Four-way valve device applied to organic waste gas treatment

An organic waste gas, four-way valve technology, applied in valve devices, multi-way valves, valve details, etc., can solve the problems of pipeline distribution limitation, structural optimization to be improved, complicated operation, etc., to simplify operation, facilitate popularization and application, The effect of optimizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

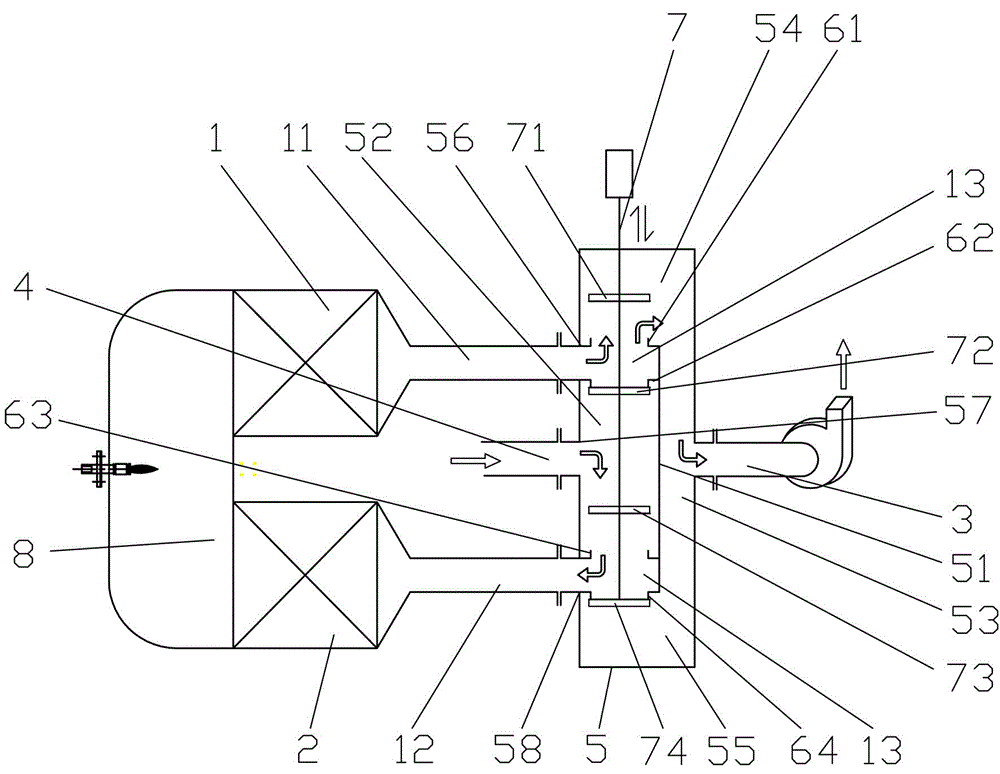

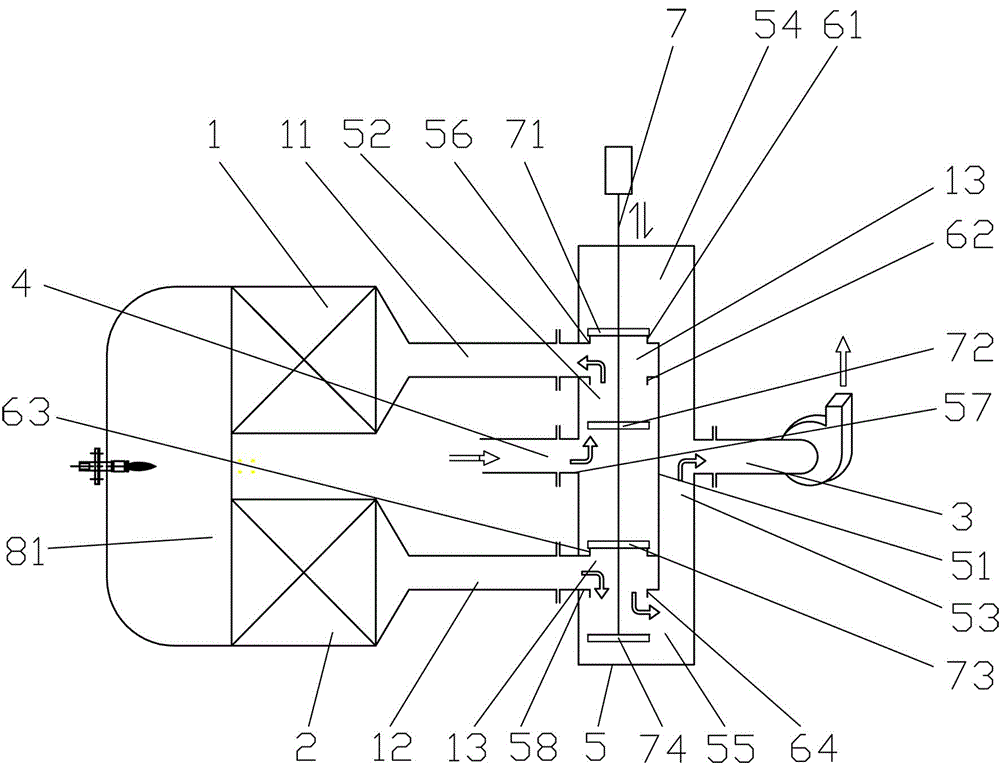

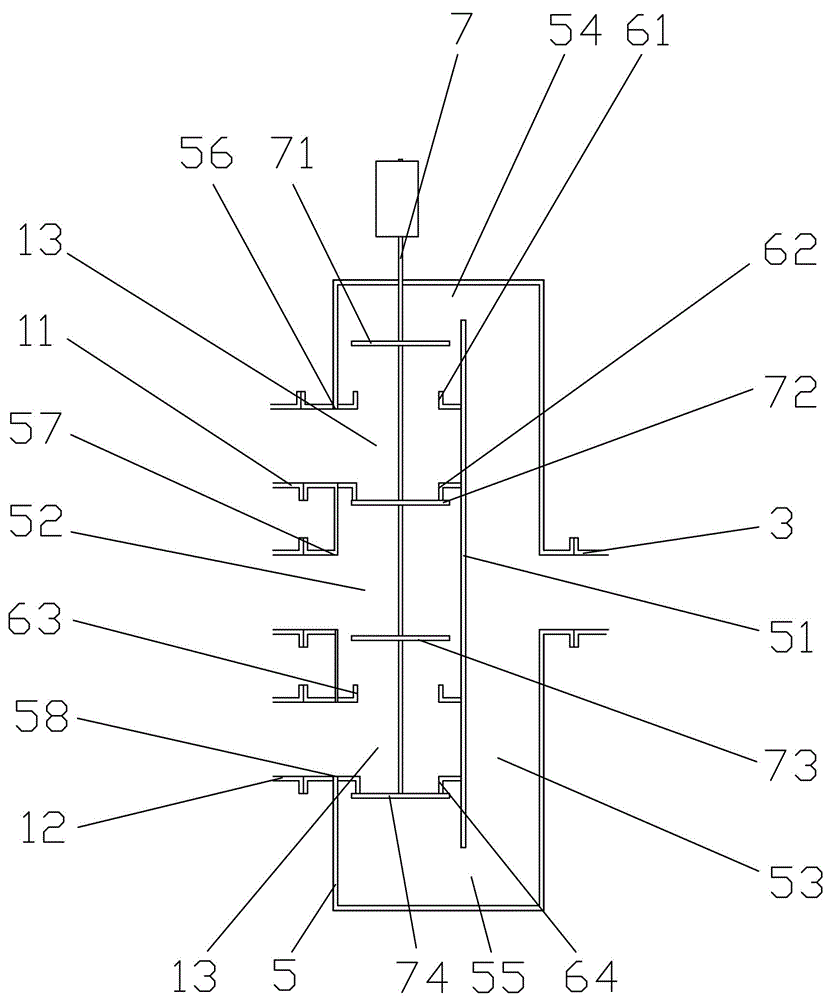

[0015] Reference figure 1 , figure 2 , image 3 , A four-way valve device for organic waste gas treatment, including a four-way valve device for organic waste gas treatment, including a first regenerator 1, a second regenerator 2, a main exhaust pipe 3 and a main In the intake pipe 4, when the device is applied to the double-bed type regenerative combustion, the first regenerator 1 and the second regenerator 2 are connected to the combustion chamber 8 respectively. The main exhaust pipe 3 and the main intake pipe 4 can be connected with external equipment as required. For example, an exhaust fan can be installed at the air outlet end of the main exhaust pipe 3.

[0016] The first heat storage chamber 1 and the second heat storage chamber 2 are respectively connected with a first heat storage vent pipe 11 and a second heat storage vent pipe 12, next to the first heat storage chamber 1 and the second heat storage chamber 2 A valve cylinder 5 is provided. The valve cylinder 5 is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com