Device and method for fabricating liquid-crystal display device

A liquid crystal display and sealing device technology, applied in identification devices, static indicators, optics, etc., can solve the problems of prolonging the entire process, complexity, and inappropriateness of manufacturing LCD panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Embodiments of the present invention will now be explained in detail, specific examples of which are given in the accompanying drawings.

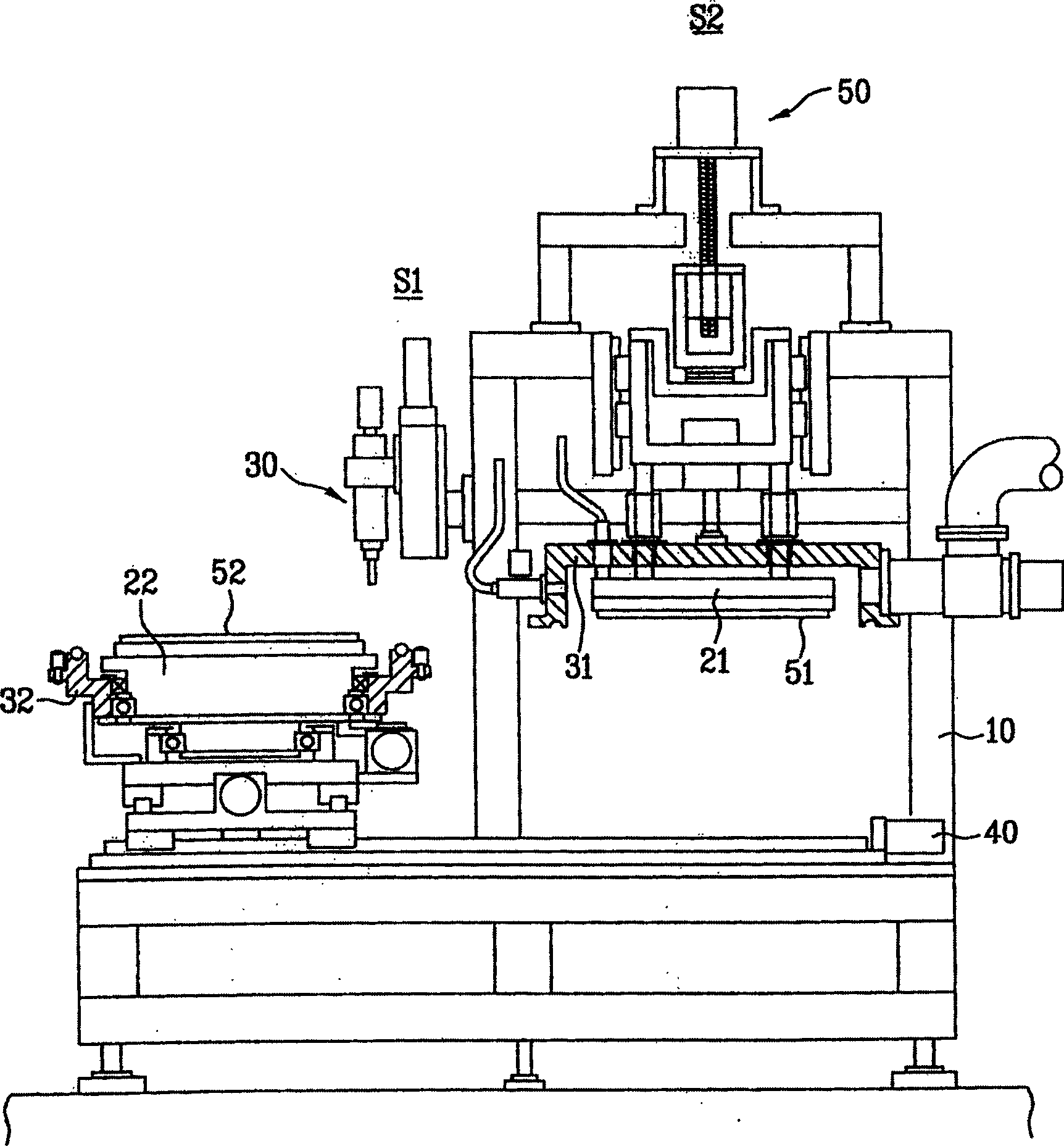

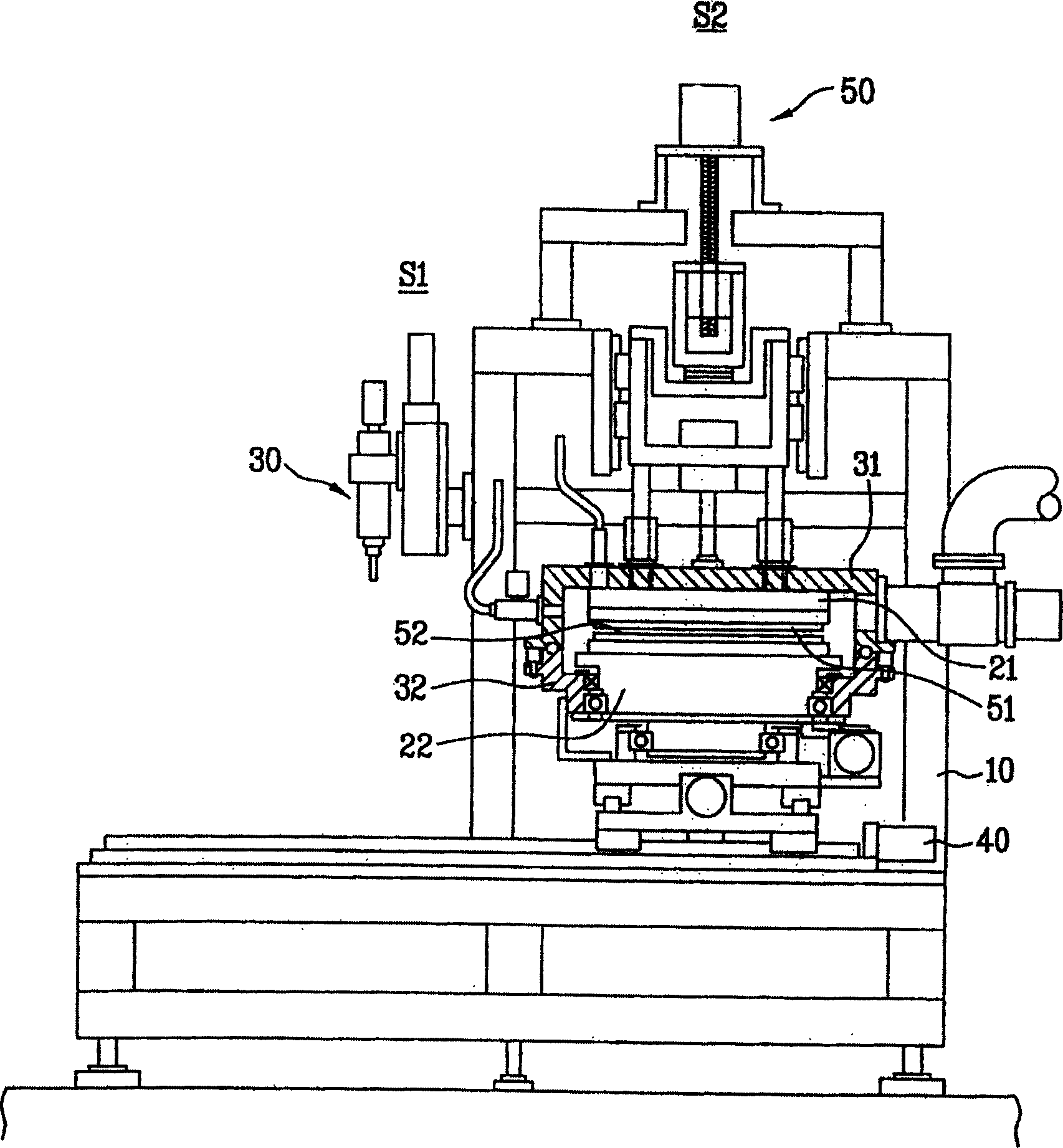

[0048] image 3 A substrate bonding apparatus for manufacturing LCD panels according to the principles of the present invention is shown in an unloaded state.

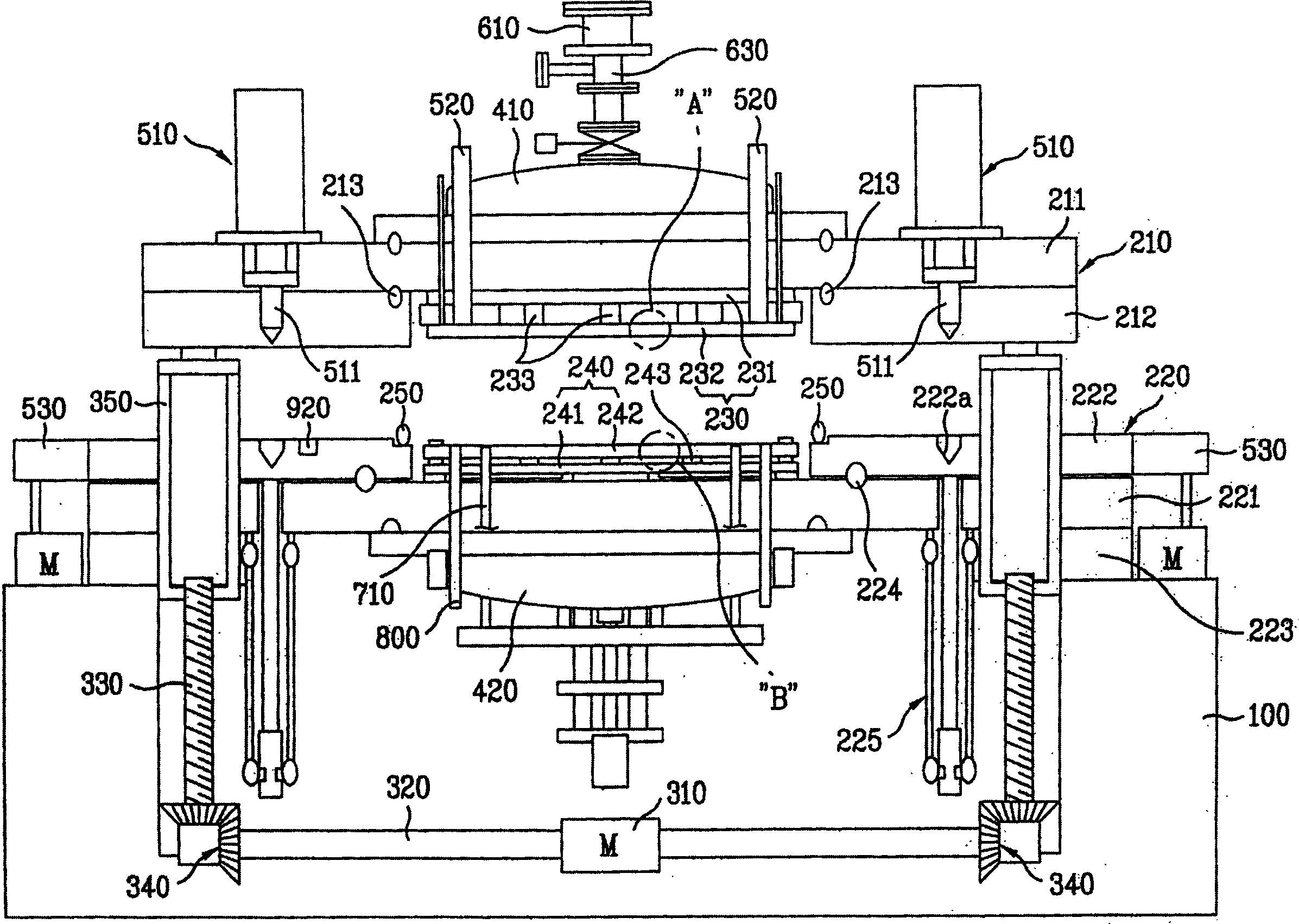

[0049] overall reference image 3 , the substrate bonding apparatus of the present invention may include, for example, a base 100; an upper chamber unit 210; a lower chamber unit 220; a chamber moving device (for example, 310, 320, 330, 340 and 350); an upper workbench 230; and lower table 240; sealing device (eg, 250); upper rough vacuum unit 410; lower rough vacuum unit 420; Figure 5 Alignment devices (for example, 510, 520, 530 and 540) shown in Figure 6 Vacuum pump units (for example, 610, 621 and 622) shown in Figure 7 support means shown in (eg 710 and 720); and phototypesetter 800.

[0050] In a portion of the present invention, base 100 can be secured to a sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com