High-power laser automatic coupling device and coupling method

An automatic coupling and laser technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of difficult to guarantee yield, easy burning of optical fibers, complicated operation, etc., to avoid collision between optical fibers and lasers, and avoid direct large-scale The effect of coupling and improving coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The preferred implementation of the high-power laser automatic coupling device and method of the present invention will be further described in detail below with reference to the accompanying drawings.

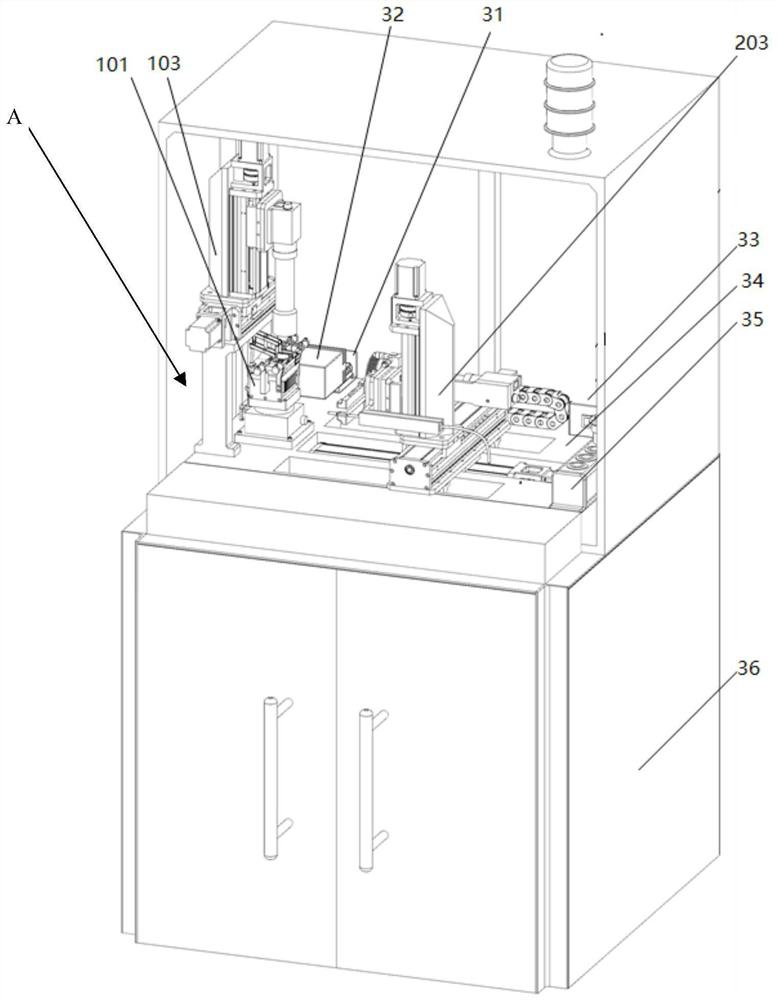

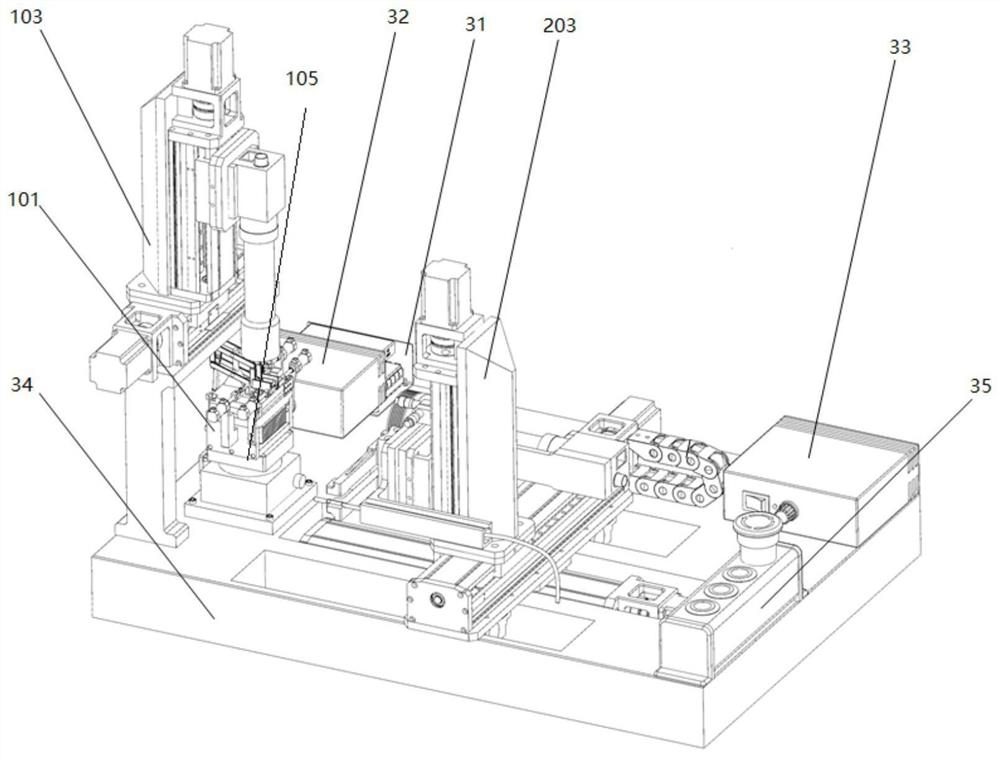

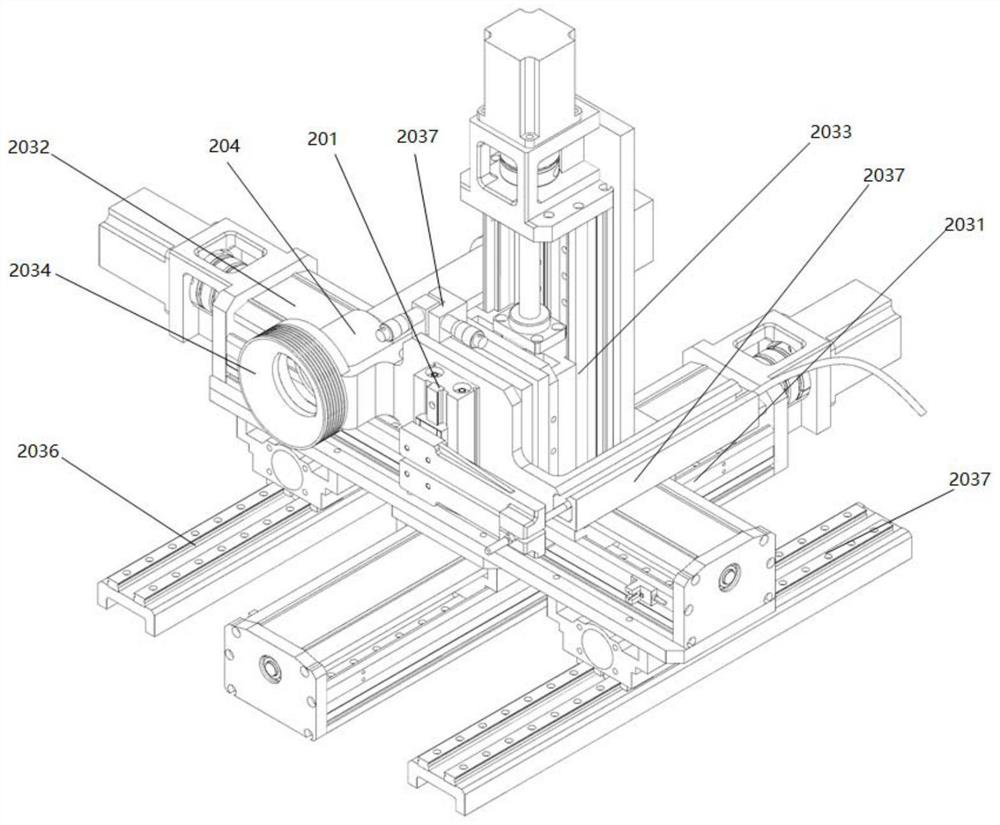

[0049] Such as Figure 1-2 as shown, figure 1 It is a perspective view of a high-power laser automatic coupling device in an embodiment of the present invention; figure 2 yes figure 1 The enlarged picture of part A in the middle, the coupling operation of the laser and the optical fiber is in figure 2 The automatic coupling device includes a laser assembly 10 and an optical fiber assembly 20, the laser assembly 10 includes a laser base 101, a laser single-axis rotation mechanism 105 is arranged on the laser base 101, and a laser single-axis rotation mechanism 105 is provided There is a laser box body 102, and one side of the laser base 101 is provided with a laser two-axis moving mechanism 103, and the laser two-axis moving mechanism 103 is provided with a vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com