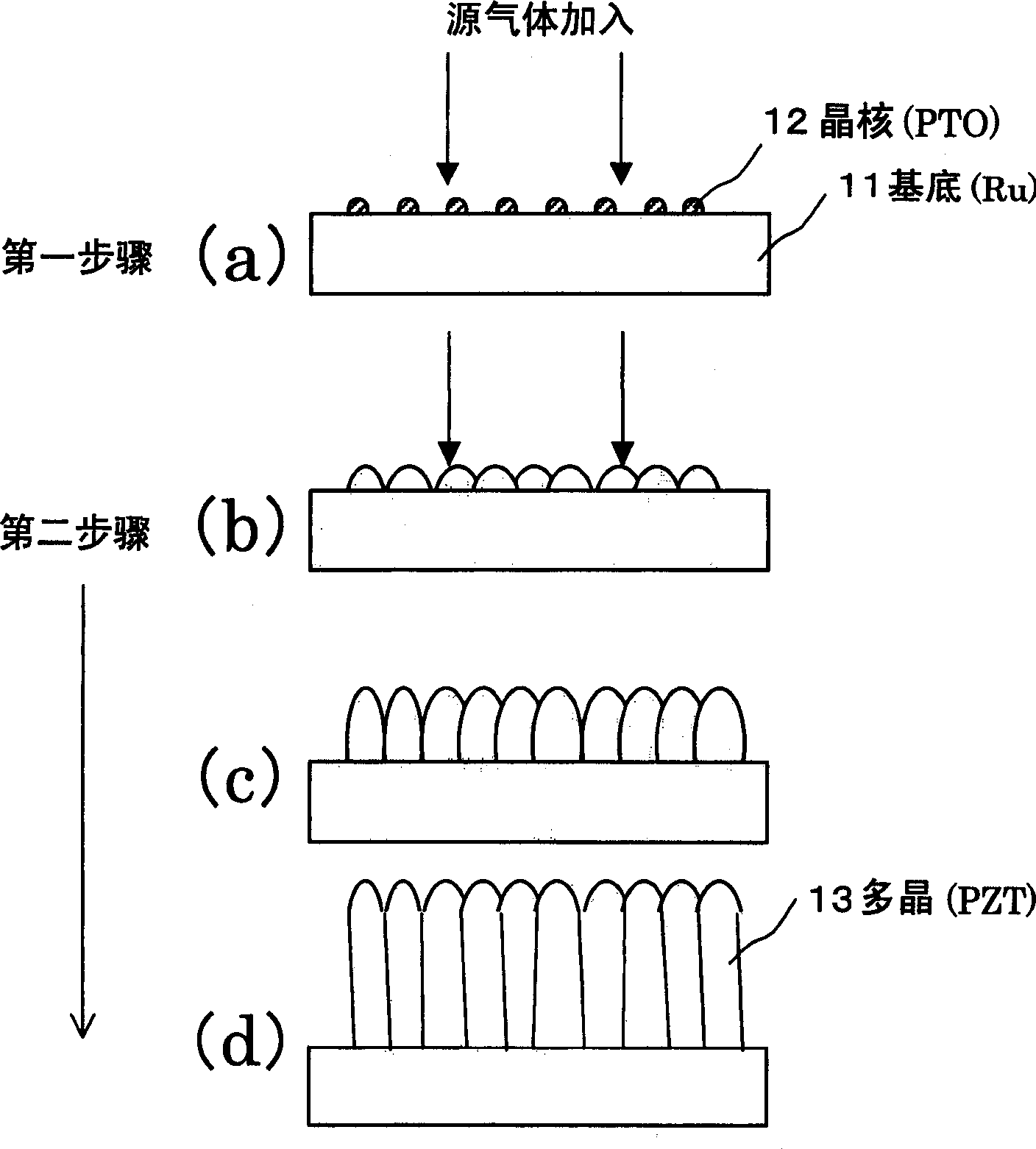

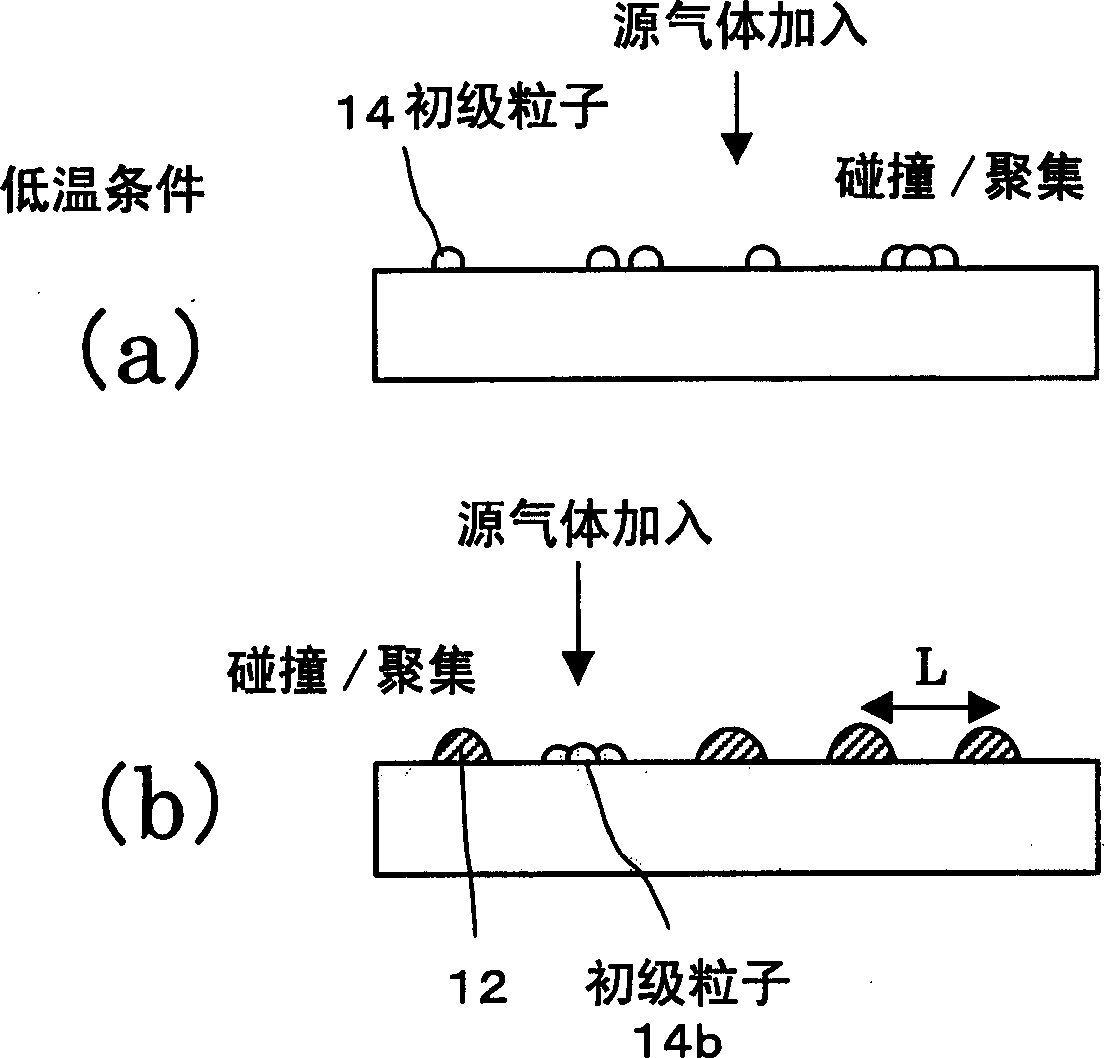

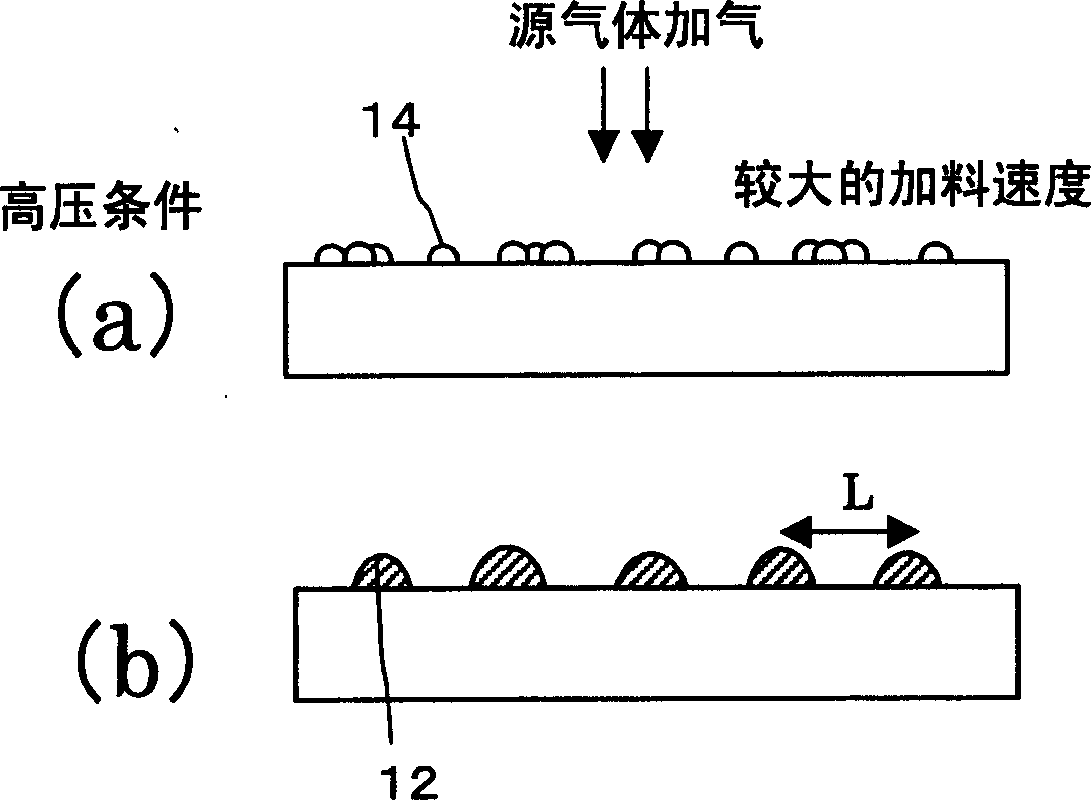

Vapor growth method for metal oxide dielectric film and PZT film

For forming a metal-oxide dielectric film having a perovskite type of crystal structure represented by ABO3 on a base conductor material using organometallic source gases, initial perovskite crystal nuclei or an initial amorphous layer having an amorphous structure are formed on the base conductor material under the first deposition conditions; and a film having a perovskite crystal structure is further grown on the initial crystal nuclei or the initial amorphous layer under the second deposition conditions. In the process, the first deposition conditions meet at least one of the requirements: (a) a lower substrate temperature than that in the second deposition conditions; and (b) a higher source gas pressure than that in the second deposition conditions. This process can be used to deposit a film such as PZT exhibiting a reduced leak current.

Owner:NEC CORP

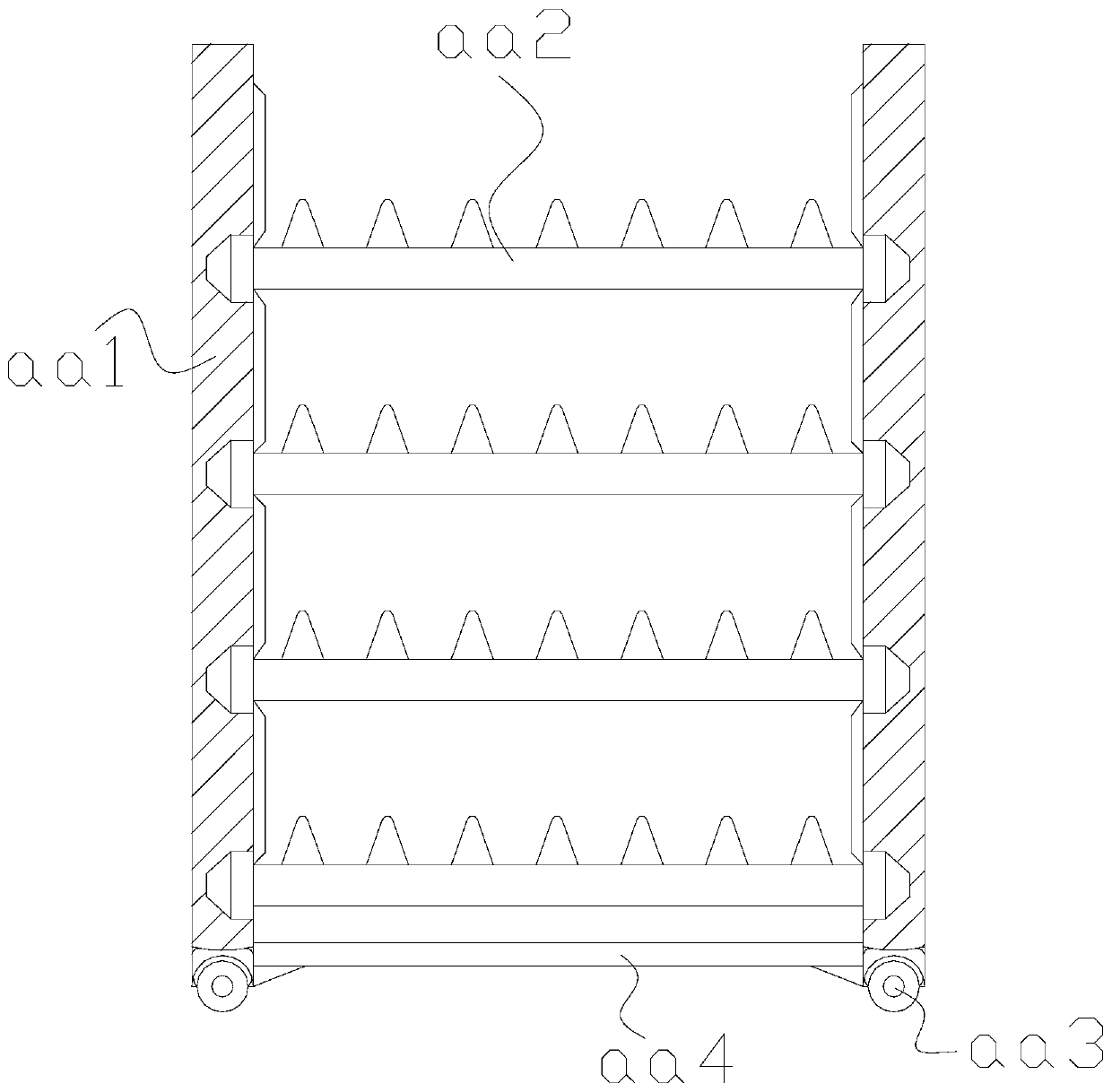

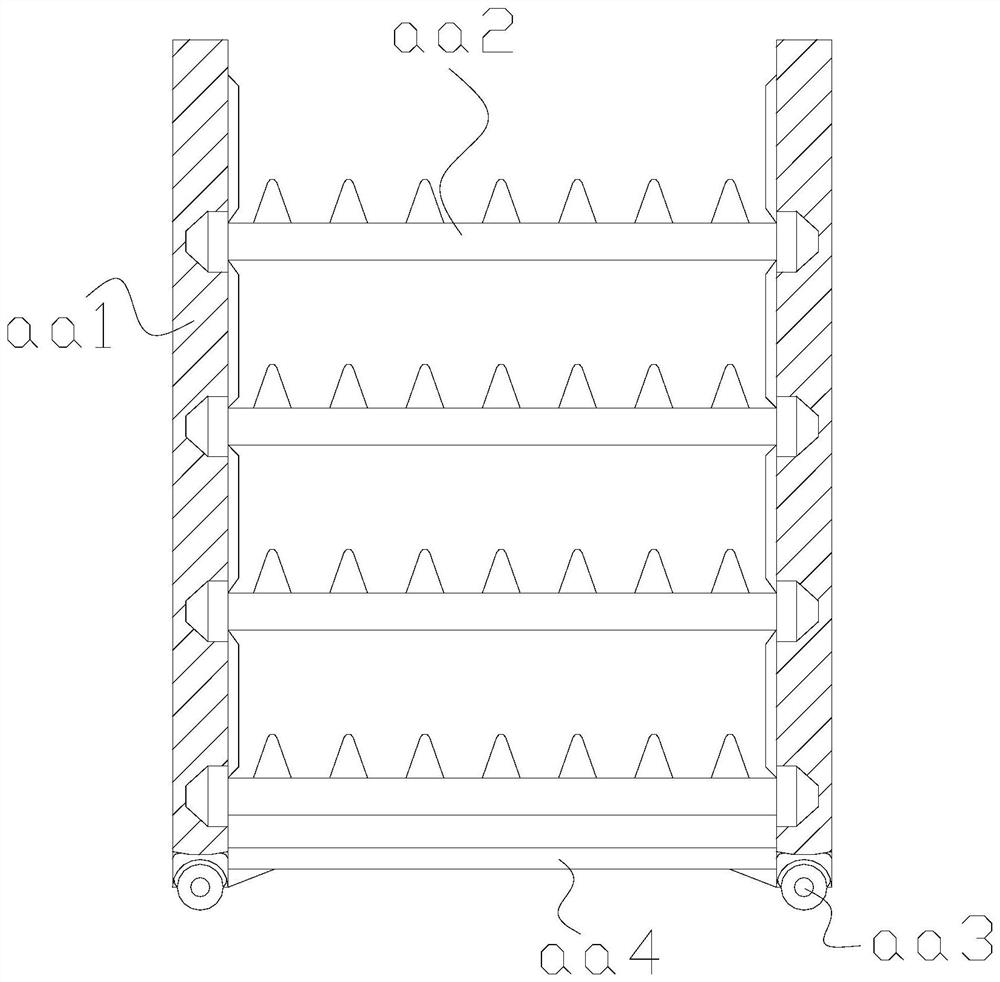

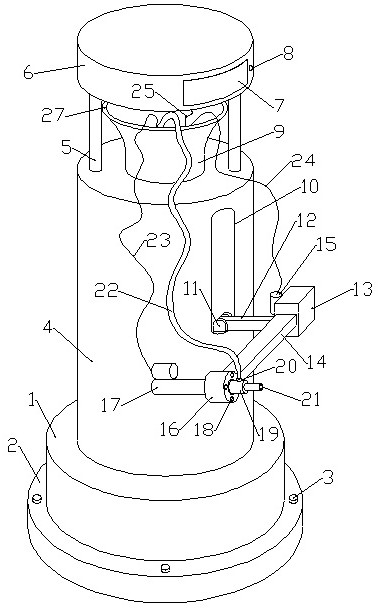

Point-to-point unmanned fragile product sparse transportation system

The invention discloses a point-to-point unmanned fragile product sparse transportation system. The system structurally comprises a storage groove, wherein the storage groove is embedded into a sparsegoods stabilizing groove, an article is placed in the storage groove, the article can be placed inside a soft groove, horizontal supporting rods are used for partitioning the storage groove into layers, corner clamping heads are used for fixing the position of the horizontal supporting rods and supporting rod layers, when the article is added into a pocket, a push bag is pressed, and can be generate certain deformation when being subjected to external force, and is timely reset when resistance is lost, a point alignment rod can be smoothly aligned with a specified point, the point alignment rod corresponds to an external corresponding point and is sucked and stops operation, due to the fact that a smooth strip slide along a movable core ball, a supporting curved adhesive layer on the other side abuts against the article through reverse force, so that the article cannot shake or dislocate, when point-to-point equipment is suddenly stopped, an inner soft layer can be pushed through theinner article through inertia, and the article is fixed again, so that the article can be prevented from being excessively staggered or misplaced and impacted.

Owner:温州博辉新材料科技有限公司

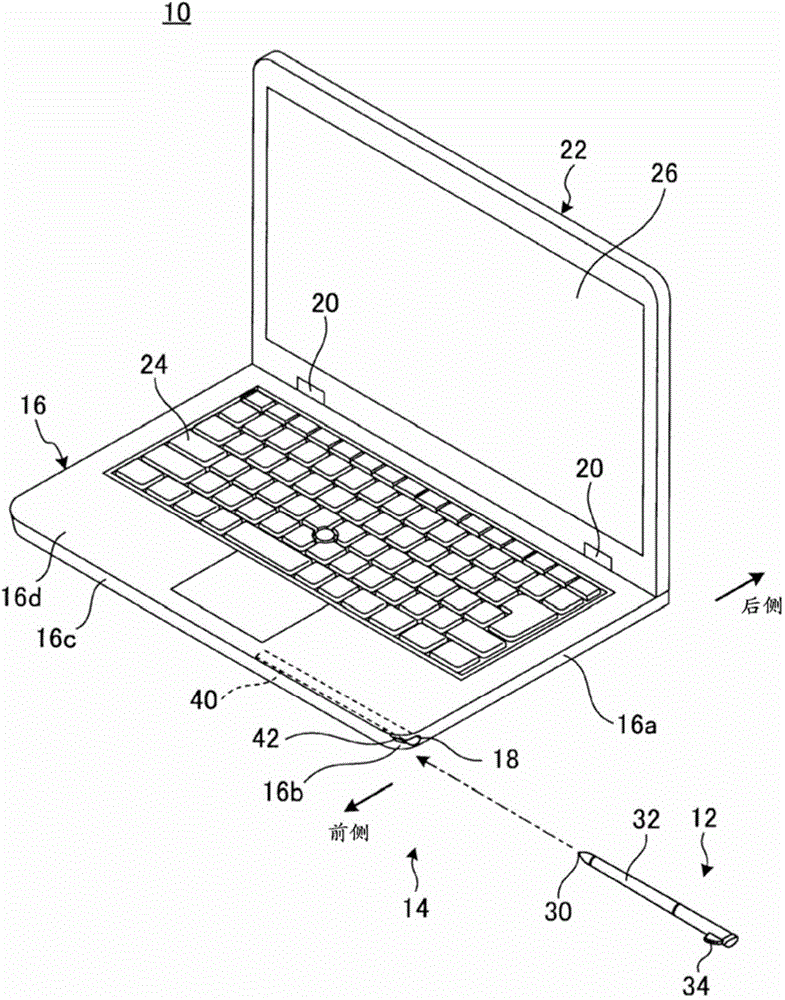

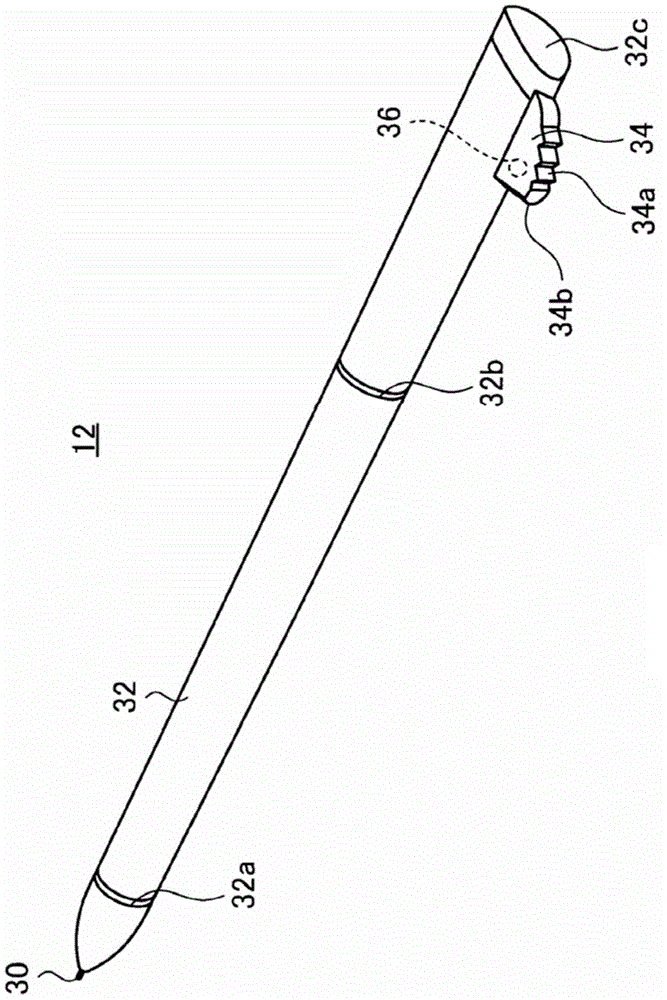

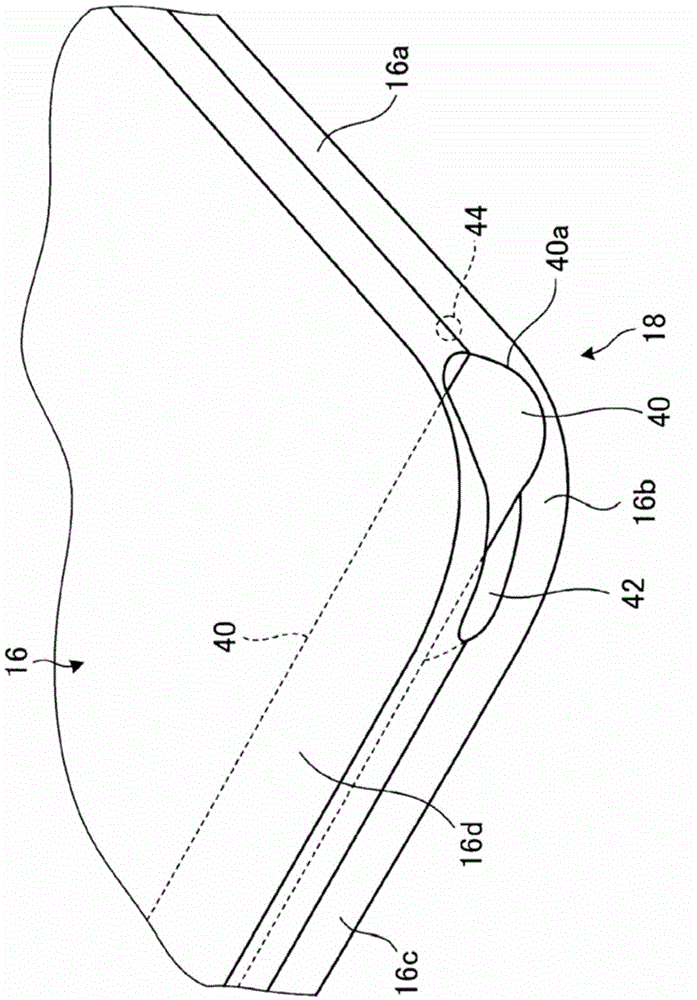

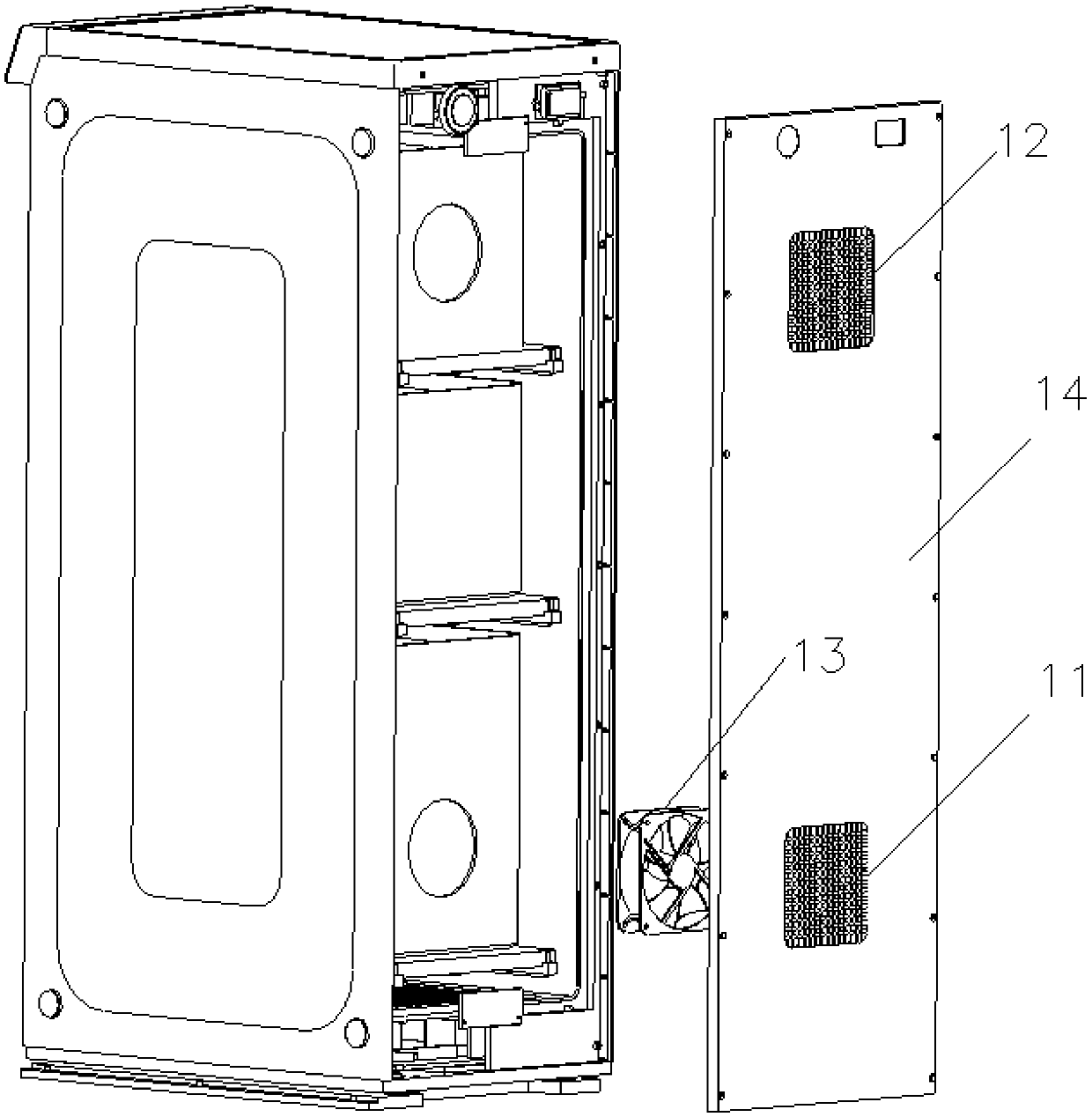

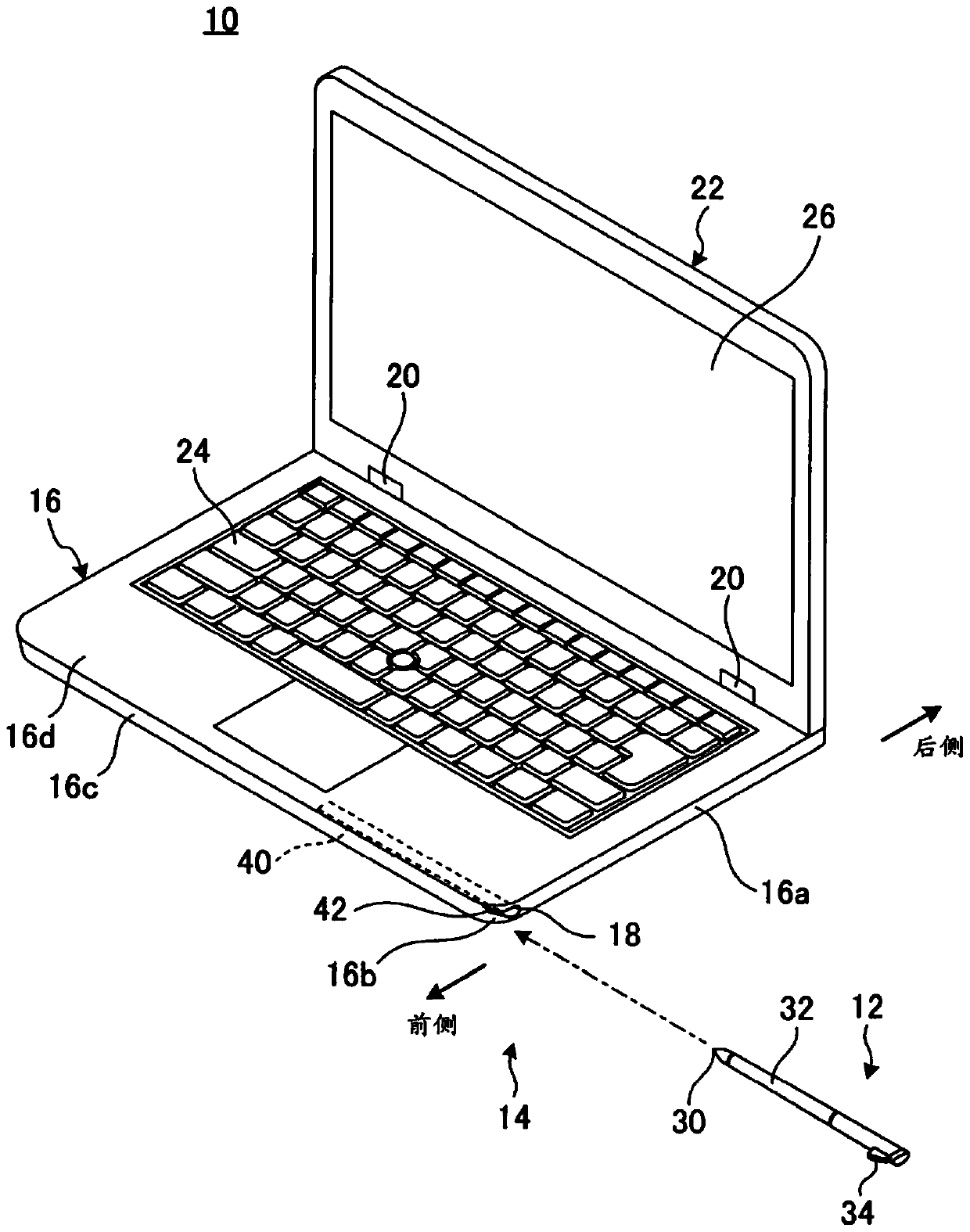

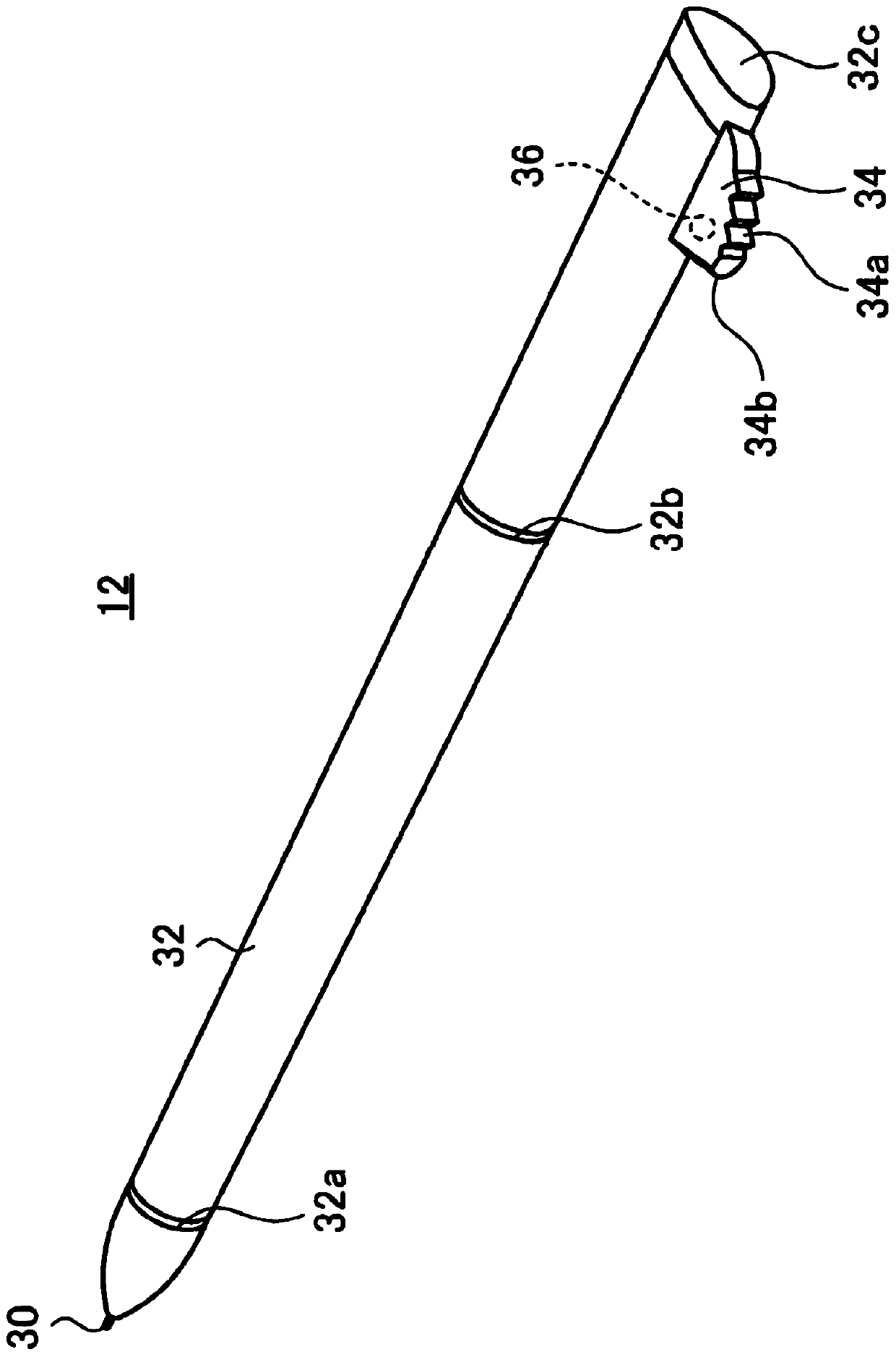

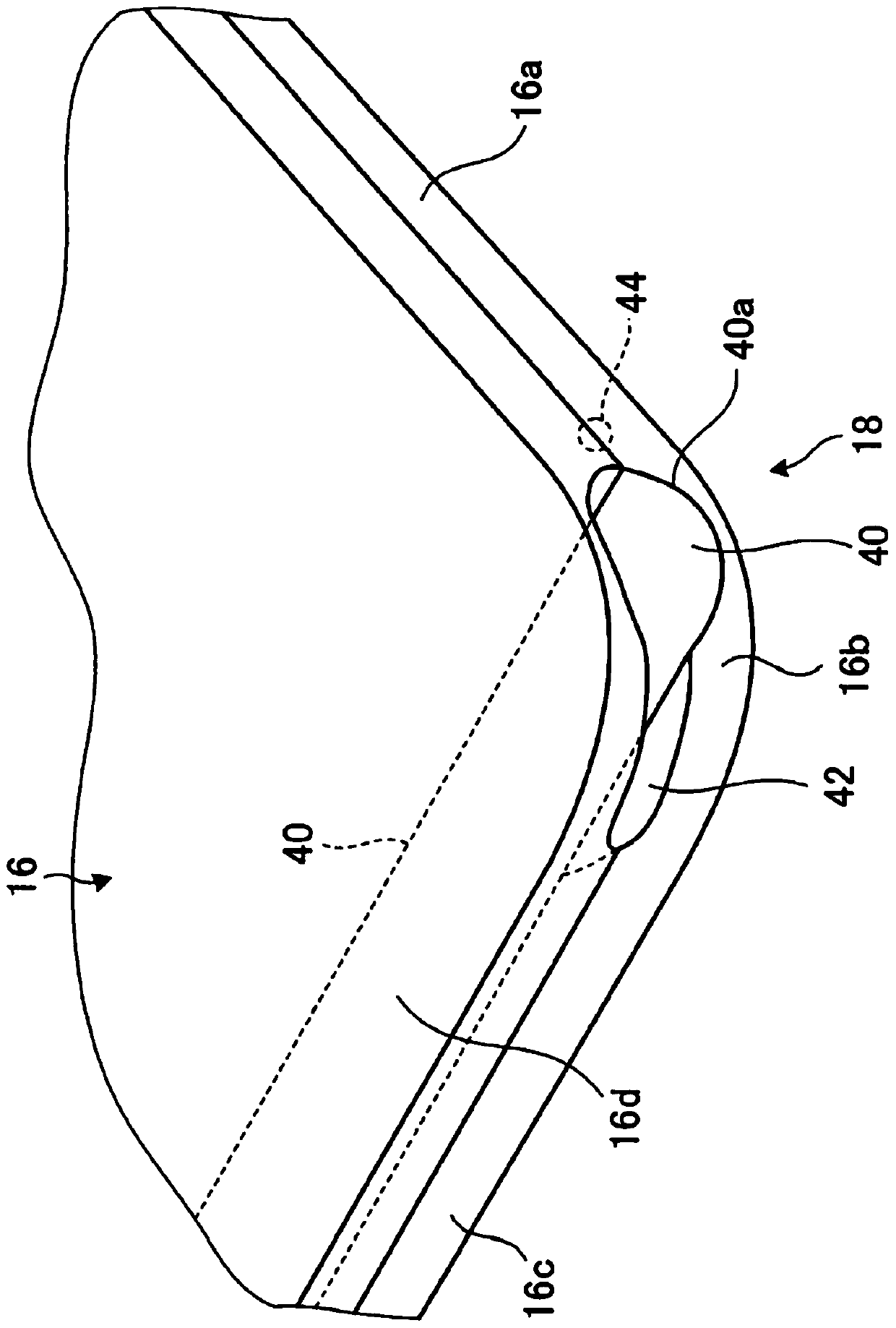

Accommodating structure and electronic device

Owner:LENOVO (SINGAPORE) PTE LTD

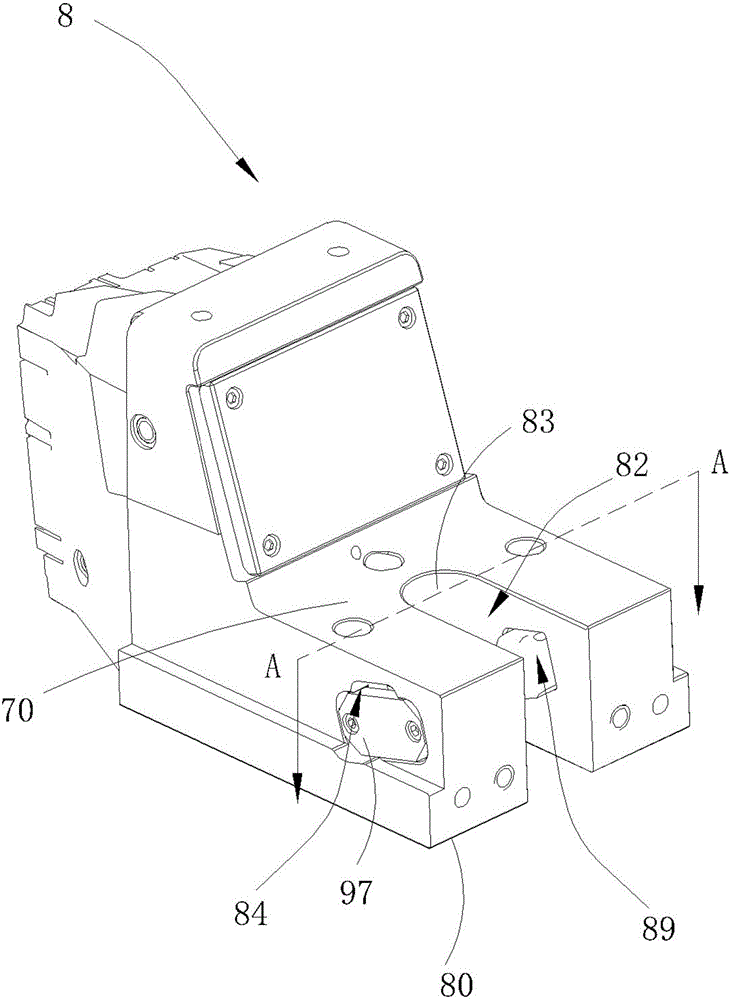

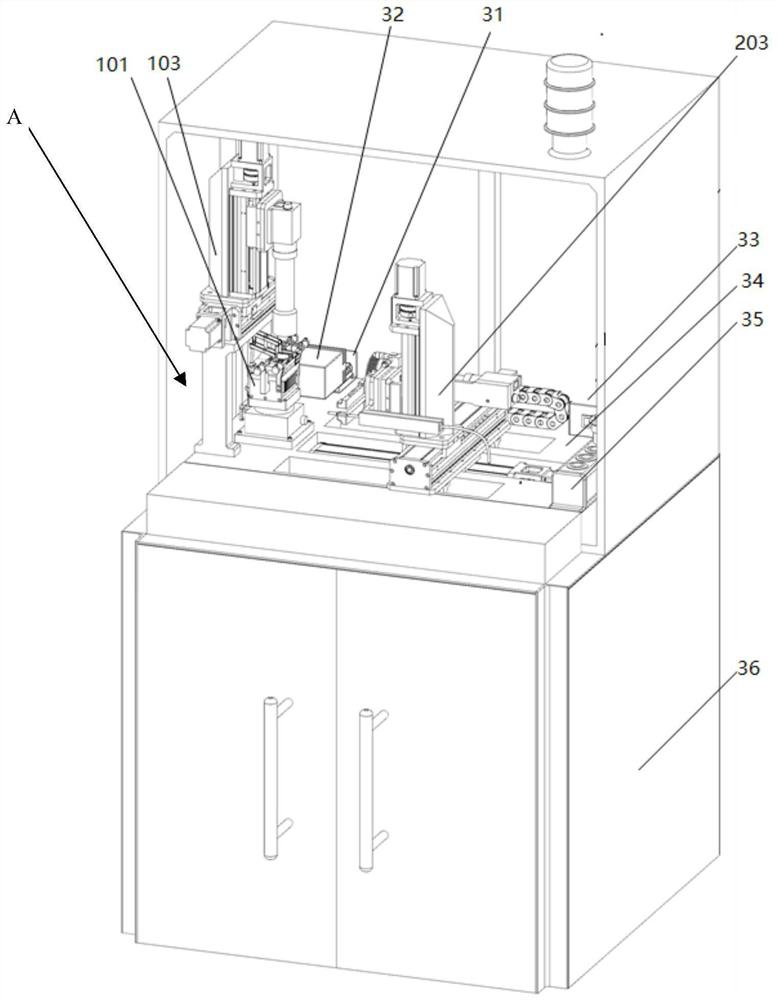

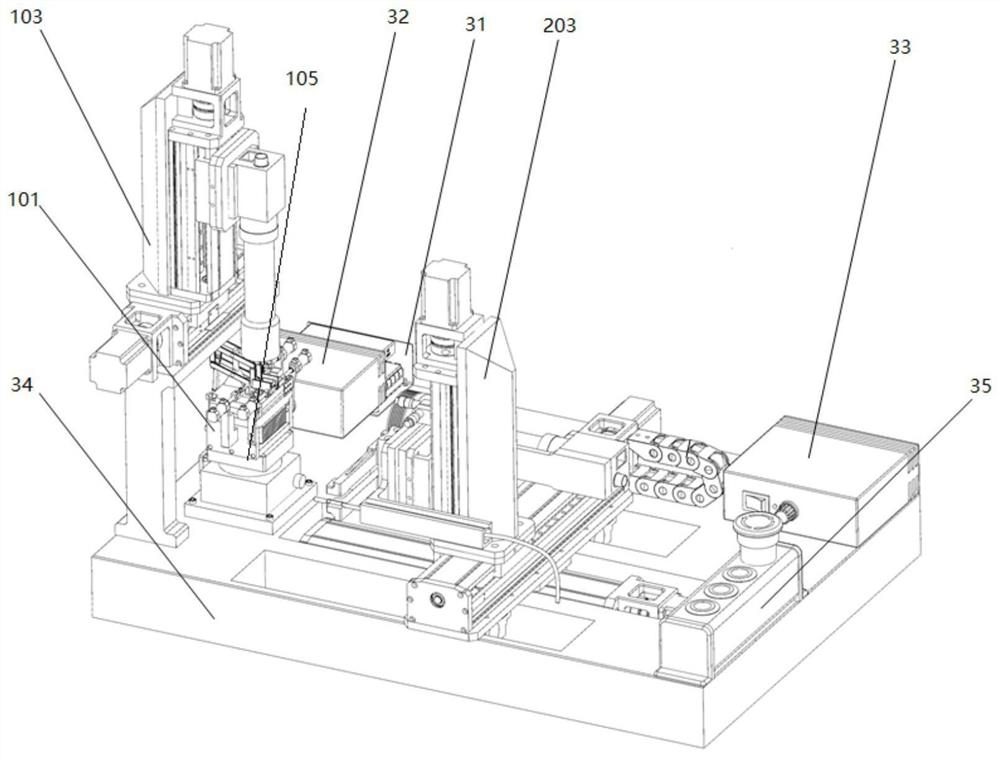

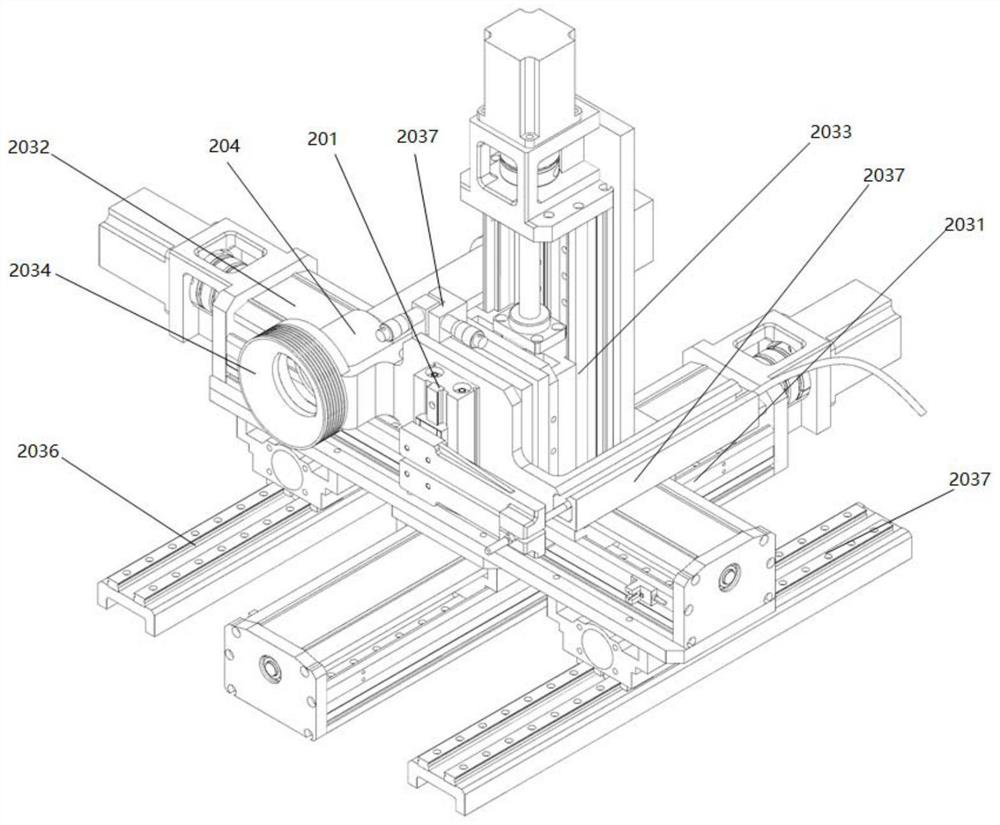

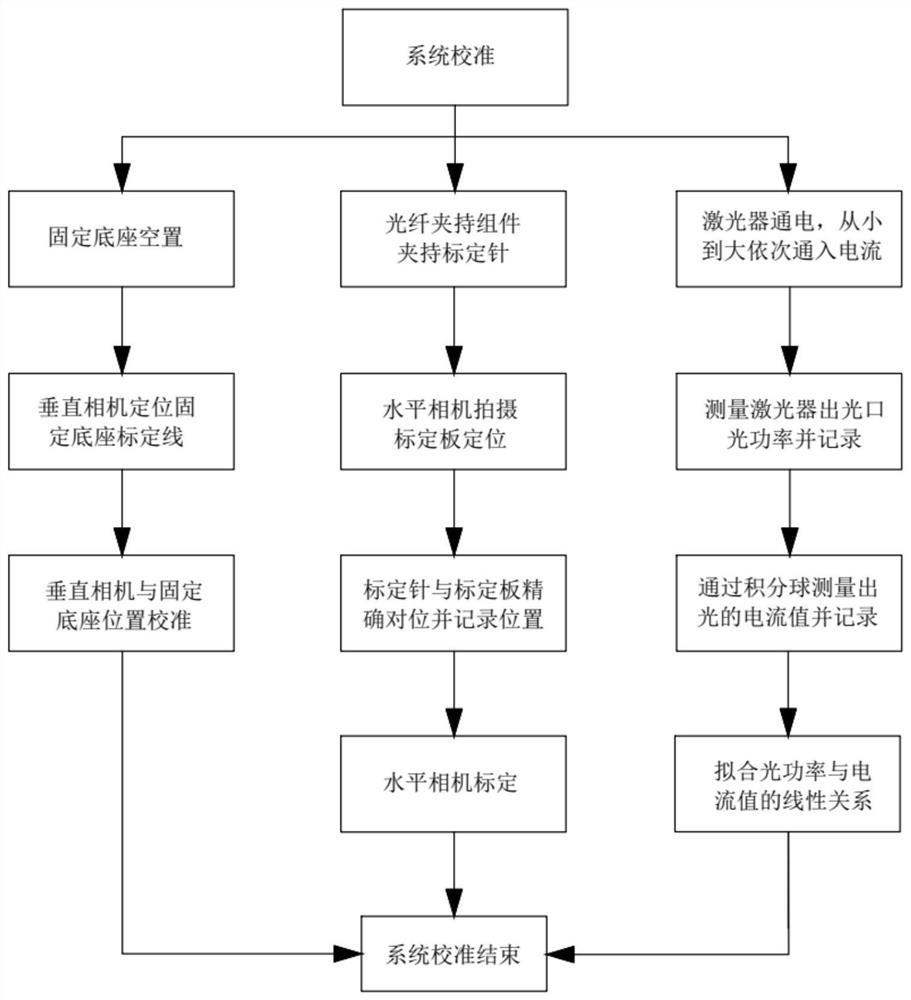

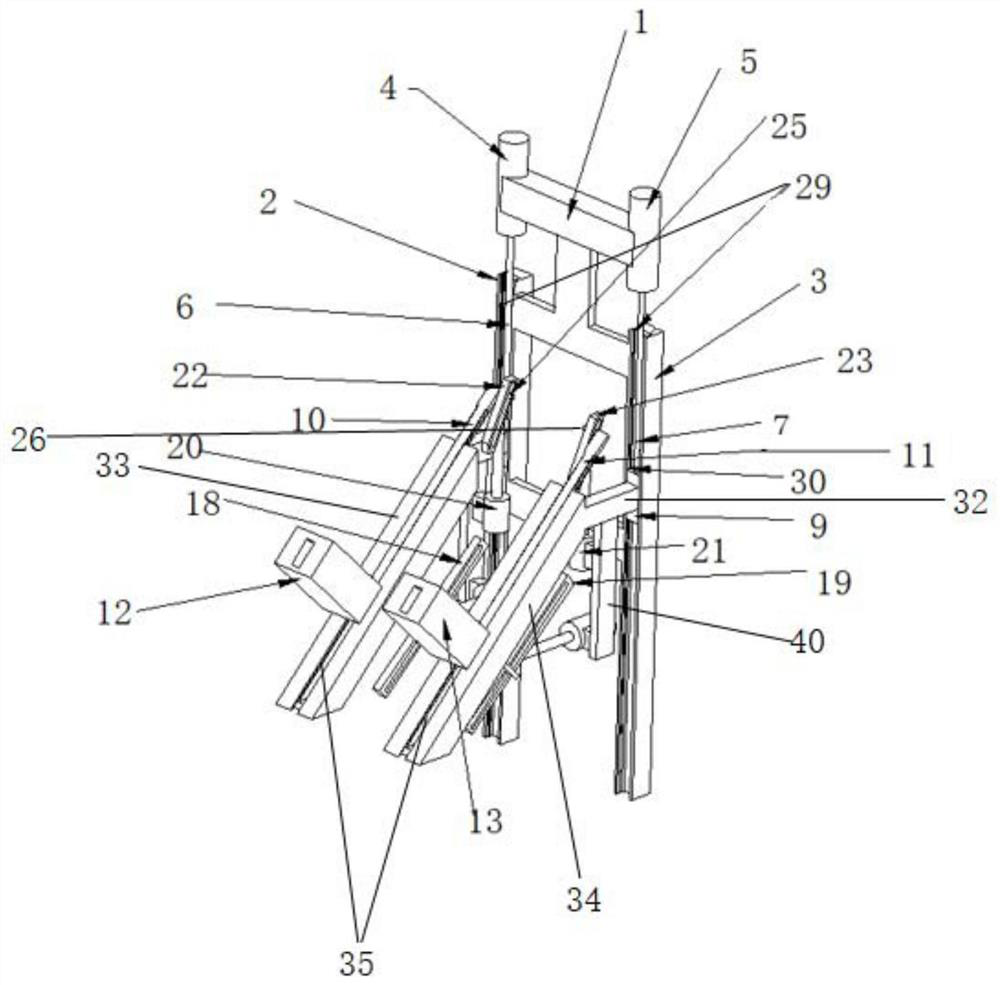

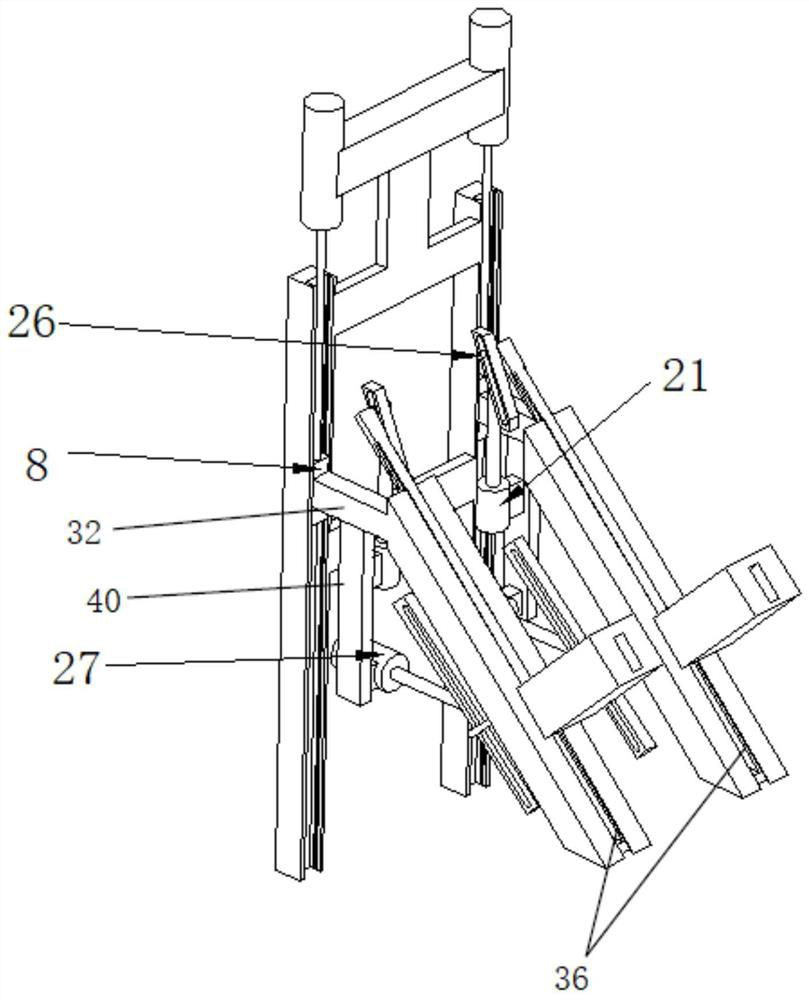

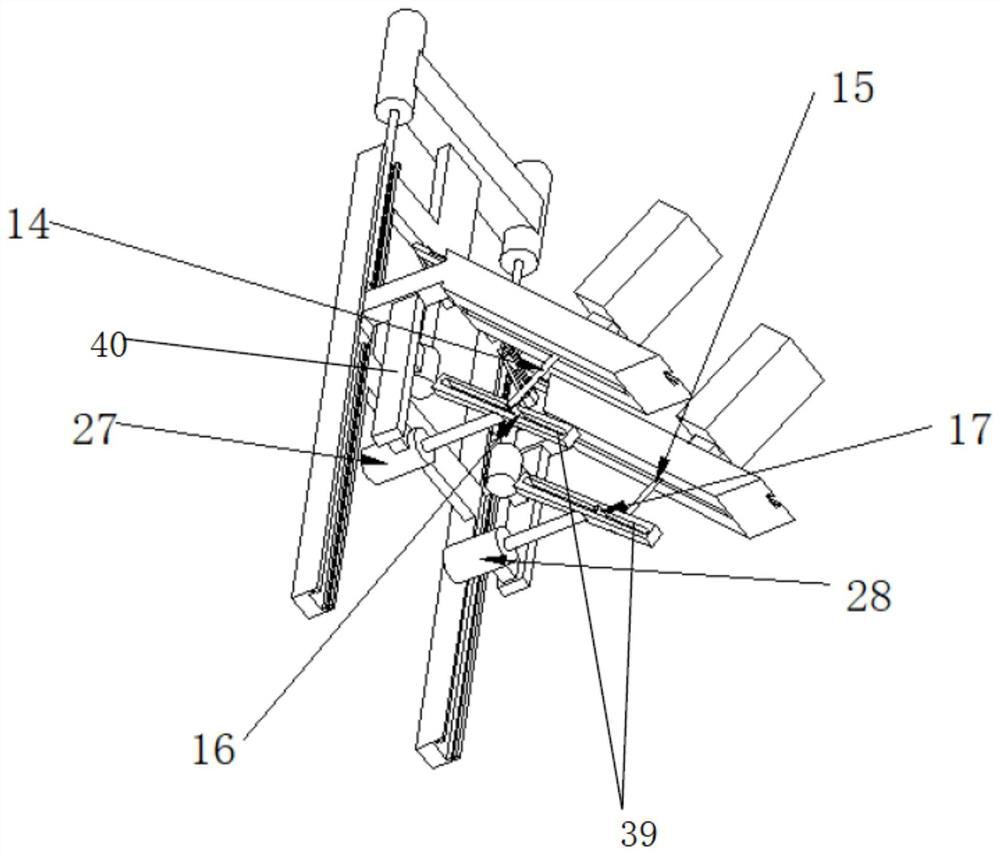

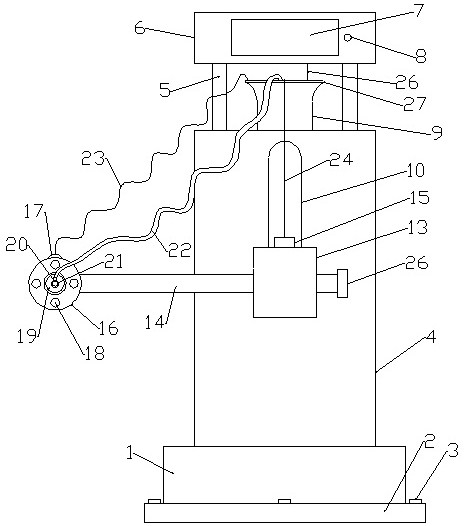

High-power laser automatic coupling device and coupling method

PendingCN112269229AAvoid Fiber and Laser CollisionsAvoid direct large-scale couplingCoupling light guidesErbium lasersDual axis

The invention discloses a high-power laser automatic coupling device and a coupling method thereof. The automatic coupling device comprises a laser assembly and an optical fiber assembly, wherein thelaser assembly comprises a laser pedestal, a laser single-axis rotating mechanism, a laser double-axis moving mechanism, a vertical camera system, the optical fiber assembly comprises an optical fiberclamping mechanism for clamping an optical fiber, an optical fiber three-axis moving structure and a horizontal camera system, the vertical camera system shoots the position of a laser box body, thelaser single-axis rotating mechanism corrects the position of the laser box body to obtain the coupling position of the laser box body, and the horizontal camera system shoots the coupling position ofthe laser box body, and obtains the relative position of an optical fiber and the center of an optical fiber hole of the laser box body, the optical fiber three-axis moving mechanism adjusts the position of the optical fiber and inserts the optical fiber into the optical fiber hole, the optimal coupling position is determined based on preset coupling conditions, and the optical fiber three-axis moving mechanism drives the optical fiber to move to the optimal coupling position for coupling. The laser automatic coupling device and the coupling method thereof are high in coupling precision and high in coupling speed.

Owner:苏州格拉尼视觉科技有限公司

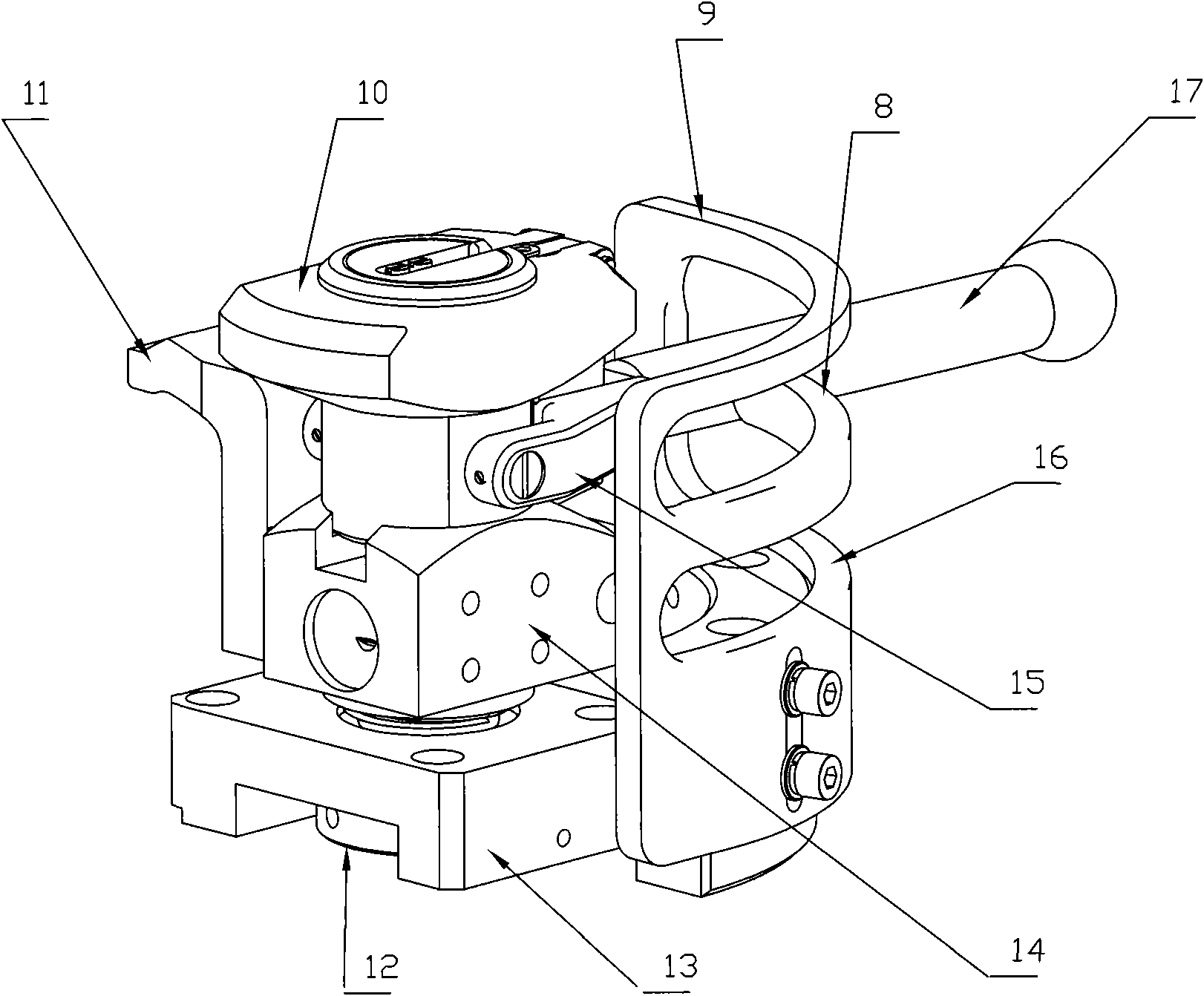

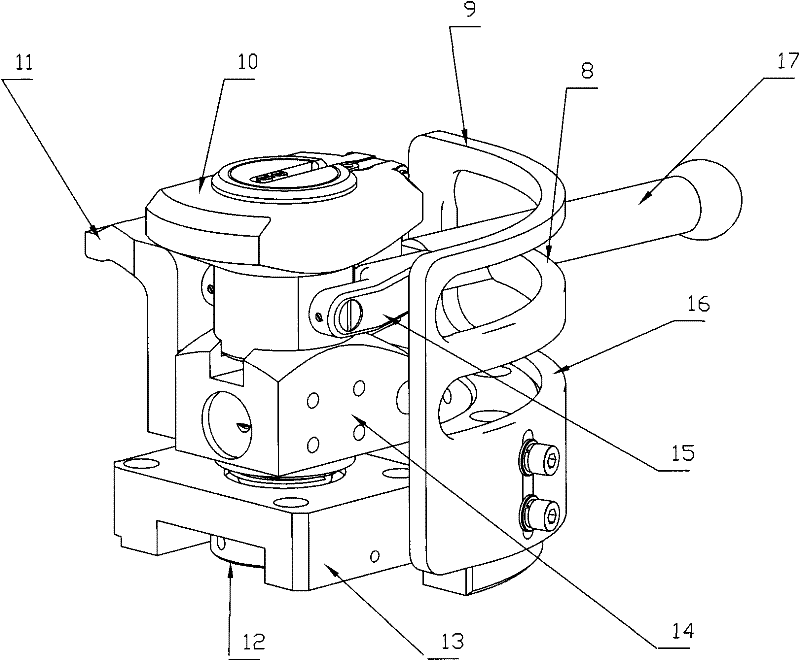

Clamping device

InactiveCN101885165AReduce the labor intensity of clampingFree counterpointWork holdersHydraulic pumpEngineering

The invention relates to a clamping device, which comprises a hoisting claw. A transposition locking clamp is arranged at the lower end of the hoisting claw; the hoisting claw is connected with a steel wire rope and is connected with a counterweight block through a pulley; and a cam is arranged at the lower end of the counterweight block, so that the hole aligning arrangement of a spline or a flat key shaft of a hydraulic pump is labor-saving and efficient, the clamping labor strength is reduced greatly, and the clamping device has the characteristics of labor saving and high efficiency.

Owner:九江七所精密机电科技有限公司

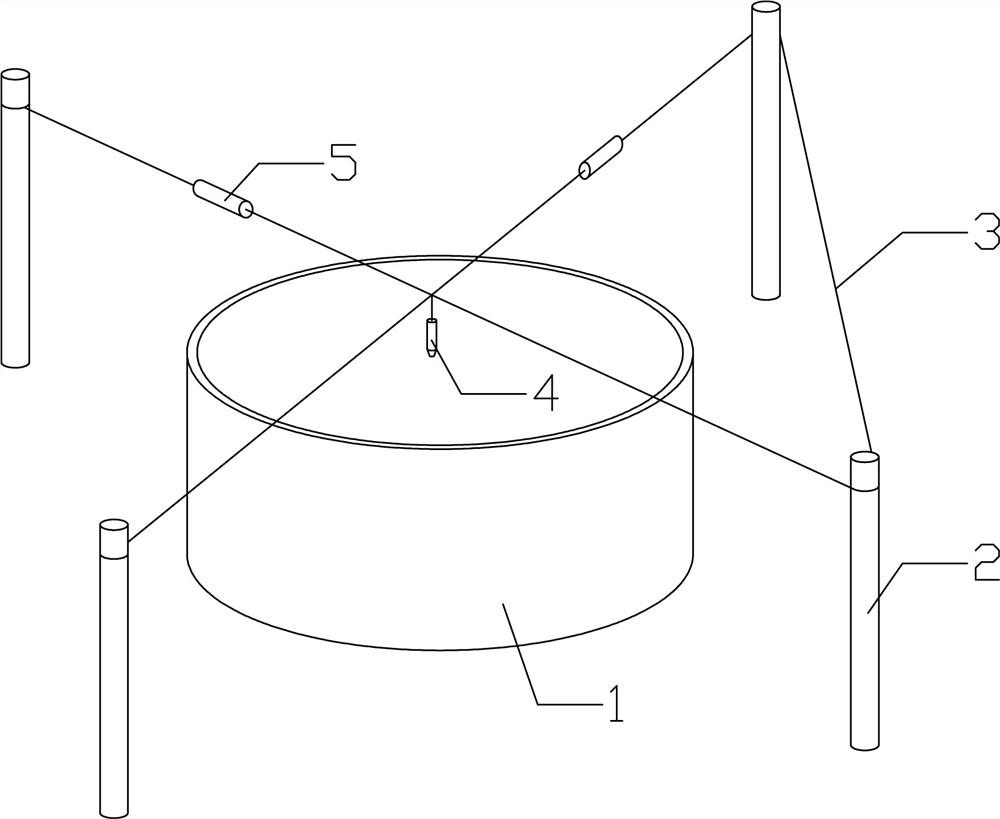

Centering device and method for reinforced cage of bored pile

ActiveCN111455987BImprove securityGuaranteed tensionFoundation testingBulkheads/pilesLaser transmitterClassical mechanics

A reinforcement cage centering device for bored piles, comprising two sets of guard piles arranged on the ground around the pile hole and a centering plate arranged on the reinforcement cage, the single set of guard piles includes two guard piles, the same The connection line between the two protective piles in the group passes through the center of the pile hole. The first pair of centering ropes are arranged on the two groups of protective piles. The first pair of centering ropes bypass the protective piles and are arranged in a cross shape. A downward-facing laser transmitter is bound; a centering plate is set at the center of the inner circle in the steel cage, and the center of the centering plate is printed with a centering qualified area. The above-mentioned device can effectively solve the safety hazards of the hand-held pendant hammer, and saves the installation of the pedal. It is suitable for construction conditions with dark light, and the structure of "ring plate + movable rod" can be further improved. The centering accuracy provides favorable prerequisites for subsequent pile foundation construction.

Owner:CCCC SECOND HARBOR ENG +1

Automatic fiber laying prepreg stiffness detection method

ActiveCN113050736AReduce detection errorGuaranteed measurement accuracySimultaneous control of multiple variablesManufacturing engineeringMeasurement precision

The invention relates to the technical field of automatic laying of composite materials, and discloses an automatic fiber laying prepreg stiffness detection method, which measures the maximum bending force of a multi-layer prepreg lamination through a three-point bending test, amplifies the tiny value of the tow stiffness, reduces the detection error, ensures the measurement precision, and has the advantages of higher detection speed and more visual result compared with an existing method for inspecting the stiffness of the prepreg tow by adopting a suspension method.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

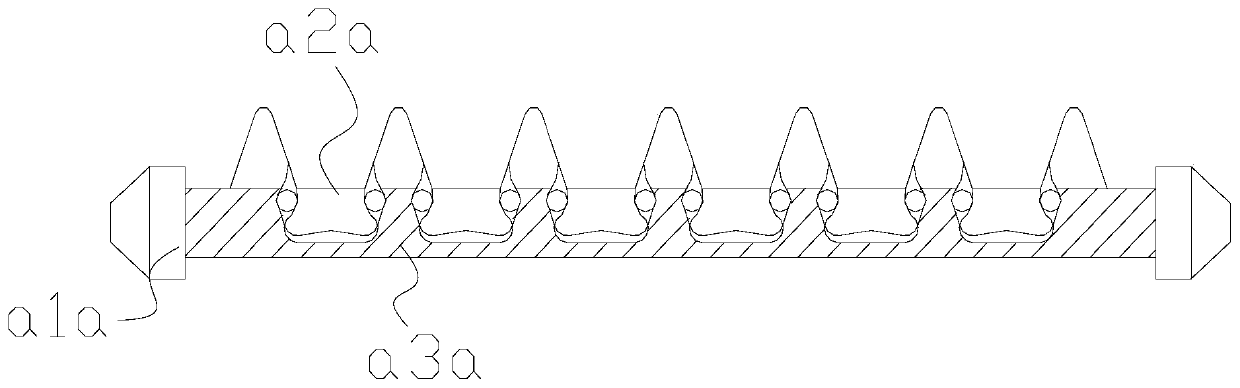

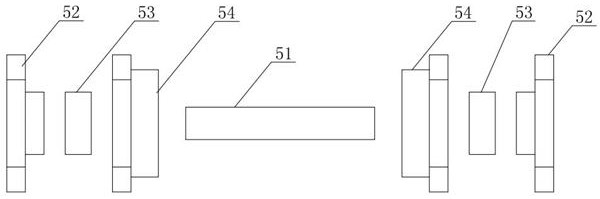

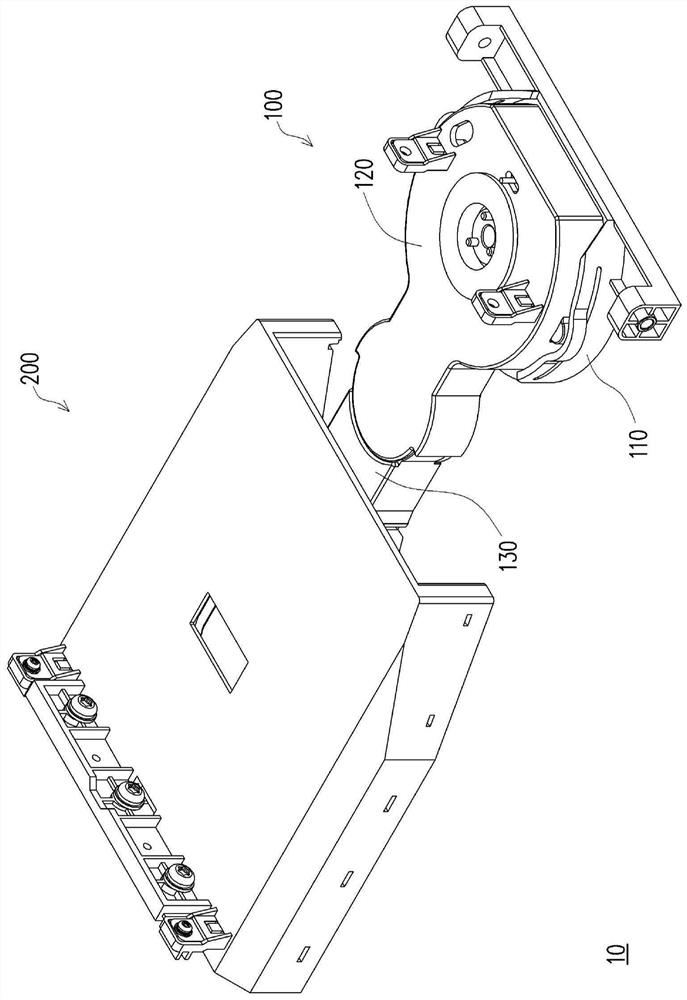

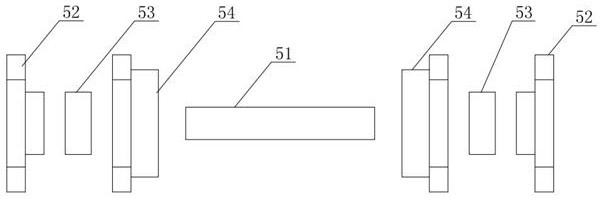

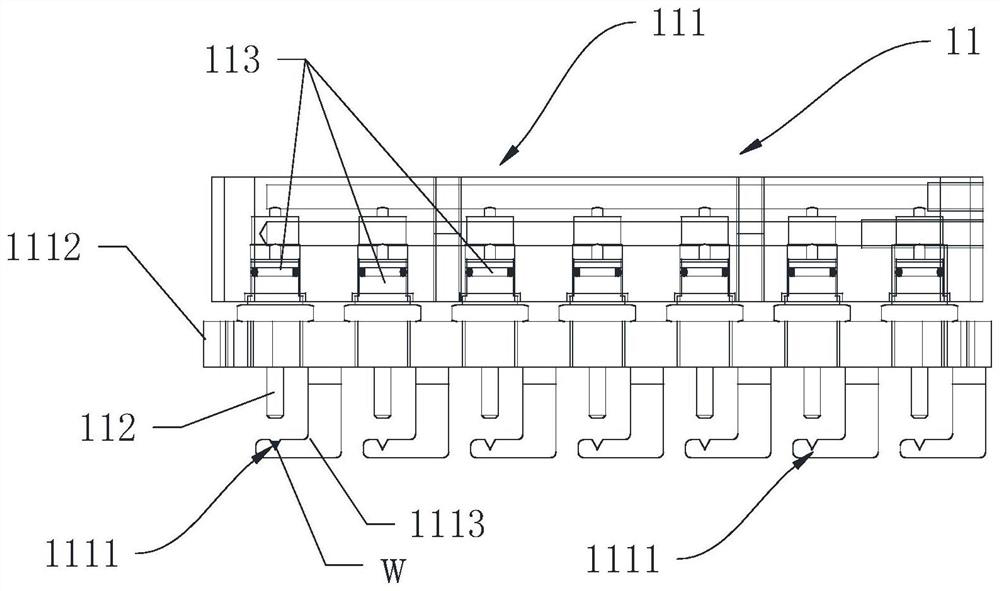

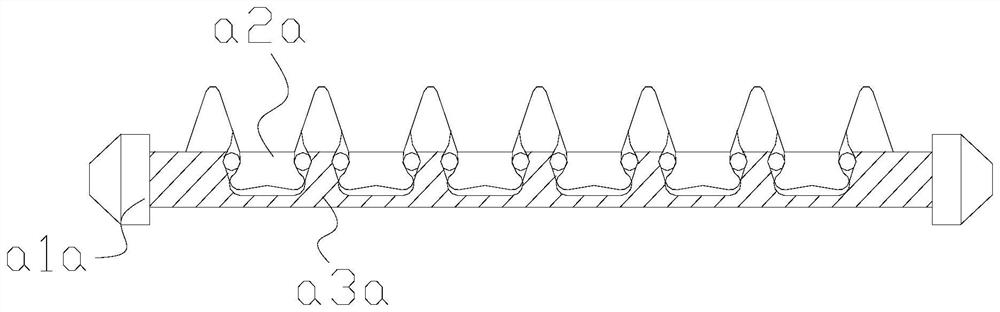

Grippers, fixing and carrying mechanism and special-shaped welding strip feeding device

ActiveCN108942003ANo distortionPlay a positioning roleWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides grippers, a fixing and carrying mechanism and a special-shaped welding strip feeding device. Each gripper comprises a grabbing piece and pressing needles. The grabbing pieces are provided with first positioning grooves. The first positioning grooves and special-shaped welding strips are matched in shape, so that the special-shaped welding strips are limited in the first positioning grooves operationally. The pressing needles are located at the tops of the first positioning grooves and movably pressed downwards in the first positioning grooves. The fixing and carrying mechanism comprises the grippers and a motion module. The grippers are mounted on the motion module. After the special-shaped welding strips are placed in the first positioning grooves of the grippers, the motion module drives the grippers to move. According to the grippers, the fixing and carrying mechanism and the special-shaped welding strip feeding device, the special-shaped welding strips are positioned and carried through the first positioning grooves, matched with the special-shaped welding strips in shape, in the grippers, distortion of the special-shaped welding strips can be avoided, efficient feeding of the special-shaped welding strips is achieved, and the problem that the special-shaped welding strips fall off in the feeding and carrying processes is eradicated fundamentally.

Owner:HANGZHOU JOY ENERGY TECH CO LTD

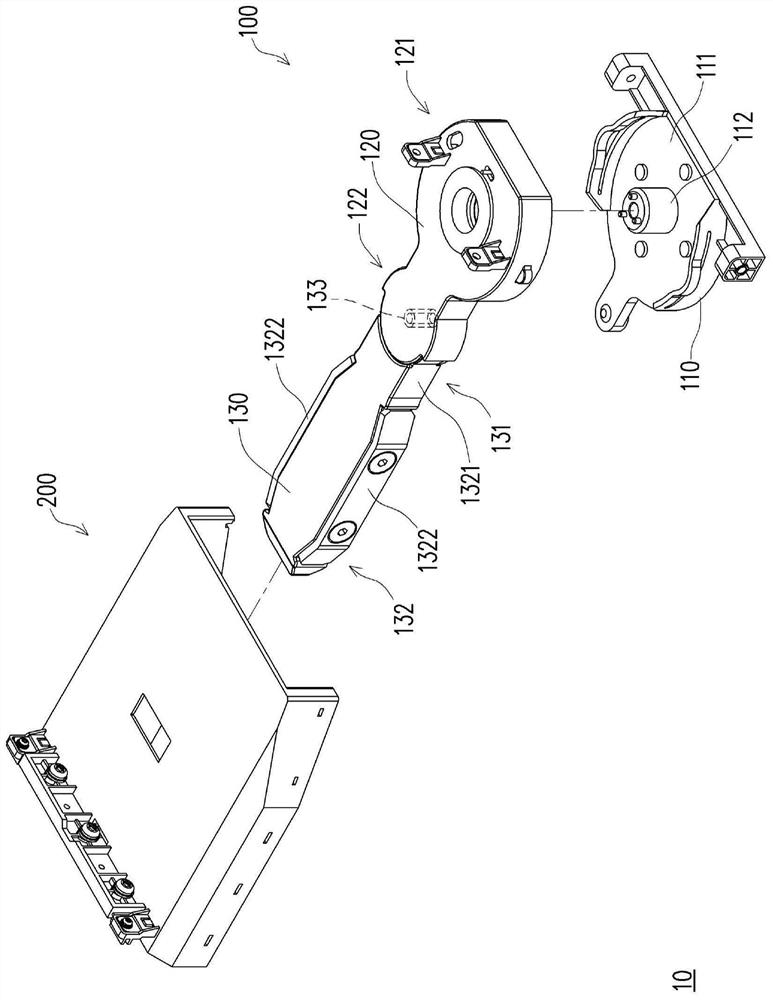

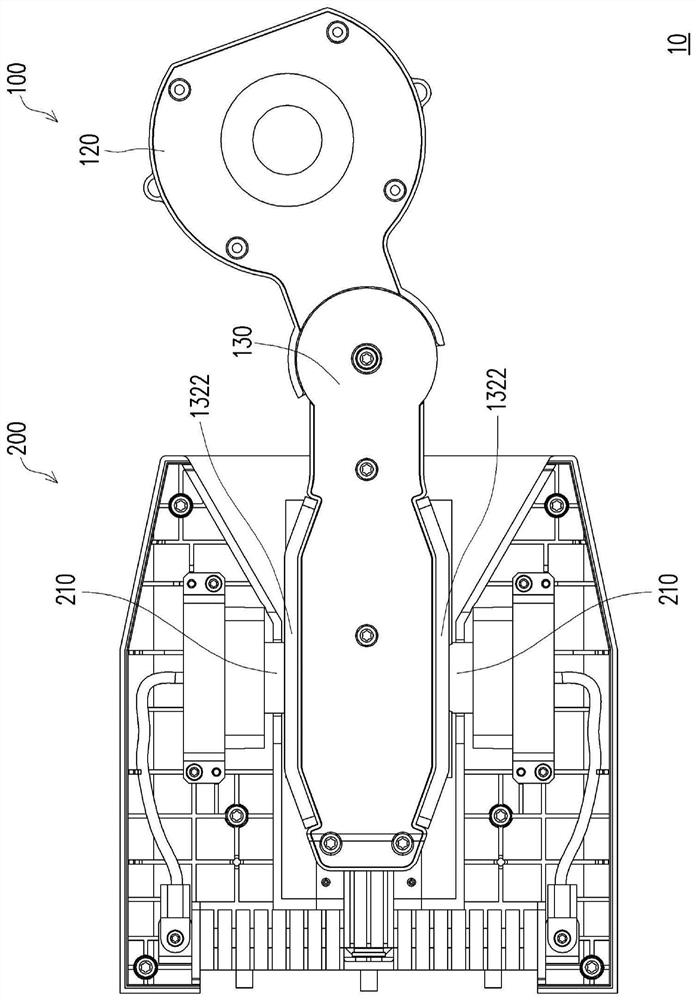

Charging device and charging system

PendingCN113224805ALarge rotation angleSmooth alignmentBatteries circuit arrangementsAutonomous decision making processControl theoryMechanical engineering

The invention discloses a charging device and a charging system. The charging device comprises a fixed base, a charging support arm and a pivot rod piece. The charging support arm is provided with a first end part and a second end part which are opposite to each other; the pivot rod piece is provided with a first part and a second part, the first part is pivoted to the fixed base, the pivot rod piece is suitable for rotating relative to the fixed base, the second part is pivoted to the first end part, and the charging support arm is suitable for rotating relative to the pivot rod piece. The invention further provides a charging system.

Owner:PEGATRON

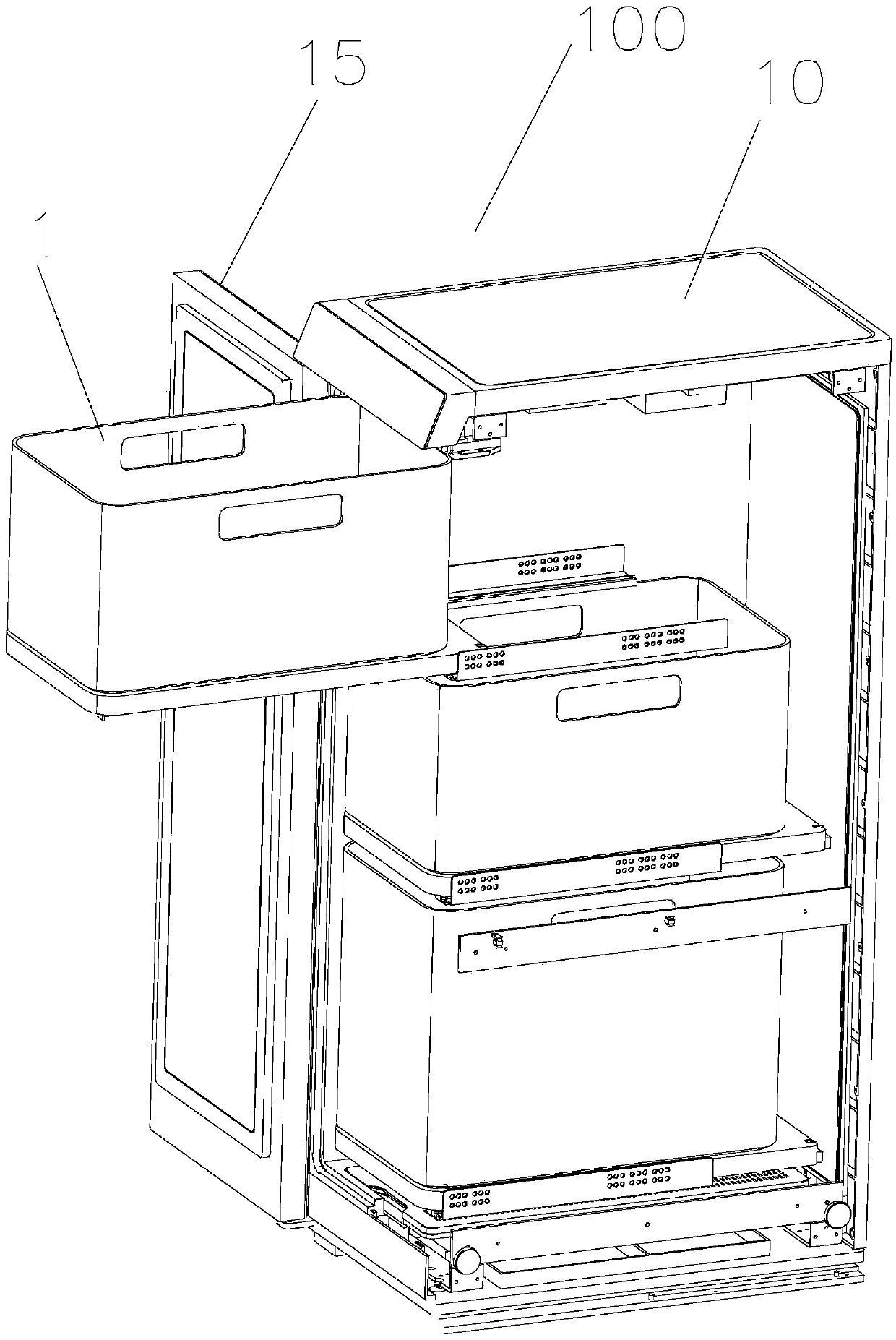

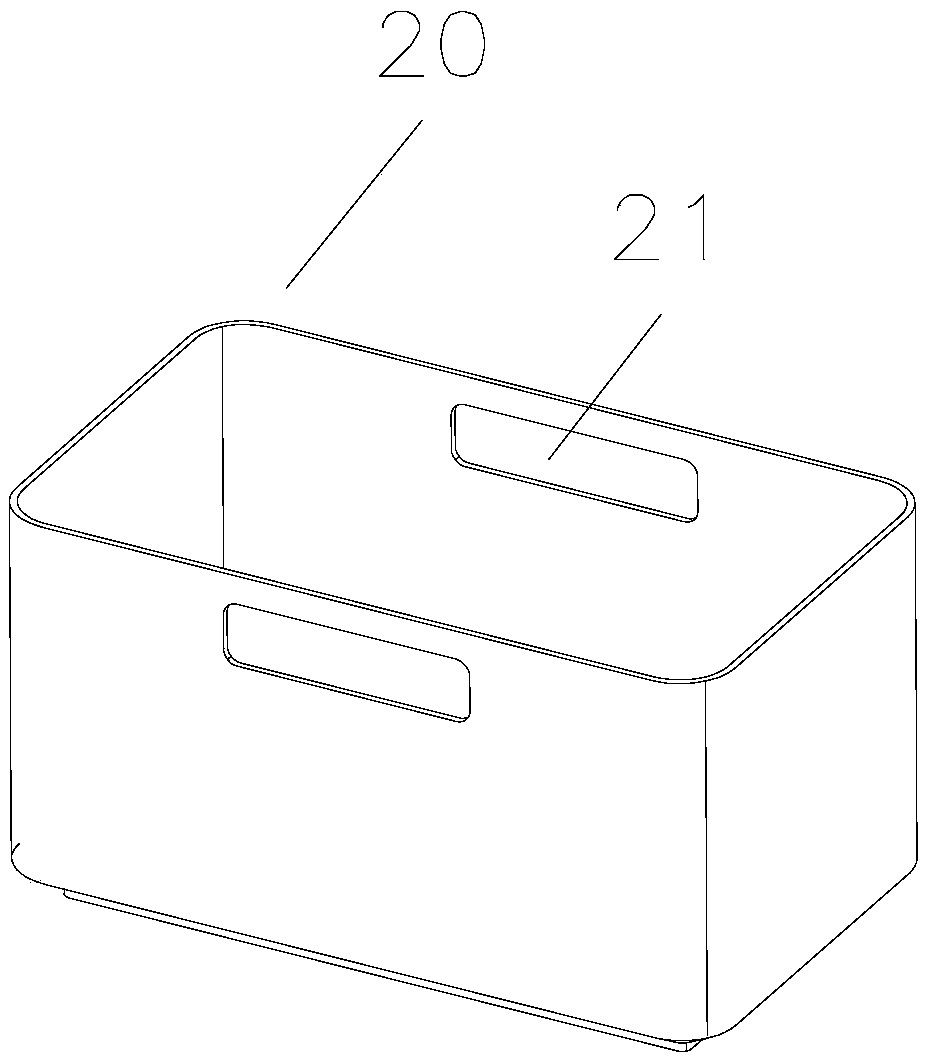

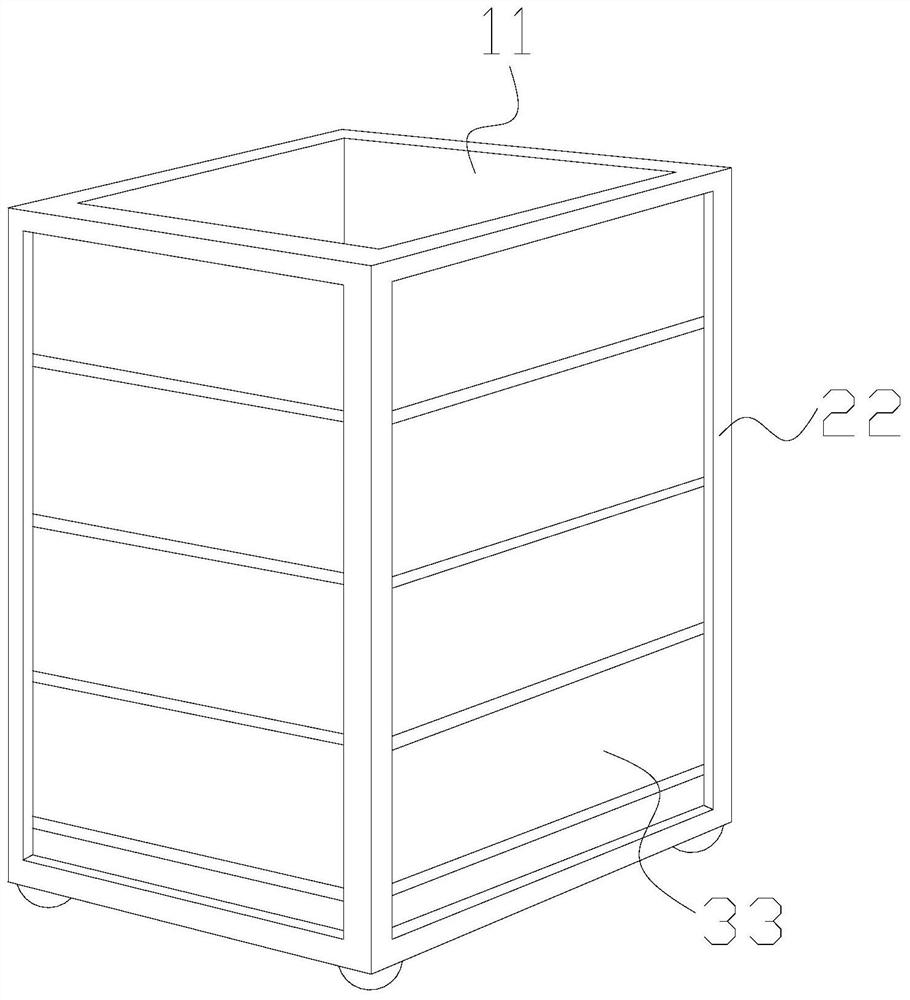

Drawing structure of containing box body and clothes storage device

Owner:QINGDAO HAIGAO DESIGN MFG CO LTD

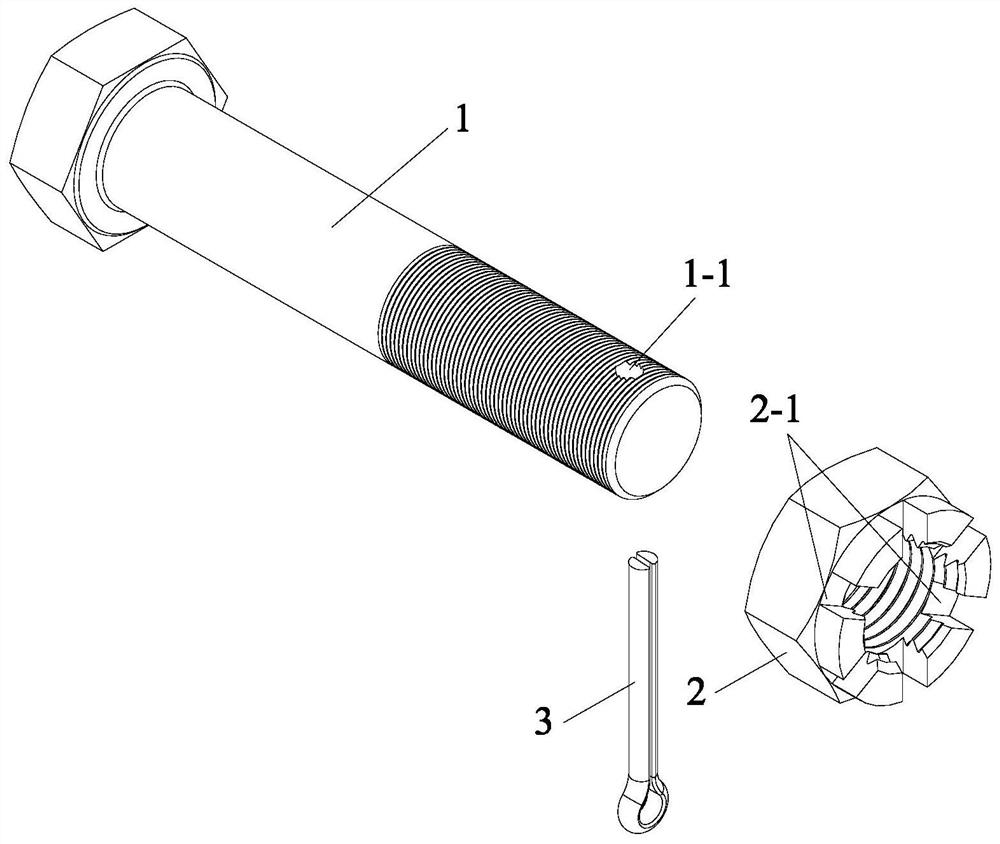

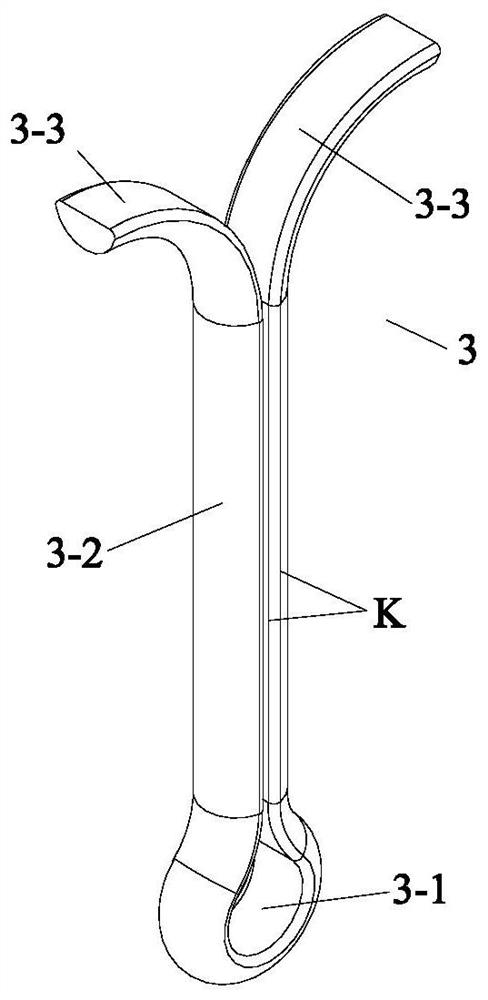

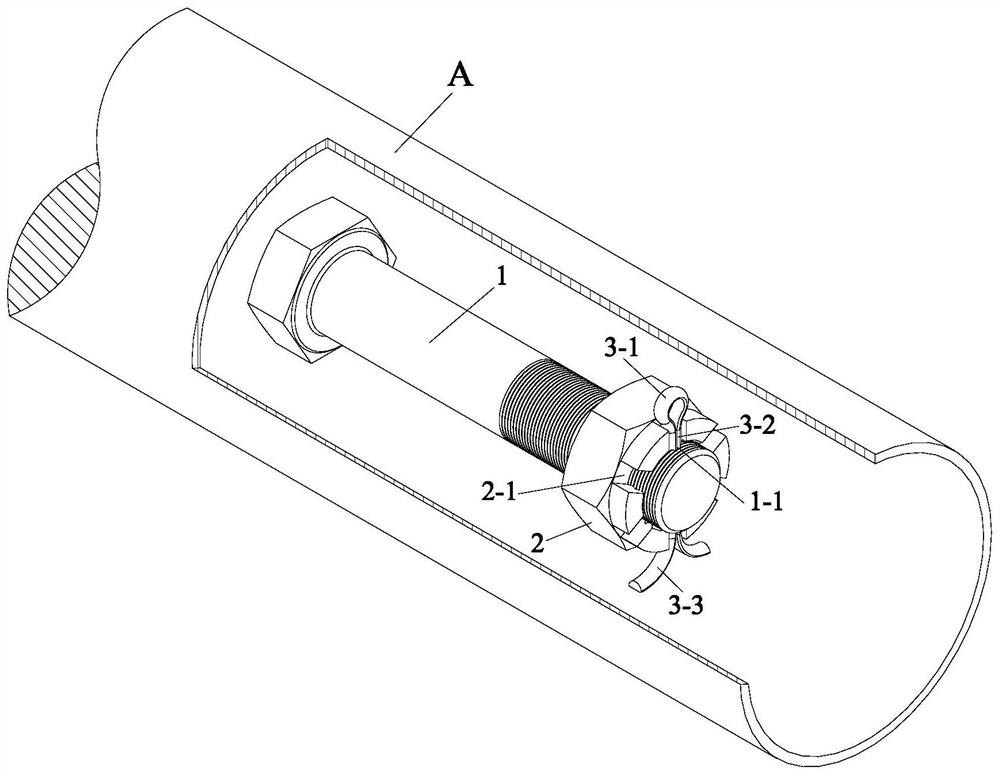

Pin splitter applied to narrow space and using method thereof

PendingCN112828825AAvoid being scratchedAvoid smashingMetal-working hand toolsHand heldField of view

The invention discloses a pin splitter applied to narrow space and a using method thereof, and belongs to the technical field of handheld special fastening tools. The pin splitter comprises a coaxial positioning sleeve, a pin splitting firing pin mechanism, a handheld probe and a bolt lantern ring positioning rod, and the handheld probe comprises a handle, a sliding groove base, an opening clamping ring, a positioning rod inserting hole, a firing pin guiding sliding groove, a firing pin pull rod through hole and a sleeve inserting hole. The pin splitter applied to the narrow space is suitable for the special situations that due to the fact that the diameter of a round pipe component A is too small, conventional tools and visual fields are limited, and pin splitting operation lacks necessary operation space, the operation process can be greatly simplified, the pin splitting quality and the acceptance efficiency can be enhanced, meanwhile, the operation difficulty is effectively reduced, and the risks that an operator is scratched, injured by a crashing object or sprained and the like are avoided.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

A method for detecting the stiffness of automatic laying prepreg

ActiveCN113050736BReduce detection errorGuaranteed measurement accuracySimultaneous control of multiple variablesClassical mechanicsStructural engineering

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Handle, fixed transport mechanism and special-shaped ribbon feeding device

ActiveCN108942003BNo distortionPlay a positioning roleWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringGrippers

The invention provides grippers, a fixing and carrying mechanism and a special-shaped welding strip feeding device. Each gripper comprises a grabbing piece and pressing needles. The grabbing pieces are provided with first positioning grooves. The first positioning grooves and special-shaped welding strips are matched in shape, so that the special-shaped welding strips are limited in the first positioning grooves operationally. The pressing needles are located at the tops of the first positioning grooves and movably pressed downwards in the first positioning grooves. The fixing and carrying mechanism comprises the grippers and a motion module. The grippers are mounted on the motion module. After the special-shaped welding strips are placed in the first positioning grooves of the grippers, the motion module drives the grippers to move. According to the grippers, the fixing and carrying mechanism and the special-shaped welding strip feeding device, the special-shaped welding strips are positioned and carried through the first positioning grooves, matched with the special-shaped welding strips in shape, in the grippers, distortion of the special-shaped welding strips can be avoided, efficient feeding of the special-shaped welding strips is achieved, and the problem that the special-shaped welding strips fall off in the feeding and carrying processes is eradicated fundamentally.

Owner:HANGZHOU JOY ENERGY TECH CO LTD

A point-to-point unmanned sparse transportation system for fragile objects

The invention discloses a point-to-point unmanned fragile product sparse transportation system. The system structurally comprises a storage groove, wherein the storage groove is embedded into a sparsegoods stabilizing groove, an article is placed in the storage groove, the article can be placed inside a soft groove, horizontal supporting rods are used for partitioning the storage groove into layers, corner clamping heads are used for fixing the position of the horizontal supporting rods and supporting rod layers, when the article is added into a pocket, a push bag is pressed, and can be generate certain deformation when being subjected to external force, and is timely reset when resistance is lost, a point alignment rod can be smoothly aligned with a specified point, the point alignment rod corresponds to an external corresponding point and is sucked and stops operation, due to the fact that a smooth strip slide along a movable core ball, a supporting curved adhesive layer on the other side abuts against the article through reverse force, so that the article cannot shake or dislocate, when point-to-point equipment is suddenly stopped, an inner soft layer can be pushed through theinner article through inertia, and the article is fixed again, so that the article can be prevented from being excessively staggered or misplaced and impacted.

Owner:温州博辉新材料科技有限公司

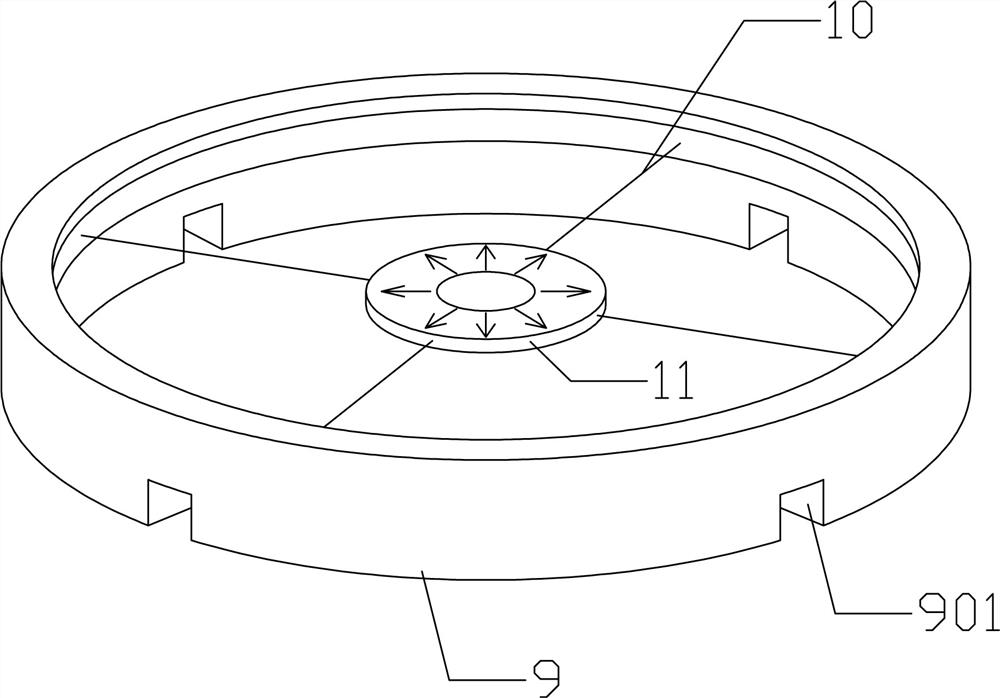

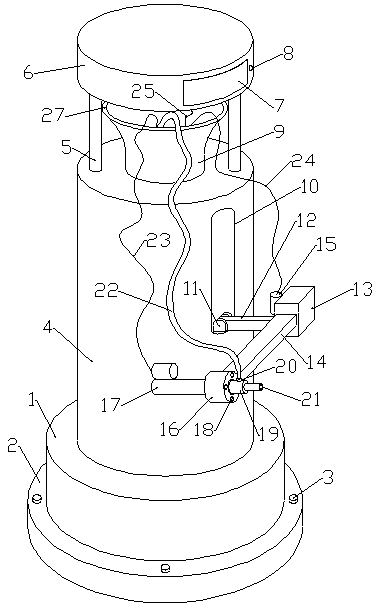

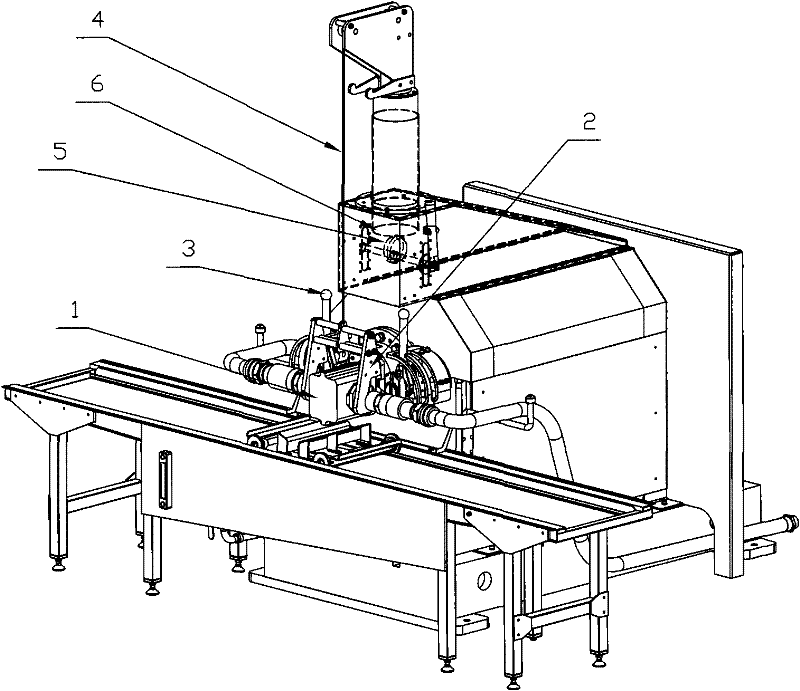

Robot intelligent oiling equipment

ActiveCN110509294AEasy to operateWork and run efficientlyLiquid transferring devicesManipulatorEngineeringPayment

The invention relates to robot intelligent oiling equipment. One end of a transverse lifting rod is located in a center fixing sleeve, an inner connecting seat is fixedly mounted at the end, located in the center fixing sleeve, of the transverse lifting rod, the bottom of the inner connecting seat is fixedly connected with the output end of a lifting electric push rod, the bottom of the lifting electric push rod is fixedly connected with a rotary toothed disc, the other end of the transverse lifting rod is located outside the center fixing sleeve, a transverse supporting seat is fixedly mounted at the end, located outside the center fixing sleeve, of the transverse lifting rod, a transverse motion groove is formed in the transverse supporting seat, a transverse motion rod is movably mounted in the transverse motion groove, a transverse motion rod rotary gear is in engaged connection to a transverse motion rod tooth groove, and the transverse motion rod rotary gear is connected with theoutput end of a transverse motion rod motion motor fixedly mounted on the transverse supporting seat. The complex steps such as payment and oil quantity selection are reduced, and the oiling requirements of high-flow oiling vehicles can be met.

Owner:河南英高能源科技有限公司

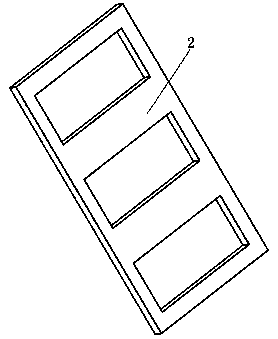

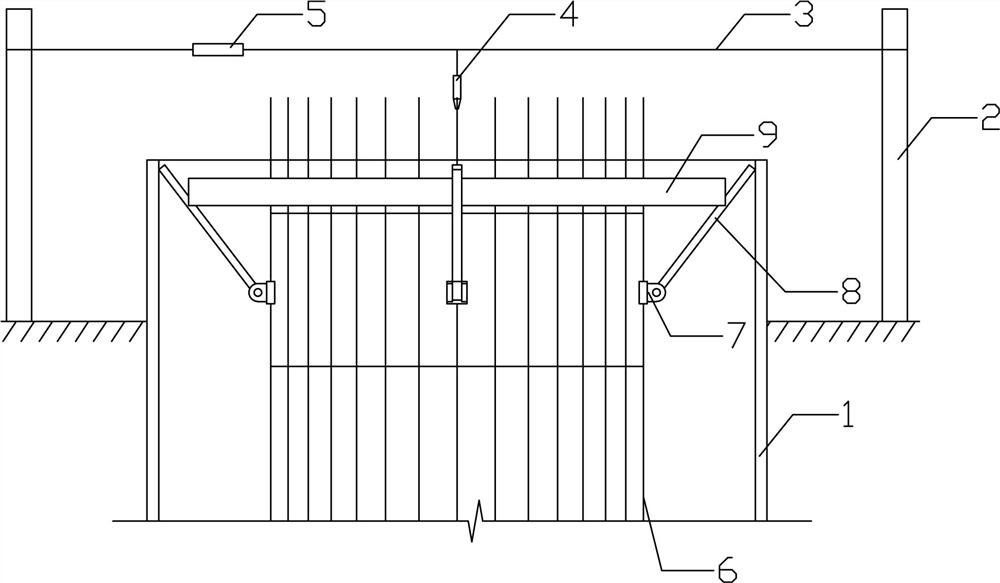

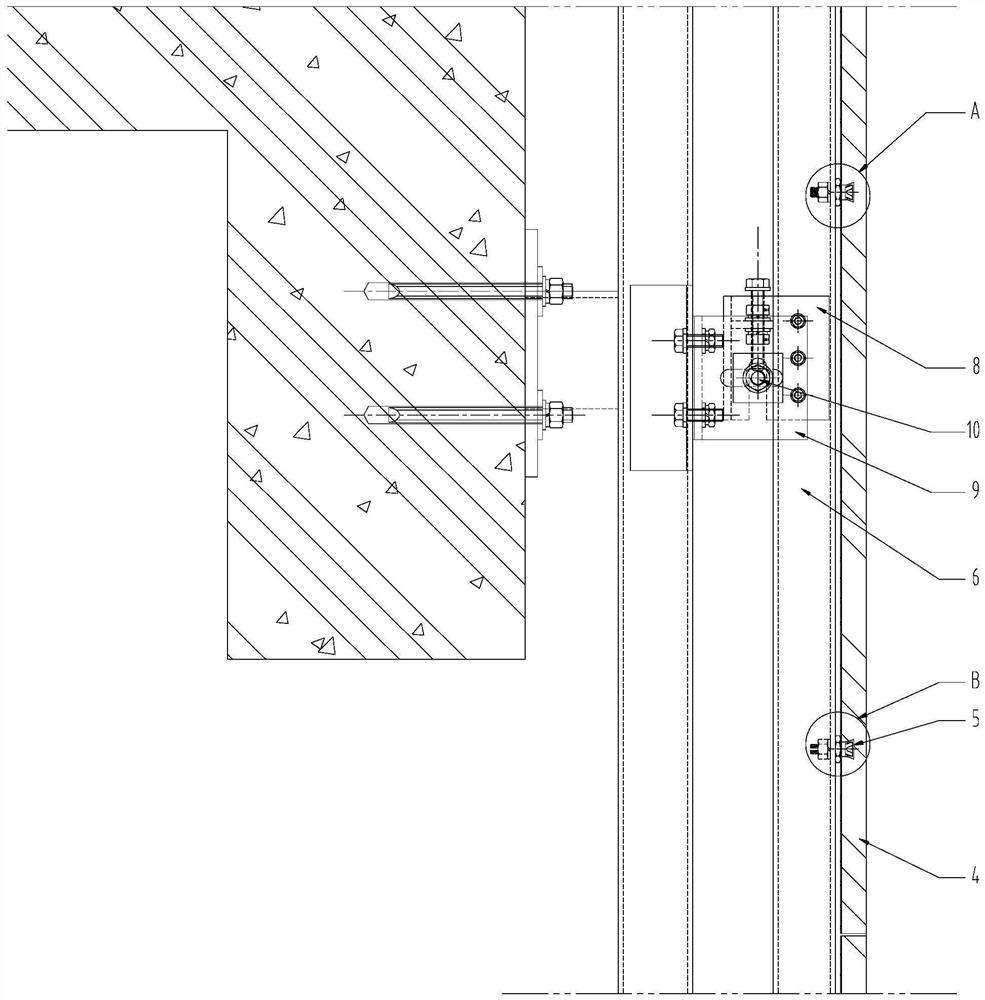

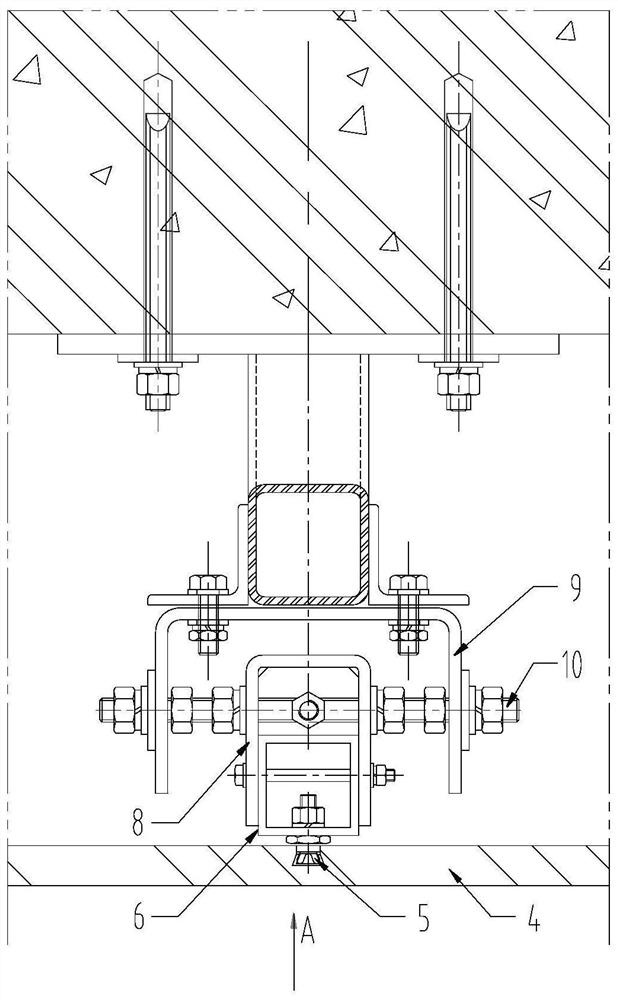

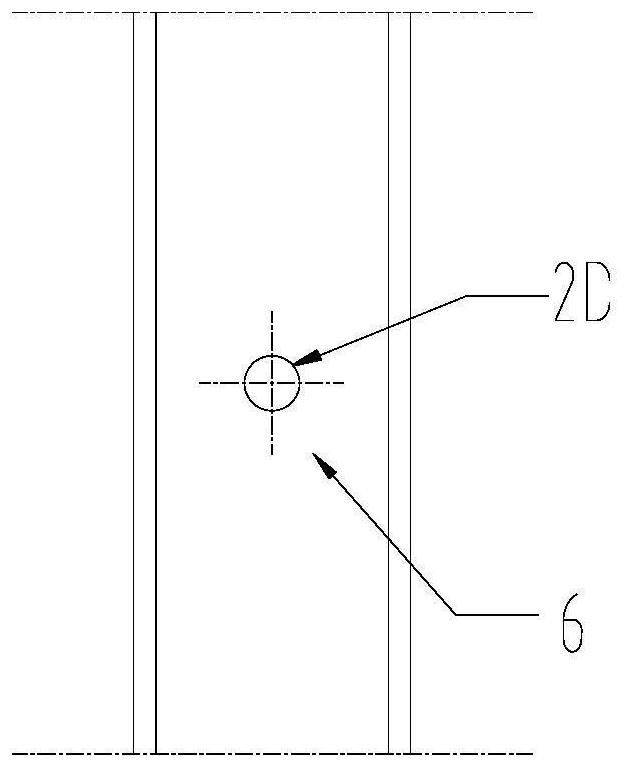

Unit type stone curtain wall fine adjustment system and installation method

ActiveCN113463804ARealize adjustableEliminate hole position deviationWallsBuilding material handlingEngineeringCurtain wall

The invention discloses a unit type stone curtain wall fine adjustment system and an installation method, and belongs to the field of building curtain walls. The system aims to quickly and effectively eliminate the installation deviation of hole position parts. The system comprises a stand column, and a long-strip-shaped notch is formed in the supporting wall of the stand column; an upper fulcrum and a lower fulcrum of the stand column comprise eccentric gaskets, the cross section of an insertion part of each eccentric gasket is circular, an installation hole penetrating in the axial direction is formed in each insertion part, and the center of each installation hole deviates from the center of the corresponding insertion part; the insertion part is inserted into the notch; in the annular direction of the insertion part, the insertion part is movably matched with the notch; and in the extending direction of the notch, the insertion part is movably matched with the notch, and the eccentric gasket of the upper fulcrum is fixed to the stand column through a connecting piece. According to the method, the hole position deviation between the stone back bolt hole position and the aluminum alloy profile hole position is automatically eliminated in the installation process, it is guaranteed that the stone back bolt hole can be smoothly aligned, and the installation efficiency is improved.

Owner:苏州苏明装饰股份有限公司

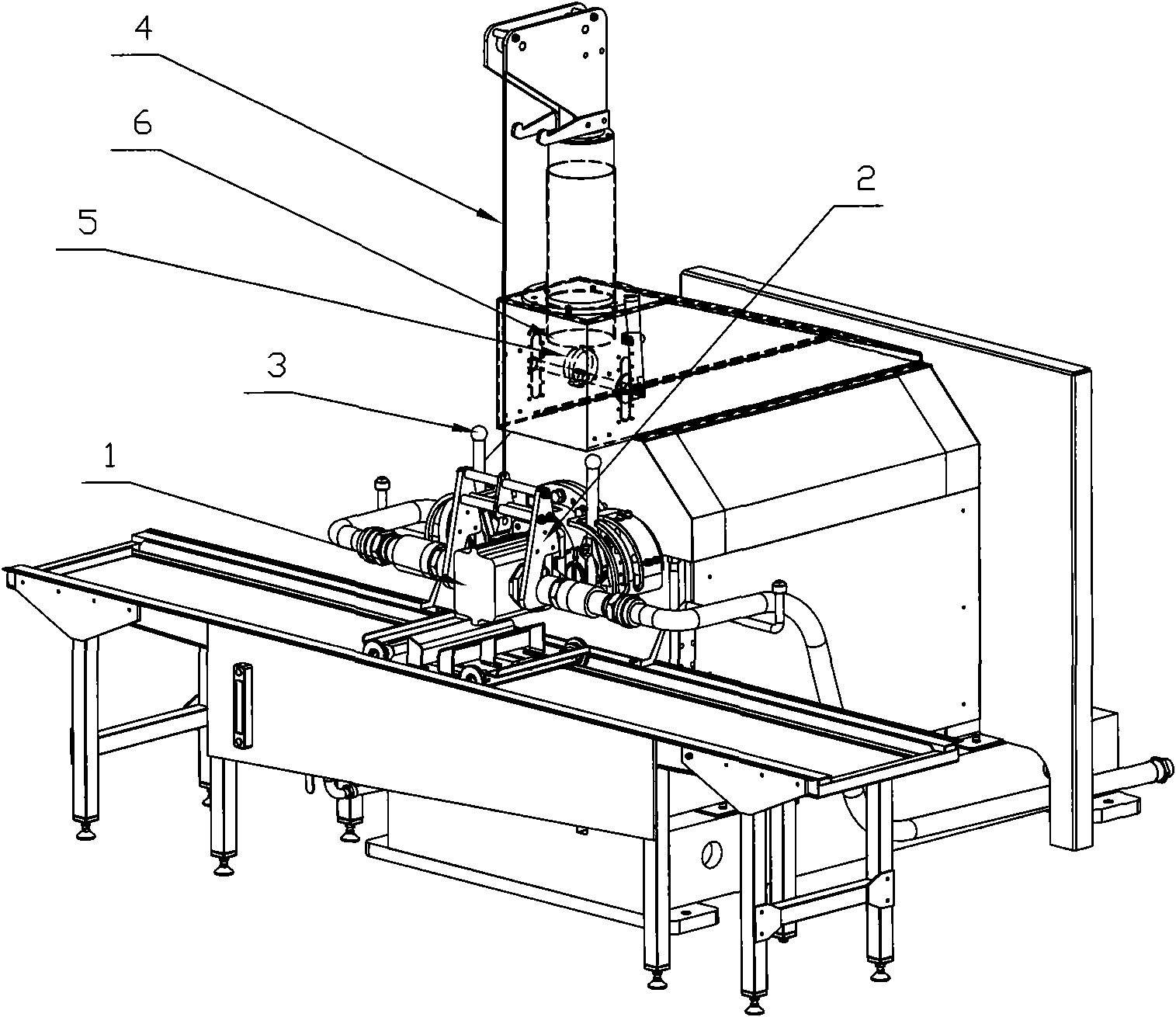

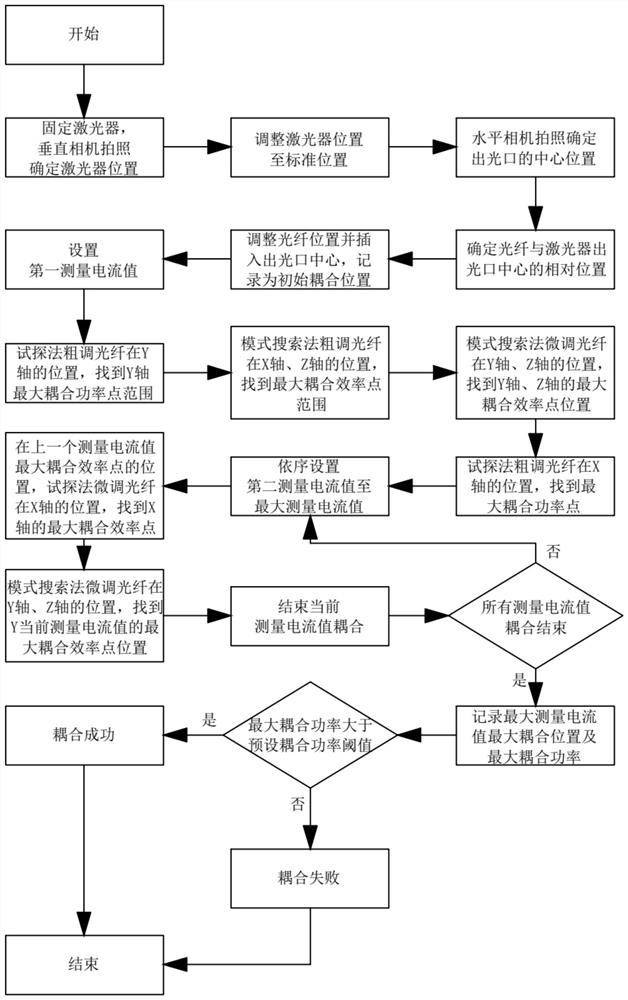

Progressive mode search coupling method based on visual guidance and active mode

The invention relates to a progressive mode search coupling method based on visual guidance and an active mode. The method comprises the following steps: 1, calibrating a vertical camera coordinate system; 2, calibrating a horizontal camera coordinate system; 3, aligning the two coordinate systems; 4, measuring the optical power of the laser to form a standard optical power value table; 5, measuring the current value converted by the integrating sphere to form a measured current value table; 6, fitting a linear relation between the measured current value table and the standard power value table, and storing the linear relation; 7, determining the central position of a light outlet of the laser; and 8, adjusting the position of the optical fiber, obtaining the position of the optical fiber at the maximum measurement current value, and completing the coupling process. In a laser fiber coupling process, the self-adjustment of relative positions of the fiber and the laser is realized, so that the fiber can be smoothly aligned with a light emitting center in the laser, high-precision coupling is performed, collision between the fiber and the laser is avoided, direct large-range coupling and fiber damage under high power are effectively avoided, the coupling efficiency is improved, and the cost is reduced.

Owner:苏州格拉尼视觉科技有限公司

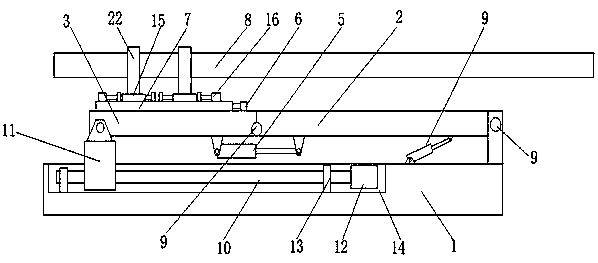

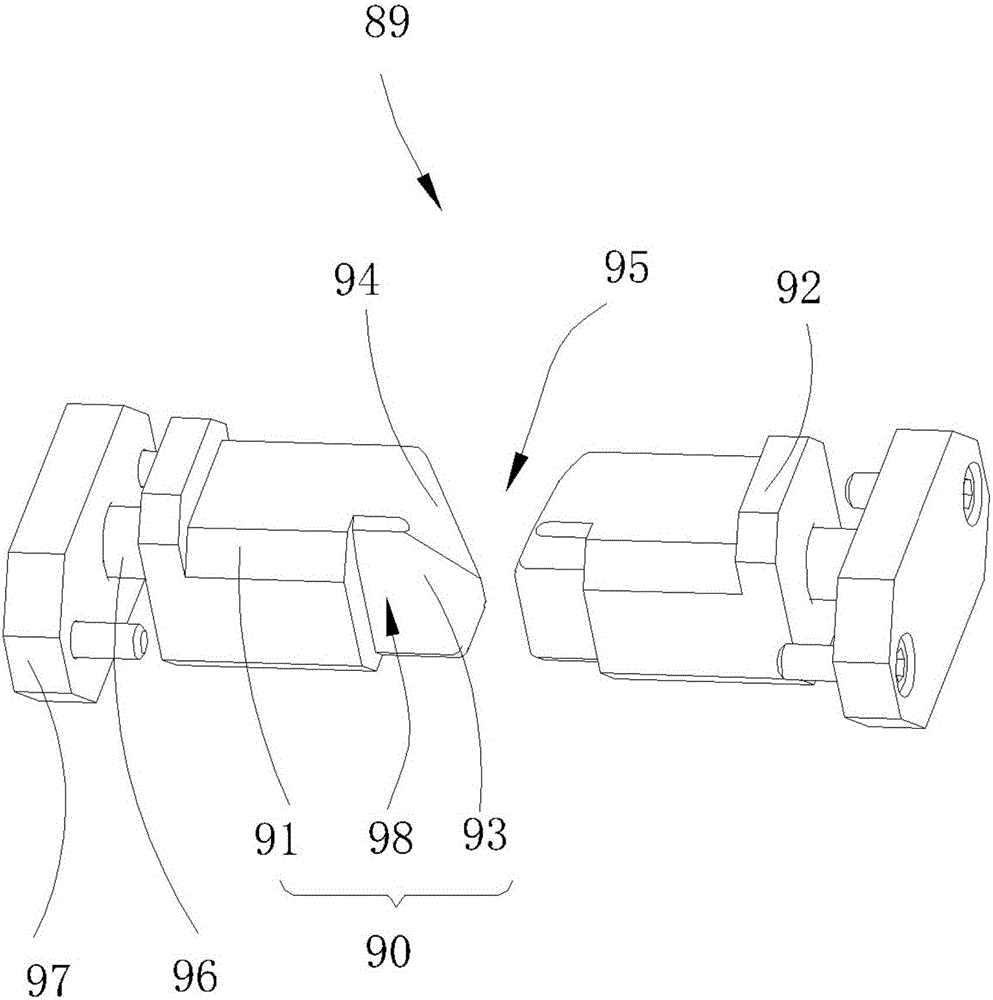

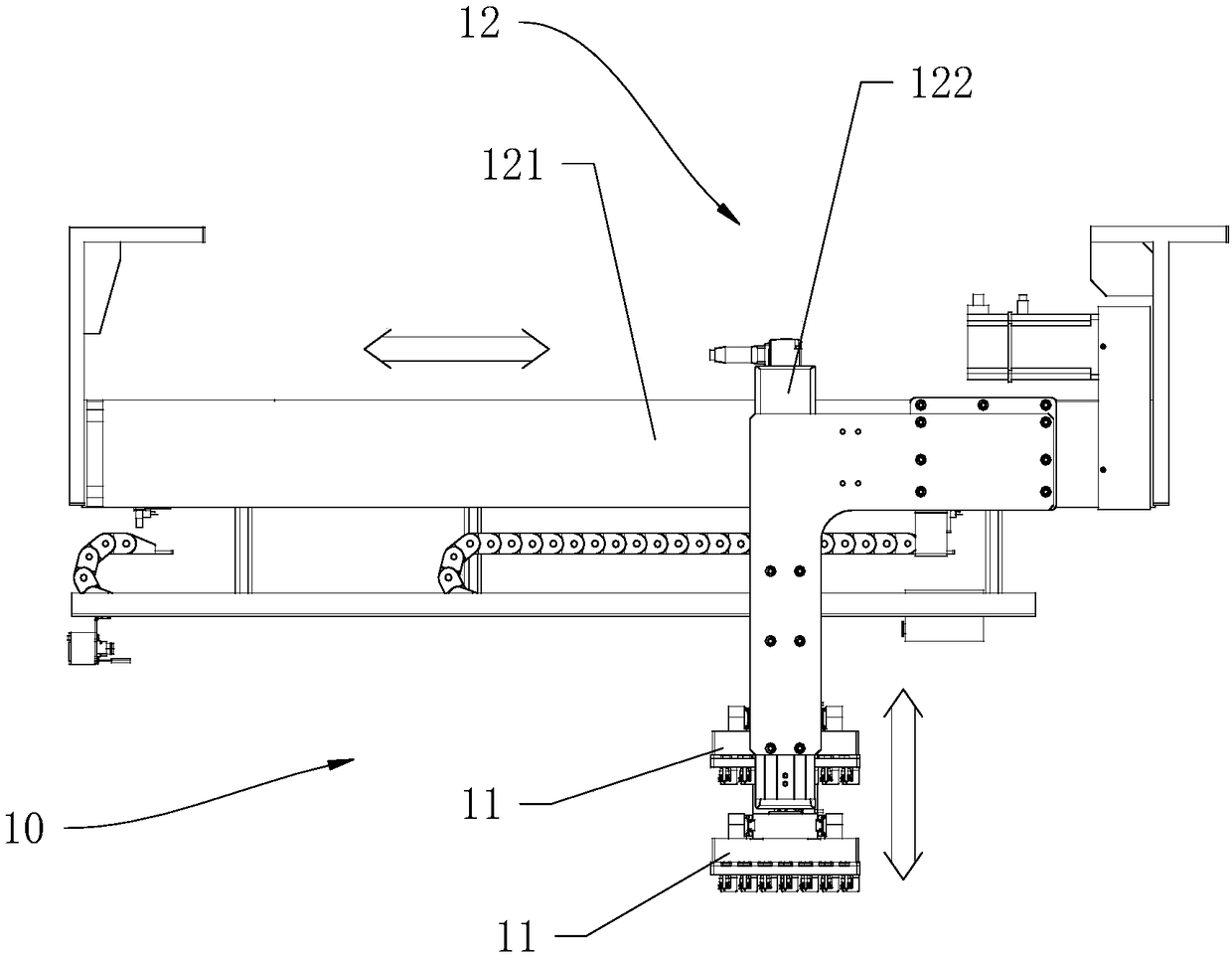

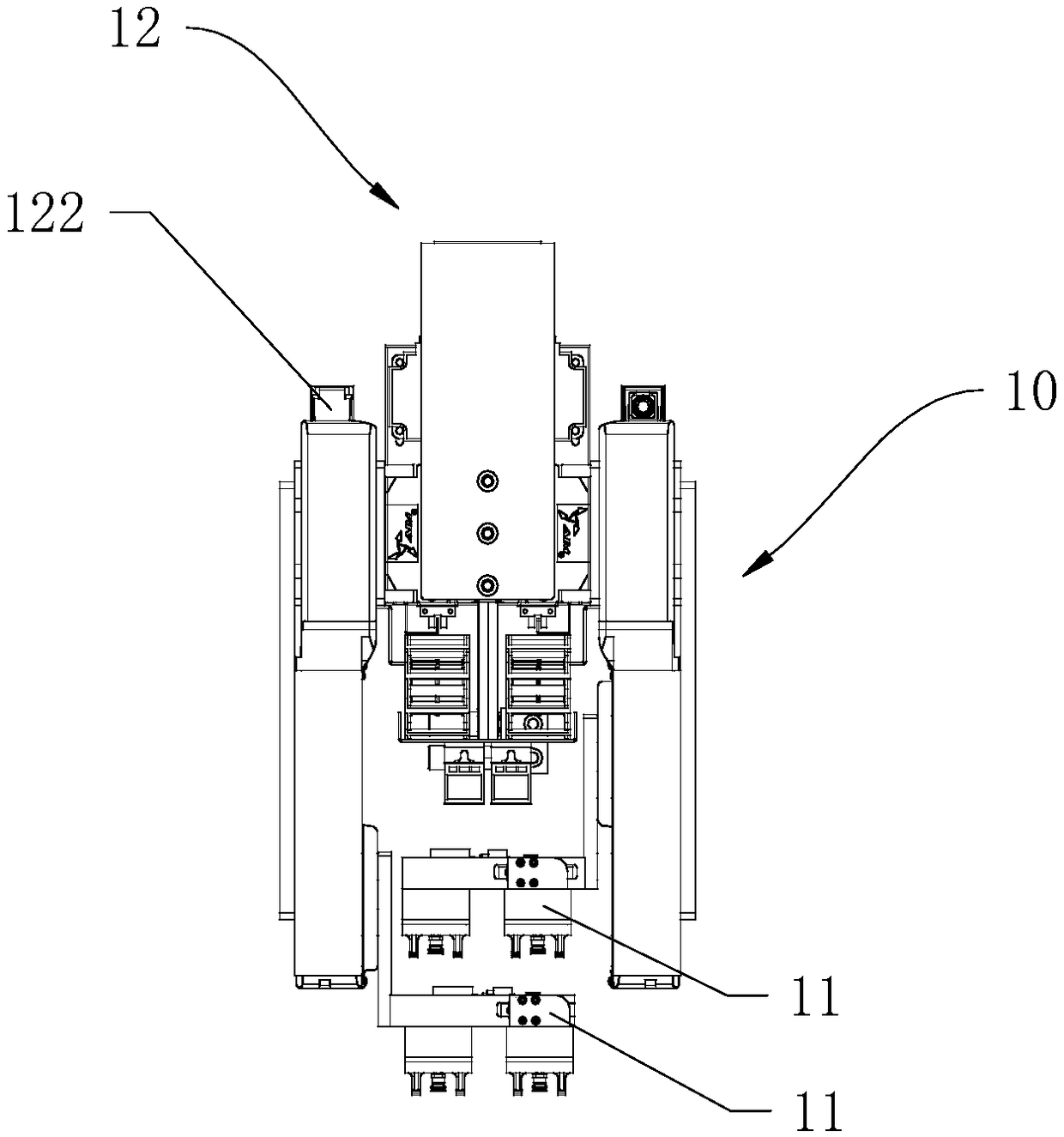

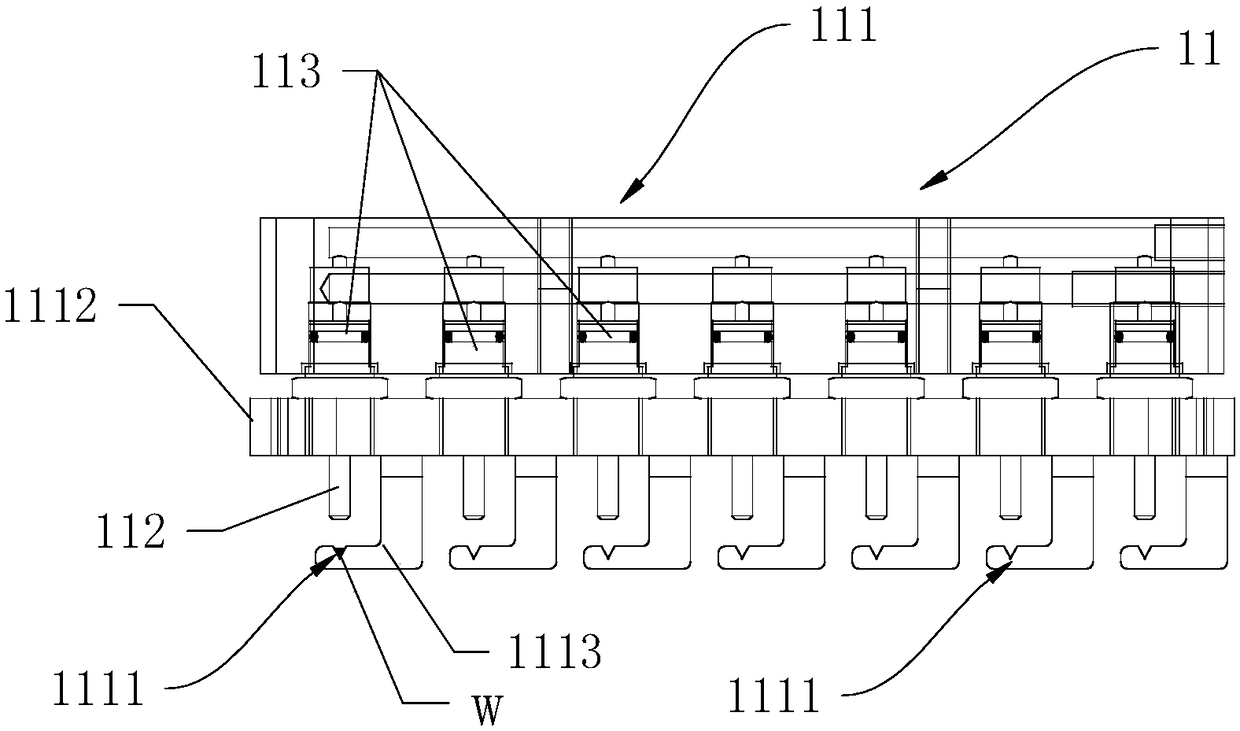

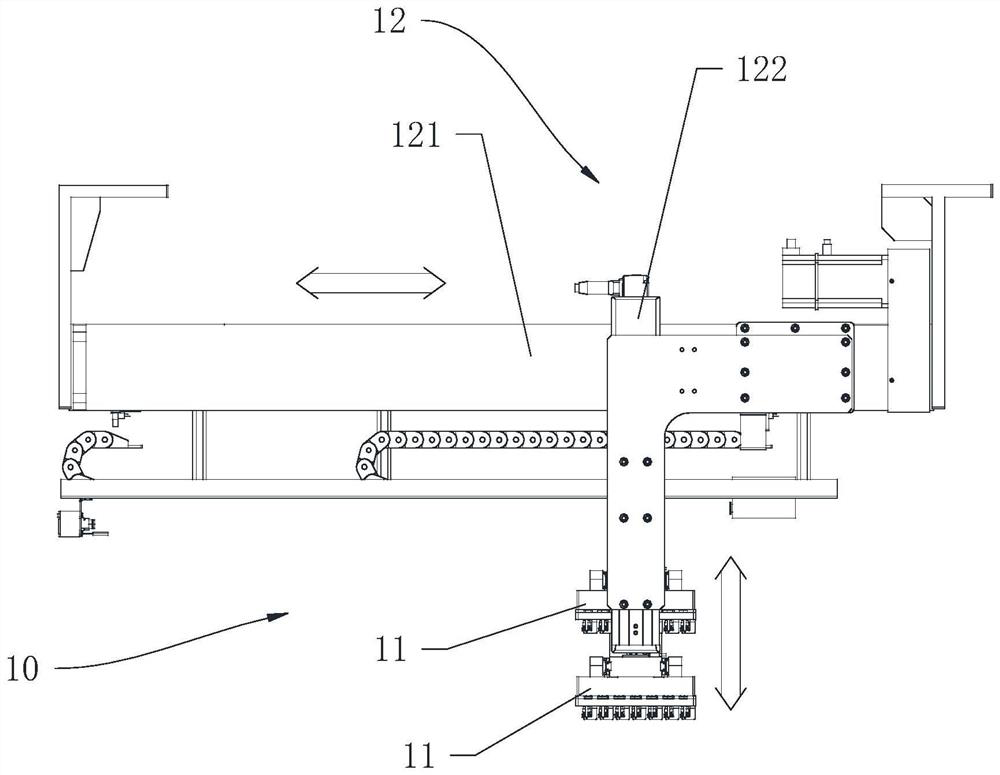

Monorail flexible clamping jaw production line

ActiveCN112975900AAvoid surface scratchesAdjust the horizontal distanceGripping headsManufacturing lineIndustrial engineering

The invention discloses a monorail flexible clamping jaw production line which comprises a girder, a first sliding way and a second sliding way are sequentially arranged on the girder from top to bottom, flexible clamping jaws are arranged on the first sliding way and the second sliding way respectively, and two sliding frames can intersect on the monorail girder and cross each other to reach the other end of the girder, therefore the problem that in the prior art, after clamping the part, the clamping jaw on the monorail girder cannot cross the other clamping jaw to reach the other end of the monorail is solved, the moving range of the two sliding frames on a monorail is widened, and the working efficiency of the flexible clamping jaws on the two sliding frames in the process of grabbing and carrying shaft parts is improved. Due to the fact that the flexible clamping jaws are adopted, surface scratching between the part and an original supporting object or between the part and the clamping jaws can be avoided; and the clamping jaws can clamp shaft parts with the two ends coaxial or non-coaxial, and can also clamp shaft parts with the two ends identical or different in diameter.

Owner:中井兴机器人(常州)股份有限公司

Containment Structure and Electronics

Owner:LENOVO (SINGAPORE) PTE LTD

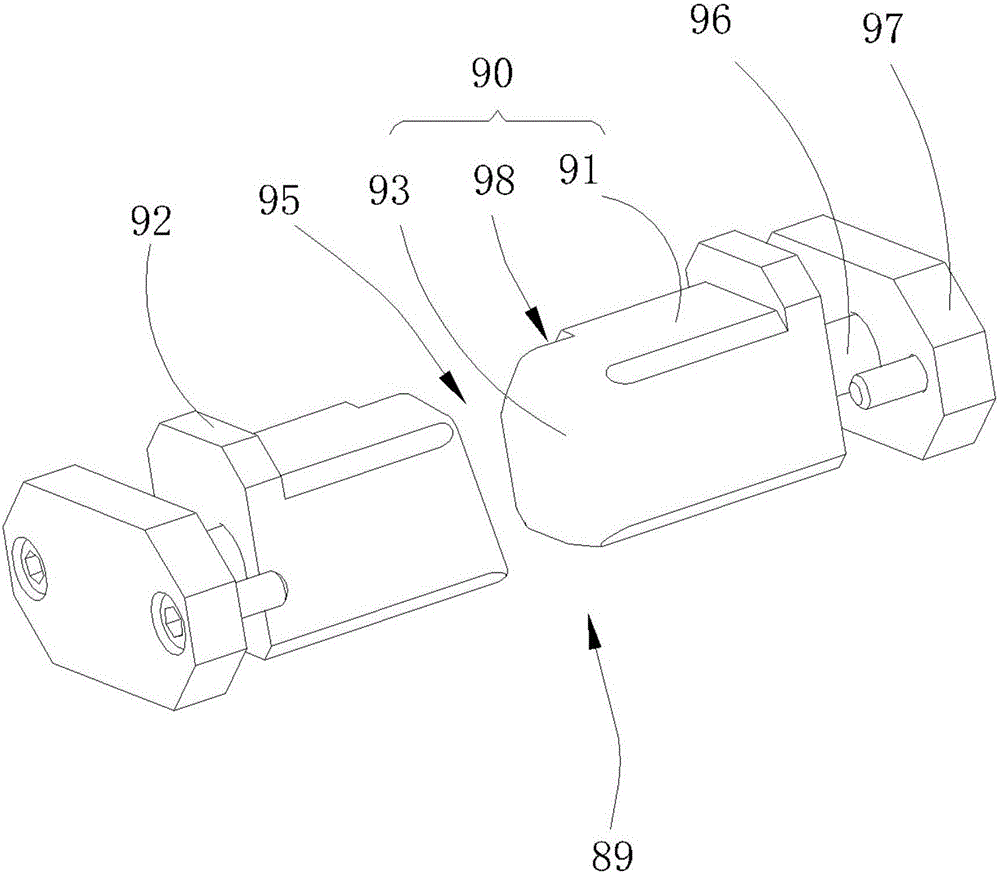

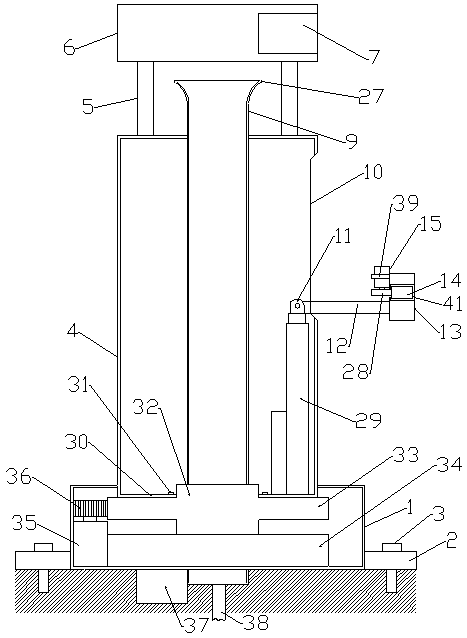

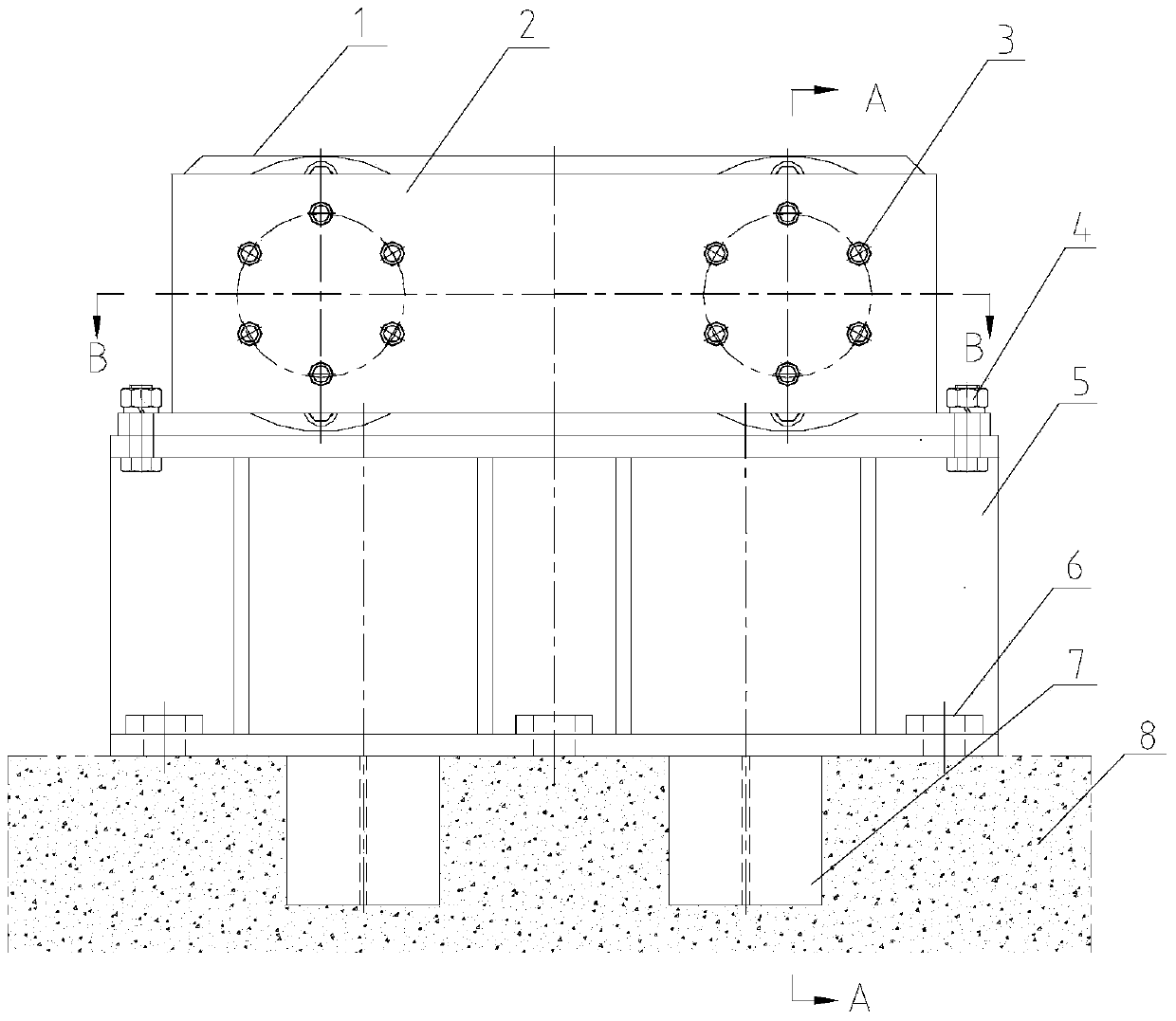

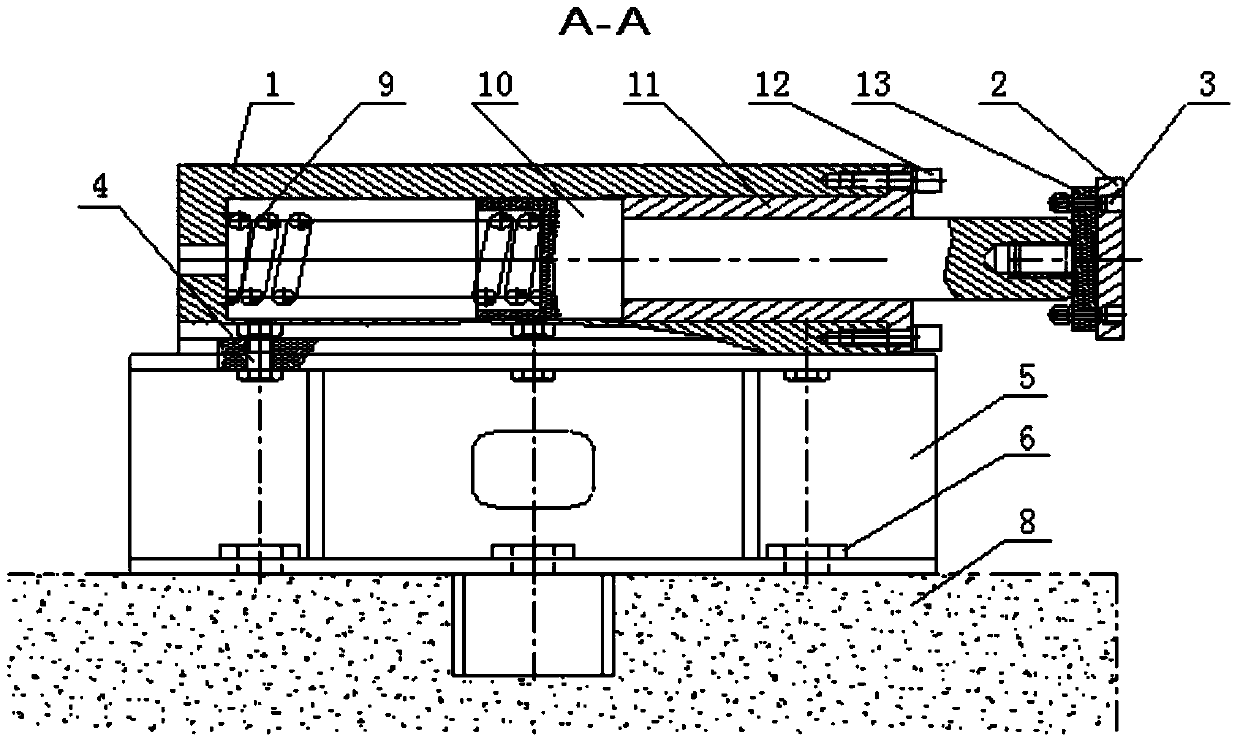

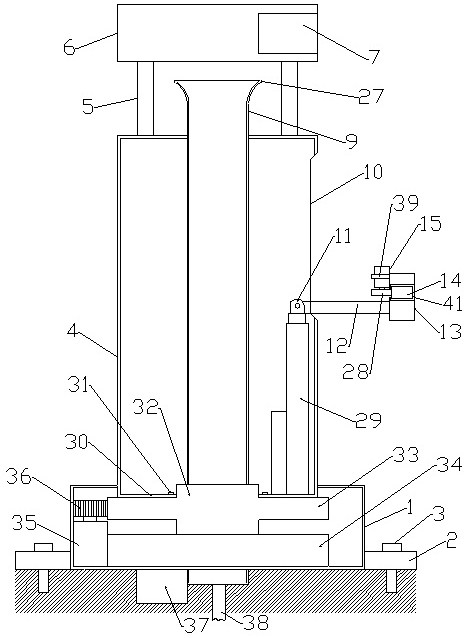

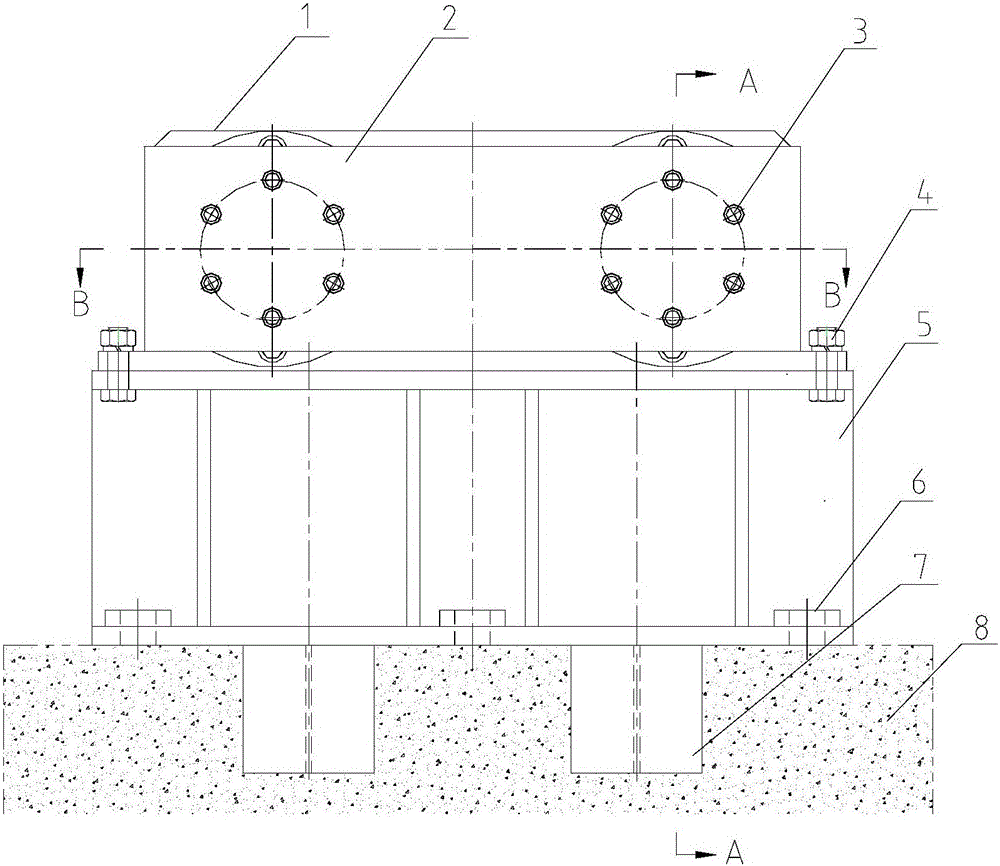

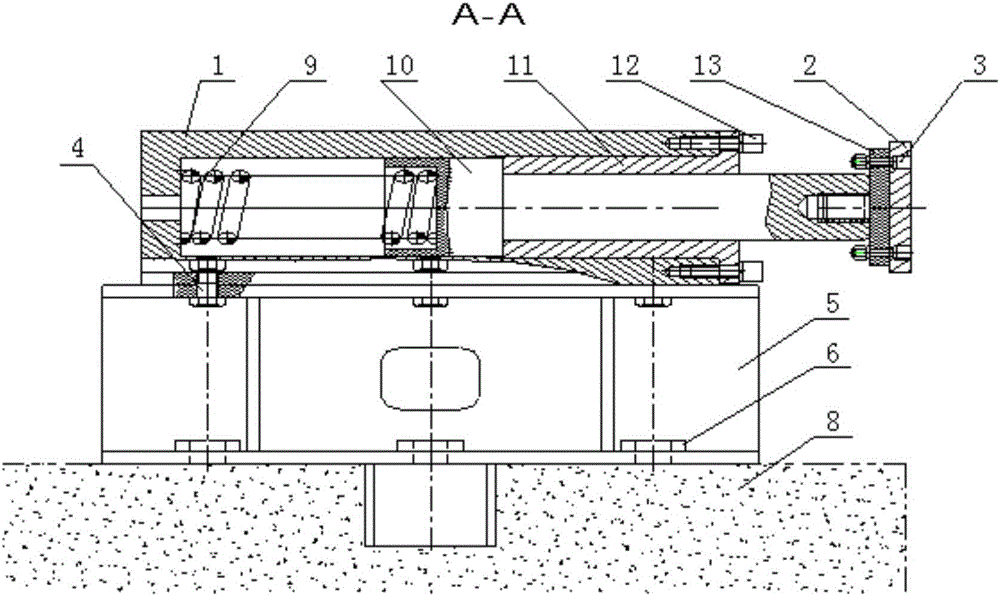

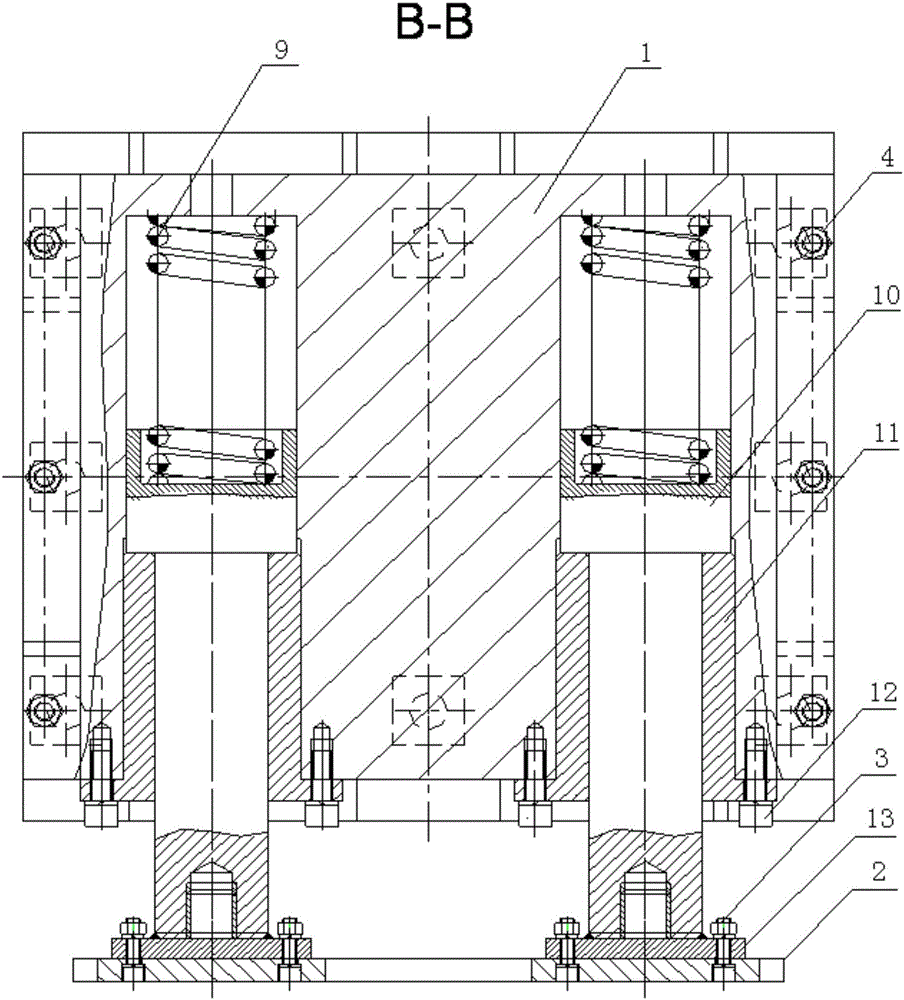

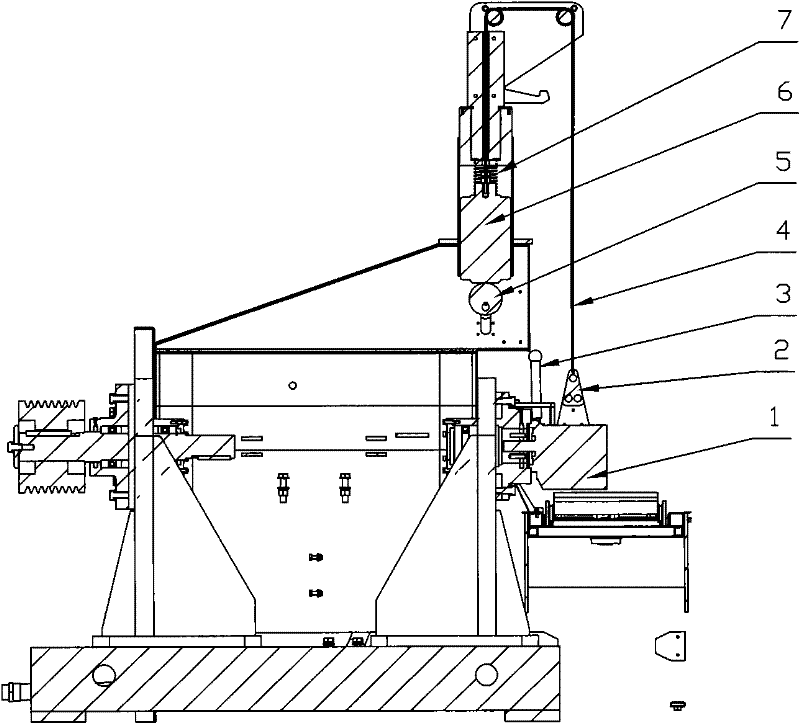

Double ejector rod type positioning device for circular pipe billets

ActiveCN103737146APlay a buffer roleSmooth alignmentMetal working apparatusGas flame welding apparatusArchitectural engineeringLarge head

The invention provides a double ejector rod type positioning device for circular pipe billets. The double ejector rod type positioning device comprises a base, buffer seats, springs, ejector rods, ejector rod sleeves, collision heads, a baffle plate and bolts; the large heads of the two T-shaped ejector rods are inward and are arranged in ejector rod holes of the buffer seats in a sliding mode respectively; the springs which are arranged at the bottoms of the ejector rod holes are pressed to abut against the bottom walls through spring grooves; the thin diameter portions of the two T-shaped ejector rods are arranged in the ejector rod sleeves in a sliding mode; the thin ends of the ejector rod sleeves abut against the large heads of the ejector rods; the outer turning edges of the thick ends of the ejector rod sleeves are fixed at the opened ends of the buffer seats through the locking bolts; the two protruding collision heads are connected into connecting holes of the small heads of the ejector rods through threads respectively; two bilateral sides of the rectangular baffle plate are fixed outside the two collision heads through the connecting bolts respectively; the buffer seats are fixed on the base through the fixing bolts. According to the double ejector rod type positioning device for the circular pipe billets, the impact force on the baffle plate of the circular pipe billets can be absorbed and eased and accordingly the two circular pipe billets can be aligned and positioned accurately in the double roller channel conveying process, the working efficiency is improved, the maintenance cost is reduced, and the device and personal safety is ensured.

Owner:ANGANG STEEL CO LTD

A robot intelligent refueling equipment

ActiveCN110509294BReduce misuseRadiation area is wideLiquid transferring devicesManipulatorElectric machineGear wheel

The invention relates to a robot intelligent refueling device. One end of a lateral lifting rod is located in a central fixed sleeve, an internal connecting seat is fixedly installed on the end of the lateral lifting rod located in the central fixed sleeve, and the bottom of the internal connecting seat is connected to the inner connecting seat. The output end of the lifting electric push rod is fixedly connected, the bottom of the lifting electric push rod is fixedly connected with the rotating tooth plate, the other end of the lateral lifting rod is located outside the central fixed sleeve, and the end of the lateral lifting rod outside the central fixed sleeve is located. A lateral support base is fixedly installed, a lateral movement slot is opened on the lateral support base, a lateral movement rod is movably installed in the lateral movement slot, and a lateral movement rod rotating gear is meshed and connected to the lateral movement rod tooth slot. The output end of the moving motor of the lateral movement rod installed on the lateral support base is connected; the tedious steps such as payment and oil quantity selection are reduced, and the refueling demand of large-flow refueling vehicles can be met.

Owner:河南英高能源科技有限公司

A circular tube billet double ejector rod positioning device

ActiveCN103737146BPlay a buffer roleSmooth alignmentMetal working apparatusGas flame welding apparatusDouble tubeArchitectural engineering

The invention provides a double ejector rod type positioning device for circular pipe billets. The double ejector rod type positioning device comprises a base, buffer seats, springs, ejector rods, ejector rod sleeves, collision heads, a baffle plate and bolts; the large heads of the two T-shaped ejector rods are inward and are arranged in ejector rod holes of the buffer seats in a sliding mode respectively; the springs which are arranged at the bottoms of the ejector rod holes are pressed to abut against the bottom walls through spring grooves; the thin diameter portions of the two T-shaped ejector rods are arranged in the ejector rod sleeves in a sliding mode; the thin ends of the ejector rod sleeves abut against the large heads of the ejector rods; the outer turning edges of the thick ends of the ejector rod sleeves are fixed at the opened ends of the buffer seats through the locking bolts; the two protruding collision heads are connected into connecting holes of the small heads of the ejector rods through threads respectively; two bilateral sides of the rectangular baffle plate are fixed outside the two collision heads through the connecting bolts respectively; the buffer seats are fixed on the base through the fixing bolts. According to the double ejector rod type positioning device for the circular pipe billets, the impact force on the baffle plate of the circular pipe billets can be absorbed and eased and accordingly the two circular pipe billets can be aligned and positioned accurately in the double roller channel conveying process, the working efficiency is improved, the maintenance cost is reduced, and the device and personal safety is ensured.

Owner:ANGANG STEEL CO LTD

Clamping device

InactiveCN101885165BReduce the labor intensity of clampingFree counterpointWork holdersHydraulic pumpCam

The invention relates to a clamping device, which comprises a hoisting claw. A transposition locking clamp is arranged at the lower end of the hoisting claw; the hoisting claw is connected with a steel wire rope and is connected with a counterweight block through a pulley; and a cam is arranged at the lower end of the counterweight block, so that the hole aligning arrangement of a spline or a flat key shaft of a hydraulic pump is labor-saving and efficient, the clamping labor strength is reduced greatly, and the clamping device has the characteristics of labor saving and high efficiency.

Owner:九江七所精密机电科技有限公司

Precise six-degree-of-freedom assembly robot

InactiveCN113352352AEnsure safetyAvoid workpiece damageManipulatorControl engineeringStructural engineering

The invention discloses a precise six-degree-of-freedom assembly robot, and relates to the technical field of six-degree-of-freedom assembly robots. The precise six-degree-of-freedom assembly robot comprises a six-axis robot body and an assembly table, the six-axis robot body is located at the front side of the assembly table, and two symmetrically-arranged shelving plates are slidably connected to the top of the assembly table; and the top of the assembly table is connected with a driving mechanism used for driving the two shelving plates to move towards the middle of the assembly table simultaneously. According to the precise six-degree-of-freedom assembly robot, when the six-axis robot body is used for fastening a bolt every time, the bolt is guided through a through groove formed by a first connecting plate and a second connecting plate, so that the bolt can be smoothly aligned to a threaded hole of a workpiece every time, the bolt does not need to be clamped by the six-axis robot body for thread fastening, the situation that the bolt cannot be aligned with the threaded hole of the workpiece and the workpiece is damaged due to track changes caused by deviation or fixing looseness in operation of the six-axis robot body is avoided, and the working safety is guaranteed.

Owner:陕西天睿创达电子科技股份有限公司

A monorail flexible gripper production line

ActiveCN112975900BAvoid surface scratchesAdjust the horizontal distanceGripping headsMonorailManufacturing line

The invention discloses a single-track flexible gripper production line, which comprises a girder, on which a slideway 1 and a slideway 2 are sequentially arranged from top to bottom, flexible grippers are respectively arranged on the slideway 1 and slideway 2, and two sliding frames Intersection can be carried out on the girder of the monorail, crossing each other to reach the other end of the girder, thus solving the problem in the prior art that the jaws of the monorail girder cannot cross the other jaw to reach the other end of the monorail after clamping the parts , improving the moving range of the two carriages on the monorail, that is, improving the working efficiency of the flexible jaws on the two carriages for grabbing shaft parts and carrying them. Because flexible jaws are used in the present invention, it is possible to avoid surface scratches between the parts and the original support or between the parts and the jaws; The jaws are used to pick up shaft parts with the same or different diameters at both ends.

Owner:中井兴机器人(常州)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com