Unit type stone curtain wall fine adjustment system and installation method

A stone curtain wall and unitized technology, which is applied in the processing of walls, building materials, building components, etc., can solve problems such as hole position deviation, and achieve the effects of eliminating hole position deviation, ensuring reliability, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

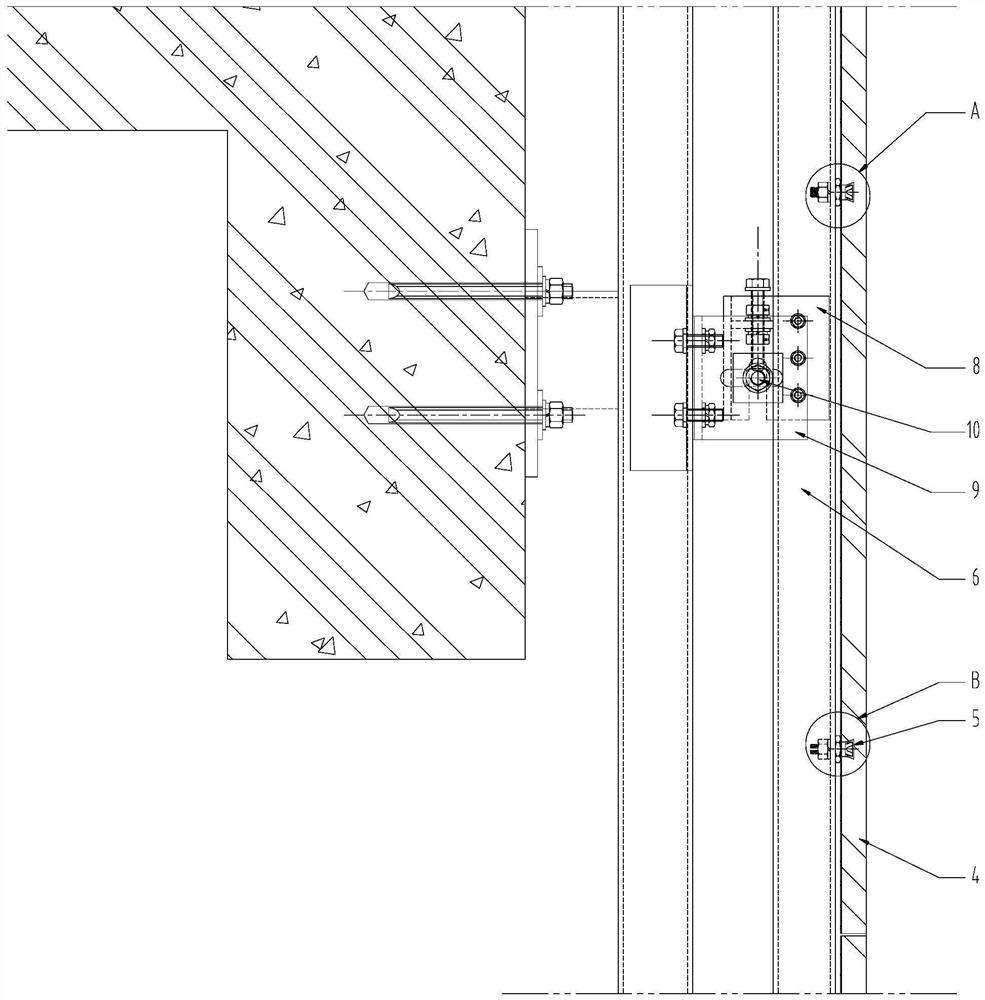

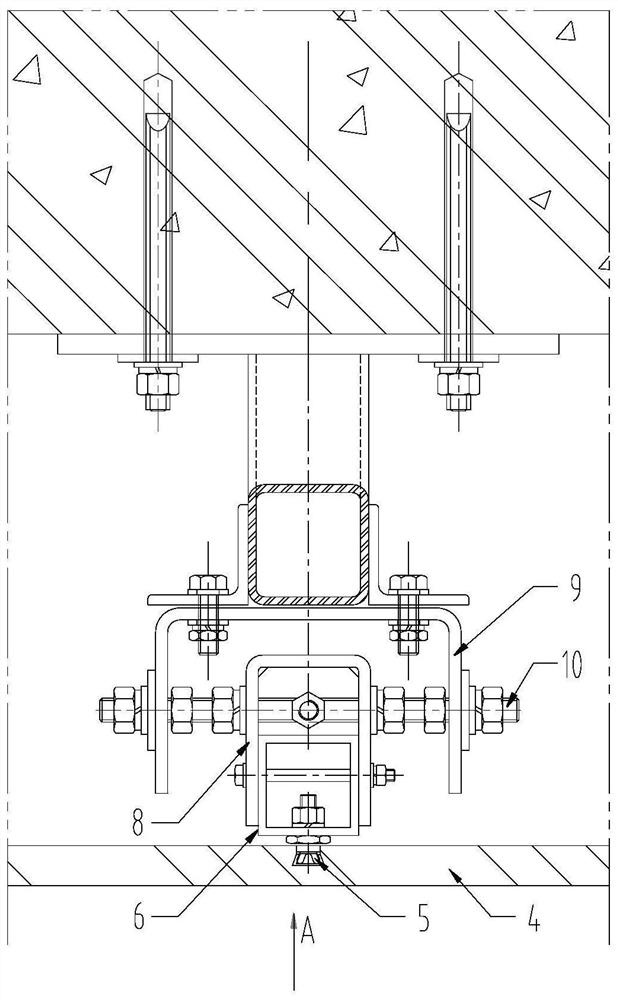

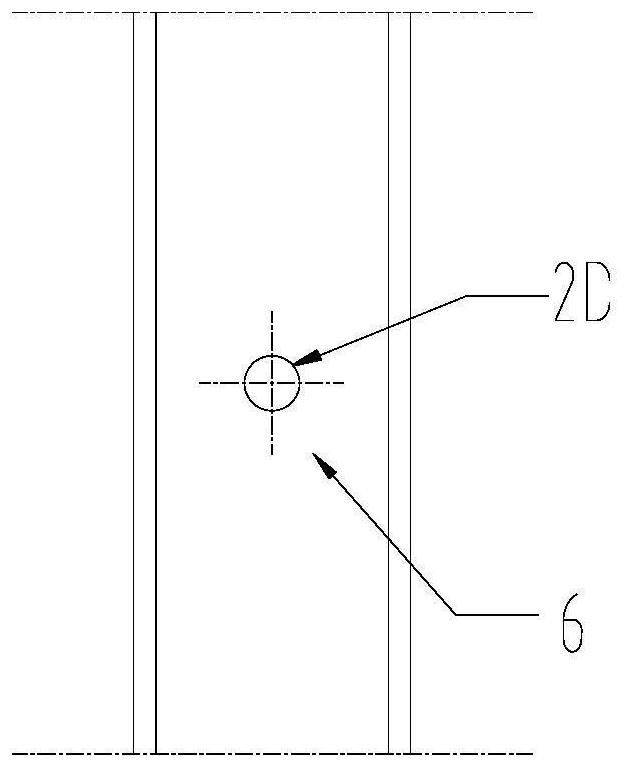

[0044] Embodiment one: if figure 1 and Figure 8 As shown, the hole position deviation adjustment structure includes a column 6, and the column 6 is as Figure 5 As shown, it includes a front side wall 6A, a rear side wall 6B, a left side wall 6C and a right side wall 6D; it is surrounded by the front side wall 6A, the rear side wall 6B, the left side wall 6C and the right side wall 6D to form two ends through In the hollow area, a notch 1A is provided on the front side wall 6A of the column 6 . The notch 1A passes through the bottom end of the column 6 from the top end of the column 6 . The setting of the notch 1A will reduce the strength of the column 6. In order to avoid this problem, a partition 6E is also provided in the hollow area. One end of the partition 6E extends to the left side wall 6C, and the other end extends to the right side wall 6D. Surrounded by the partition 6E, the left side wall 6C and the right side wall 6D, a cavity with both ends penetrating and ci...

Embodiment 2

[0055] Embodiment two, see attached Figure 15 and Figure 16 As shown, this embodiment is basically the same as Embodiment 1, except that the aluminum alloy column 6 is the same as the traditional aluminum alloy column, and consists of a front side wall 6A, a rear side wall 6B, a left side wall 6C and a right side wall 6D Surrounding and forming a hollow cavity with both ends penetrating and closed in the circumferential direction, vertical oblong holes 12 are provided at the positions corresponding to the upper fulcrum A and the lower fulcrum B of the front side wall 6A.

[0056] The eccentric washer 2 only has an inner limiting portion 2B and an inserting portion 2A. At the upper fulcrum A, an outer gasket 11 independent of the eccentric gasket 2 is provided on the outer surface of the front side wall 6A, and the eccentric gasket 2, the front side wall 6A of the column 6 and the outer gasket 11 are simultaneously connected by a set screw 7, The limit between the eccentric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com