Loading and unloading equipment and method for oil pump housing processing

An oil pump housing and oil pump technology, which is applied in metal processing equipment, metal processing, metal processing mechanical parts, etc., can solve the problems of difficult to meet the fully automated processing requirements of oil pump housing and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

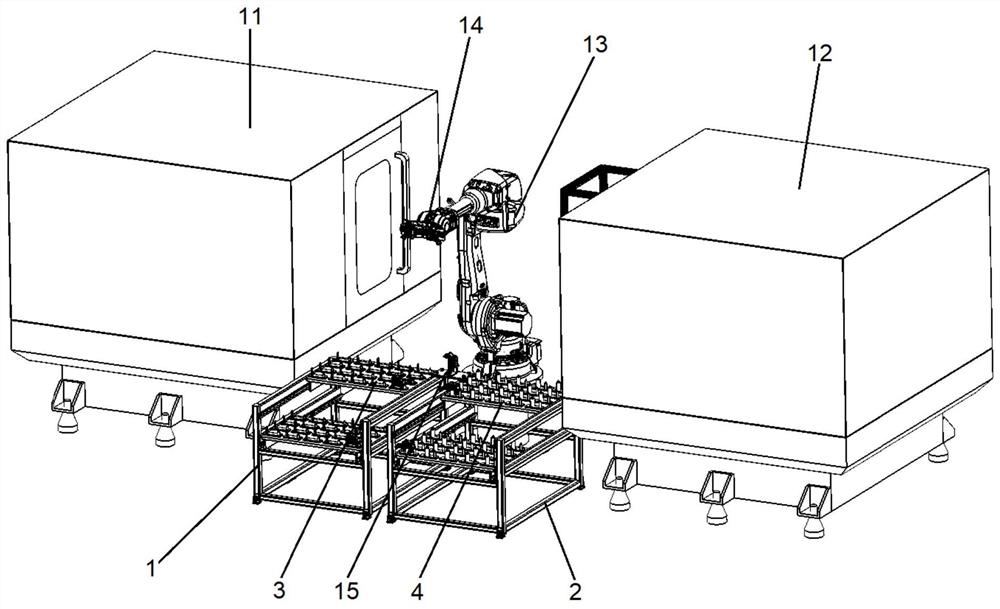

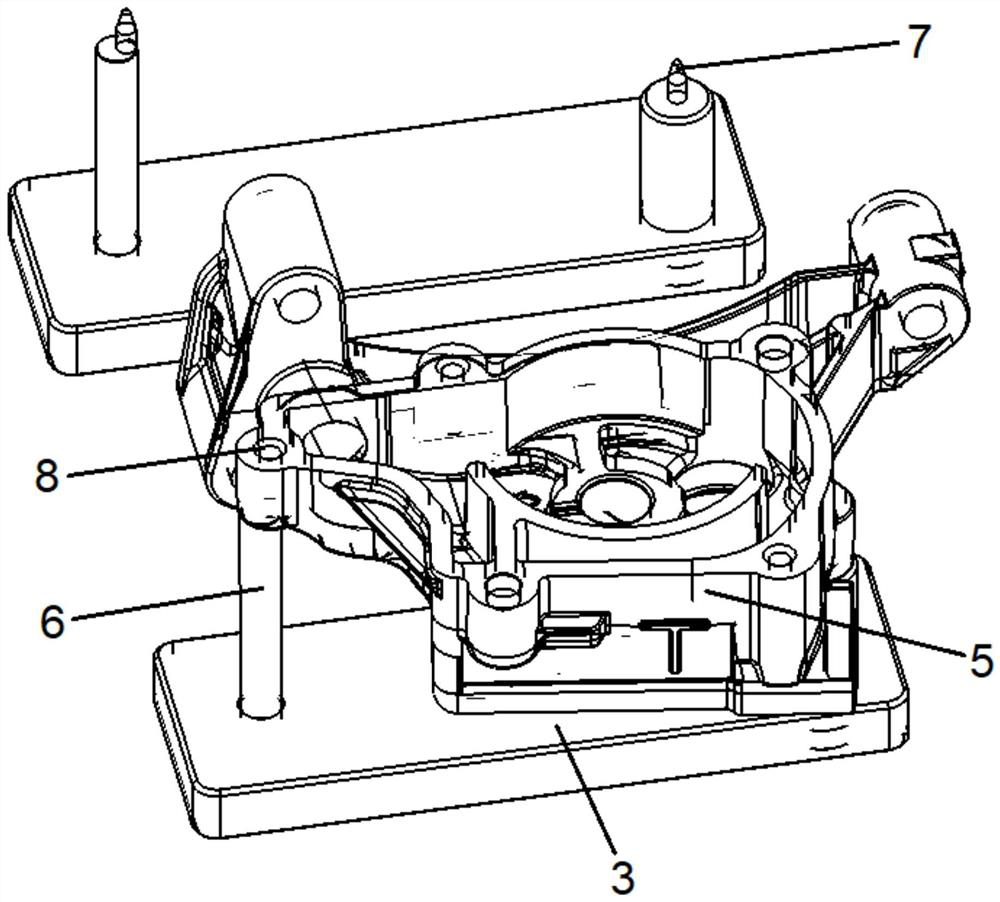

[0031] Such as figure 1 As shown, Embodiment 1 of the present invention provides a kind of loading and unloading equipment for the processing of the oil pump casing, including a loading rack 1 and a blanking rack, a loading tray 3 is arranged on the loading rack 1, and a The unloading tray 4, the loading tray 3 and the unloading tray 4 are all provided with a positioning structure for positioning the oil pump housing 5. Due to the irregularity of the oil pump housing 5, the oil pump housing 5 is positioned by the positioning structure arranged on the pallet, so that the oil pump housing 5 maintains a fixed posture after being positioned on the pallet, ensuring subsequent accurate clamping. Specific as figure 2 As shown, the positioning structure includes two positioning columns 6, and the tops of the positioning columns 6 are provided with conical protrusions 7. During positioning, the conical protrusions 7 are inserted into the through holes 8 connecting the front and the ...

Embodiment 2

[0041] Embodiment 2 of the present invention provides a method for loading and unloading the oil pump casing, which specifically includes the following steps:

[0042] Step 1, placing the oil pump housing 5 with the back facing up on the loading tray 3, and positioning it through the positioning structure of the loading tray 3, so as to facilitate the accurate gripping and handling of the mechanical arm 13;

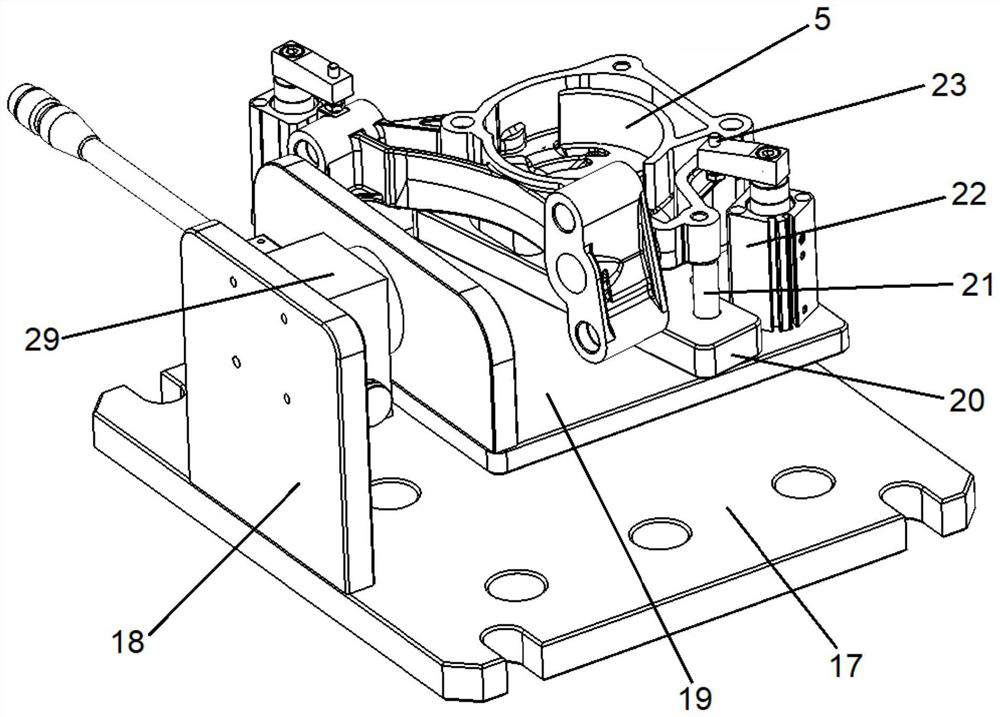

[0043] Step 2, the clamping tool 14 of the mechanical arm 13 clamps the oil pump casing 5, makes its back close to the clamping surface of the clamping seat 32, maintains a horizontal posture so that the back of the oil pump casing 5 faces upward, and loads it to the The first positioning jig 9 aligns the through hole 8 with the conical protrusion 7 of the first support column 21. After the clamping tool 14 is placed, the first corner cylinder 22 of the first positioning jig 9 rotates and presses down, and the oil pump casing 5 fixed on the first positioning fixture 9;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com