A circular tube billet double ejector rod positioning device

A positioning device and a round tube billet technology, applied in the direction of tubular objects, gas flame welding equipment, applications, etc., can solve the problems of affecting operation efficiency, unfavorable tube billet cutting work, increasing maintenance costs, etc., to ensure equipment and personal safety, The effect of shortening alignment and positioning time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

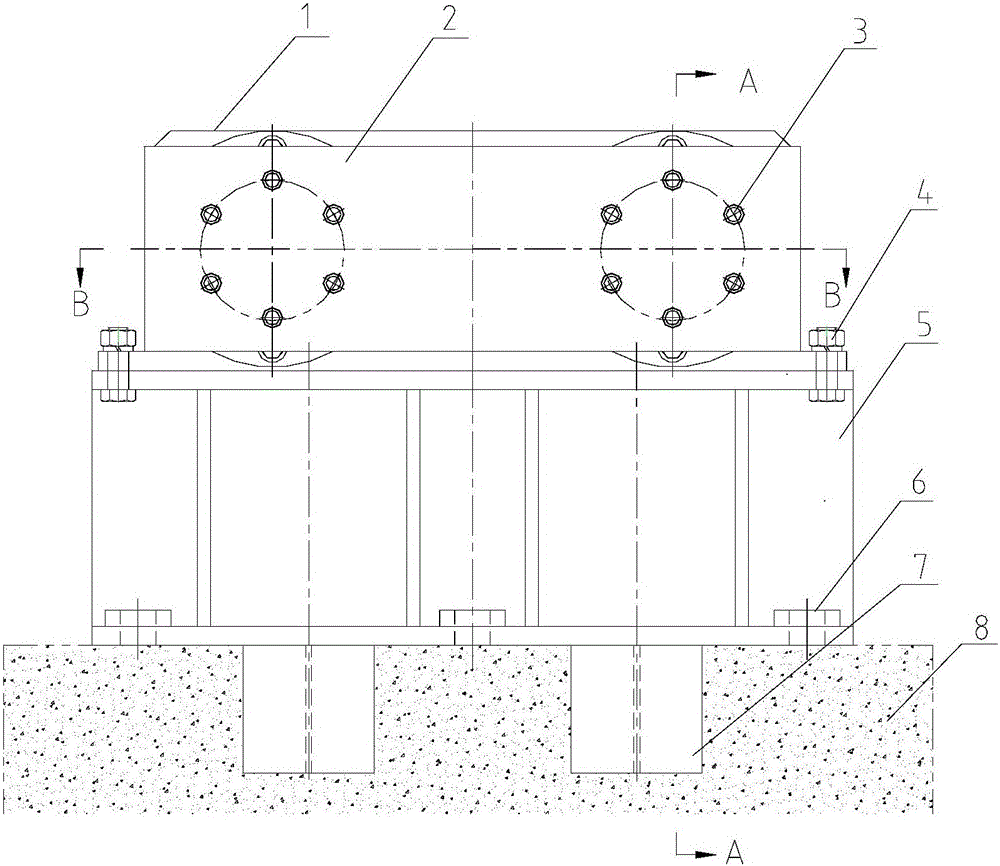

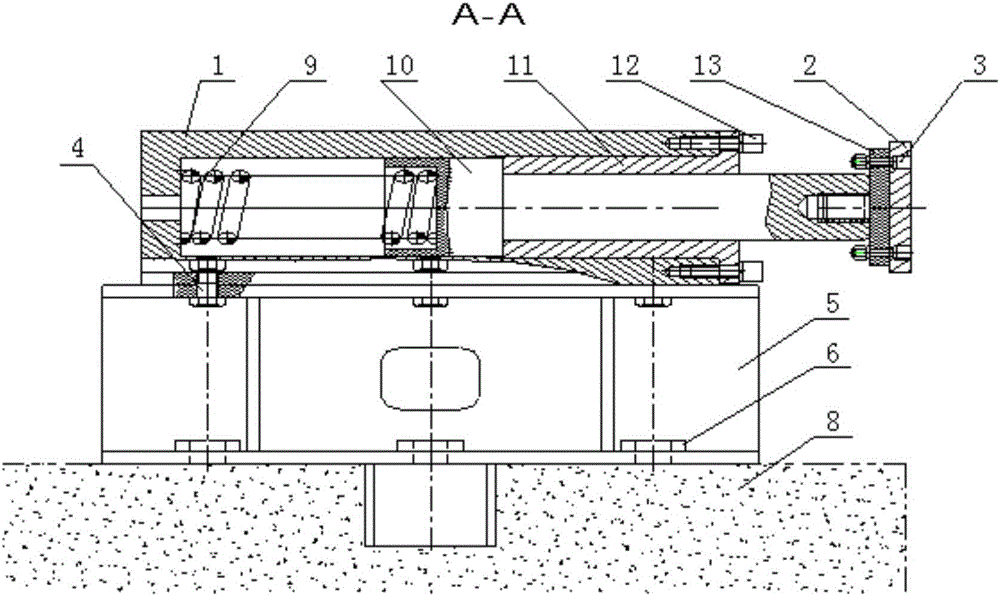

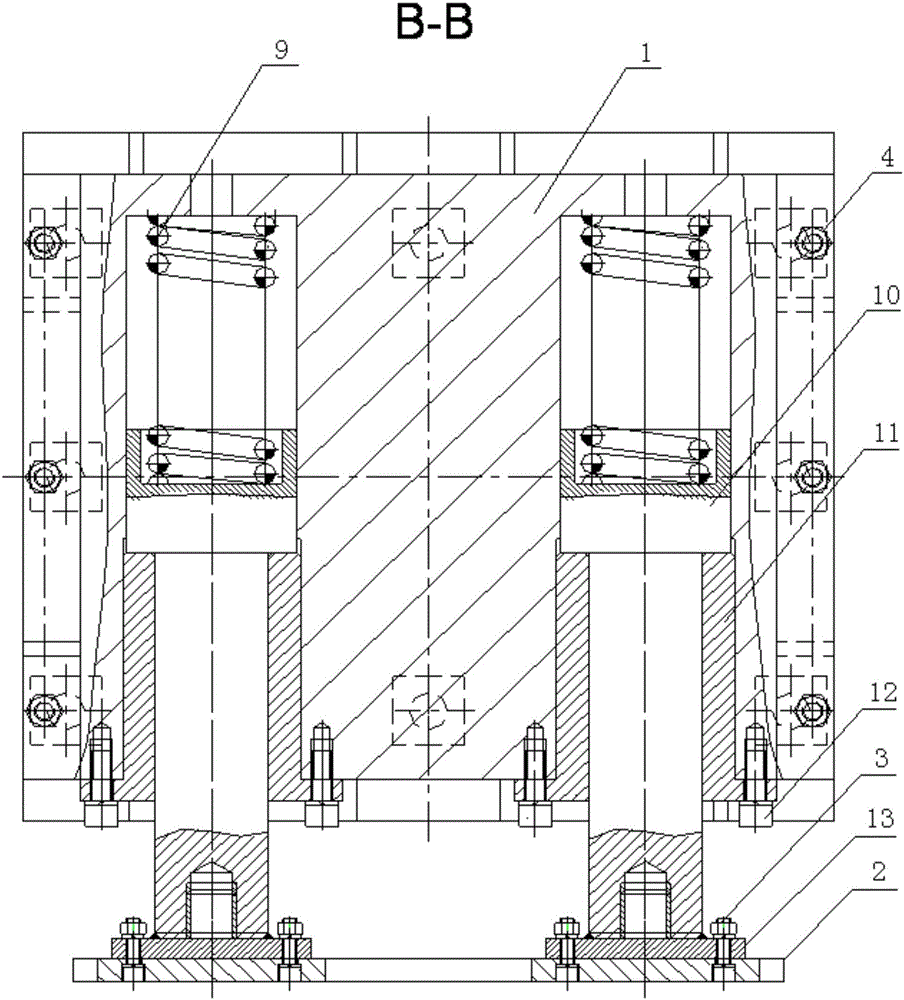

[0019] It can be seen from the accompanying drawings that the circular tube blank double ejector rod positioning device of the present invention is mainly composed of a buffer seat 1, a baffle plate 2, a connecting bolt 3, a fixing bolt 4, a base 5, an anchor bolt 6, a spring 9, a ejector rod 10, a Rod sleeve 11, locking bolt 12, bumper 13 are formed.

[0020] There are two push rods 10, which are "T" shaped rods made of two sections of cylinders with different diameters and lengths processed from round steel. There is a spring groove at the big end of the "T" shaped push rod 10, and a small end is provided with a spring groove. There is a connecting hole with an internal thread, so as to be connected with the bumper 13.

[0021] The push rod sleeve 11 is a "T" shaped sleeve with a push rod hole in the middle and a valgus edge at one end, and 12 bolt holes are arranged at equal intervals along the valgus edge circumference.

[0022] The buffer seat 1 has a convex shape as a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com